Patents

Literature

39results about How to "Less oxygen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Scintillator single crystal and process for its production

InactiveUS20070292330A1Improve variationImprove light outputPolycrystalline material growthBy pulling from meltCeriumSingle crystal

The scintillator single crystal of the invention is a specific cerium-activated silicate single crystal wherein the total content of one or more elements selected from the group consisting of elements belonging to Groups 4, 5, 6 and Groups 14, 15, 16 of the Periodic Table is no greater than 0.002 wt % based on the total weight of the single crystal.

Owner:HITACHI CHEM CO LTD

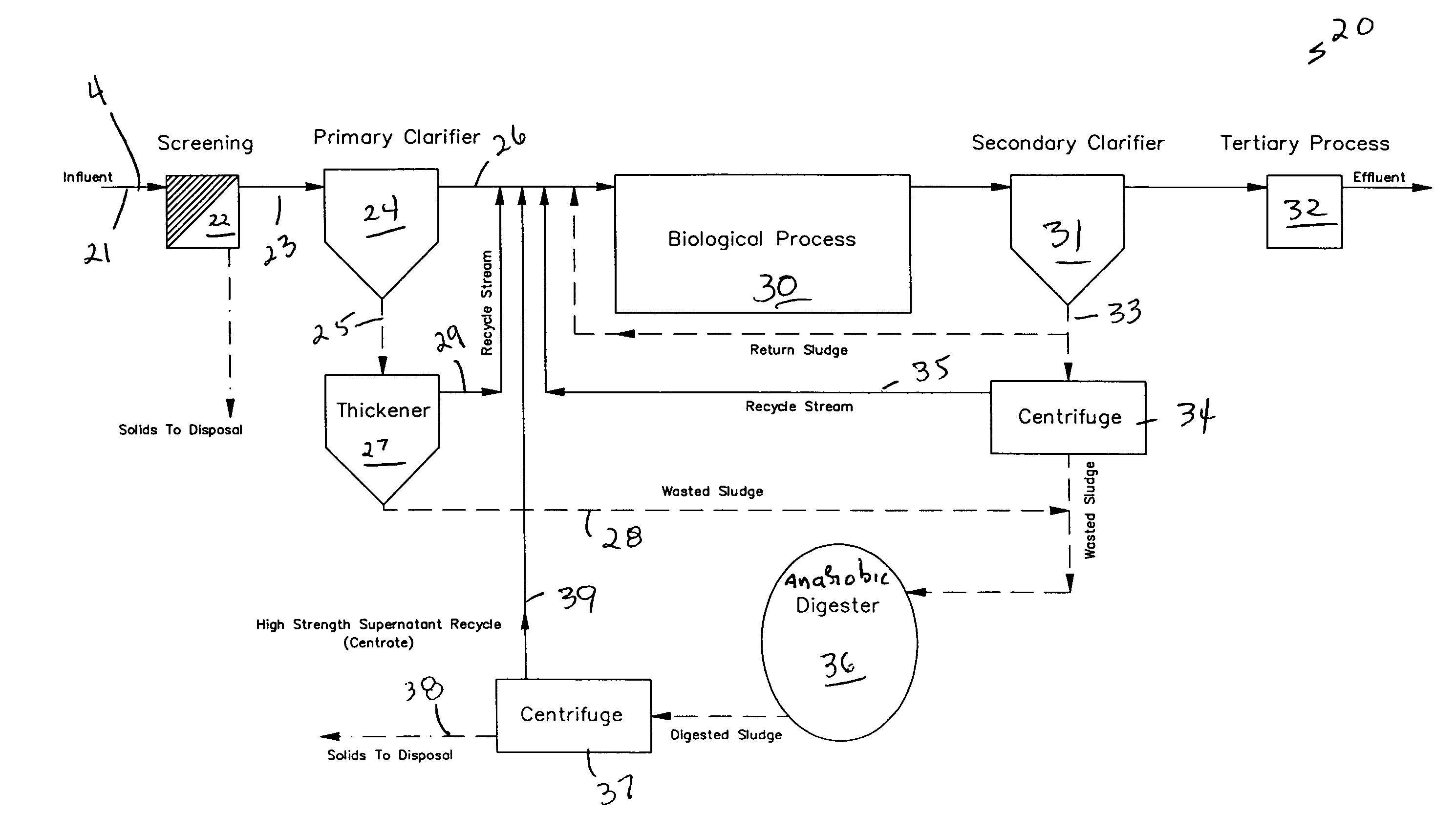

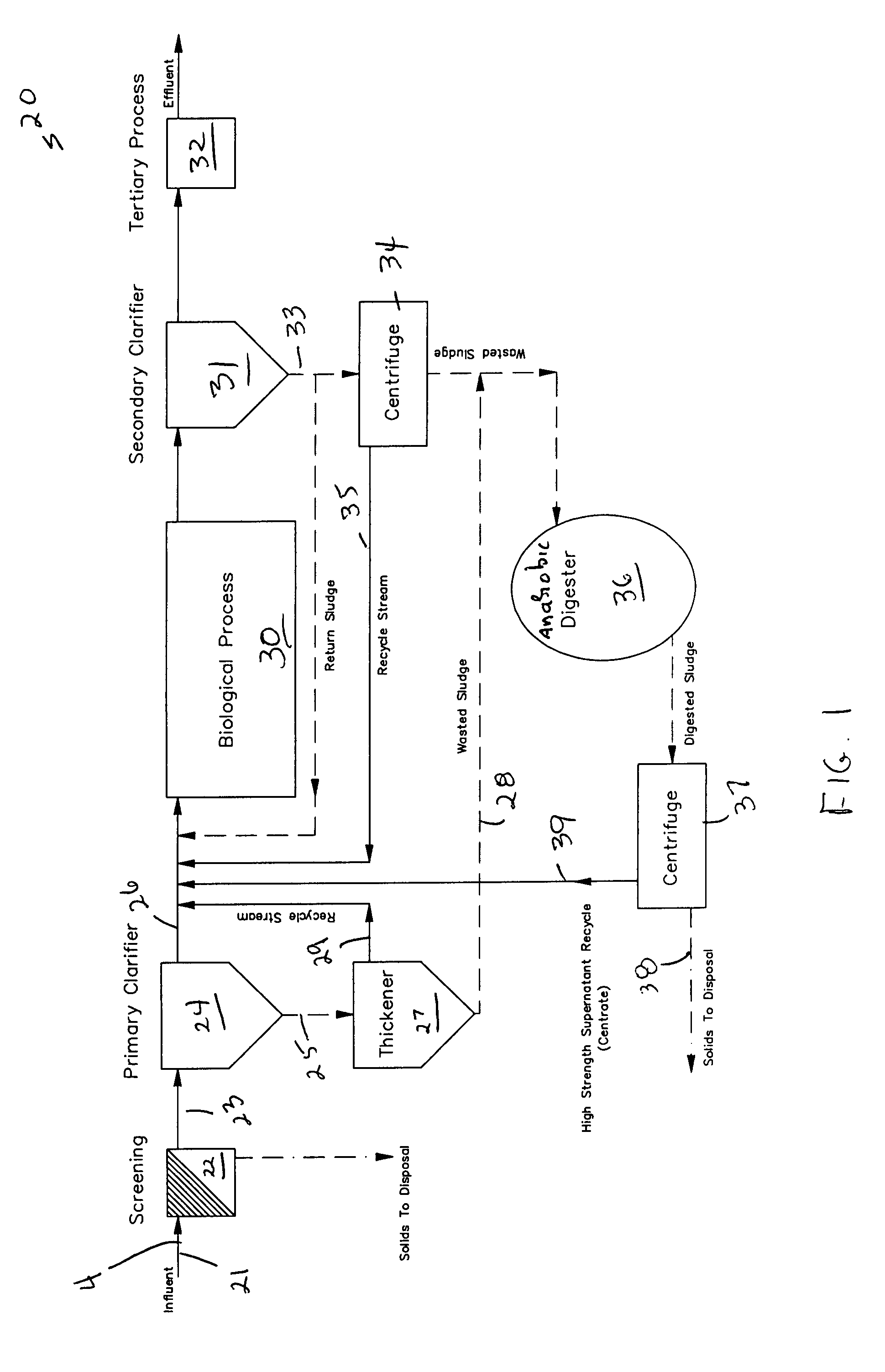

