Method for decorating ceramic products

A technology for ceramic products and handmade products, applied in the field of decoration for decorative ceramic products, can solve problems such as hindering grinding steps, difficult infiltration of decorative glaze, residues, etc., and achieve the effect of saving ceramic materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

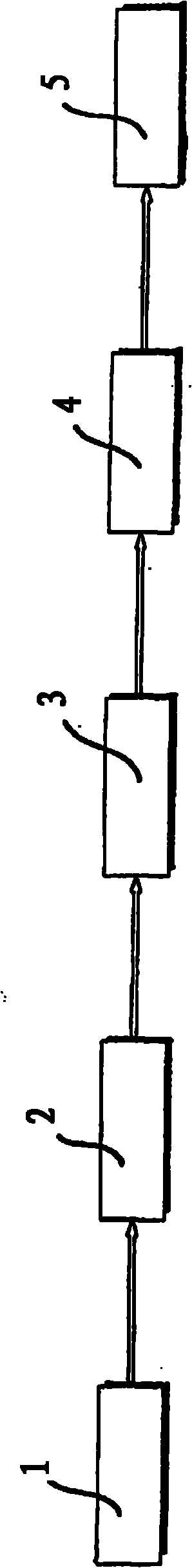

[0028] see figure 1 , the state-of-the-art decorating method for decorating ceramic handicrafts obtained by extruding ceramic material in a plastic state comprises an extrusion step denoted by numeral 1, wherein a layered ceramic strip is extruded from which strips in a plastic state are obtained. State of the original ceramic handicraft.

[0029] After the step of extruding and obtaining the original ceramic handicraft in a plastic state is followed by: a step indicated by reference number 2, in which the ceramic handicraft is baked; a step indicated by reference number 3, in which the visible surface of the ceramic article is decorated; Reference numeral 4 indicates a step in which the decorated ceramic article is sintered; and a final step in which the sintered ceramic article having planarity defects is ground.

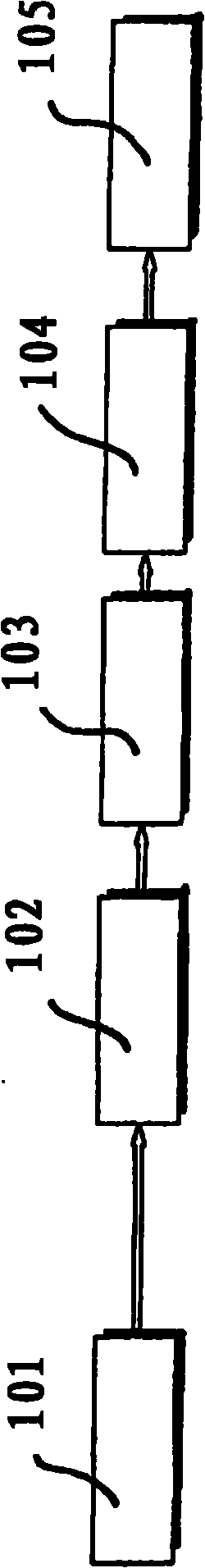

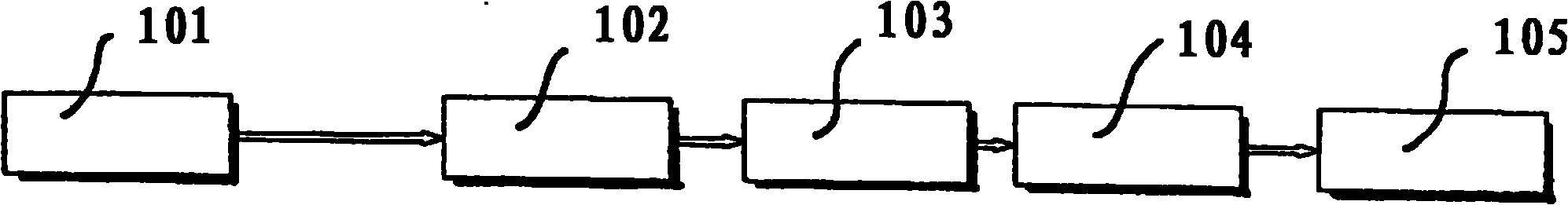

[0030] According to the invention and see figure 2 , comprising the steps of extrusion and obtaining, indicated by reference numeral 101 , an original ceramic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com