Quick-frozen steamed stuffed bun unfreezing and reheating process high-quality recovery method based on steamed stuffed bun wrapper special flour

A steamed bun skin and special powder technology, which is applied in application, food freezing, food heat treatment, etc., can solve the problems of difficult synchronous recovery of steamed bun skin and filling, long reheating time of frozen products, easy collapse of steamed bun skin, etc., and achieve moisture suppression Migration, shorten reheating time, and improve the effects of physical field effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a special powder for quick-frozen steamed buns, including 55 parts of flour, 2.9 parts of nanometer high acyl gellan gum-ultra-high pressure modified gluten powder, 1 part of ionic baking powder calcium dihydrogen phosphate, 0.7 part of yeast, 0.7 part of lard, 1.7 part of sugar, 0.7 part of salt.

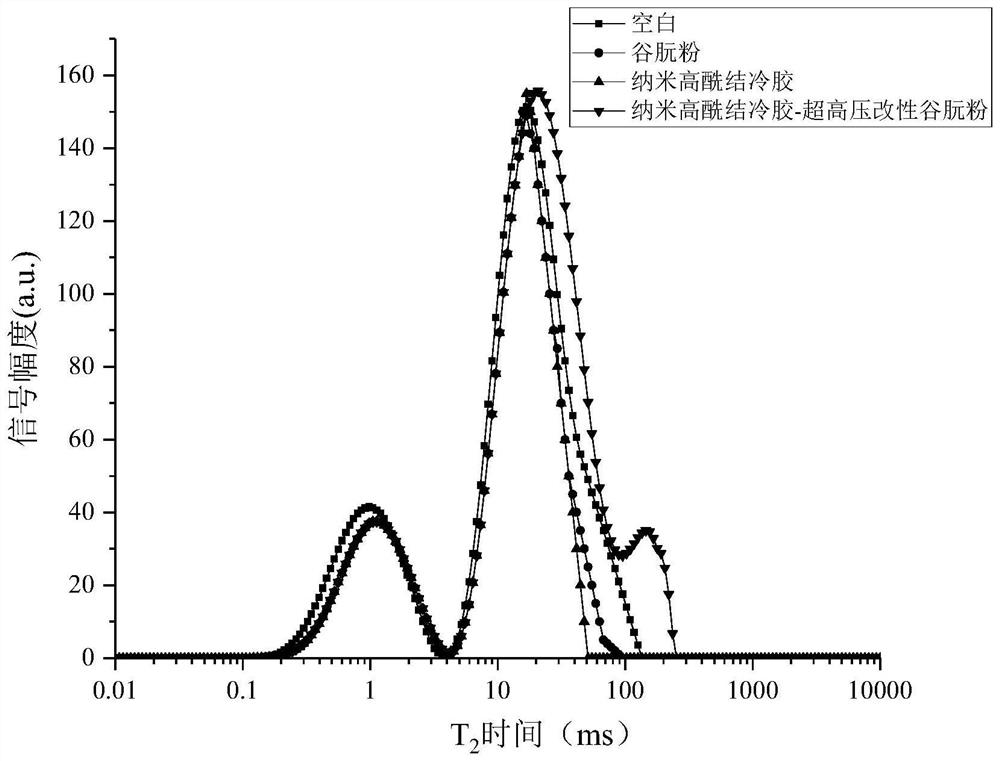

[0038] The preparation method of the nanometer high acyl gellan gum-ultra-high pressure modified gluten powder is as follows: the nanometer high acyl gellan gum and the gluten powder are evenly mixed according to the mass ratio of 1:13, and sealed in a place where the oxygen permeability is less than 4000cm 3 Then put it into the pressure-bearing container of the ultra-high pressure equipment, immerse it in water, adjust the pressure to 500MPa at room temperature, the action time is 19min, and store the mixture at 4°C after processing.

[0039] Using the above special powder to prepare quick-frozen steamed buns, the steps are as follows:

[0040] (...