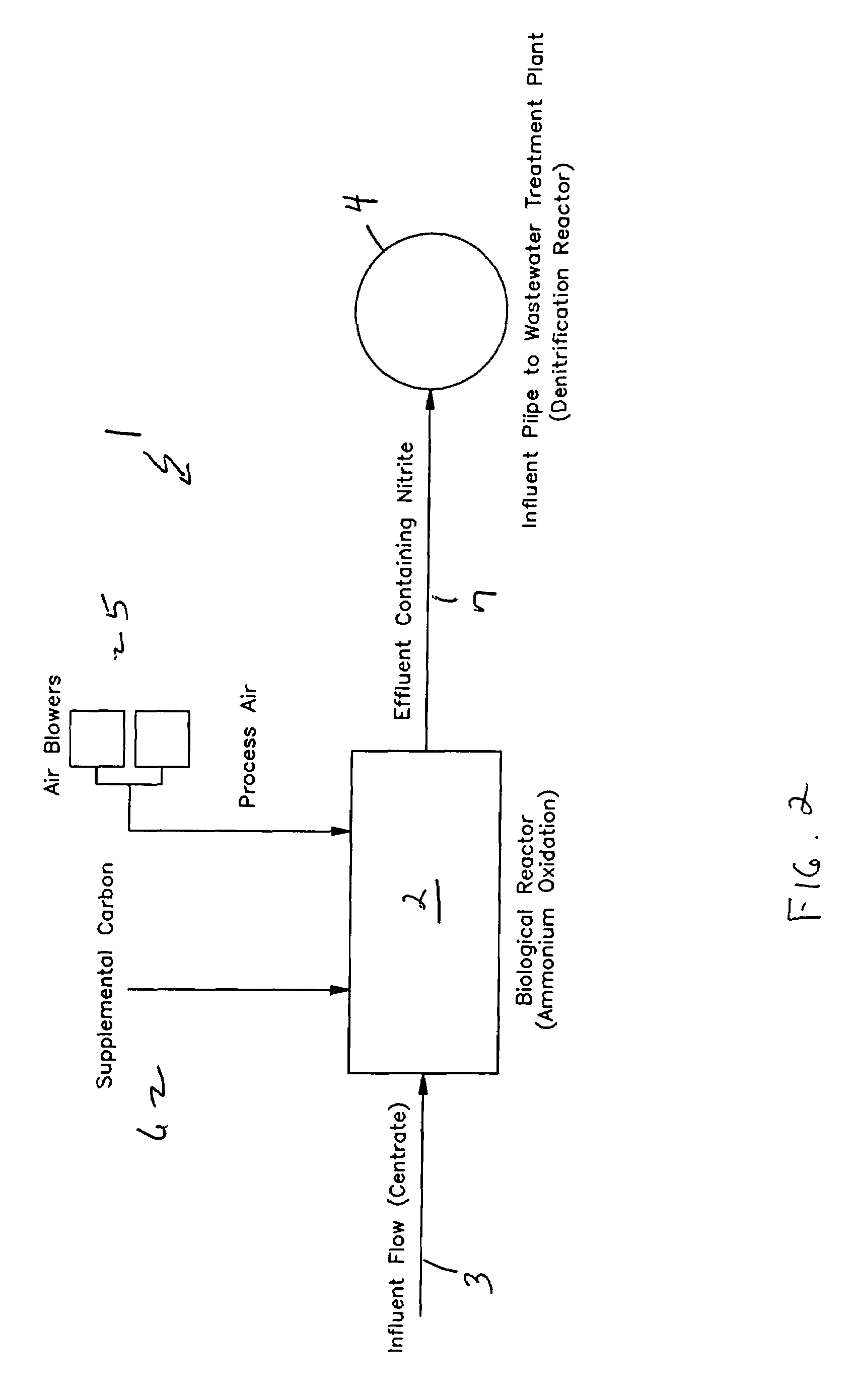

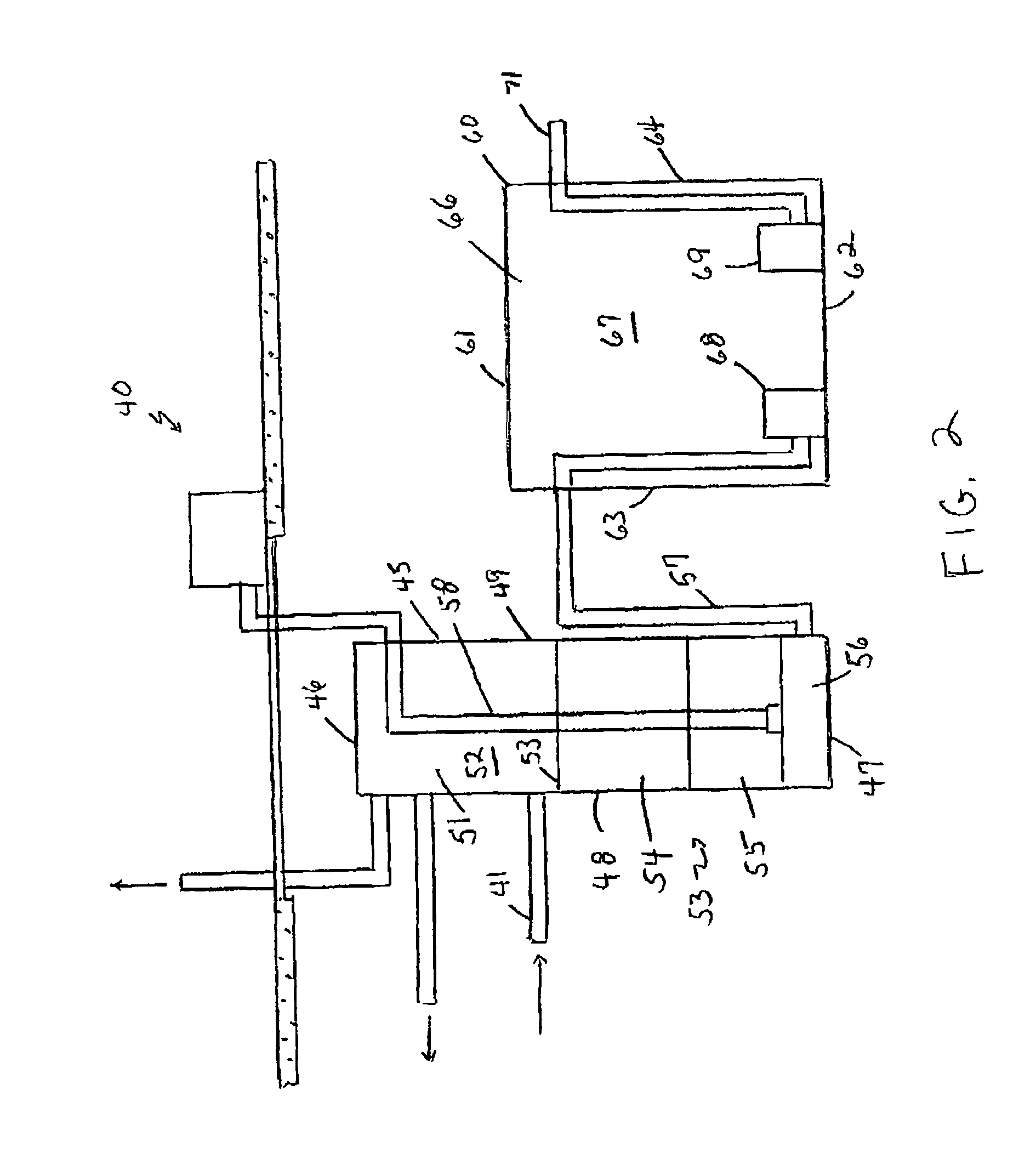

Ammonia oxidation and pipe denitrification

InactiveUS7438813B1Thorough removalQuantity minimizationTreatment using aerobic processesMultistage water/sewage treatmentWater treatment systemCollection system

In a biological wastewater treatment system, the addition of an intermittently aerated second bioreactor to accomplish ammonium oxidation to predominately nitrite and then to achieve denitrification by introducing the effluent, containing nitrite, from the second bioreactor into the influent collection system or the head works of a wastewater treatment plant. Denitrification from nitrite occurs in the collection pipe using the influent organics as a carbon source.

