Novel environmental-protection refrigerant component for substituting 1, 1, 1, 2- tetrafluoroethane (hydrochlorofluorocarbon (HFC)-134a)

A technology of tetrafluoroethane and refrigerant, applied in the field of replacement 1, can solve the problems of reducing cooling effect, low global warming index of refrigerant, difficulty in obtaining coefficient of performance, etc., and achieve good energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] This embodiment is the first best condition:

[0064] After mixing 54 kg of propane (R-290) and 45.9 kg of isobutane (R-600a), in order to make a near-azeotropic mixed refrigerant composition, 0.1 kg of hexamethyl silicone oil was added as an additive to prepare a refrigerant composition.

Embodiment 2

[0066] Present embodiment is the 2nd best condition:

[0067] After mixing 53kg of propane (R-290) and 43.9kg of isobutane (R-600a), add 2kg of n-butane (R-600) and 1kg of propylene (R-1270) to make a near-azeotropic mixed refrigerant composition , adding 0.1 kg of hexamethicone oil additive to produce a refrigerant composition.

experiment example 1

[0068] Experimental example 1 (theoretical and actual temperature ramp test)

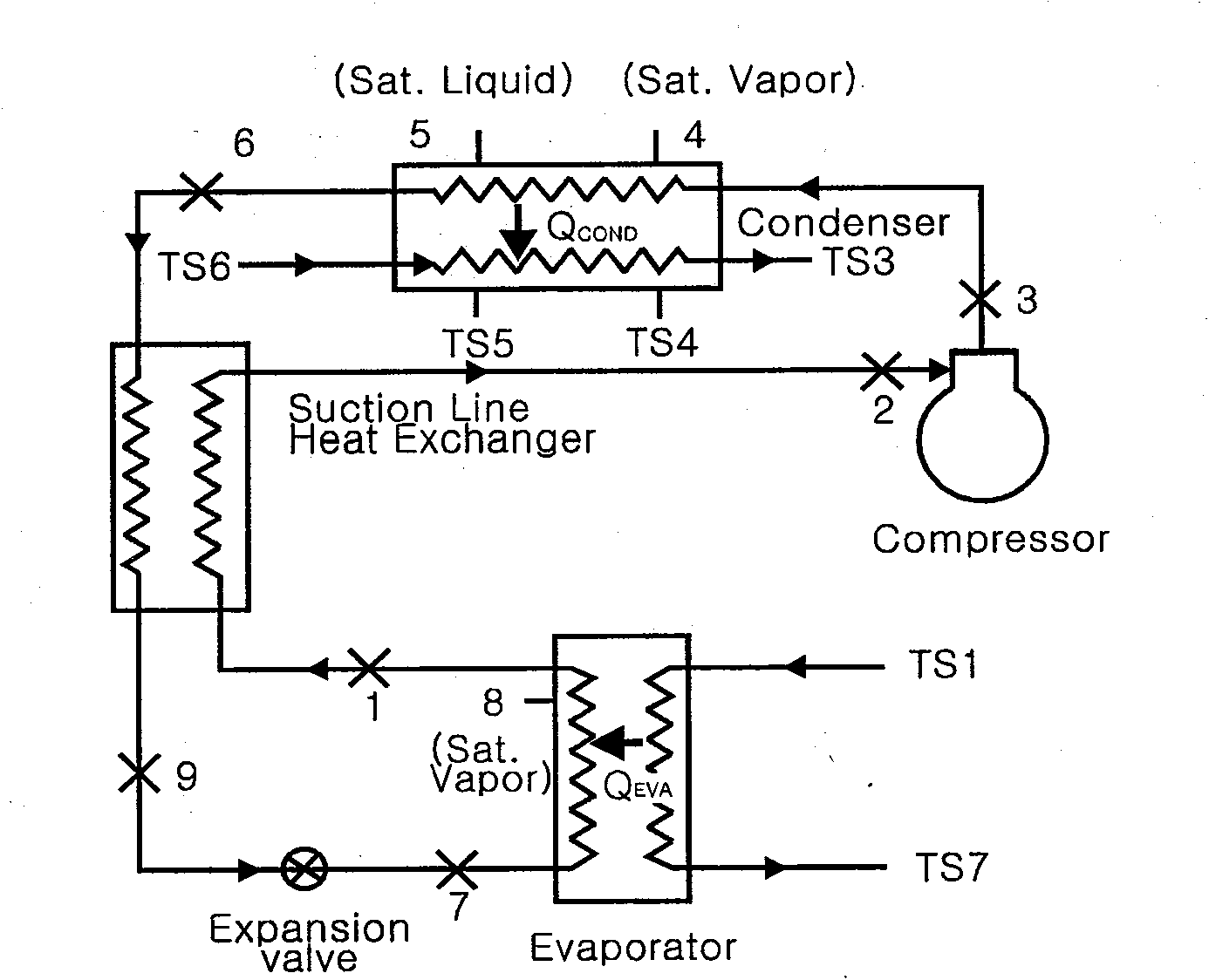

