Reinforced concrete internal mold with multi-direction fixed supports

A technology of reinforced concrete and fixed supports, which is applied to formwork/formwork/work frame, on-site preparation of building components, building components, etc. Strong impact and anti-floating ability, high floor hollowness, good self-stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

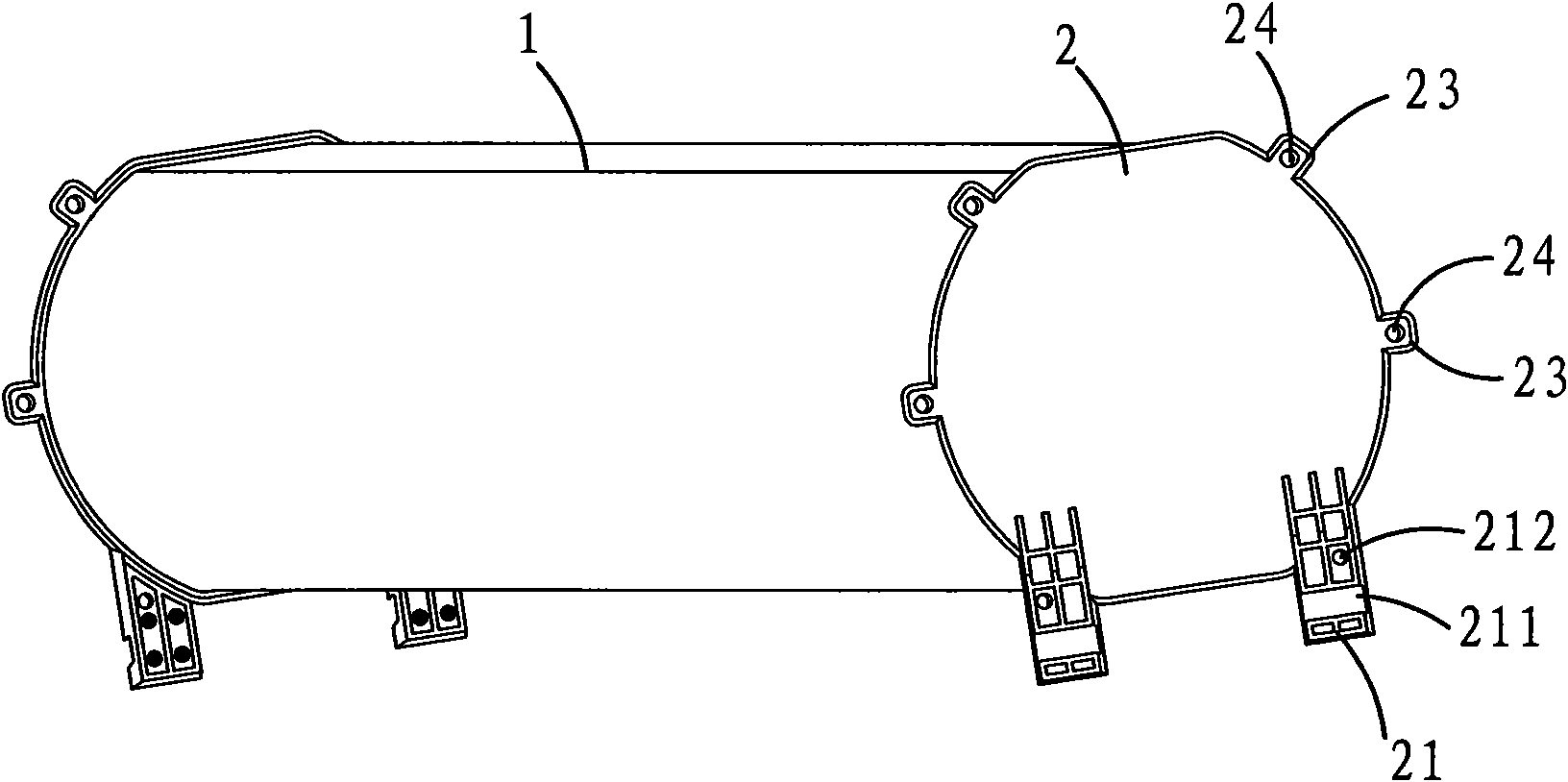

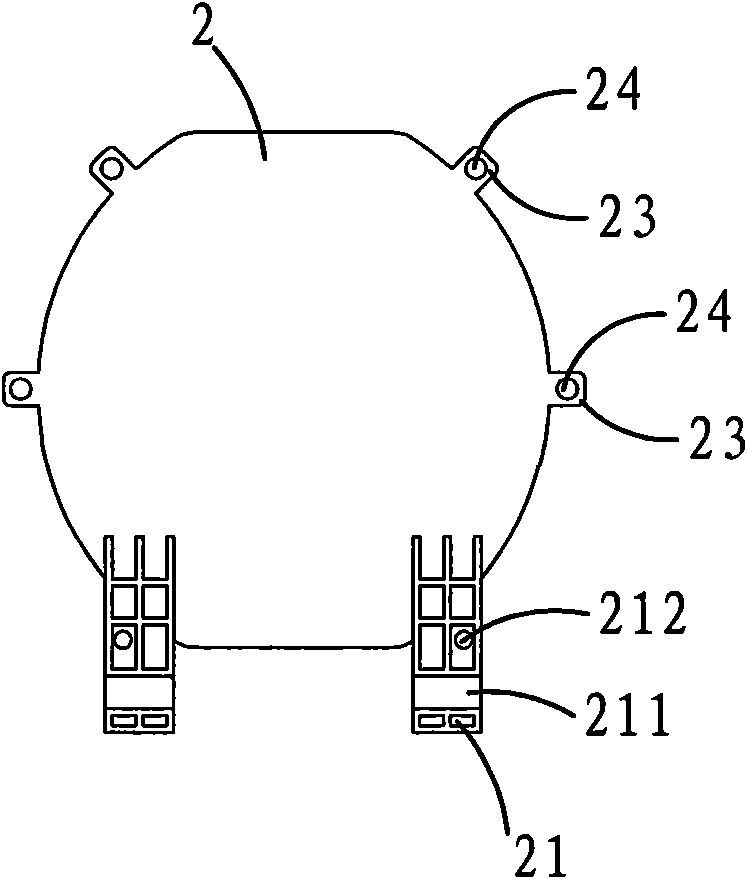

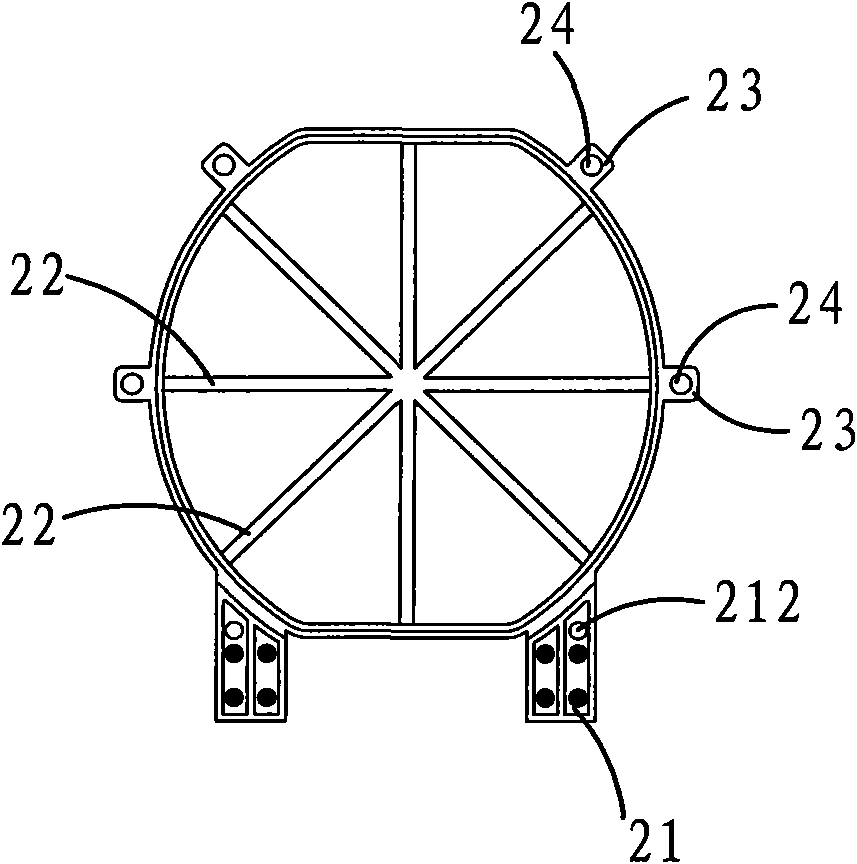

[0027] Please also see figure 1 , 2 , 3 and 4 are structural representations of the concrete inner mold with multi-directional fixed brackets of the present invention, a reinforced concrete inner mold with multi-directional fixed brackets, comprising a hollow cylinder 1 and end caps 2 at both ends, the hollow Cylinder 1 is a quasi-circular hollow cylinder, and its cross-sectional shape is a quasi-circular shape in which the upper and lower sides are straight and the left and right sides are arcs by cutting off the circular arcs at the top and bottom of the circle. The hollow cylinder is The PVC sheet is welded by ultrasonic waves. The section of the end cover 2 is corresponding to the hollow cylinder 1 to form a quasi-circular shape. The bottom of the end cover 2 is provided with two positioning pins 21, and the lower end of the positioning pins 21 is provided with a card slot 211 and a connection in a direction parallel to the end cover. In the hole 212 , two pairs of fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com