Owner:PEDROS PHILIP B +1

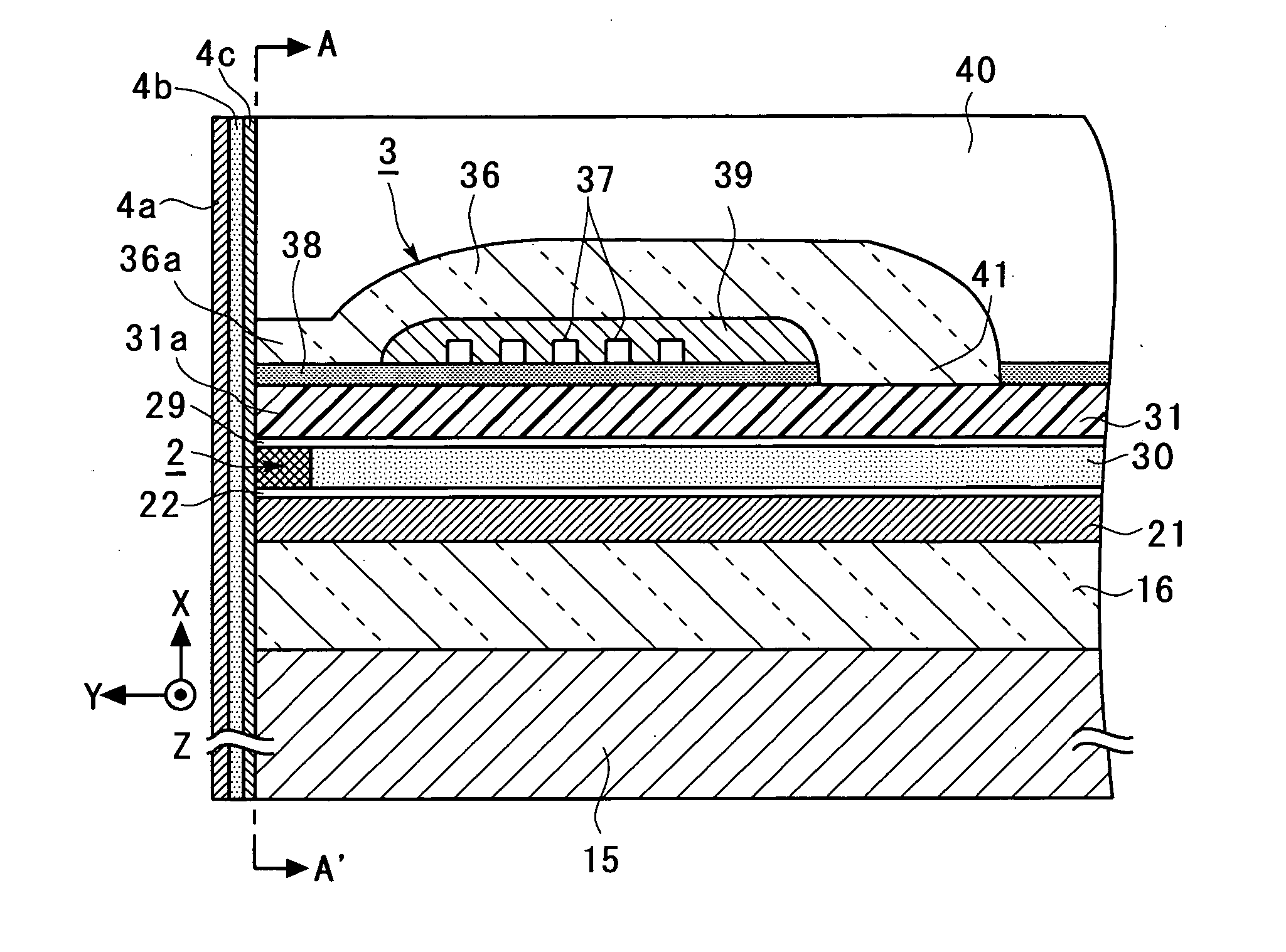

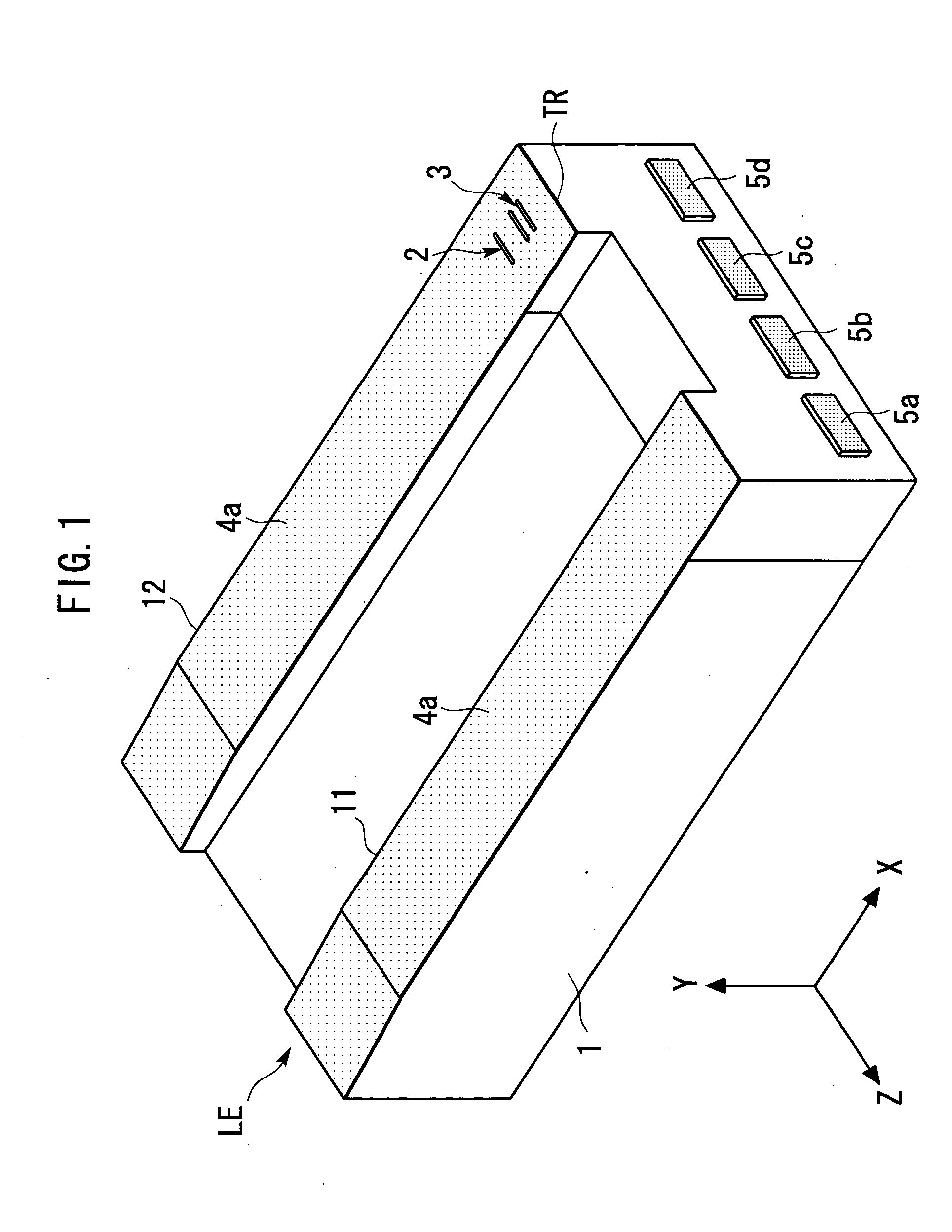

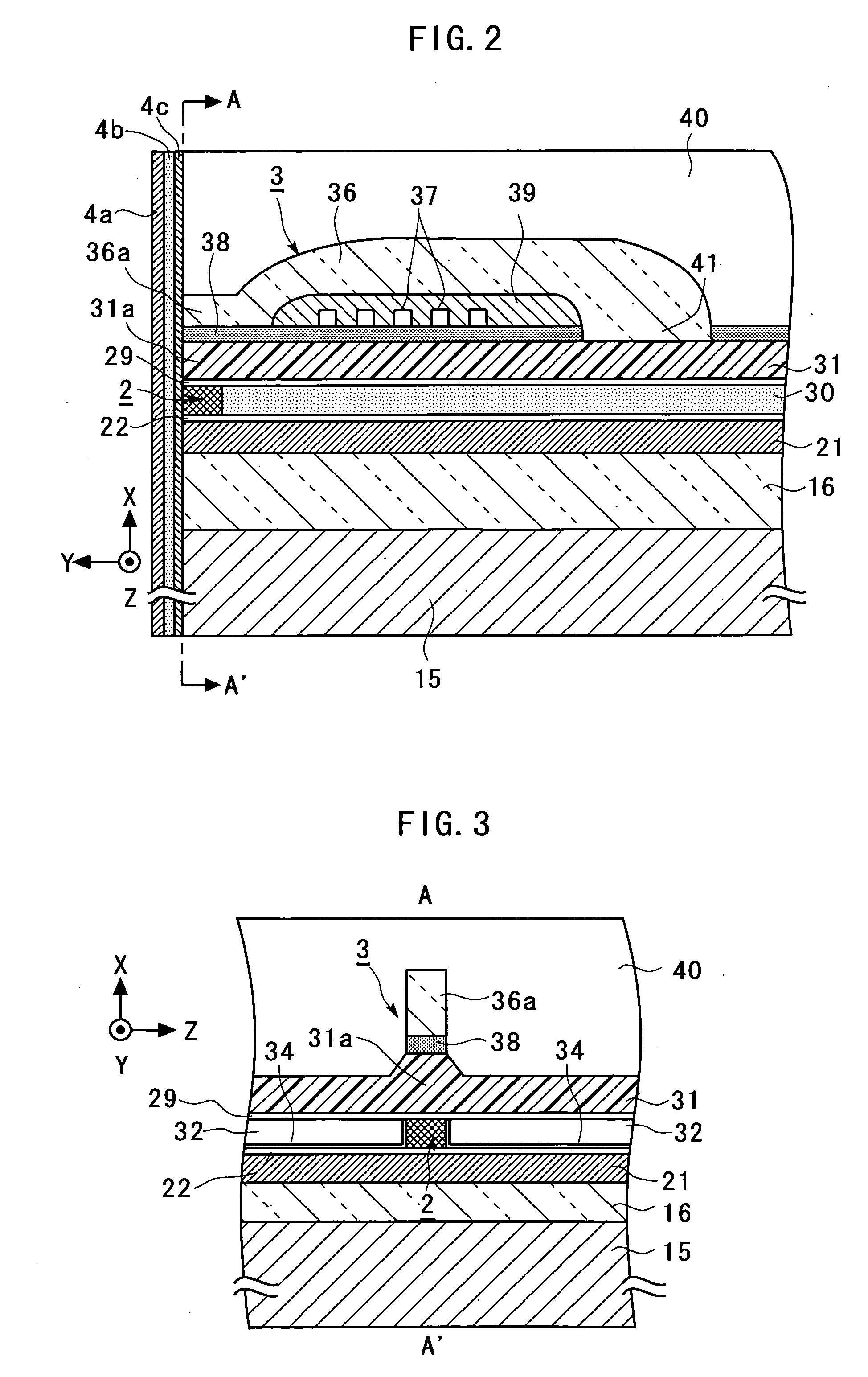

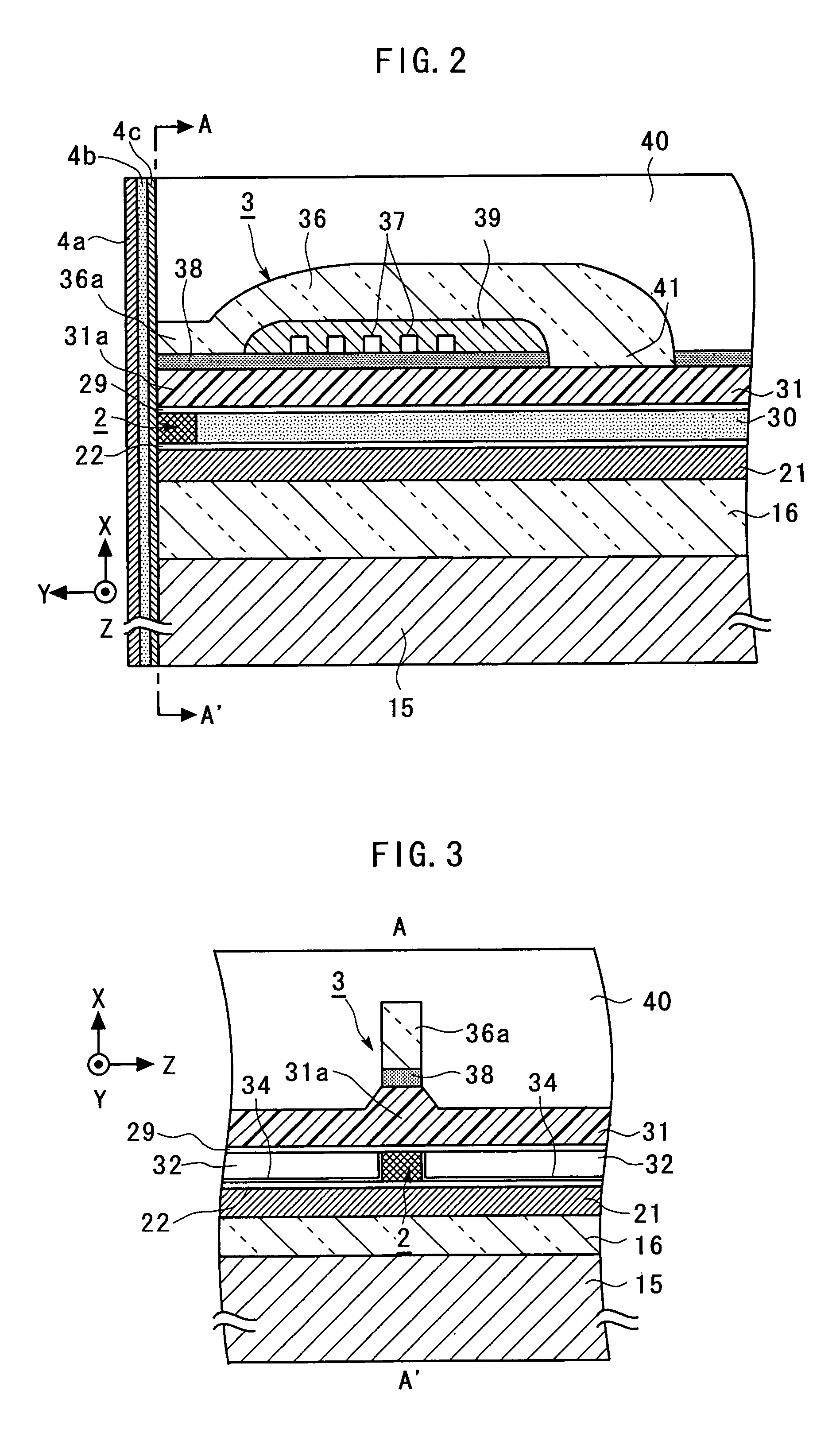

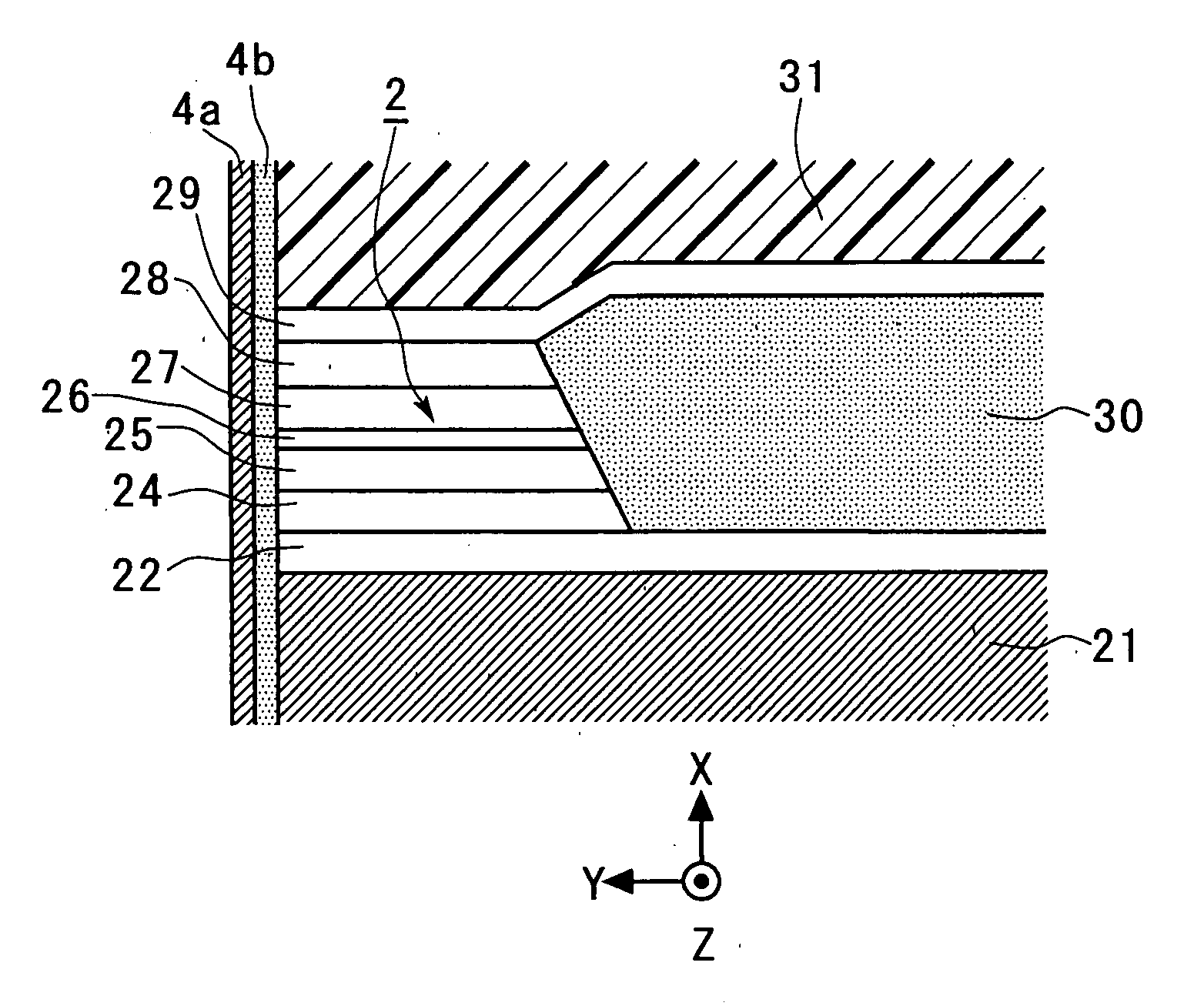

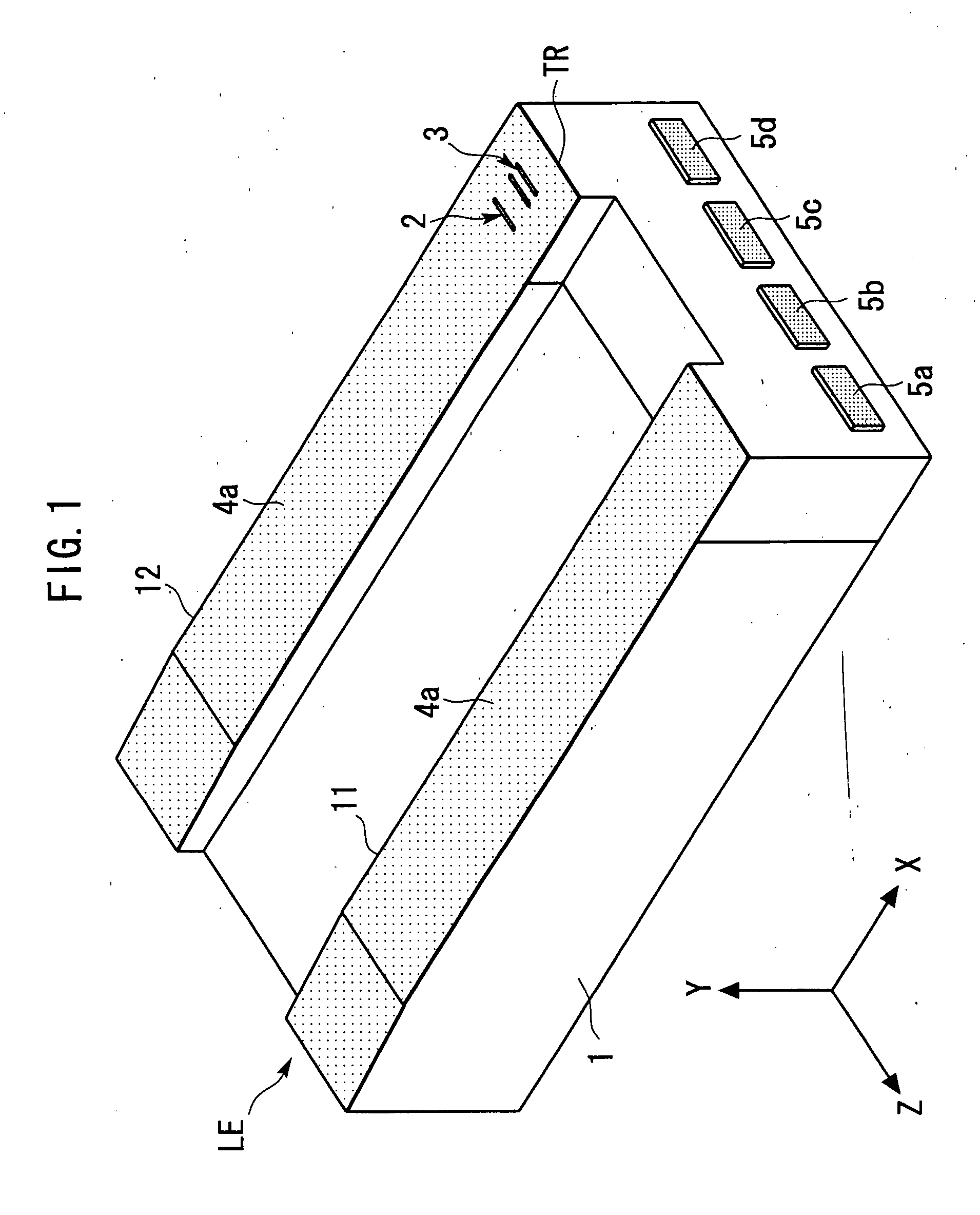

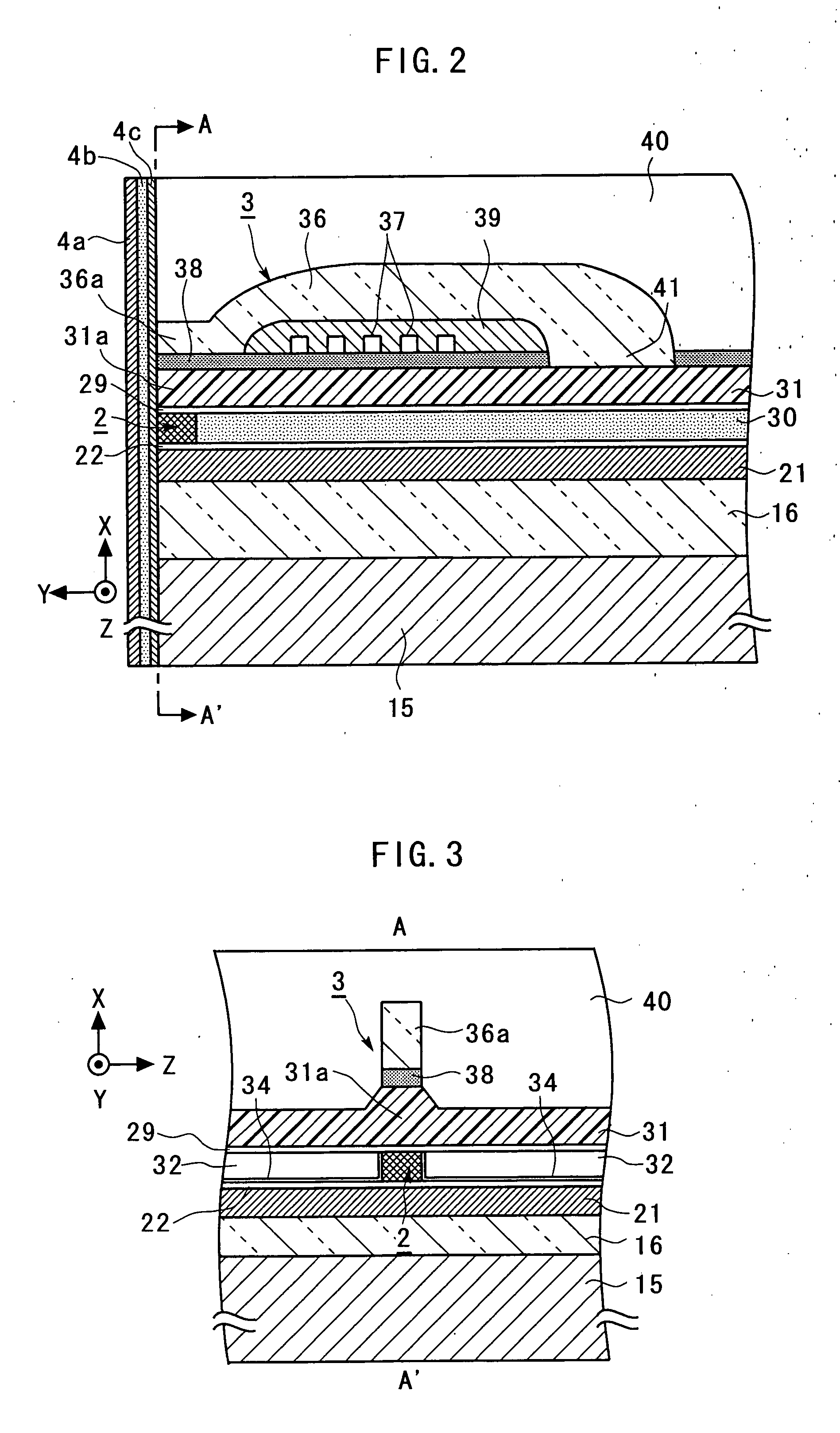

Magnetic head and method of manufacturing same, head suspension assembly and magnetic disk apparatus

ActiveUS20050068691A1Improve stabilityLess variationNanomagnetismNanoinformaticsTectorial membraneMagnetic reluctance

A magnetic head has less variations in the resistance of a magneto-resistive device before and after the magnetic head is left in a high temperature environment so as to have higher stability of the characteristics of the magnetic head against a high temperature environment. A TMR device includes a tunnel barrier layer made of an oxide layer. A DLC film serving as a protection film and an underlying layer therefor are formed on an end face of the TMR device on an air bearing surface side. A layer made of an oxide of a metal or an oxide of a semiconductor is formed between the underlying layer and the end face of the tunnel barrier layer on the air bearing surface side to be in contact with the end face of the tunnel barrier layer.

