Rectilinear manipulator for seal welding

A manipulator and straight line technology, applied in the direction of manipulators, program control manipulators, welding equipment, etc., can solve the problems of high labor intensity, difficult quality assurance, low efficiency, etc., to protect product safety, improve production quality and efficiency, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and examples, but not as a limitation to the present invention.

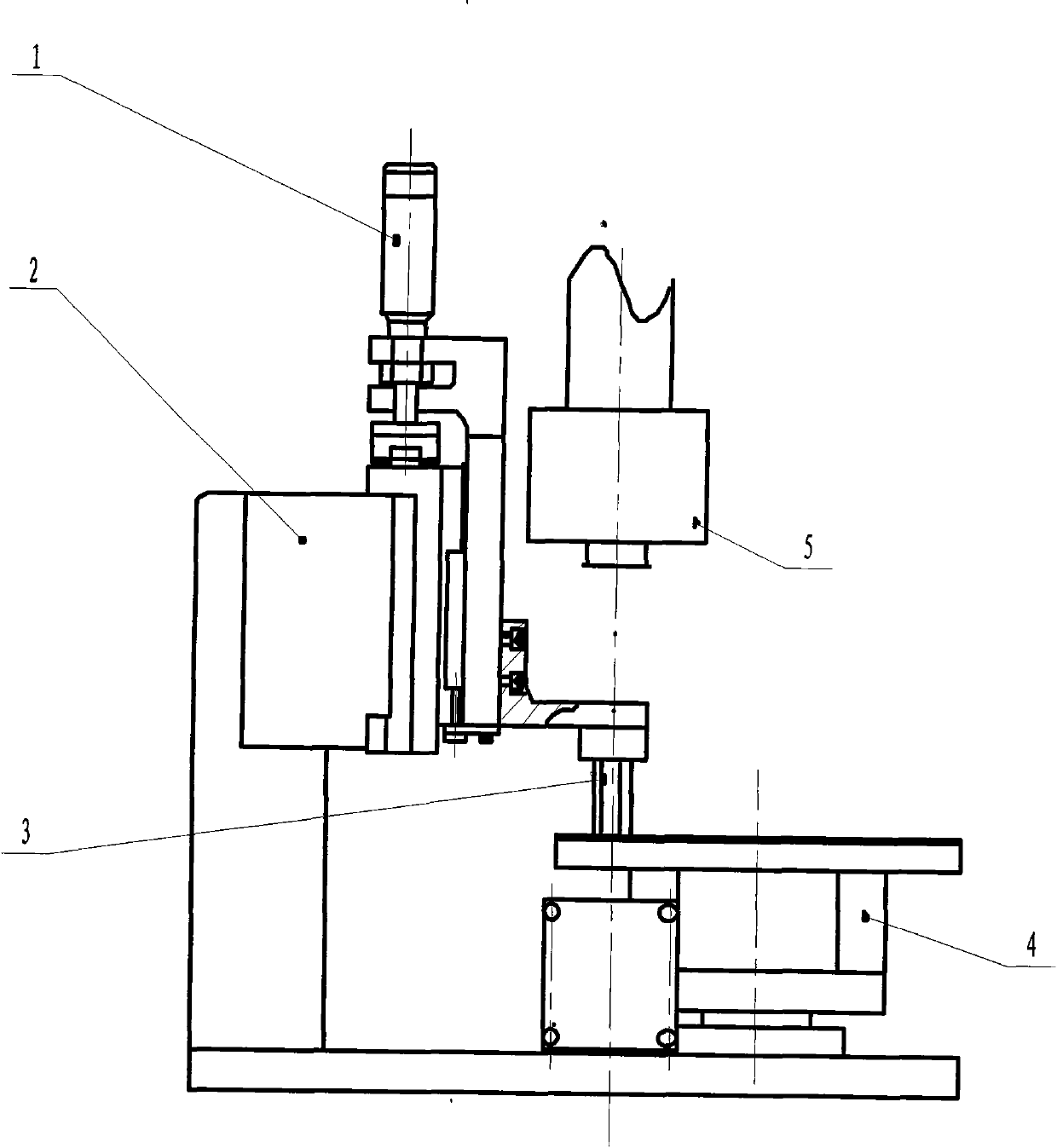

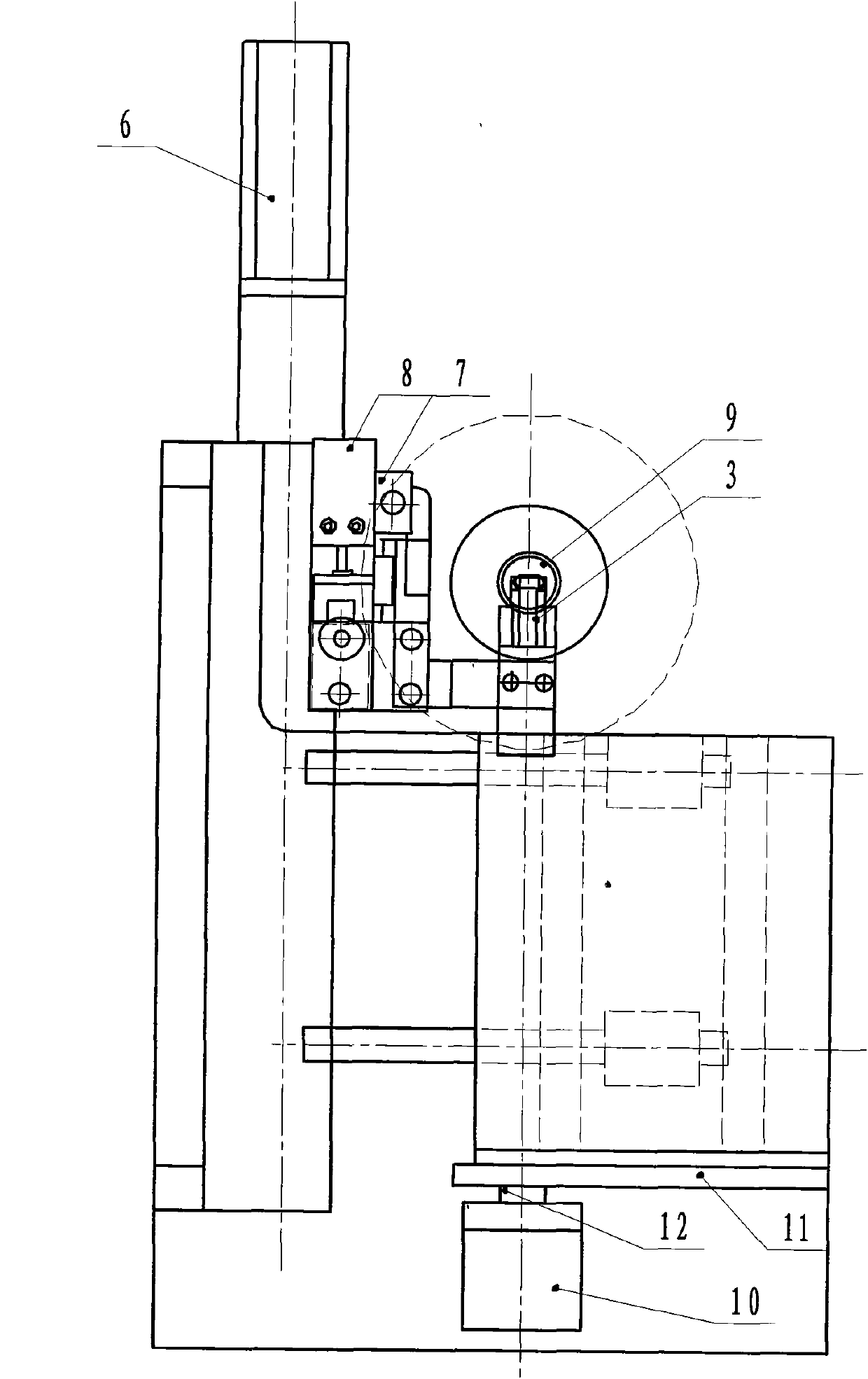

[0040] see figure 1 ~ Figure 10 . The linear manipulator for sealing and welding is characterized in that it mainly has a linear running mechanism in the X direction, a parallel