Electronic photo frame with sliding rail structure

A technology for electronic photo frames and slide rails, which is applied to mirrors, picture frames, household appliances, etc., can solve the problems of unfavorable thinning of electronic photo frames, expensive fixed force spring sets, and many components, etc., to achieve great practical value and increase convenience. The effect of sex, large load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0053] In order to describe in detail the embodiments of the present invention, please refer to the following examples:

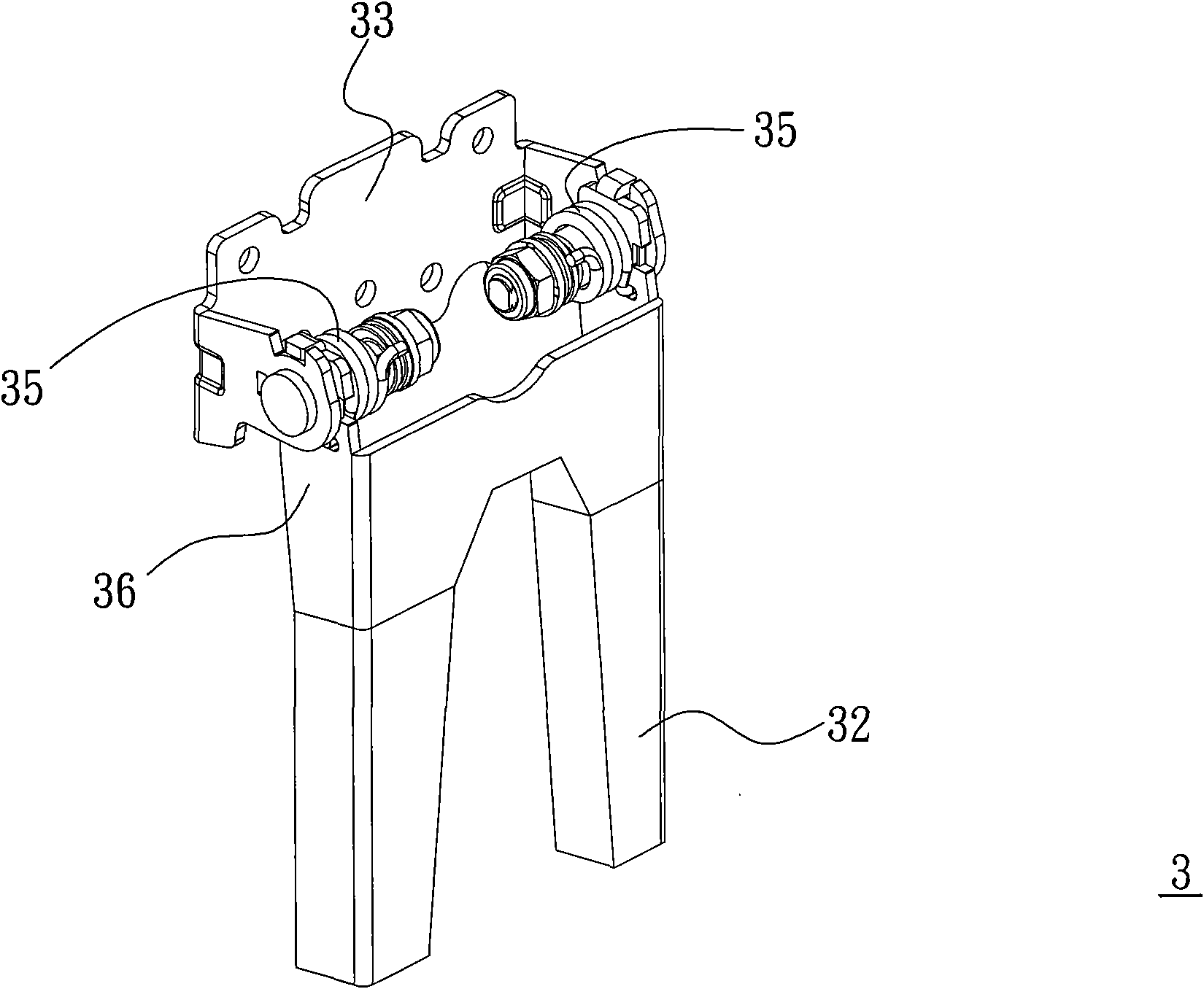

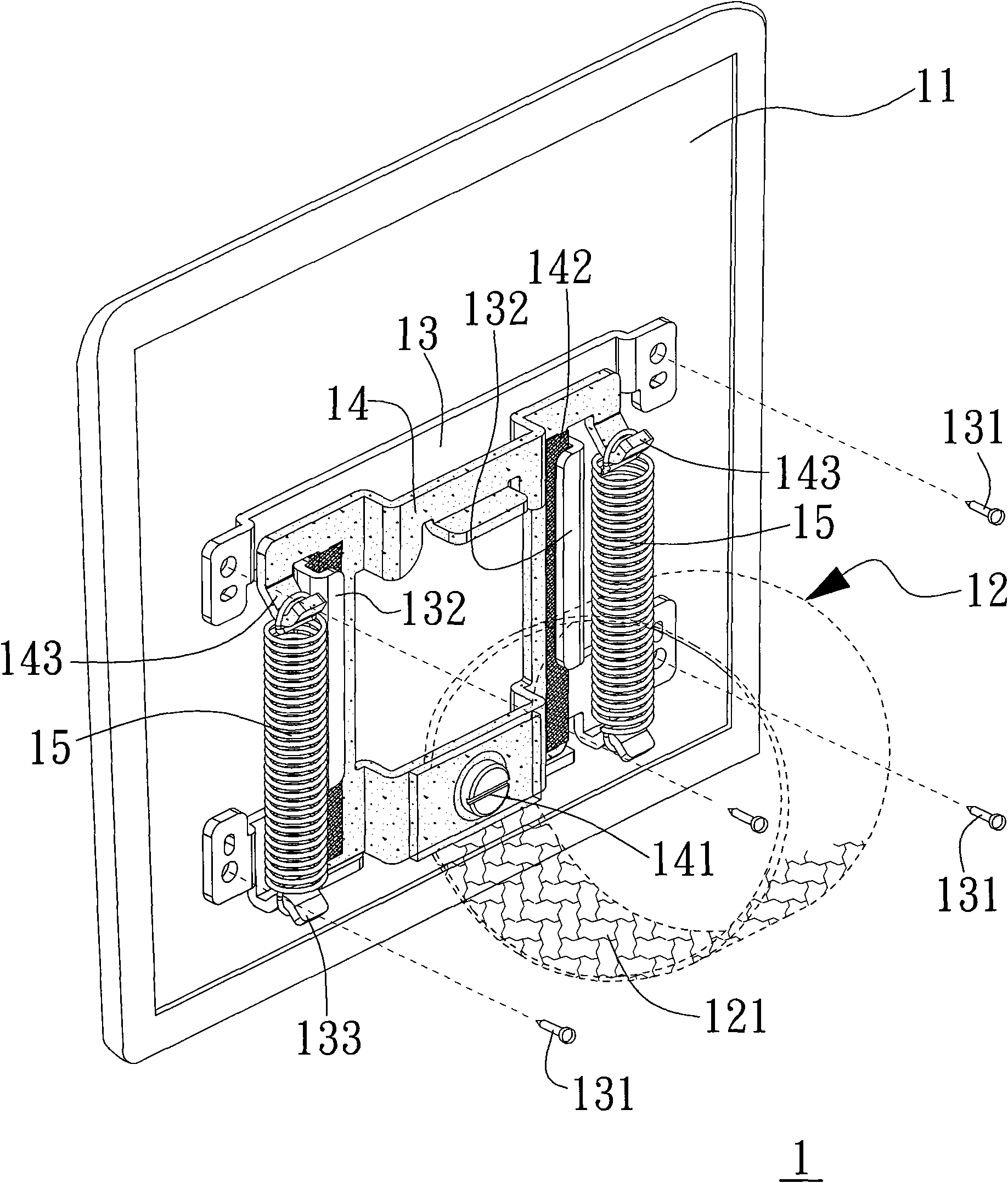

[0054] See image 3 , image 3 Shown is a schematic view of the spring of the electronic photo frame with a slide rail structure provided by the embodiment of the present invention when no force is applied. Such as image 3As shown, the electronic photo frame 1 includes a rear case 11 , a tripod 12 , a fixing part 13 , a sliding part 14 and two springs 15 . Wherein, the fixing member 13 uses a plurality of screws 131 to lock and fix the corners of the fixing member 13 on the rear shell 11, and the fixing member 13 includes two slide rails 132 and two hook-shaped first connecting parts. Section 133. The sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com