Owner:TDK CORPARATION

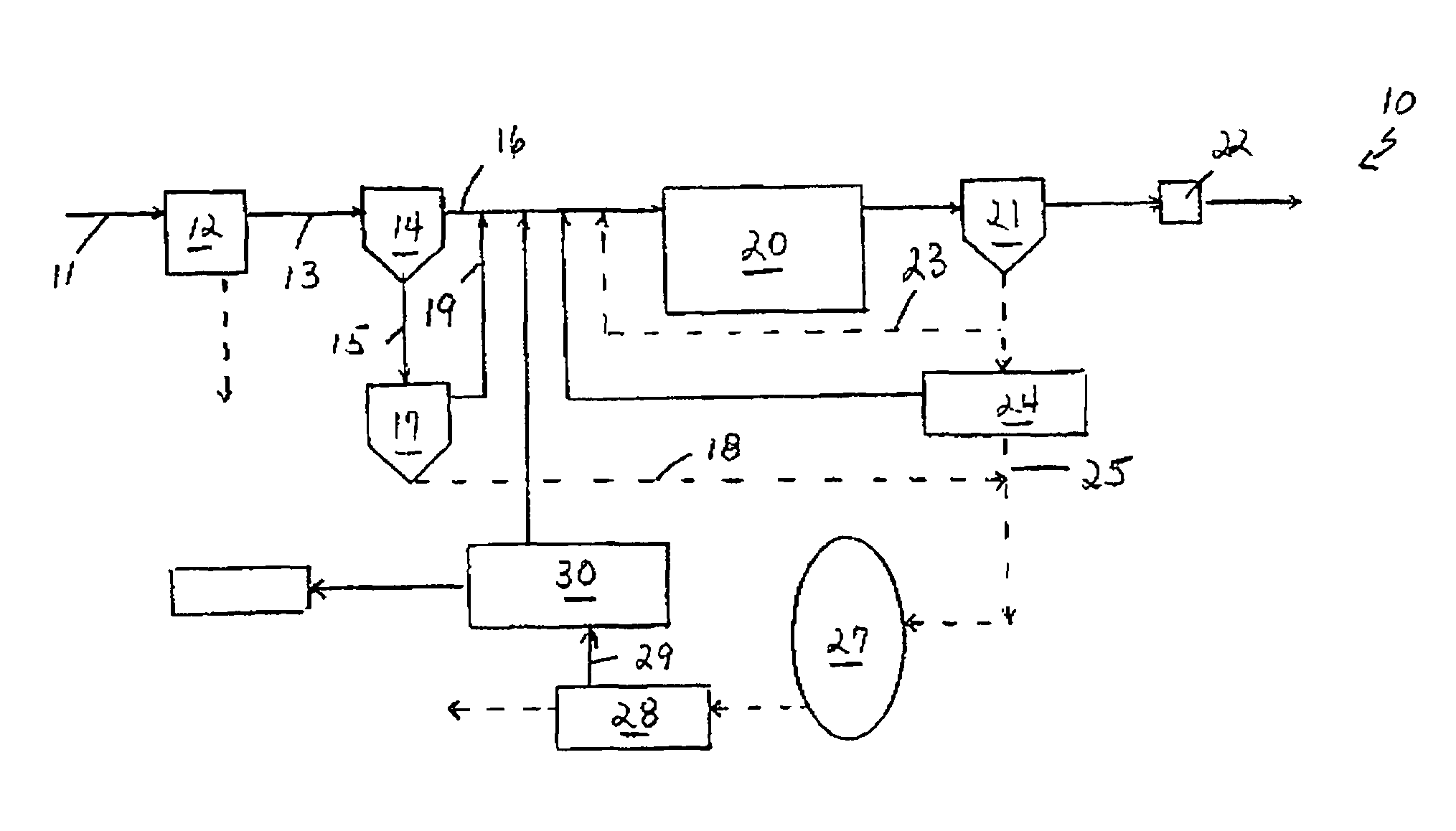

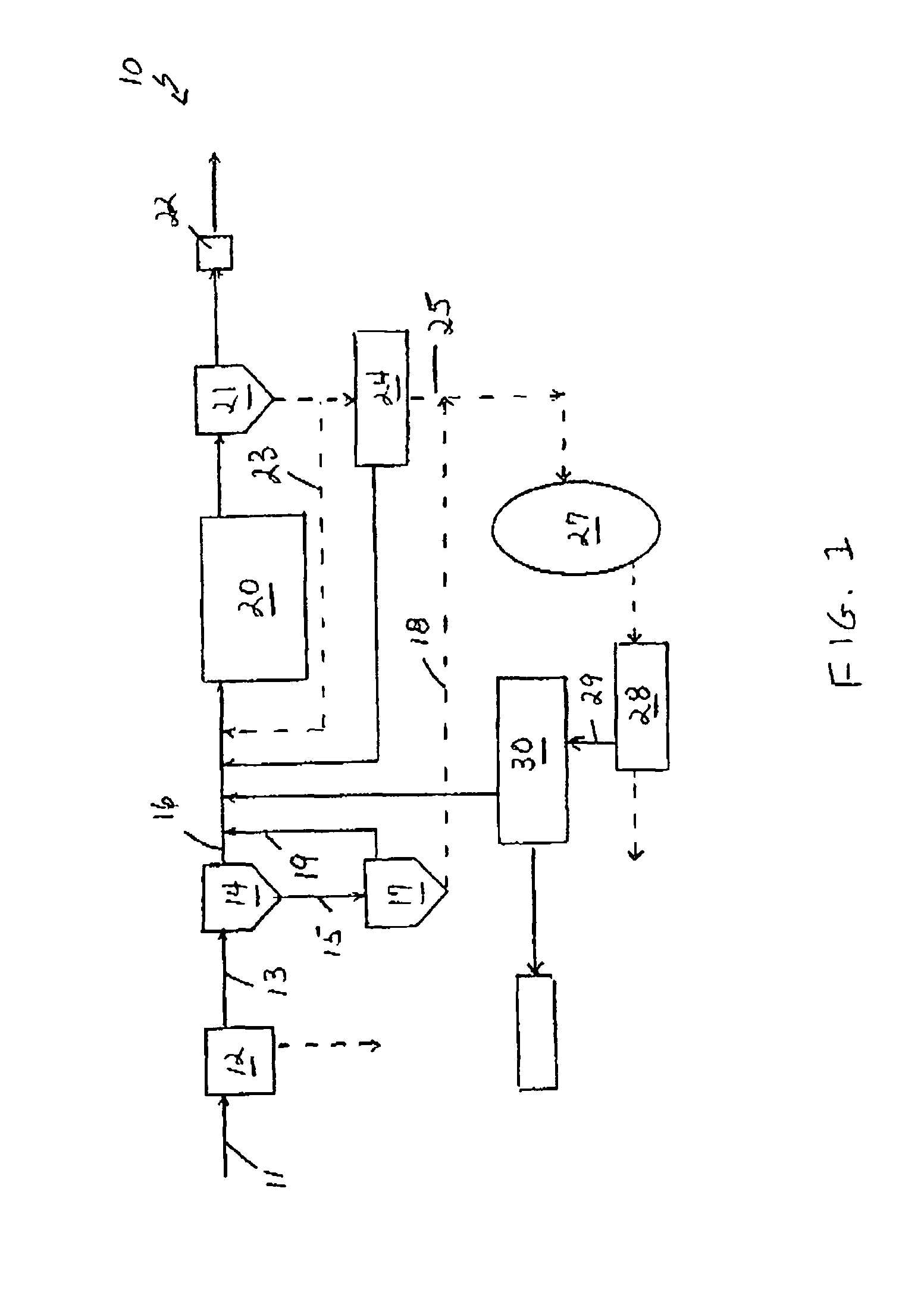

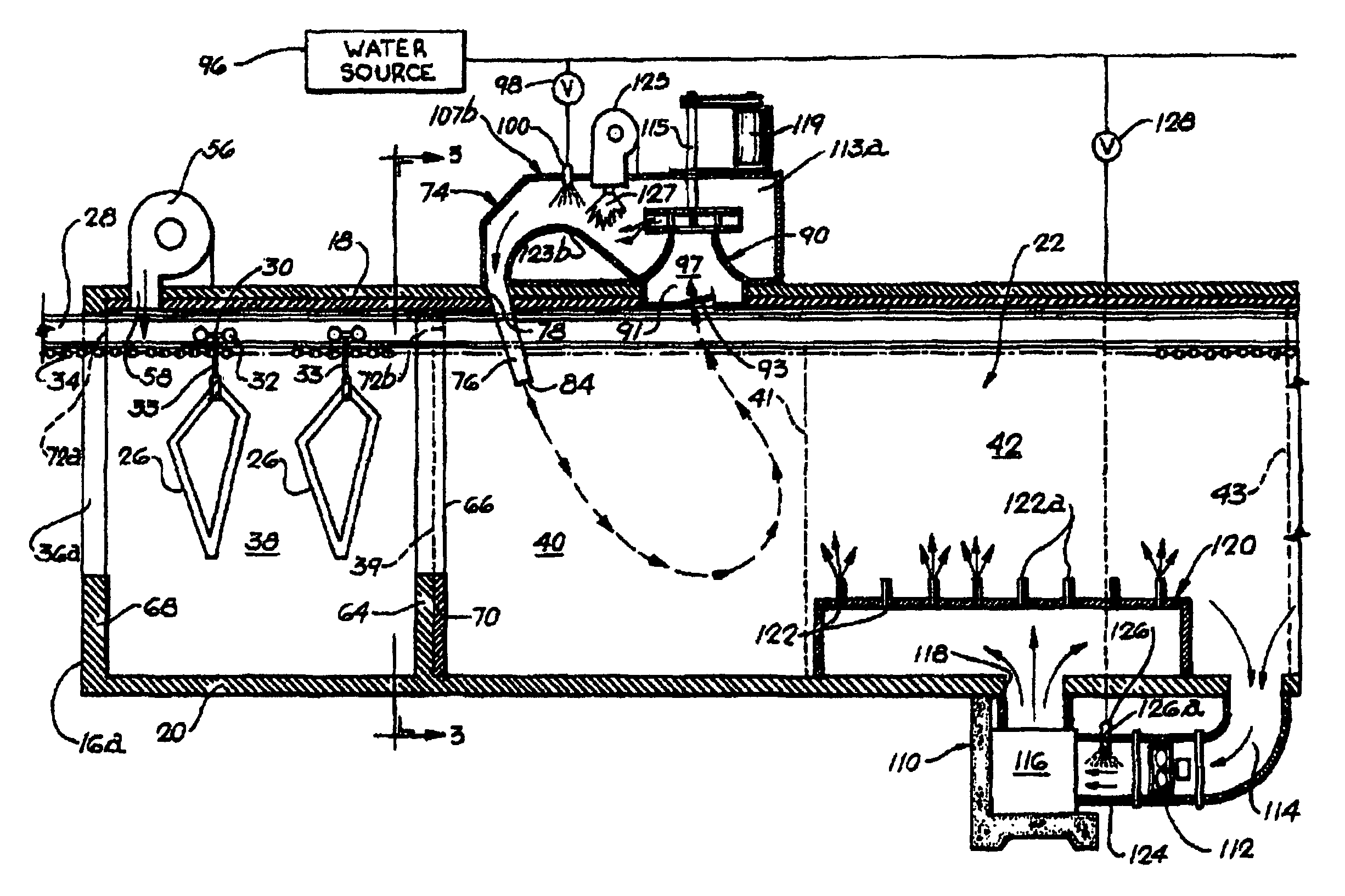

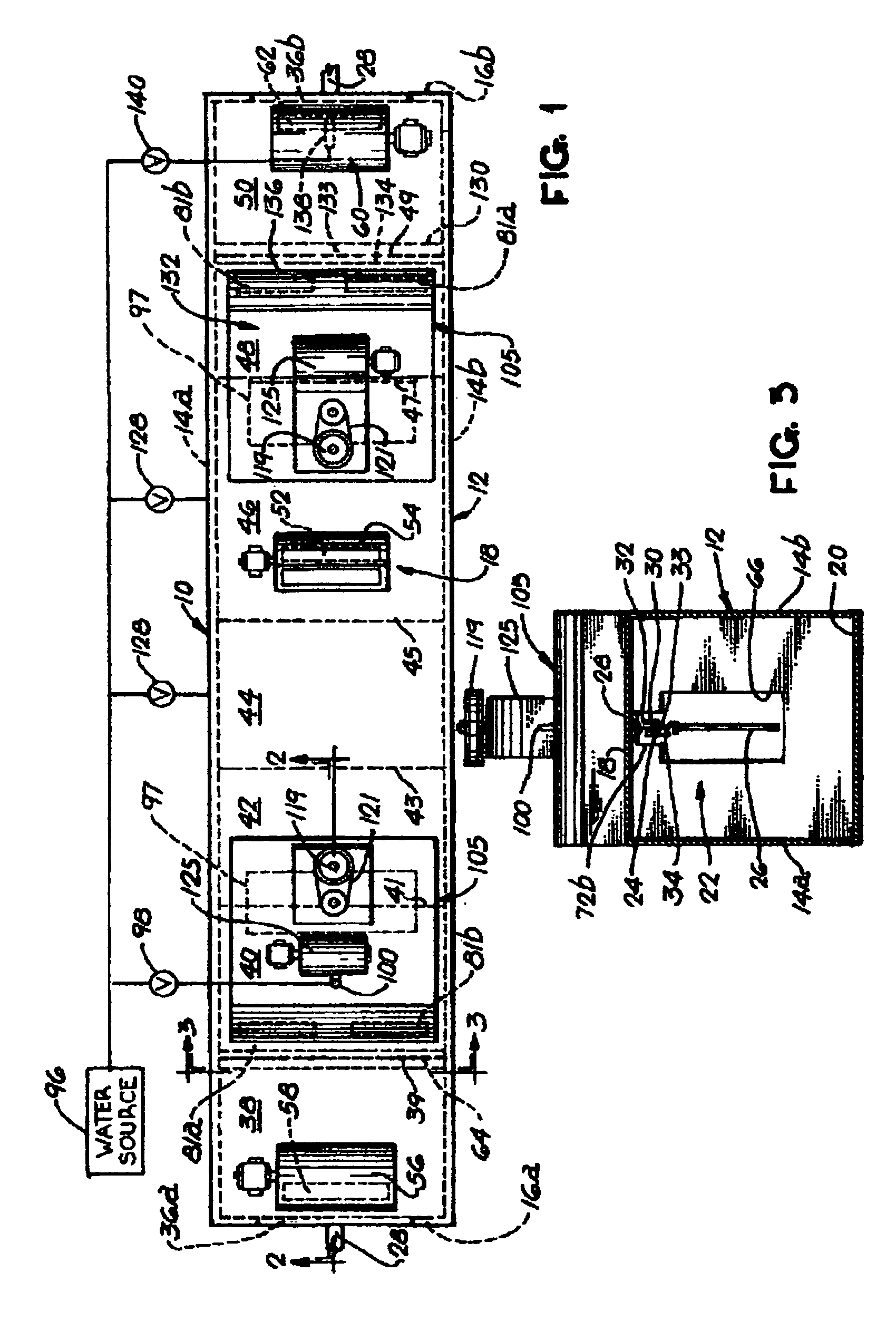

BioCAST process

InactiveUS8398855B1Ammonia reductionHigh ammonia recoveryBio-organic fraction processingTreatment using aerobic processesWaste treatmentAmmonium sulfate

A waste treatment process comprised of an ammonification system to convert soluble organic nitrogen into ammonia nitrogen, followed by a physico-chemical process to remove a substantial amount of the ammonia as a recovered ammonium sulfate fertilizer or ammonium hydroxide (“aqua ammonia”), and followed by an ammonia oxidation process to oxidize the remaining ammonia from the physico-chemical process. The process reduces ammonia and carbonaceous organic matter to less than 10 mg / l and recovers ammonia in the form of either ammonium sulfate or ammonium hydroxide.