feed mechanism in the Y direction, and a lifting mechanism on the linear running mechanism in the X direction ( Image 6 ) and its clamping mechanism, row and column arrangement type supporting mechanism (4), and operation control circuit ( Figure 7 ).

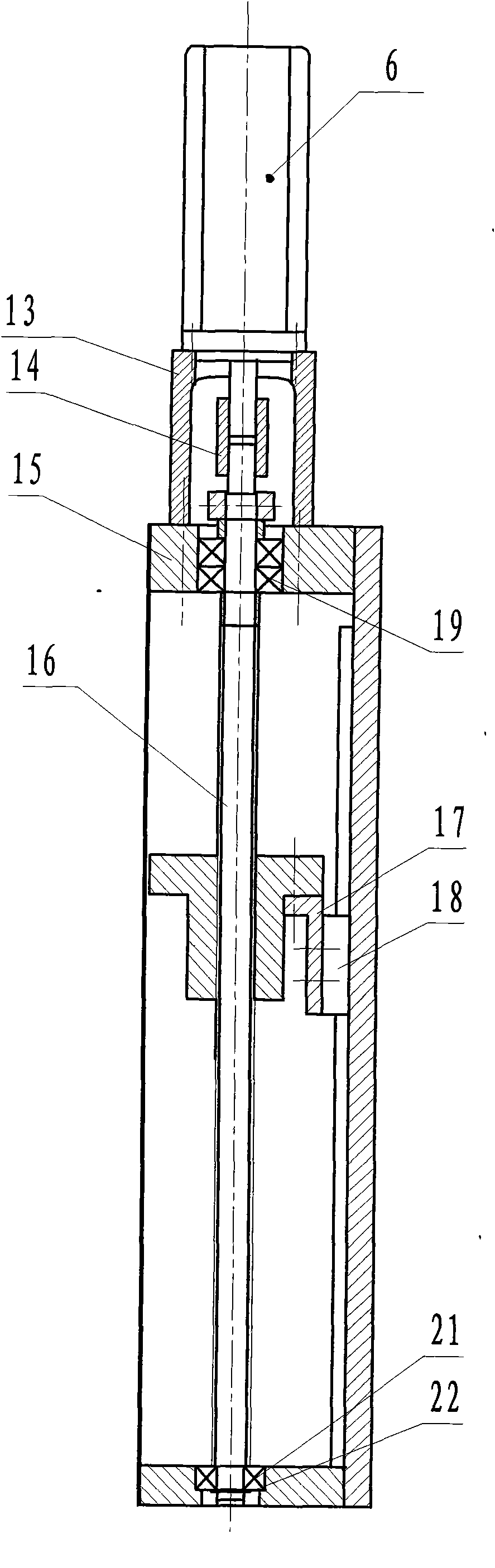

[0041] The structure of the linear movement mechanism in the X direction is as follows: the servo motor (6) or the stepper motor is connected to the rotatable rolling ball screw (16), and the lock nut of the rolling ball screw (16) is connected through the connecting plate and The linear guide rail slider (16) cooperates to limit the radial degree of freedom and drives its mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com