Transfer device and processing system having the same

A conveying device and processing system technology, applied in the field of processing systems, can solve the problems of difficult control of multiple substrate temperatures, large temperature differences, long reheating time, etc., and achieve the effect of shortening the reheating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

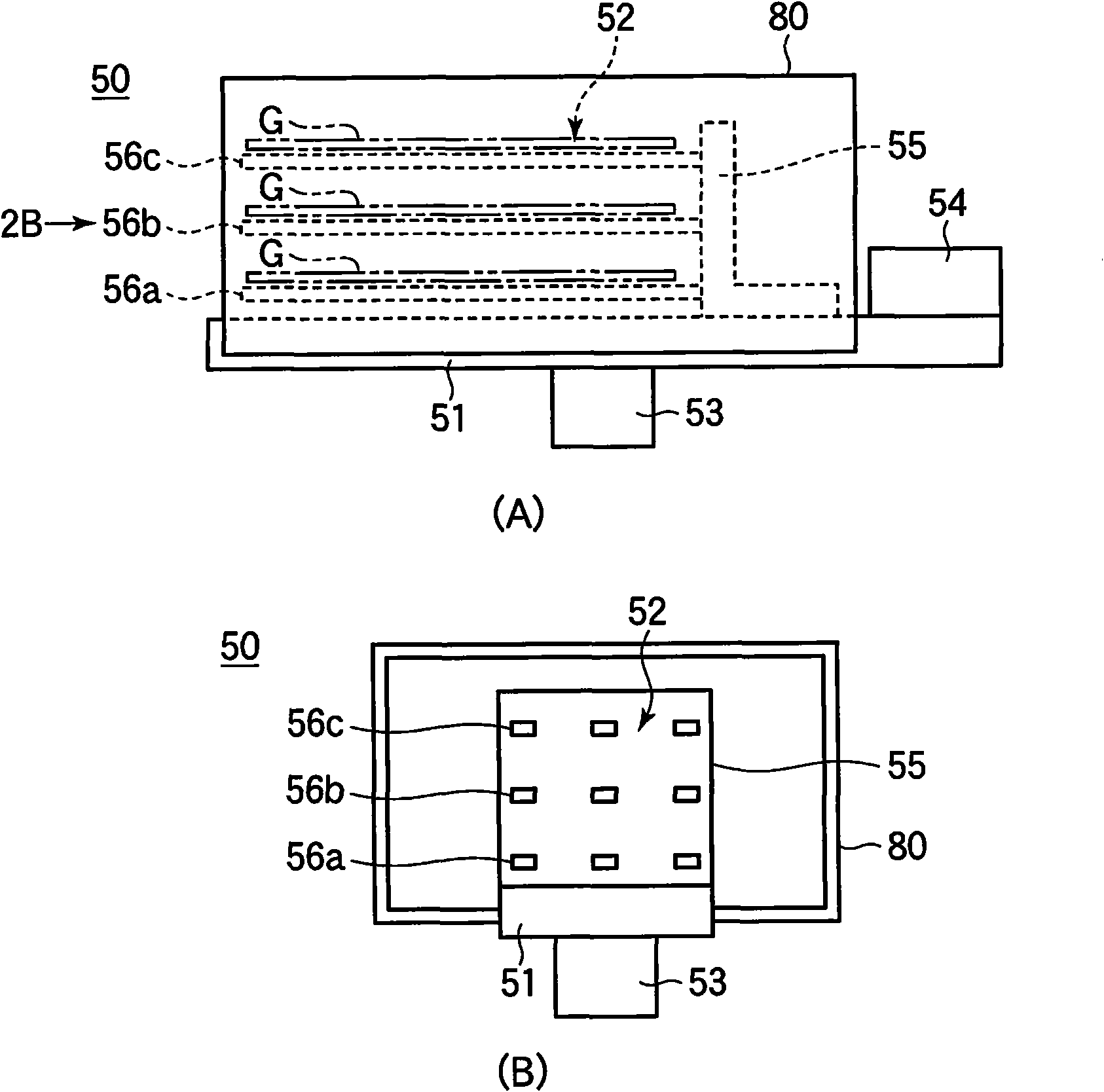

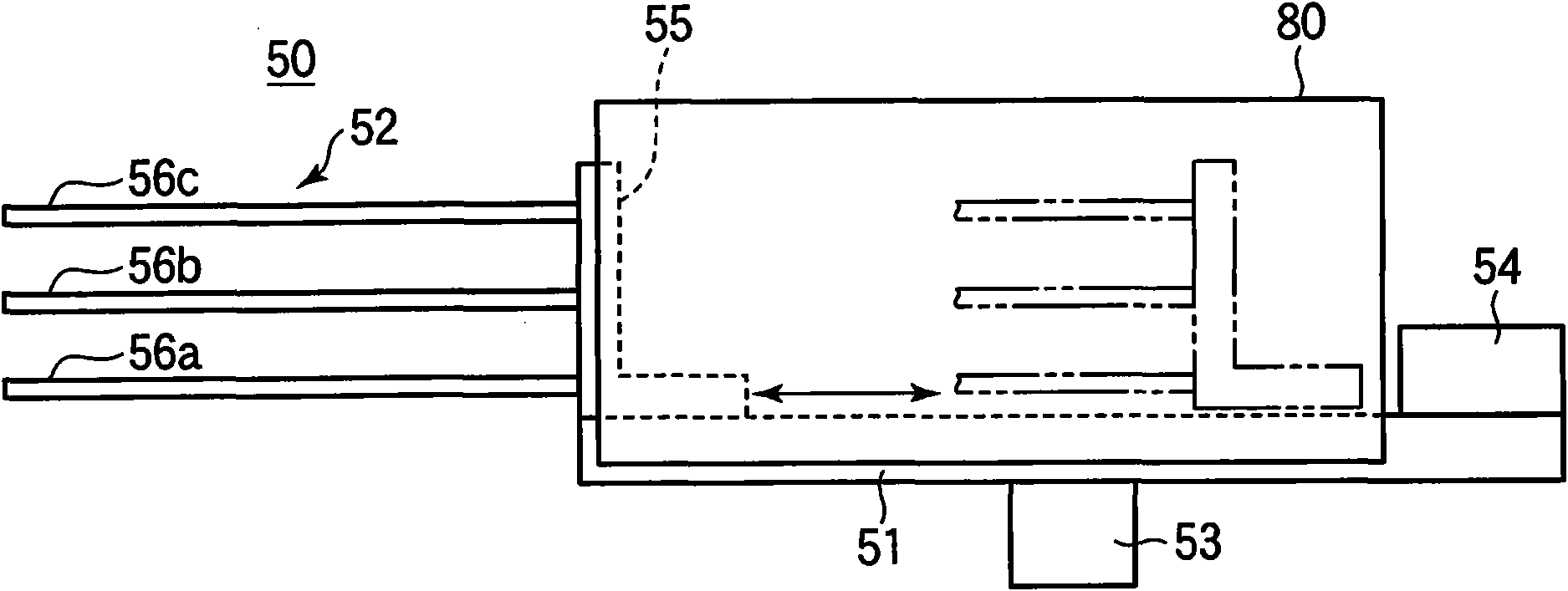

[0018] Hereinafter, an embodiment of the present invention will be described with reference to the drawings. In all the drawings referred to, the same reference numerals are attached to the same parts.

[0019] In this description, a large glass substrate for manufacturing solar cells and FPDs is cited as an example of the object to be processed, and a processing system for performing predetermined processing such as etching or film formation on the large glass substrate will be described as an example.