Owner:THERMOENERGY CORP

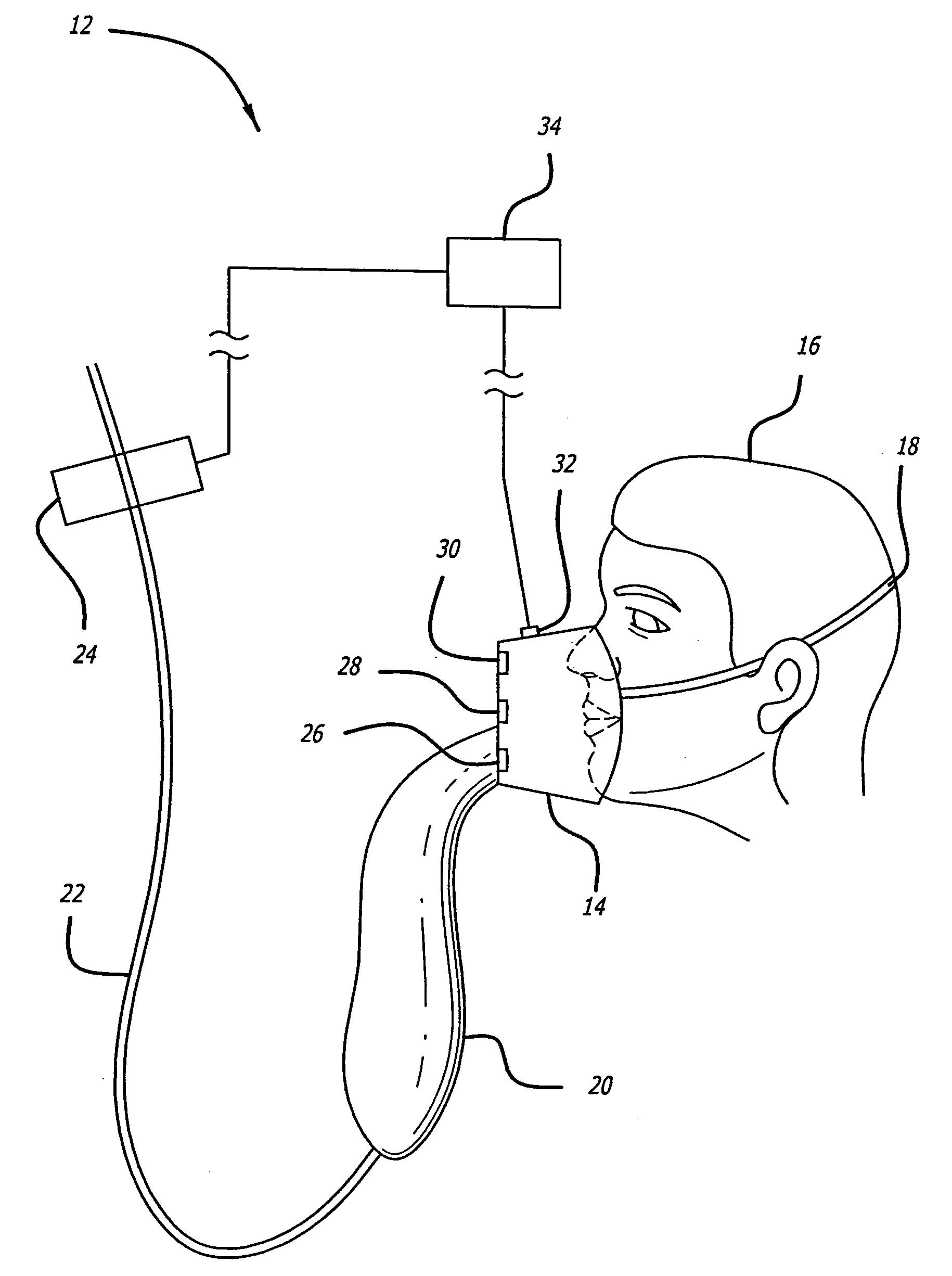

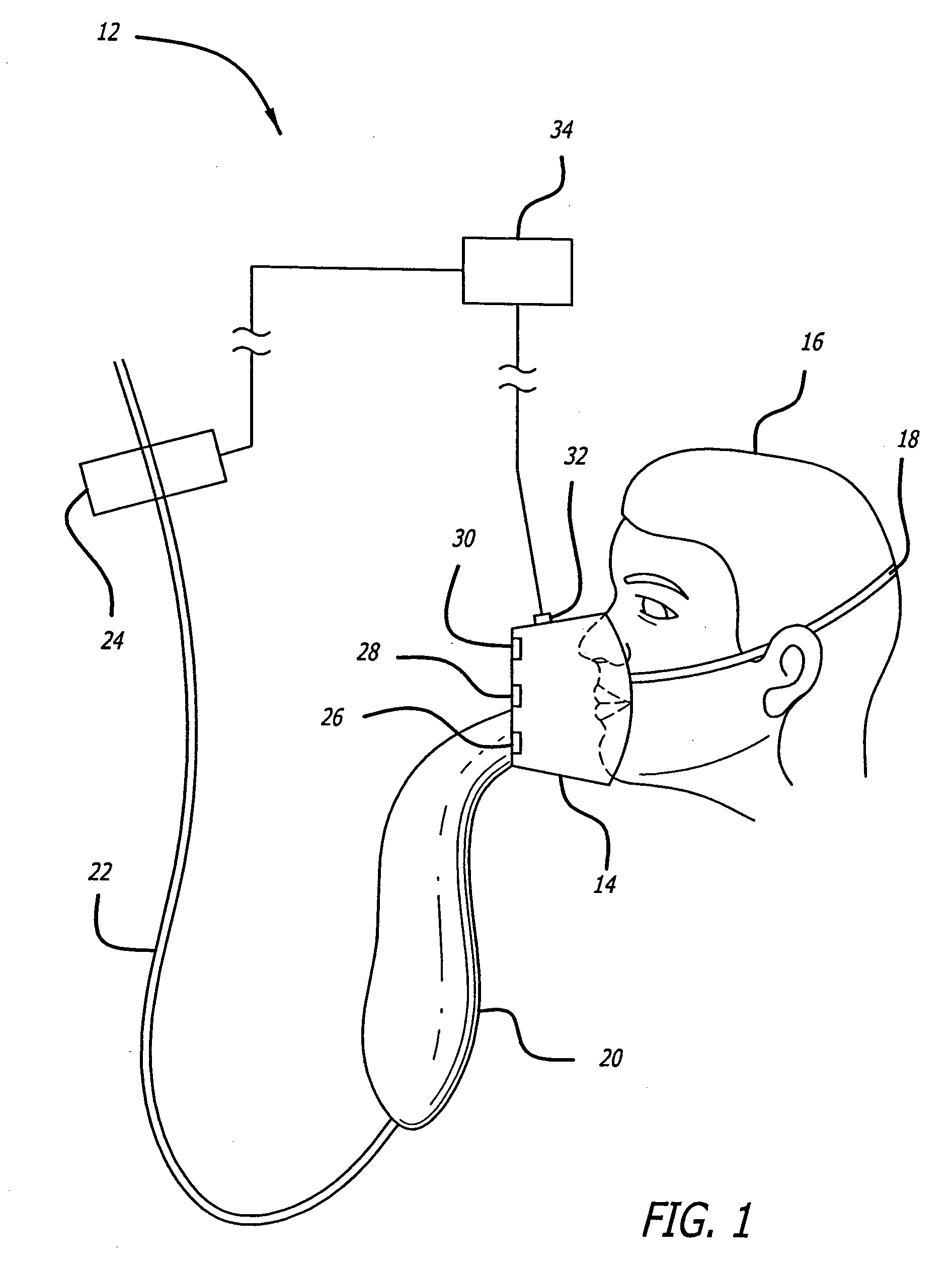

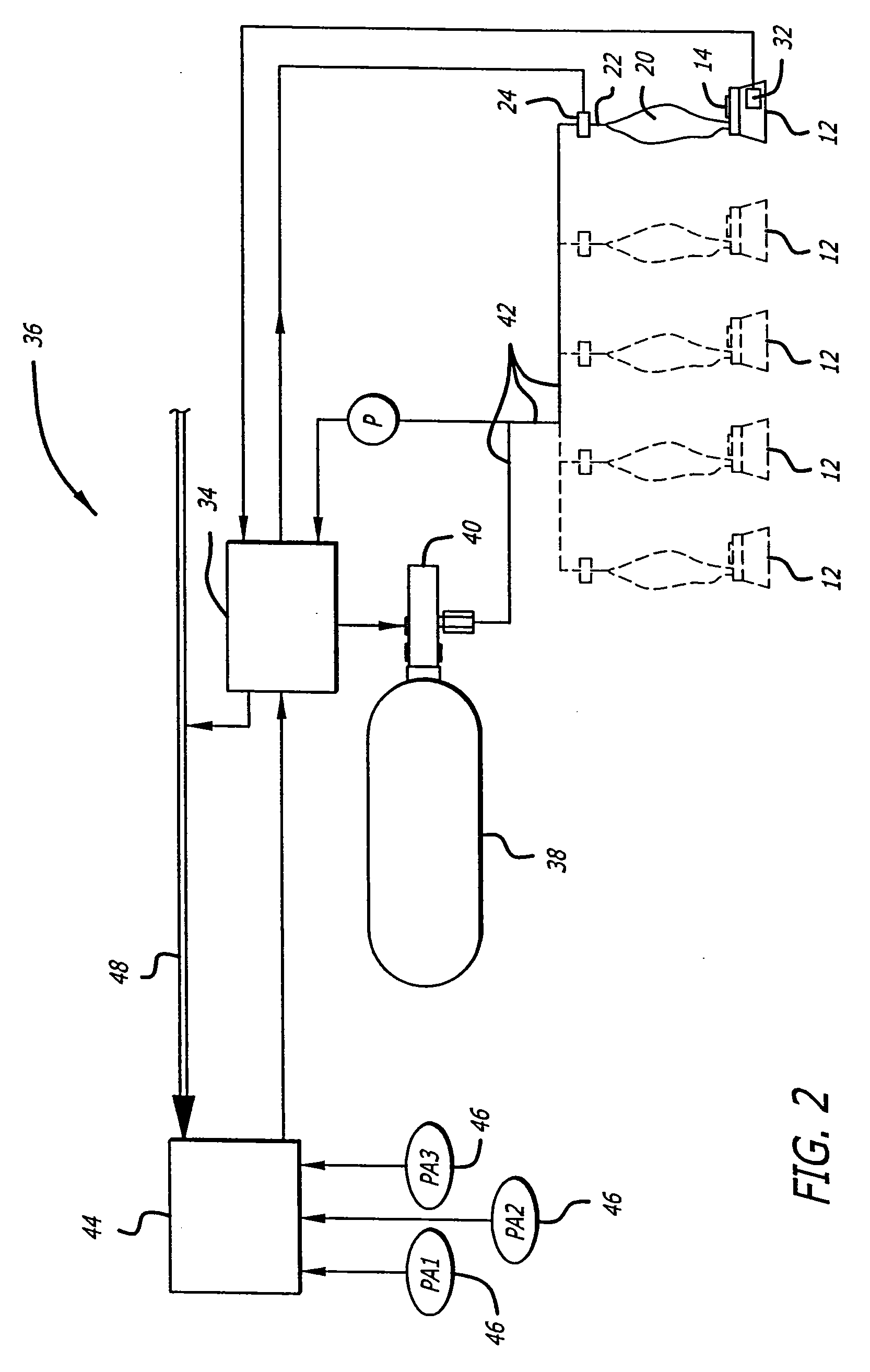

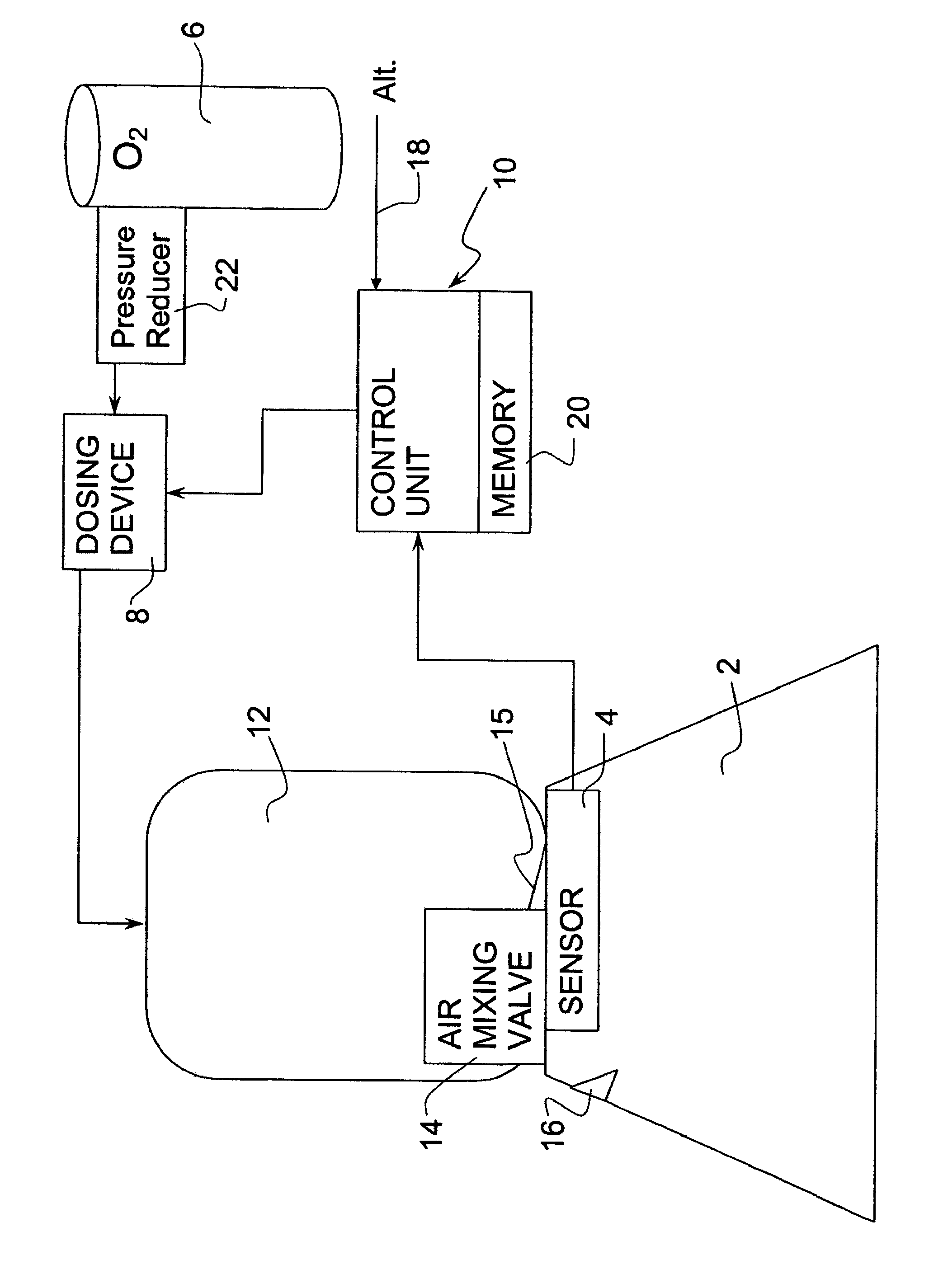

Oxygen conservation system for commercial aircraft

ActiveUS20080000480A1Reduce the amount requiredOvercomes shortcomings inherentBreathing masksEmergency oxygen systemsInhalationEngineering

An emergency oxygen supply system for use on aircraft in the event of a loss in cabin pressure is configured for delivering allotments of oxygen and timing the delivery such allotments to each passenger so as maximize the efficiency of the transfer of such oxygen into the passenger's bloodstream. The delivery of each allotment is selected so that the entire allotment is available for inhalation into the region of the lung most efficient at oxygen transfer while the volume of the allotment is selected to substantially coincide with the volume of such region of the lung.

