Hydrogen bottle mounting bracket for hydrogen fuel cell sedan

A technology for installing brackets and cars, which is applied to the layout combined with the fuel supply of internal combustion engines, power plants, vehicle components, etc., which can solve problems such as easy cracking of brackets, no visible structure, complex structure, etc., and increase support strength and anti-collision performance , Reduce installation difficulty, good support strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and implementation methods.

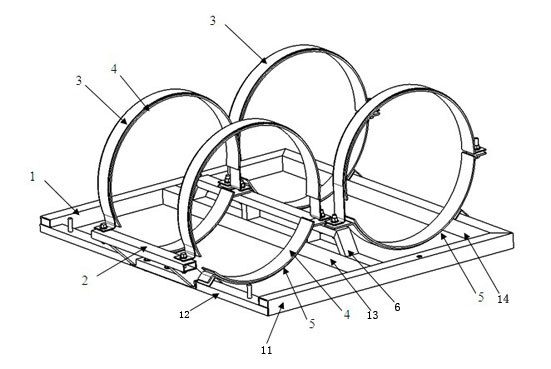

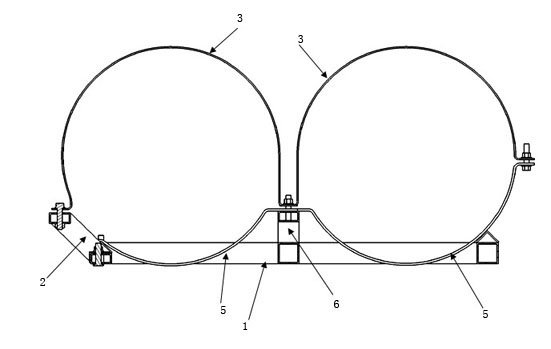

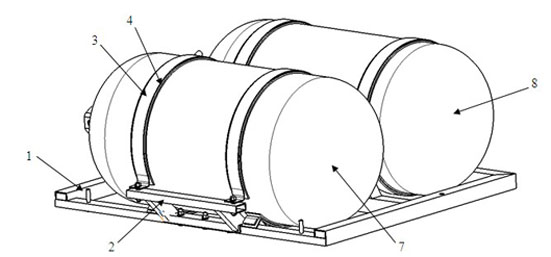

[0016] Such as figure 1 As shown, the gas cylinder mounting bracket is mainly composed of a fixed base 1, a movable bracket 2, an upper strap 3, a lower strap 5, a rubber pad 4 and a fixed bracket 6.

[0017] Among them, the fixed base 1 is welded together by two longitudinal beams 11 arranged in parallel and three parallel front, middle and rear beams 12, 13 and 14 to form a "day"-shaped frame structure, and the fixed base is fixed on the back of the car. on the back floor of the box.

[0018] On the front beam 12 of the fixed base 1, a movable bracket 2 is connected by bolts, and a fixed bracket 6 is arranged on the middle beam 13.

[0019] The upper strap 3 and the lower strap 5 encircle to form a pair of tie hoops, four pairs in total, and the rubber pad 4 is placed on the inner surface of the upper strap 3 and the lower strap 5.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com