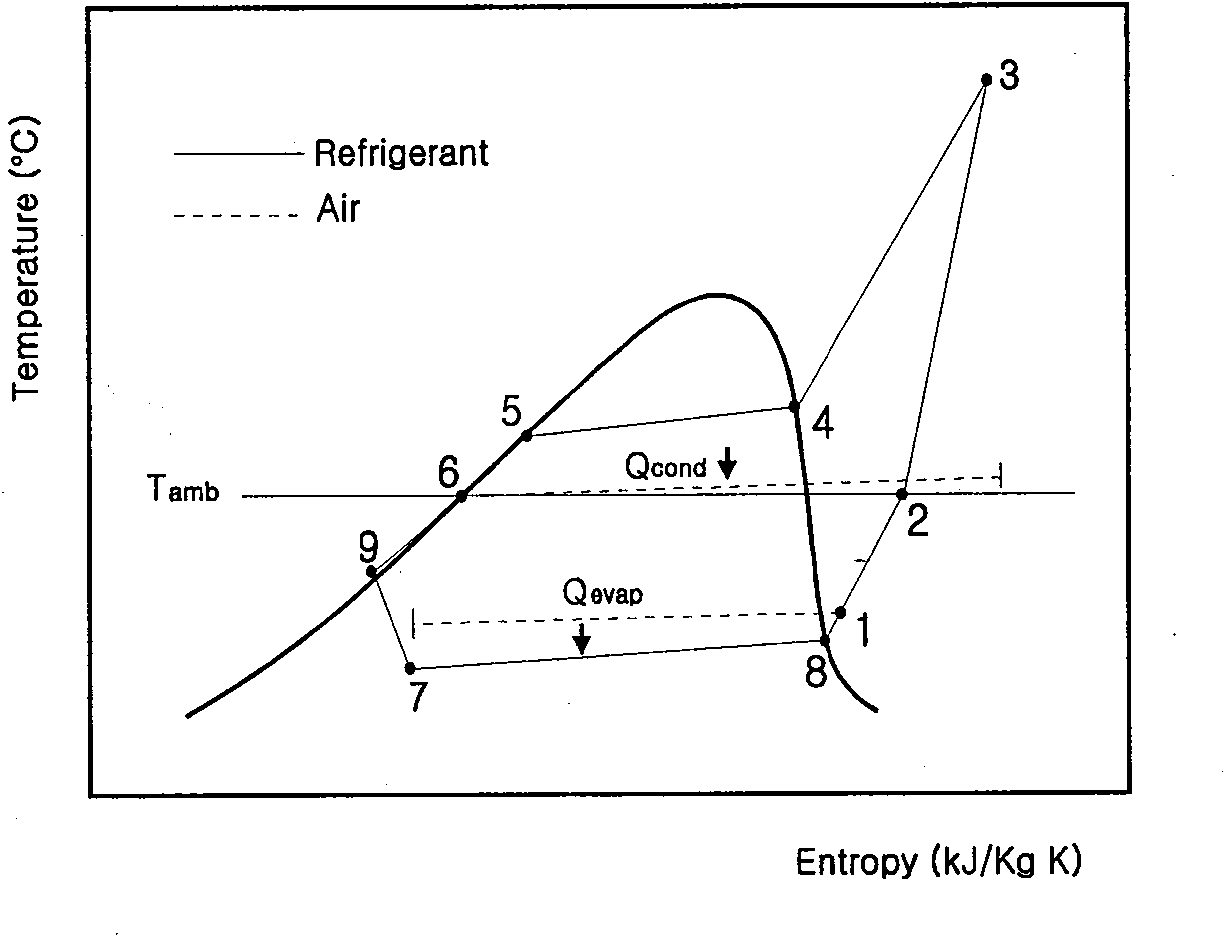

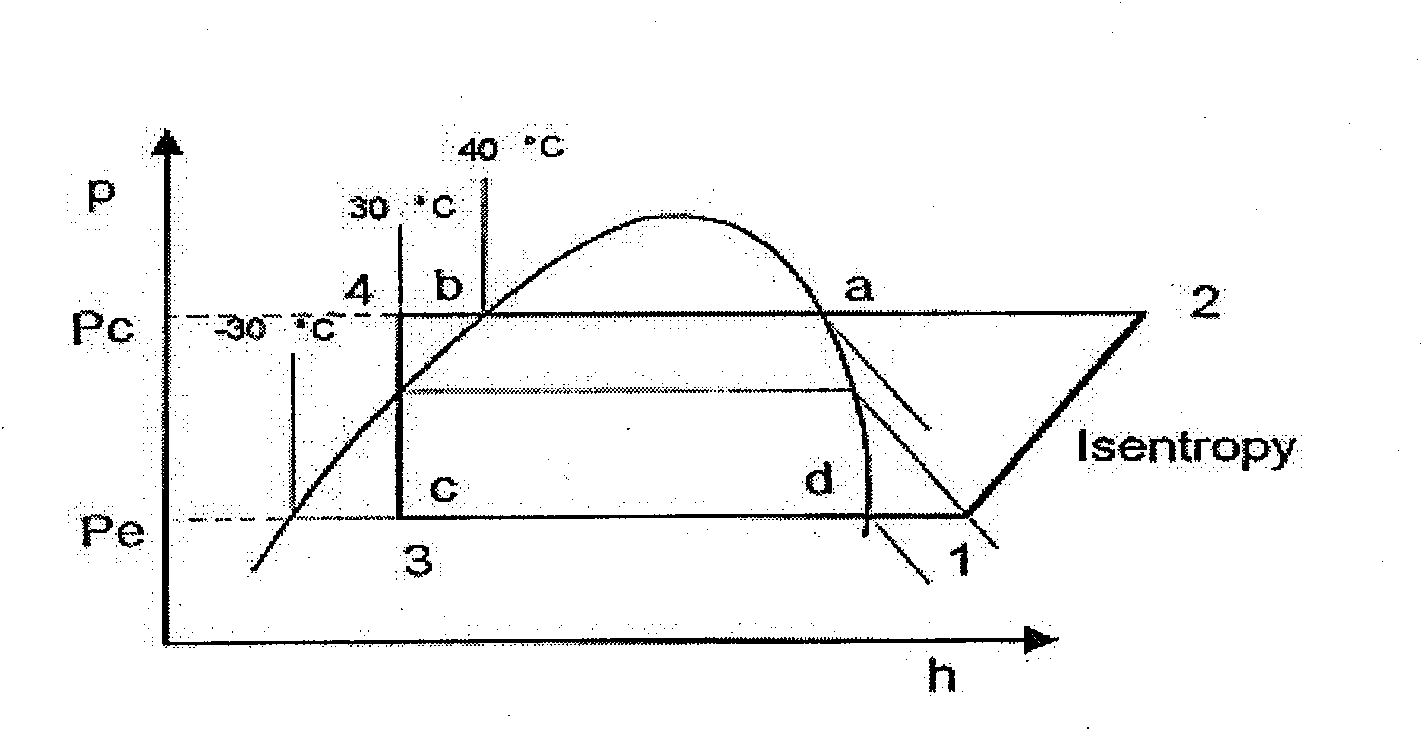

[0069] figure 2 It shows the temperature gradient line diagram of the binary mixed refrigerant composition without adding additives obtained by the REFPROP8.0 program of the present invention. However, in order to form the near-azeotropic refrigerant composition for the purpose of the present invention, after adding additives, such as test figure 1 The experimental device so that it can be known that if image 3 Its temperature ramp results are minimized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com