Owner:BE INTPROP

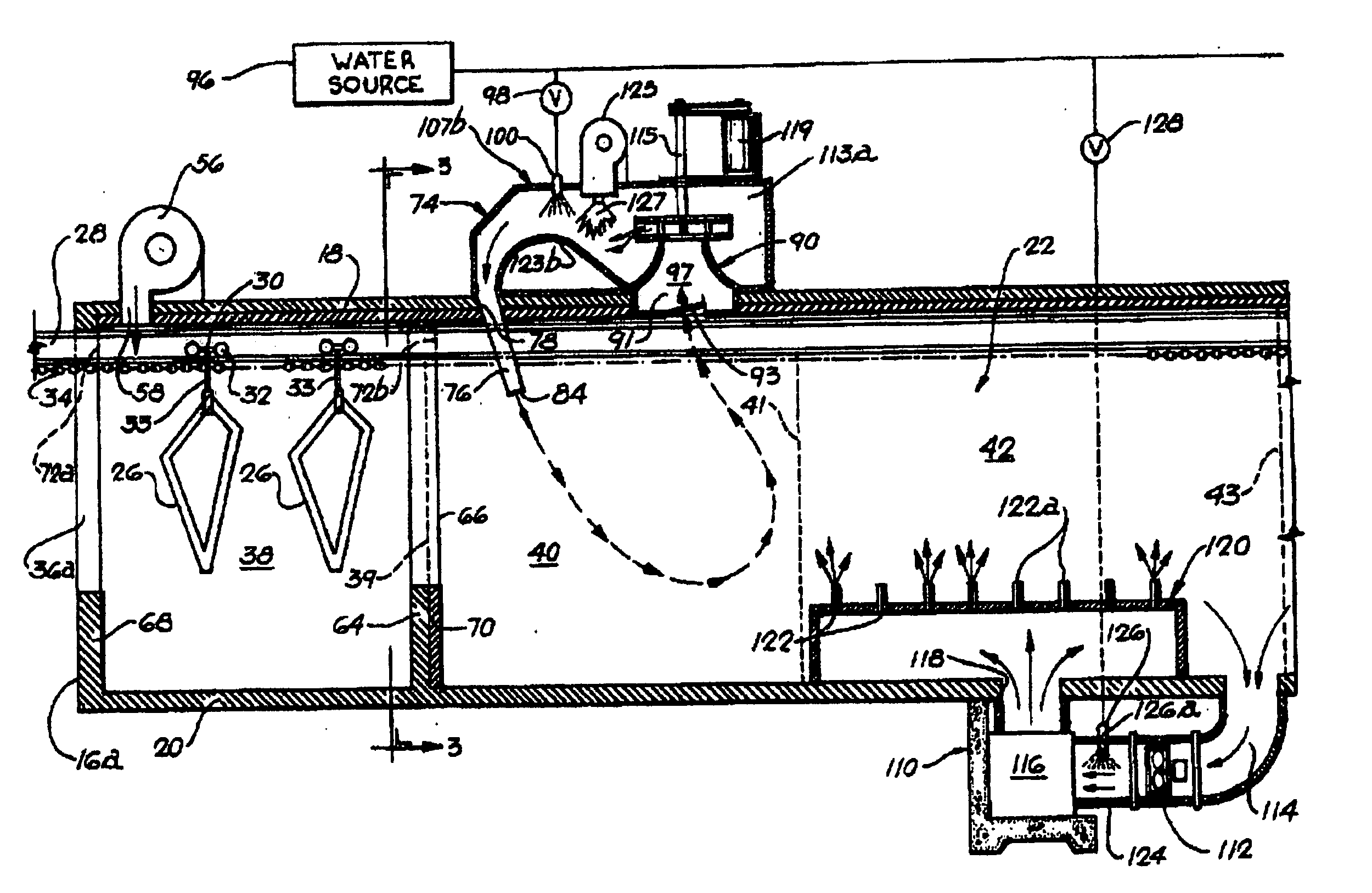

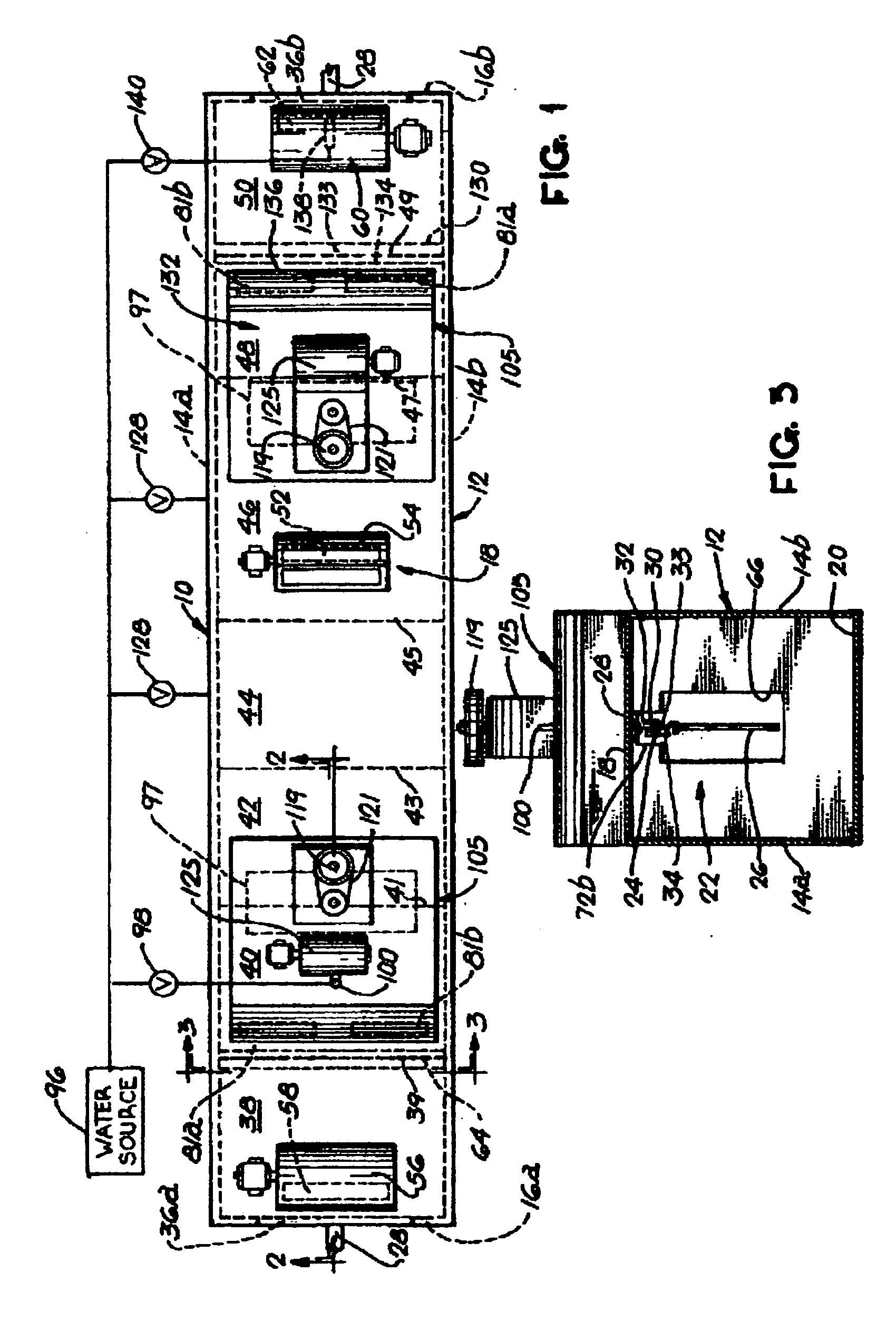

Pyrolysis methods and ovens therefor

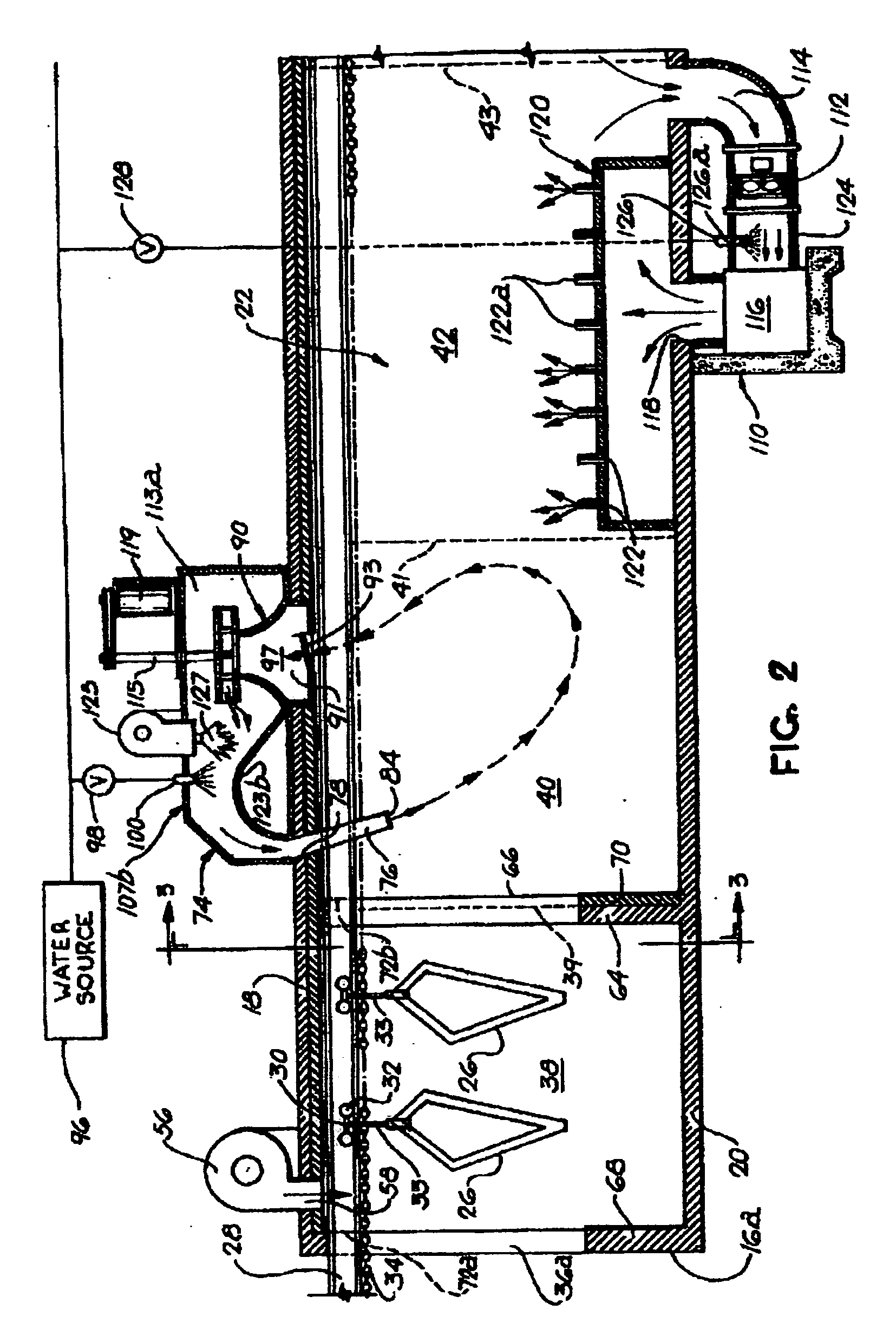

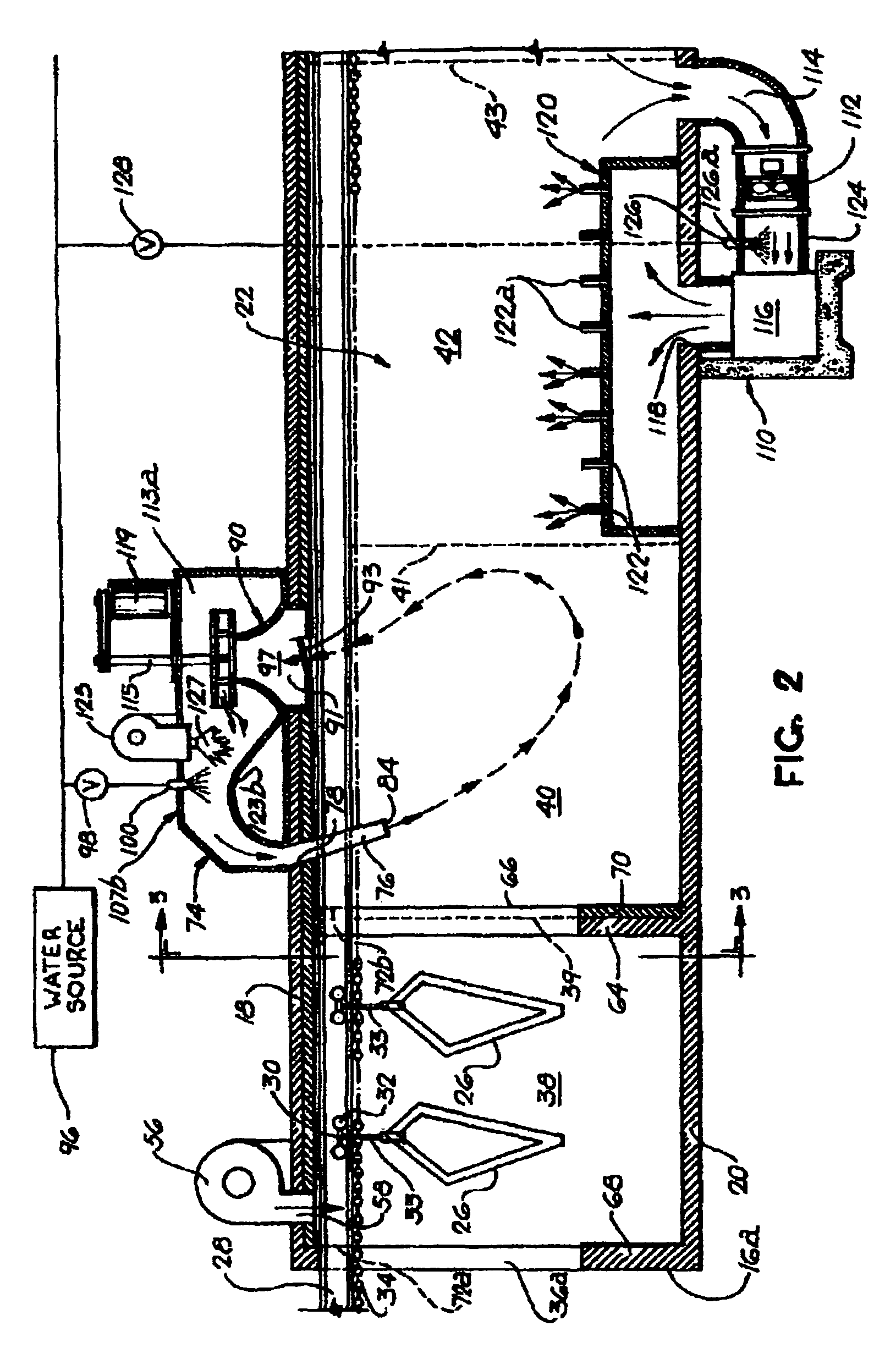

InactiveUS20060225770A1Low costLess oxygenMechanical conveying coke ovensDirect heating destructive distillationSufficient timeEngineering

Pyrolysis methods for disassociating an organic mass, or coating from an article, by placing the article in an air tight processing chamber, circulating a gaseous mixture of ambient air and at least 40% water vapor from an opening, through the processing chamber and out of an exhaust port, and maintaining the processing chamber at a temperature above 650 degrees Fahrenheit for a sufficient time to disassociate the organic material. A batch oven and a continuous processing oven including entrance and exit air closures that utilize the pyrolysis methods are described.

