Jet continuous spheroidizing process

A spheroidization and process technology, which is applied in the field of spheroidization process to realize continuous spheroidization of molten iron, can solve the problems of low spheroidization level, uneven spheroidization and spheroidization decline of ductile iron, and achieves fast dissolution and diffusion speed and saves money. Rare metals, anti-burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

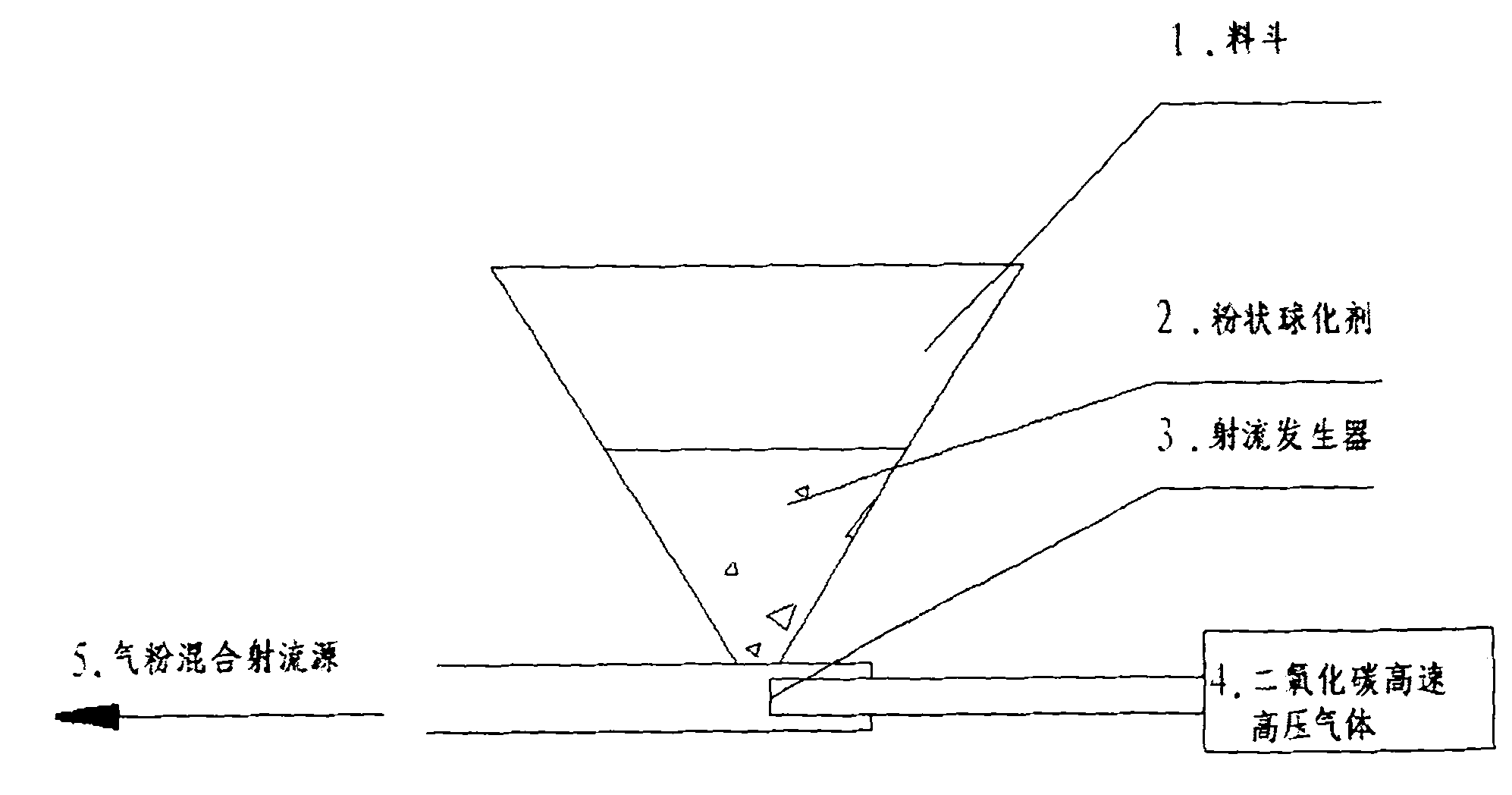

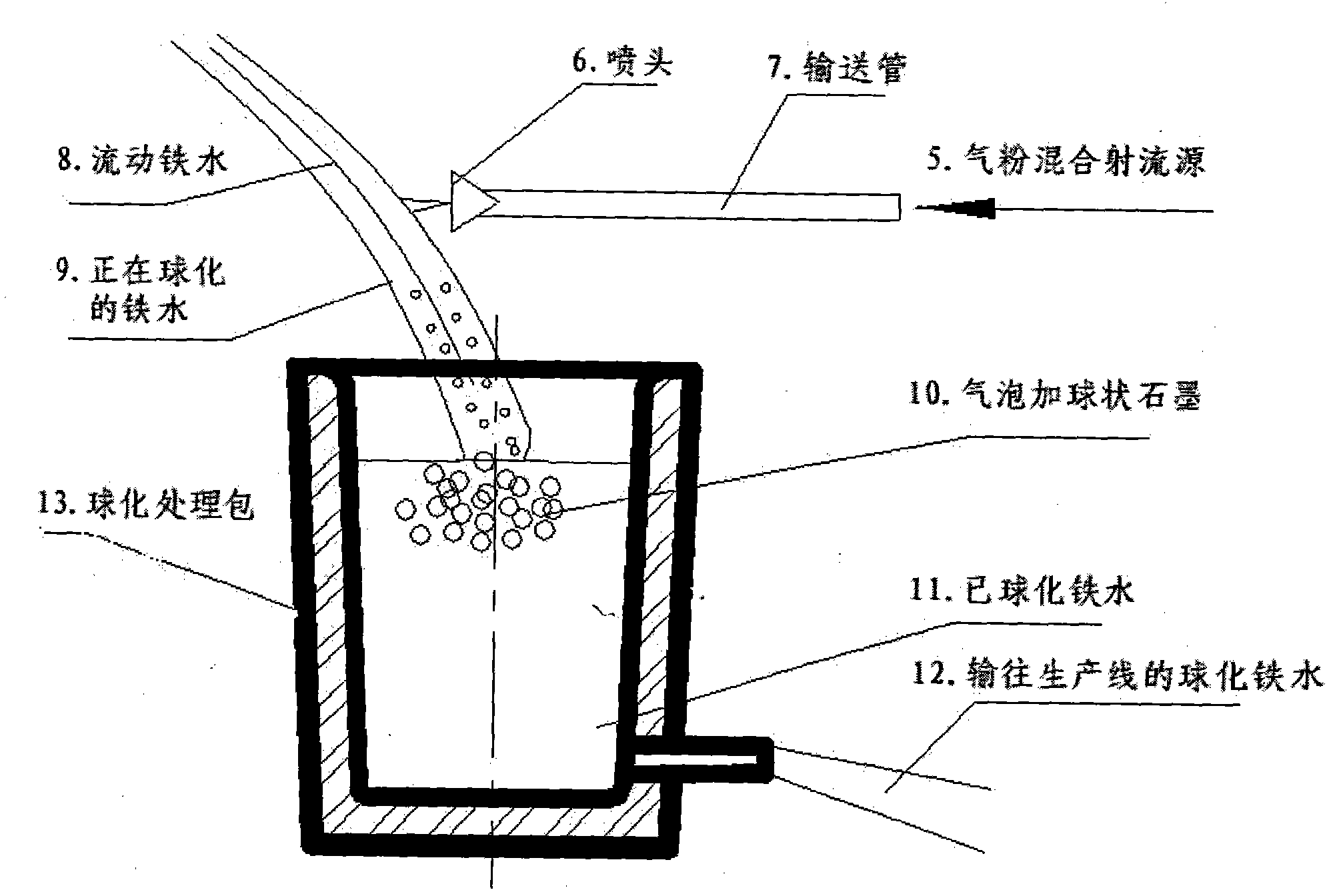

