Oxygen replenishment plate of straw gasification furnace

A technology of gasification furnace and oxygen distribution, which is applied in the manufacture of combustible gas and the petroleum industry, etc. It can solve the problems of partial burning and uneven oxygen supply, and achieve the effect of avoiding partial firing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

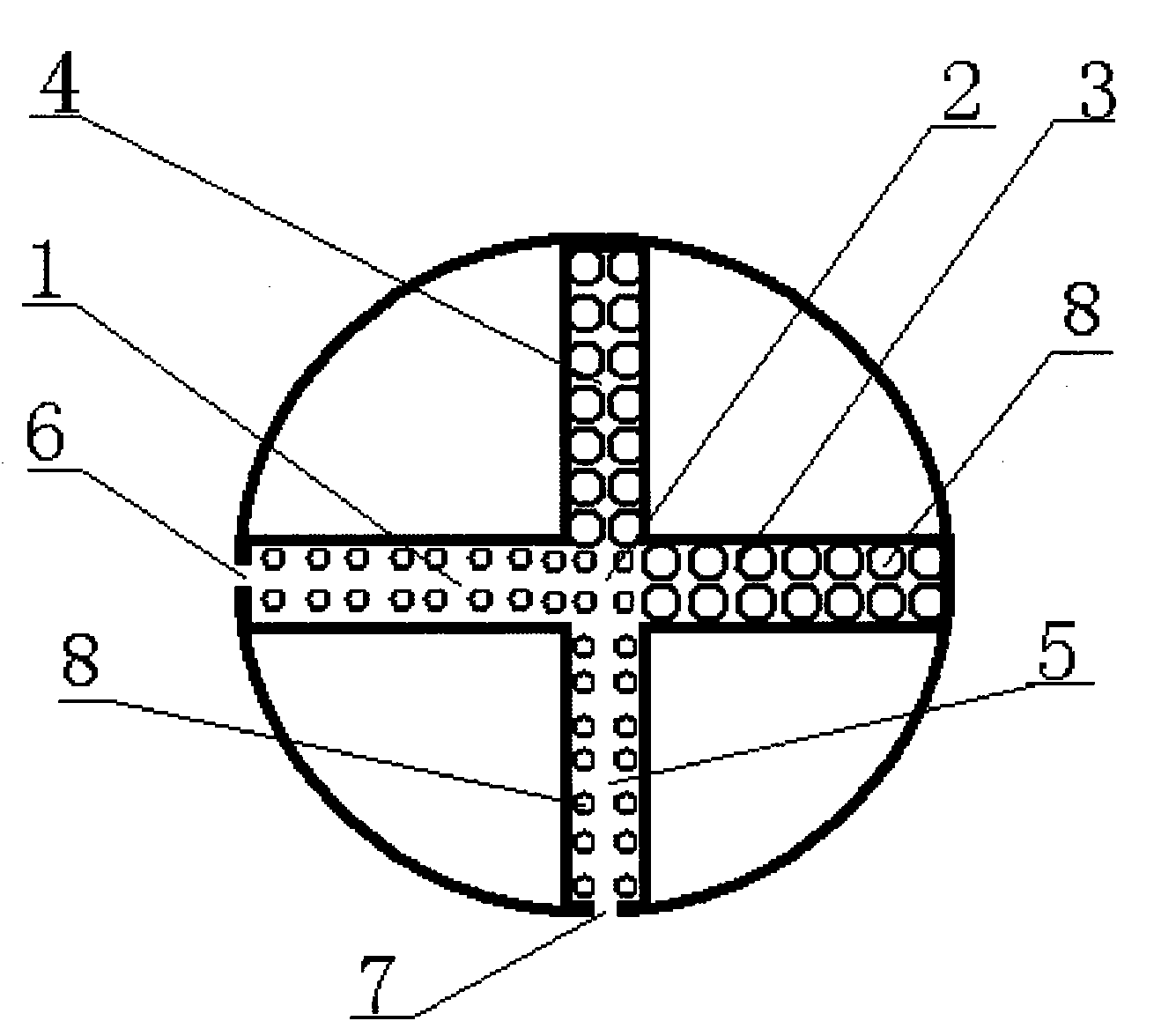

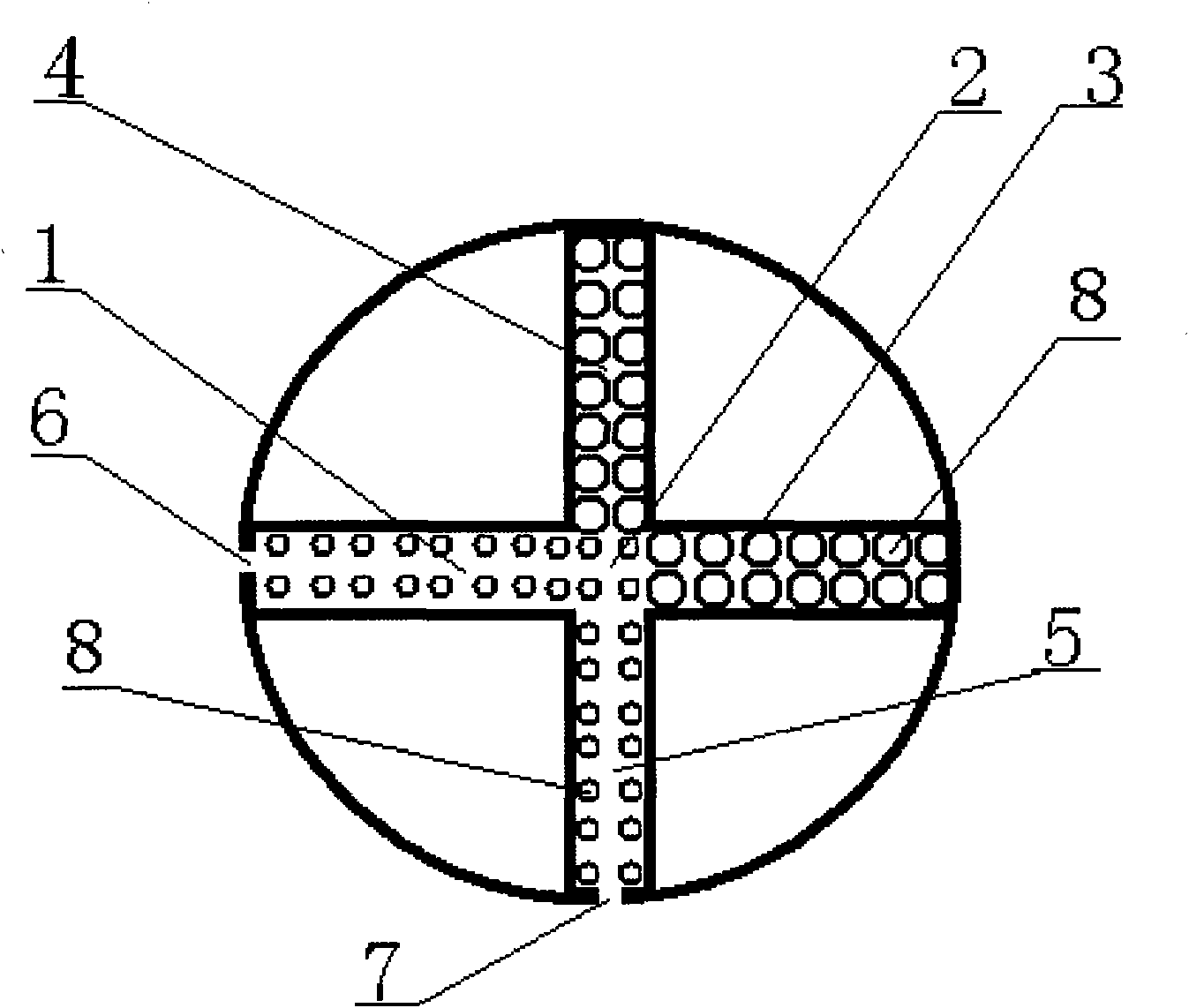

[0007] The layout of the oxygen distribution panel is a hollow "cross" shape, divided into five combustion areas: left area 1, middle area 2, right area 3, upper area 4, and lower area 5. Left area 1, right area 3, upper area 4, The lower zone 5 is respectively located in the left, right, upper and lower parts of the "cross" shape, the middle zone 2 is located at the central node of the "cross" shape, and the left zone 1 is provided with an air inlet 6. Many, φ24mm oxygen distribution holes 8 are used; the middle zone 2 is the only way to pass through other combustion areas, the concentrated flow rate of the airflow is high, and the unit oxygen content is high, so the φ24mm oxygen distribution holes 8 are also used; the airflow passes through the left zone 1. When the middle zone 2 enters the right zone 3 and the upper zone 4, the airflow is relatively diffuse and the flow rate is low, and the unit oxygen content is relatively small. The φ32mm oxygen distribution hole 8 is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com