Embodiment 2

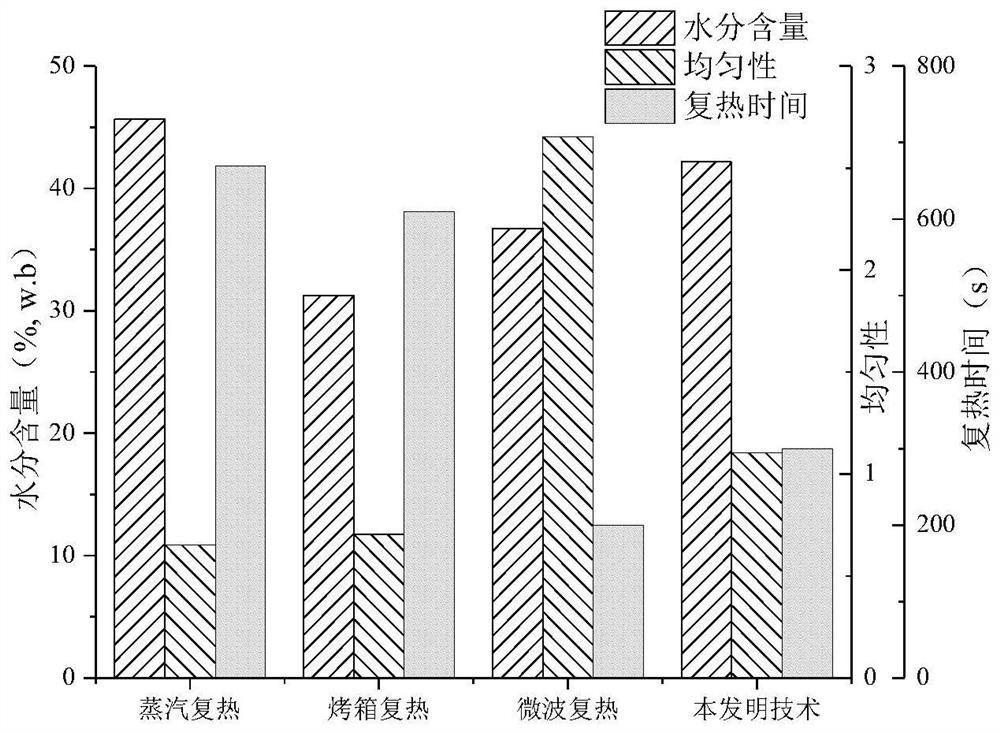

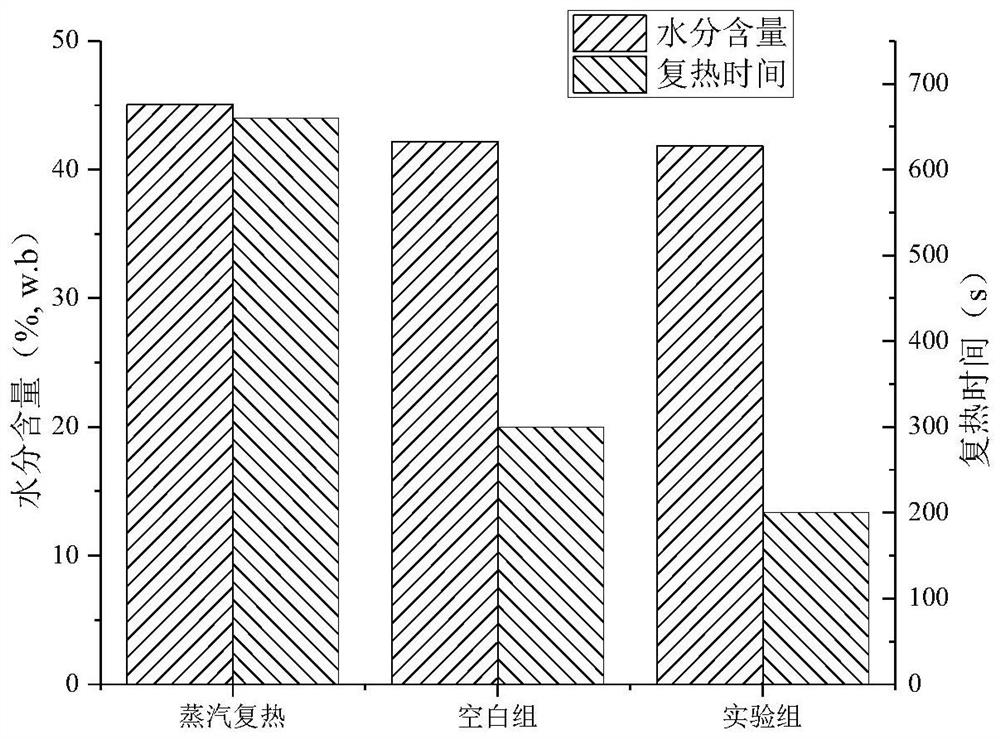

[0055] In this example, the effect of the amount of ionic baking powder added on the reheating effect was also studied, and the same special powder for quick-frozen steamed bun skins as in Example 1 was used to prepare quick-frozen steamed buns, wherein the addition of ionic baking powder to the special powder for quick-frozen steamed bun skins The mass percentages are 0%, 0.4%, 0.8%, 1.0%, 1.3%, and 1.5%. For the final prepared quick-frozen steamed buns, the same stage of humidity control and variable power radio frequency reheating as in Example 1 was carried out, and the results are shown in Table 2. Figure 4 This is the influence trend diagram of the synergistic enhancement effect of the different contents of ionic baking powder and the stage-controlled humidity and variable power RF reheating effect. Enhancement has a positive effect on shortening the reheating time, but when the content reaches 1%, the coupling effect tends to be stable, and the maximum reheating effect...

Embodiment 3

[0059] In this example, the effect of chitosan oligosaccharide-sorbitol addition on the reheating effect was also studied, and the same special powder for quick-frozen steamed buns as in Example 1 was used to prepare quick-frozen steamed steamed buns. The added mass percentage in the powder is 0%, 0.2%, 0.4%, 0.6%, 0.8%, 1.0%, 1.2%, 1.4%. For the final prepared quick-frozen steamed buns, the same stage of humidity control and variable power radio frequency reheating was performed as in Example 4. The results are shown in Table 3. It can be seen that with the increase of chitooligosaccharide-sorbitol content, the reheated meat The content of the stuffing soup is increased, the taste is more crisp and tender, and the quality is improved.

[0060] Table 3 Effects of different contents of ionic baking powder on synergistic enhancement effect

[0061]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com