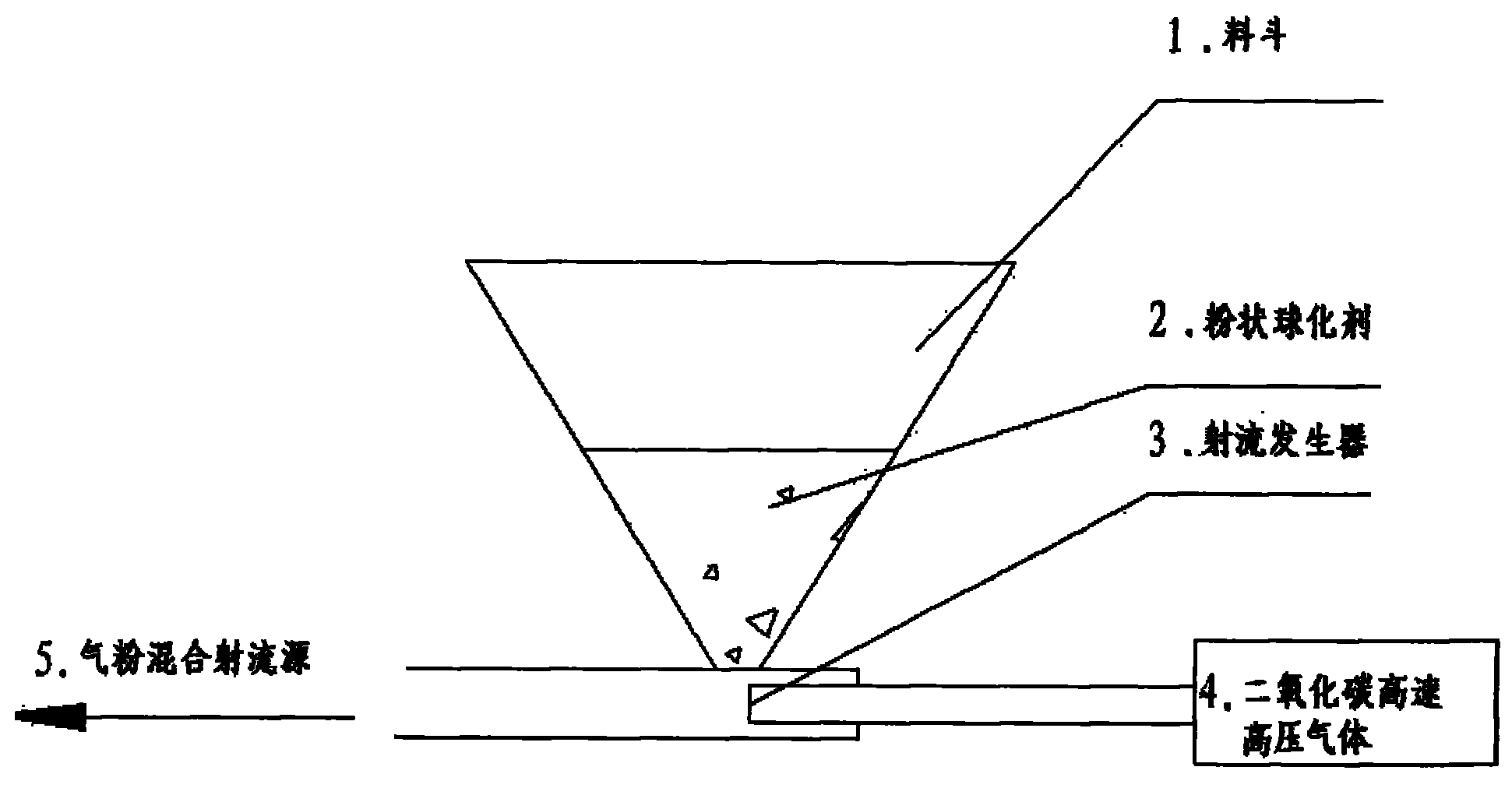

[0021] see figure 1 and figure 2 , add superfine powder spheroidizer 2 into the hopper 1, and after heating to above 800 degrees, enter the jet generator 3 connected to the bottom of the hopper 1, and input high-speed and high-pressure carbon dioxide gas 4 at one end of the jet generator 3 , forming a gas-powder mixing jet source 5 in the jet generator 3, and flowing molten iron 8 is input from the delivery pipe 6 and the nozzle 7 at the other end of the jet generator 3. The flowing molten iron 8 enters the spheroidizing treatment bag 13 for spheroidizing, and completes the whole process.

[0022] This process can directly spheroidize molten iron by using pure magnesium as a nodulizer without special equipment or special process.

[0023] The technical problem to be solved by the present invention is to provide a method that can prevent the magnesium in the nodulizer from burning during the mixing process of the nodularizer and molten iron during the production of nodular c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com