Method for manufacturing specially-shaped curved surface of main steam inlet and outlet connecting pipe

A special-shaped surface and manufacturing method technology, applied in the field of special-shaped surface processing, can solve the problems of low manufacturing precision, large surface roughness value and high cost, and achieve the effects of reducing the amount of milling processing, improving processing efficiency, and reducing processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

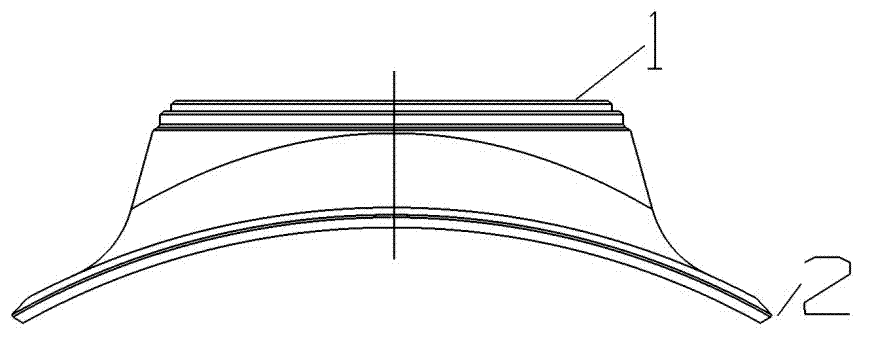

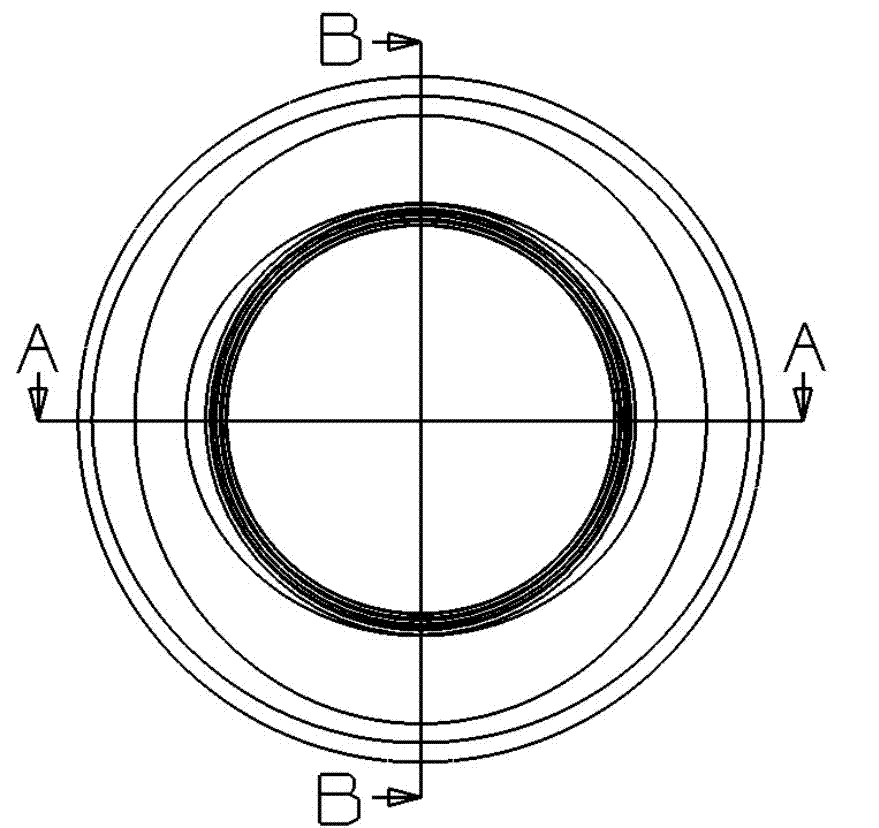

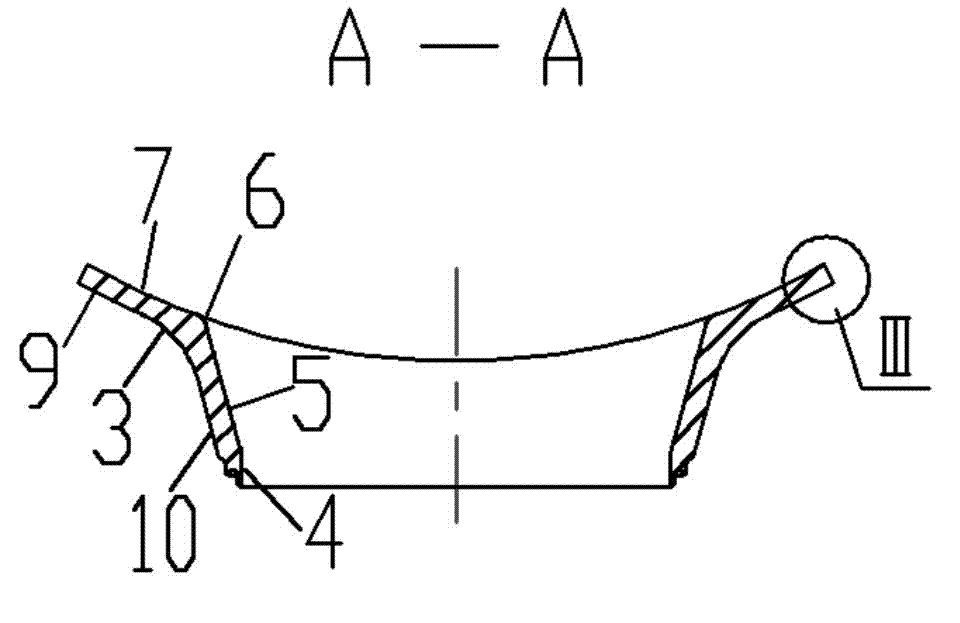

[0094] The manufacturing method of the present invention is specifically described below by taking the main steam inlet nozzle processing steps as an example, as figure 1 , figure 2 , image 3 , Figure 4 As shown, the dimensions of the main steam inlet connecting pipe are as follows: the diameter of the brim 2 is 2100mm, the height is 622mm, the diameter of the inner circle 4 at the end of the hat mouth is 1190.4mm, the opening of the large end of the conical surface is 1400mm, and the wall thickness is 55mm; image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , there are chamfers in the three directions of characteristic chamfering surfaces 20, 21, and 22 on the edge of the brim 2, and the chamfering surface 21 coincides with the large outer circle 8 of the brim end at the B-B section position; the end face 11 of the brim end is very narrow and has a slope The mouth surfaces 12 and 16 have the characteristics of deep grooves 14, and the inner circle 4 of the cap ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com