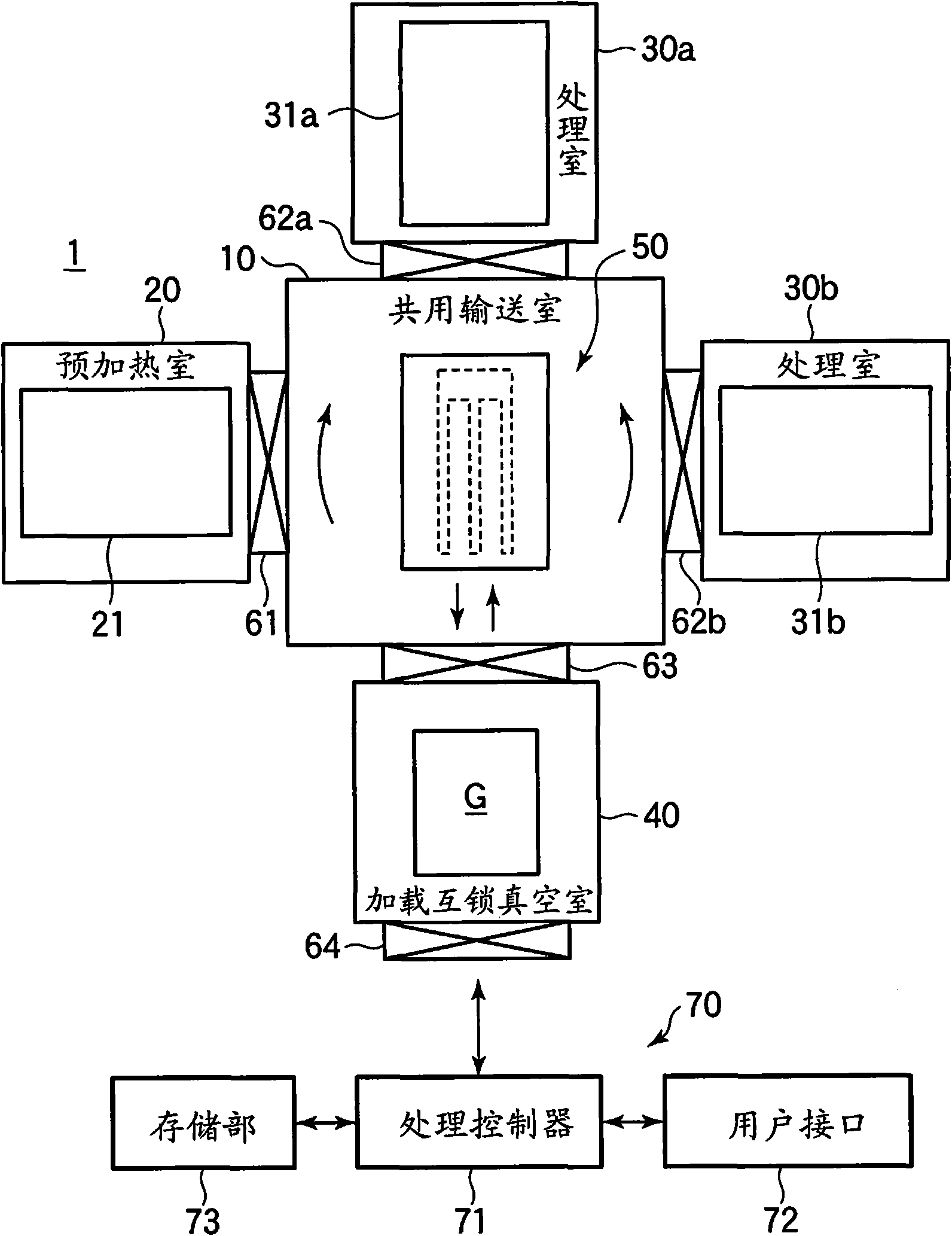

[0020] figure 1 It is a top view schematically showing the processing system of one embodiment of the present invention.

[0021] Such as figure 1 As shown, the processing system 1 of one embodiment includes: a common conveying chamber 10; a preheating chamber 20, which is connected to the common conveying chamber 10, and is used for preheating the object G to be processed; processing chambers 30a, 30b, which For performing etching, film formation, etc. on the object to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com