Atomizing and heating assembly for electronic cigarette

A technology for heating components and electronic cigarettes, applied in tobacco, smoker's products, applications, etc., can solve the problems of insufficient atomization temperature, low atomization temperature, damage to the oil guide rope, etc., to save ceramic materials and increase the contact area. , The effect of improving the oil conduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

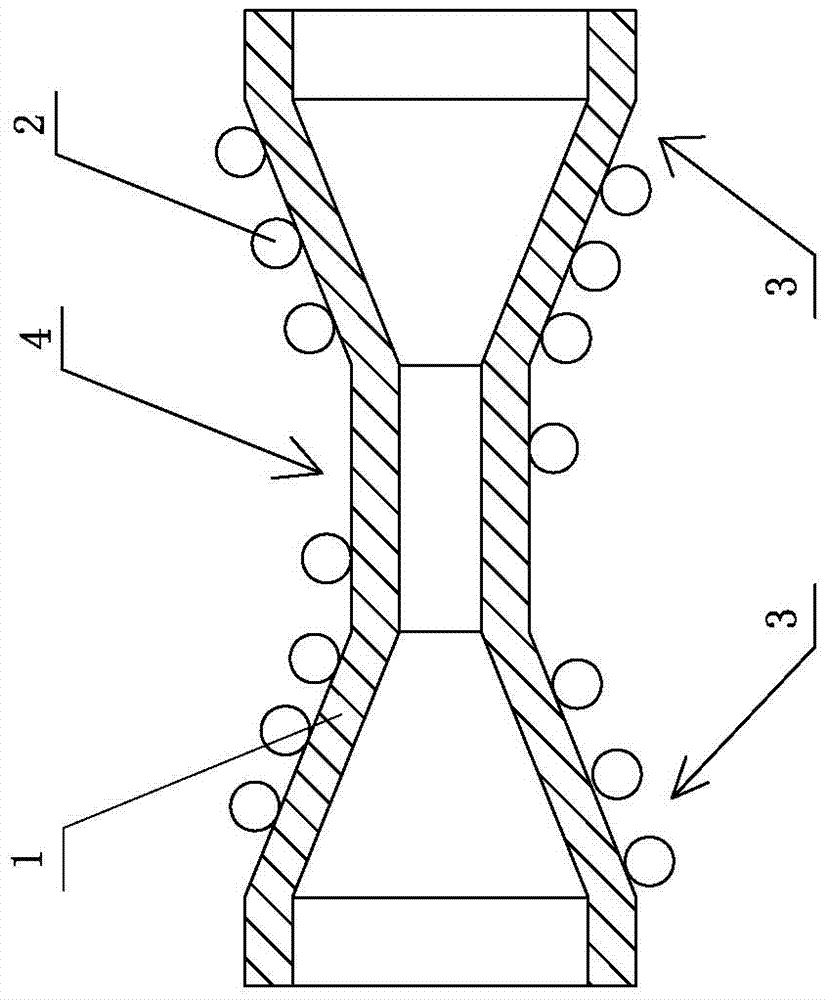

[0016] Such as figure 1 As shown, an electronic smog heating component includes a ceramic heating core 1 and a heating wire 2. The heating core 1 is in the shape of a double-circle platform, and the heating wire 2 is regularly wound on its outer surface; the ceramic heating core 1 is close to the outer end 3 The amount of e-liquid in the oil guide is relatively sufficient, and with the progress of the oil guide, from the outer end 3 to the middle part 4, the diameter of the ceramic heating core 1 is getting smaller and smaller, and the amount of e-liquid in the middle part 4 needs to be increased The less; it not only saves the ceramic material used in the heating core 1, but also increases the contact area between the smoke oil and the ceramic material, and improves the oil conduction rate. The ceramic material of the ceramic heating core 1 is porous ceramics, foam ceramics, etc. These ceramic materials have high chemical stability, high thermal conductivity, and can pass thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com