Installation structure for dustproof net

A technology of dust-proof net and configuration area, which is applied in the layout of power unit cooling combined, mechanical equipment, engine cooling, etc., can solve the problems of restriction, complicated production of dust-proof net, and difficulty in loading and unloading of dust-proof net, etc. Achieve the effect of prolonging life, low production cost and excellent versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, embodiment of the arrangement structure of the dustproof net of this invention is demonstrated based on drawing.

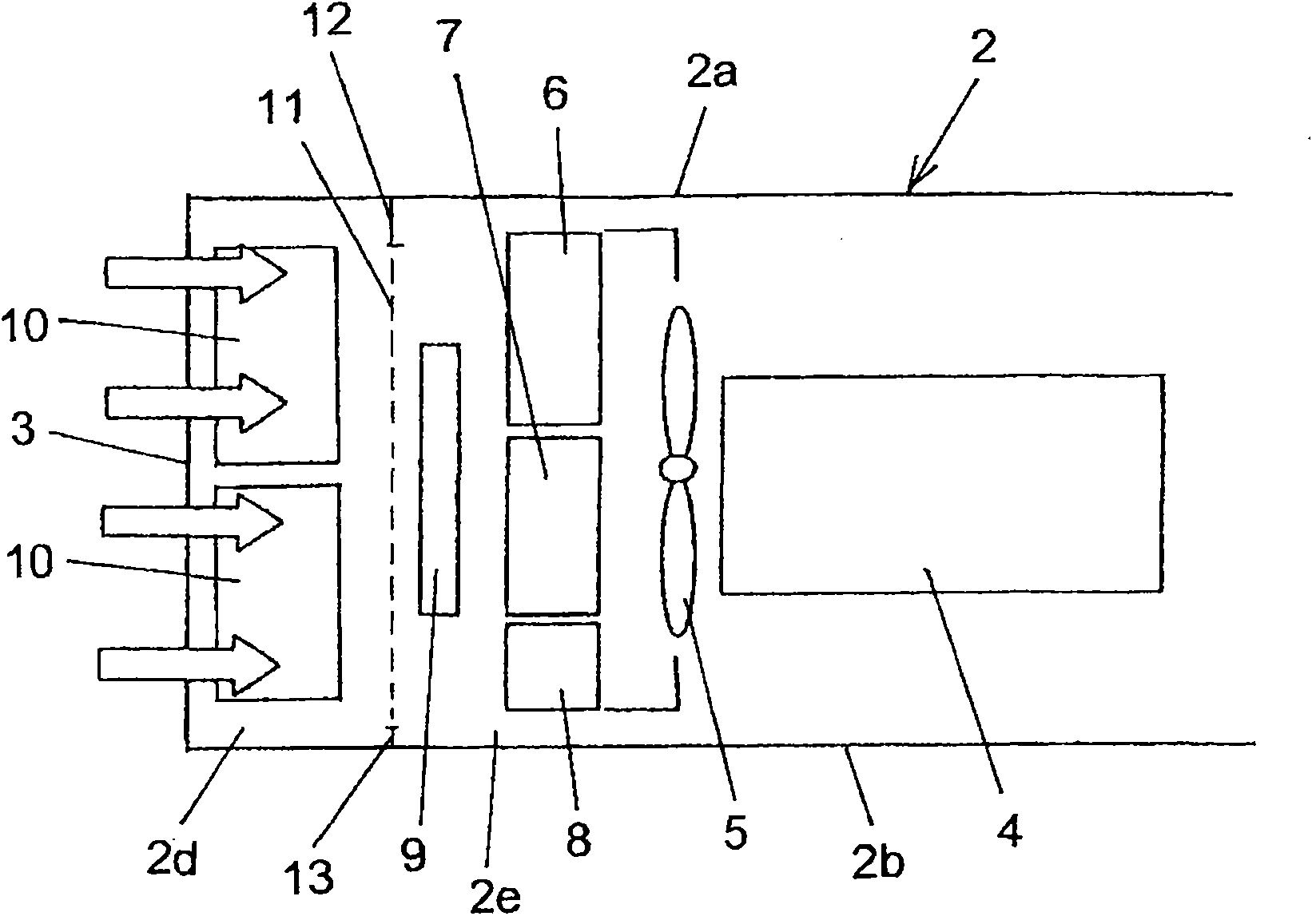

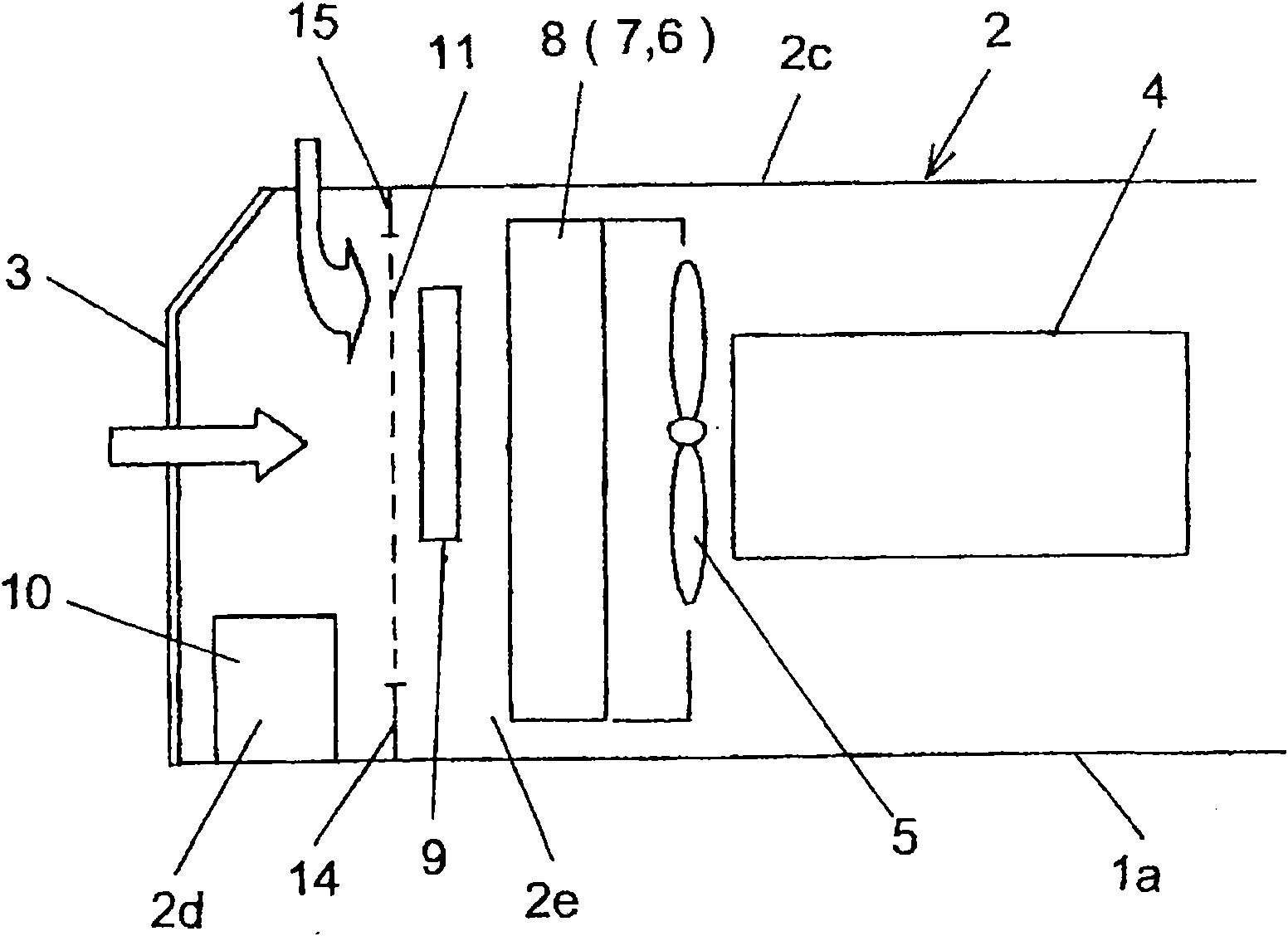

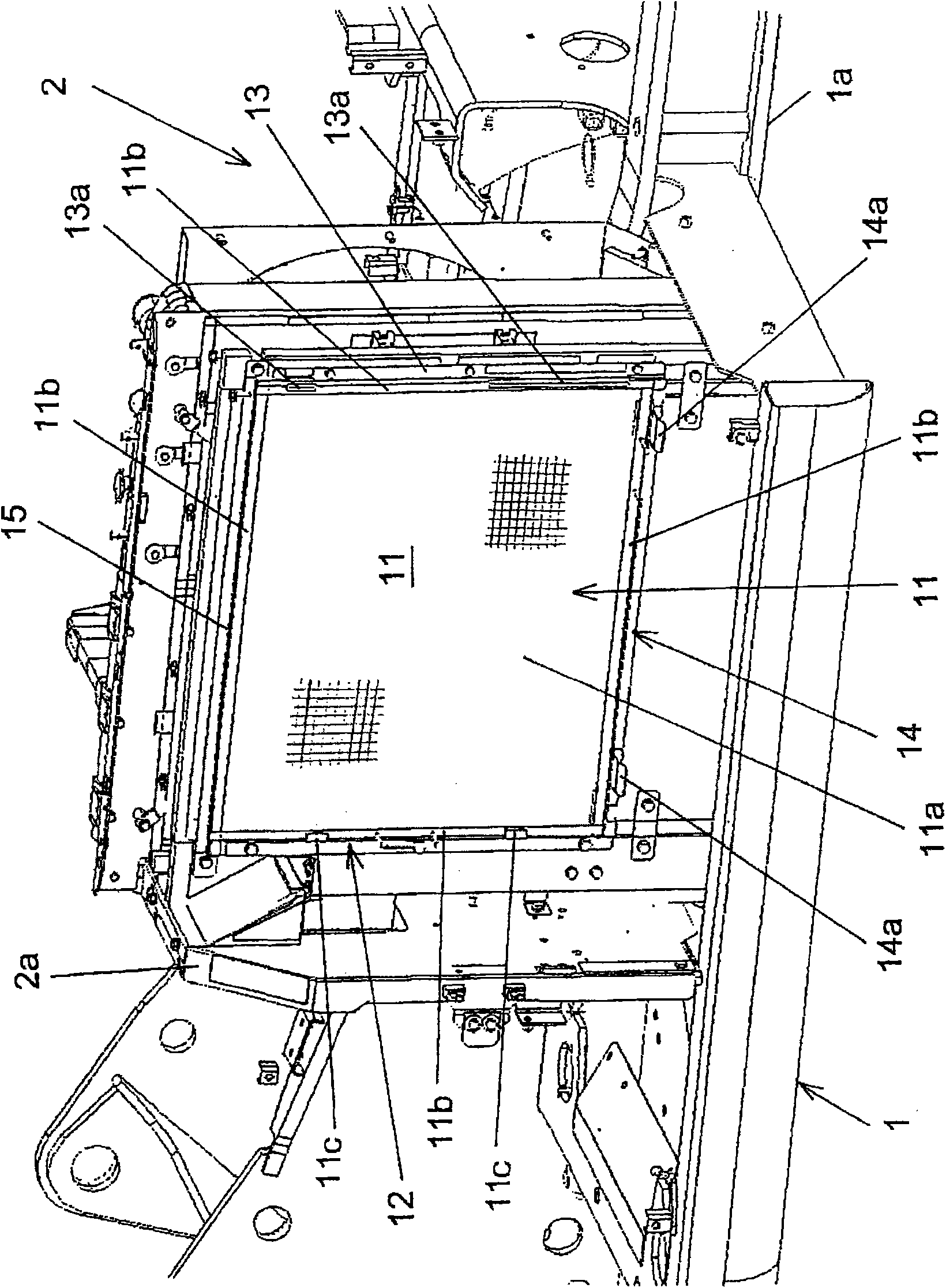

[0027] The arrangement structure of the dustproof net of this embodiment is equipped on a mechanical device such as a hydraulic excavator which is a construction machine. This hydraulic excavator has: a running body not shown in the figure; image 3 , Figure 6 and a front work machine (not shown) that is rotatably mounted on the swing body 1 in the vertical direction and performs excavation work of sand and soil. The revolving body 1 is provided with: an unillustrated driver's cab and a counterweight for ensuring weight balance; figure 1 , 2 Engine compartment 2 as shown.

[0028] as it should figure 1 , 2 and Figure 5 , 6 As shown, the engine room 2 houses: an engine 4; a cooling fan 5 that generates cooling air for cooling the engine 4; 6, radiator 7 for engine cooling, intercooler 8 for turbocharger, and condenser 9 for air condit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com