Horizontal moving device for capillary pipe and pilger mill set having same device

A technology of traverse device and capillary tube, which is applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems affecting the quality and output of steel pipe rolling, increasing energy consumption and gas emission, and long pick-up and delivery journeys, etc. Achieve the effects of shortening reheating time, reducing energy consumption and gas emissions, and improving rolling quality and output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

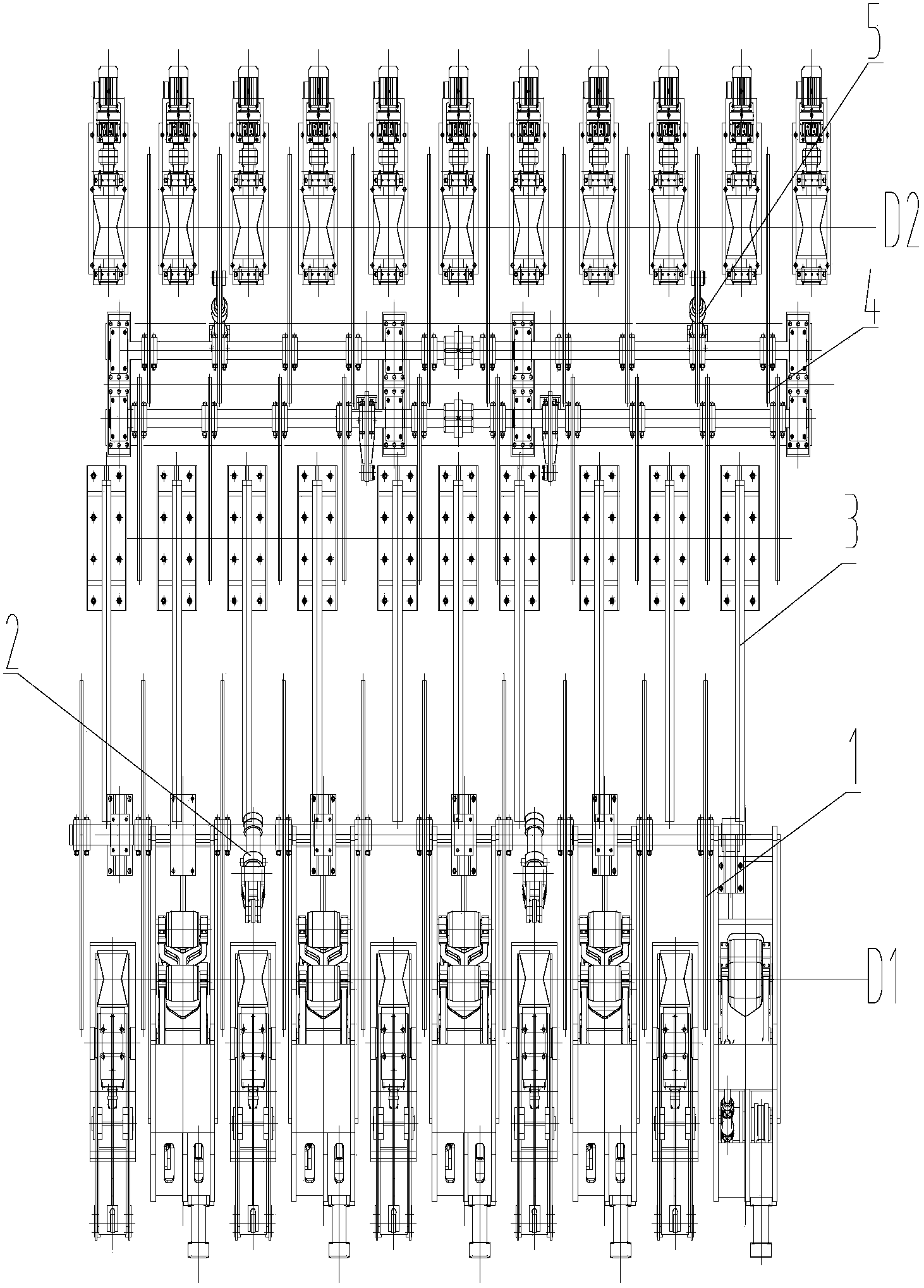

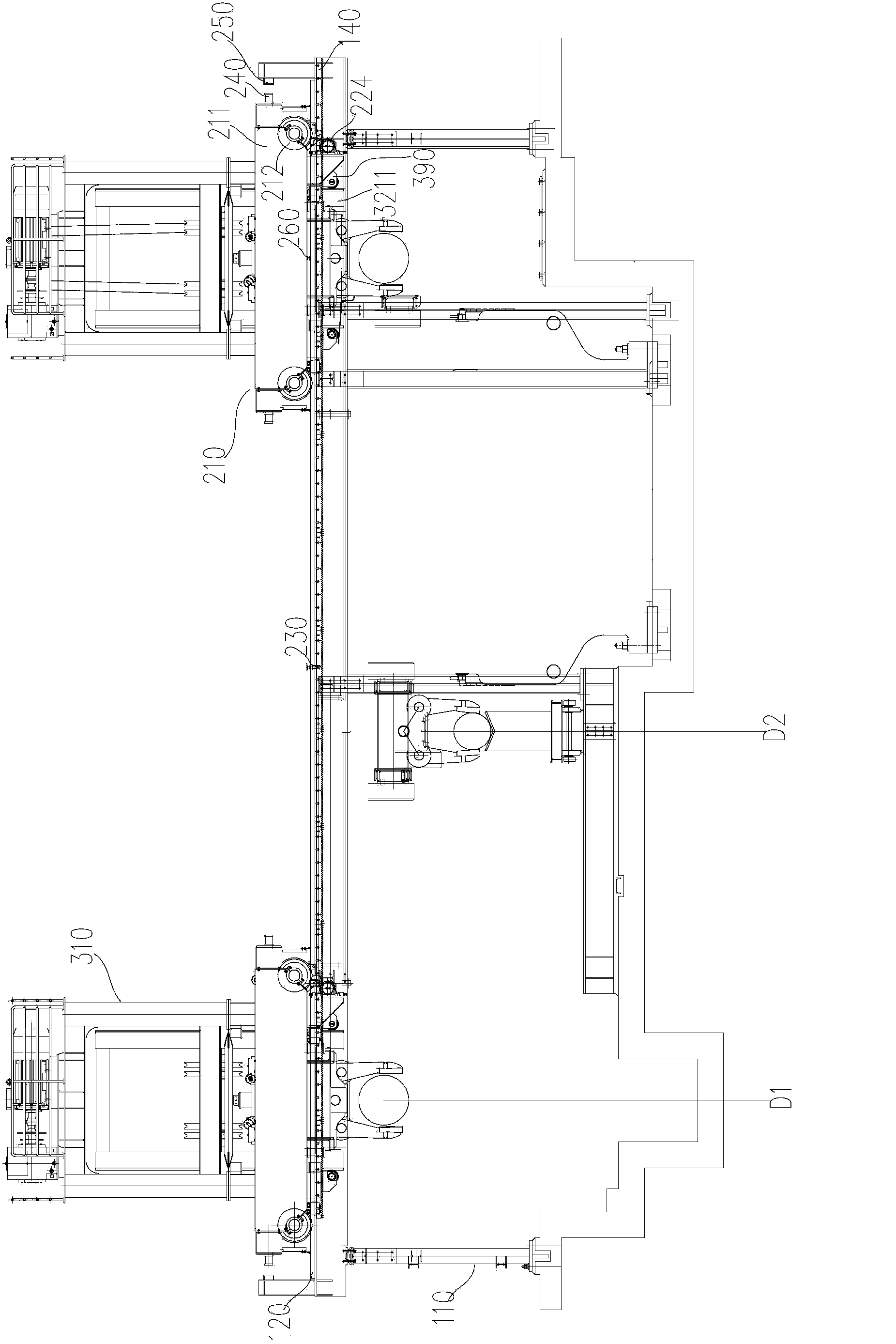

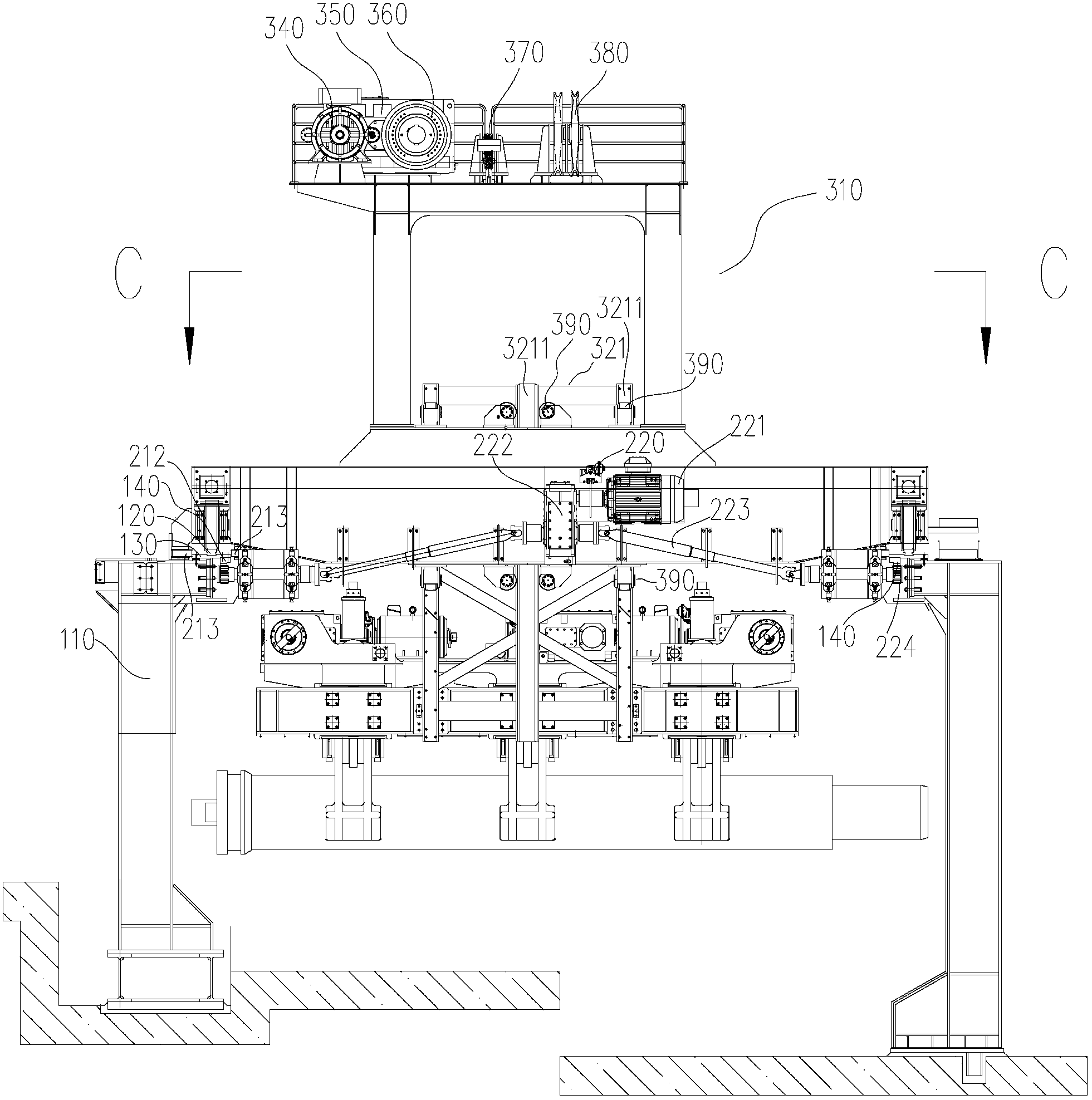

[0021] like figure 2 , 3 As shown, the capillary traversing device mainly includes a support beam frame, a traveling mechanism and a capillary lifting mechanism. The supporting beam frame includes a foot 110 fixed on the ground, a track 120 and a support frame 130 connecting the track 120 to the foot 110 . The rails 120 are arranged along both sides in the length direction of the working platform. A supporting frame 130 is provided between the supporting frame 110 and the track 120 . The supporting frame 130 is screwed to the supporting leg 110 . The lower surface of each support frame 130 is also provided with a rack 140 along the length direction of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com