Cutting device for eradicating shaping and deformation of rails

A technology of plastic deformation and cutting device, which is applied in the direction of track, track laying, track maintenance, etc., to achieve the effect of optimizing system configuration, simplifying structure, and wide voltage adaptation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

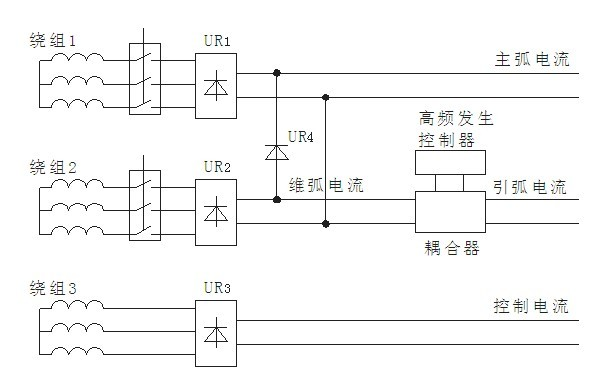

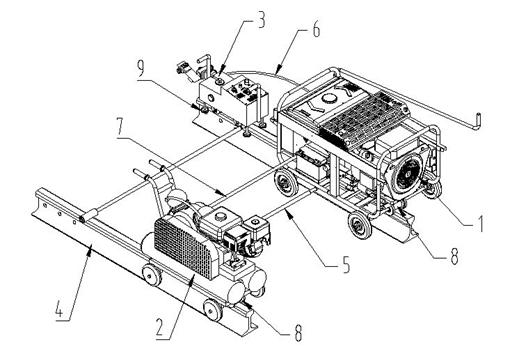

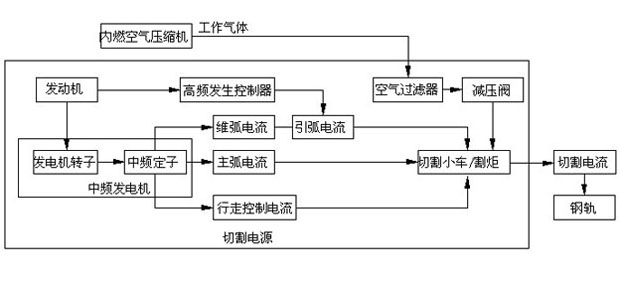

[0033]The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0034] see figure 1 , The cutting device includes an internal combustion plasma cutting intermediate frequency power supply 1, an internal combustion air compressor 2, and a self-propelled trolley 3 with a cutting torch. The intermediate frequency power supply 1 for internal combustion plasma cutting and the internal combustion air compressor 2 are respectively equipped with insulated running wheels 8, which are connected to each other through connecting rods 5, and ensure the distance between the insulating running wheels 8 between the intermediate frequency power supply 1 for internal combustion plasma cutting and the internal combustion air compressor 2. The distance between them is equal to the distance between the two steel rails 4, and is installed on the steel rails 4 to realize stable transport and push walking on the steel ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com