Owner:NOWACK WILLIAM C

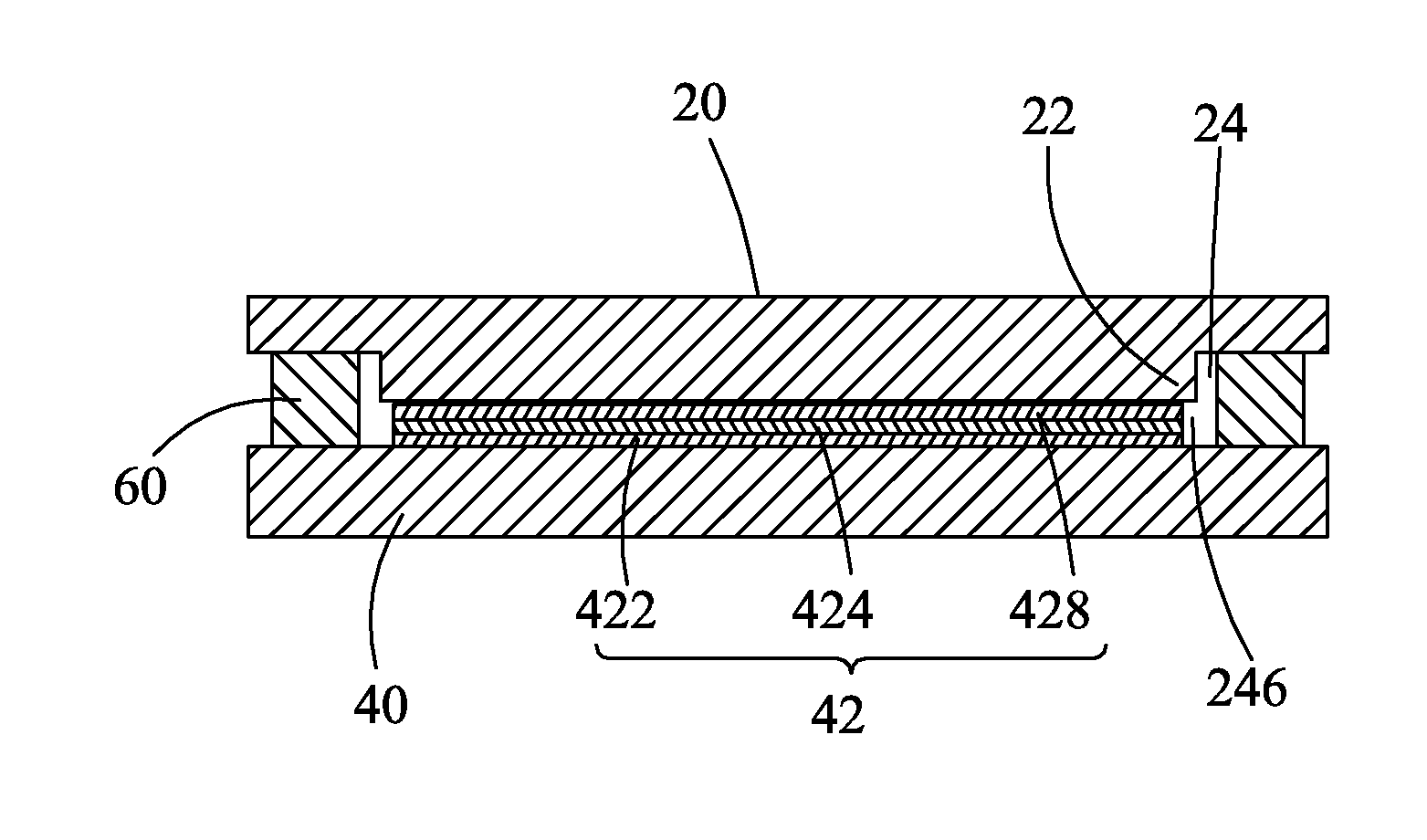

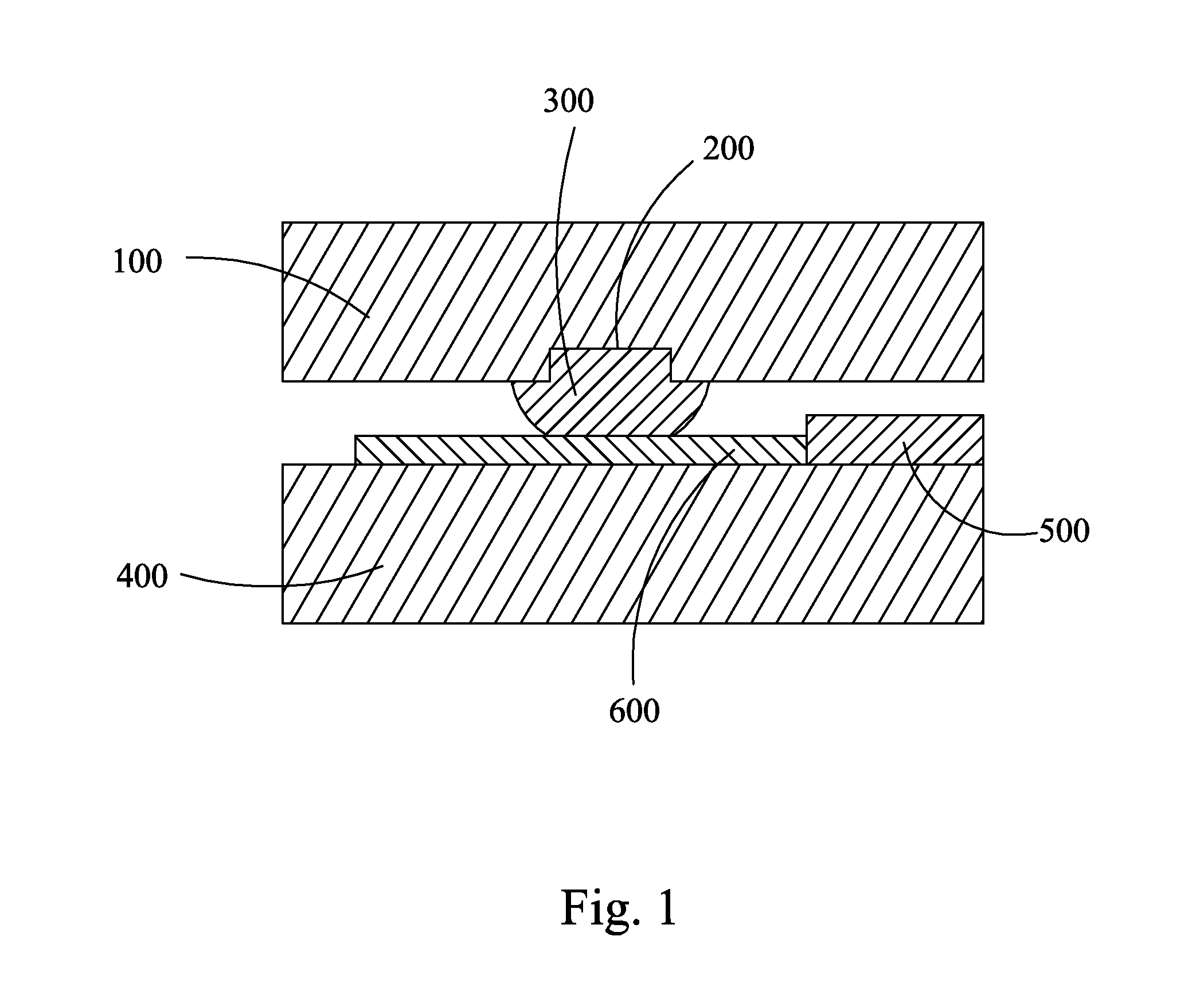

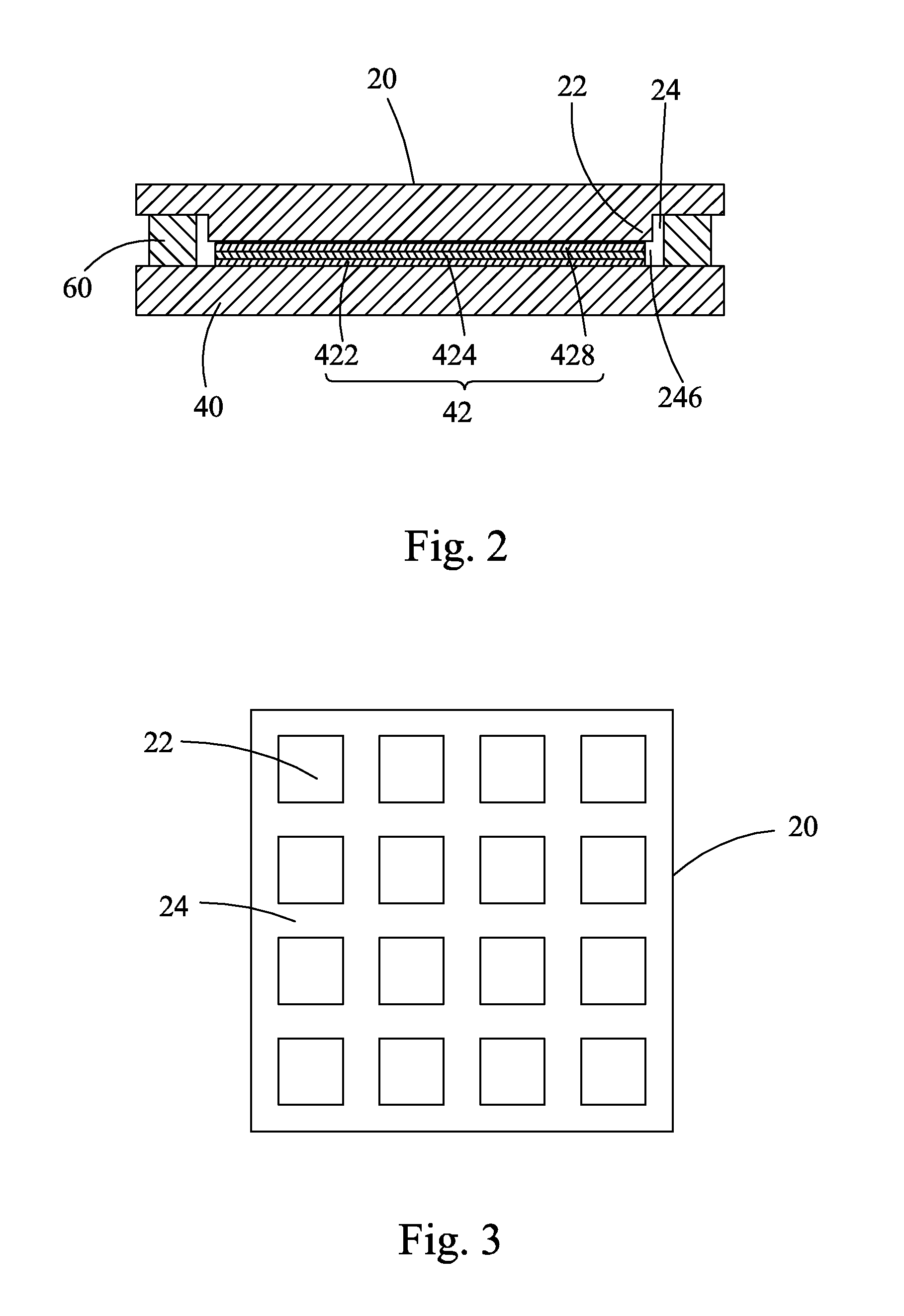

OLED Panel and Package Method Thereof

InactiveUS20150008819A1Simple structureSmall sealing spaceDischarge tube luminescnet screensElectroluminescent light sourcesEngineeringSurface plate

The present invention provides an OLED panel and the package method thereof. The OLED panel comprises: a substrate 40, multiple OLED devices 42 formed on the substrate 40, a package cover 20 attached oppositely to the substrate 40 and multiple sealed plastic frame 60 provided between the substrate 40 and the package cover 20 and corresponding to the OLED device 42. The package cover 20 is provided with multiple protrusions 42 corresponding to the multiple OLED devices 22. A groove 24 is formed around the protrusion 22. The sealed plastic frame 60 is located in the groove 24. The lower surface of the protrusion 22 is close to the upper surface of the OLED device 42.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

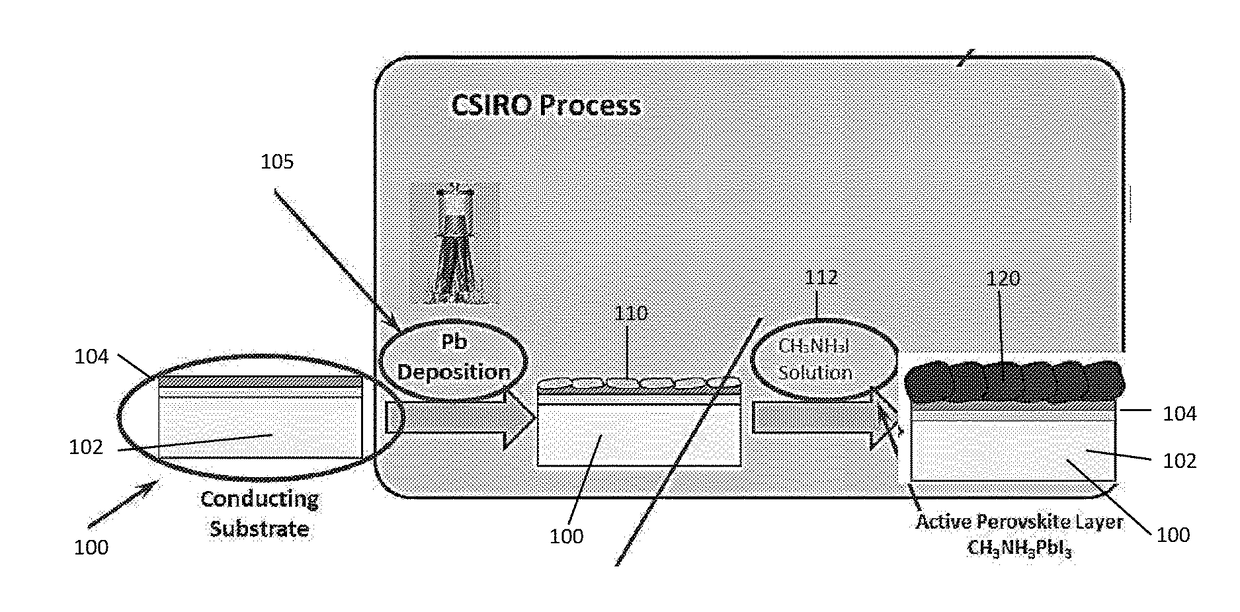

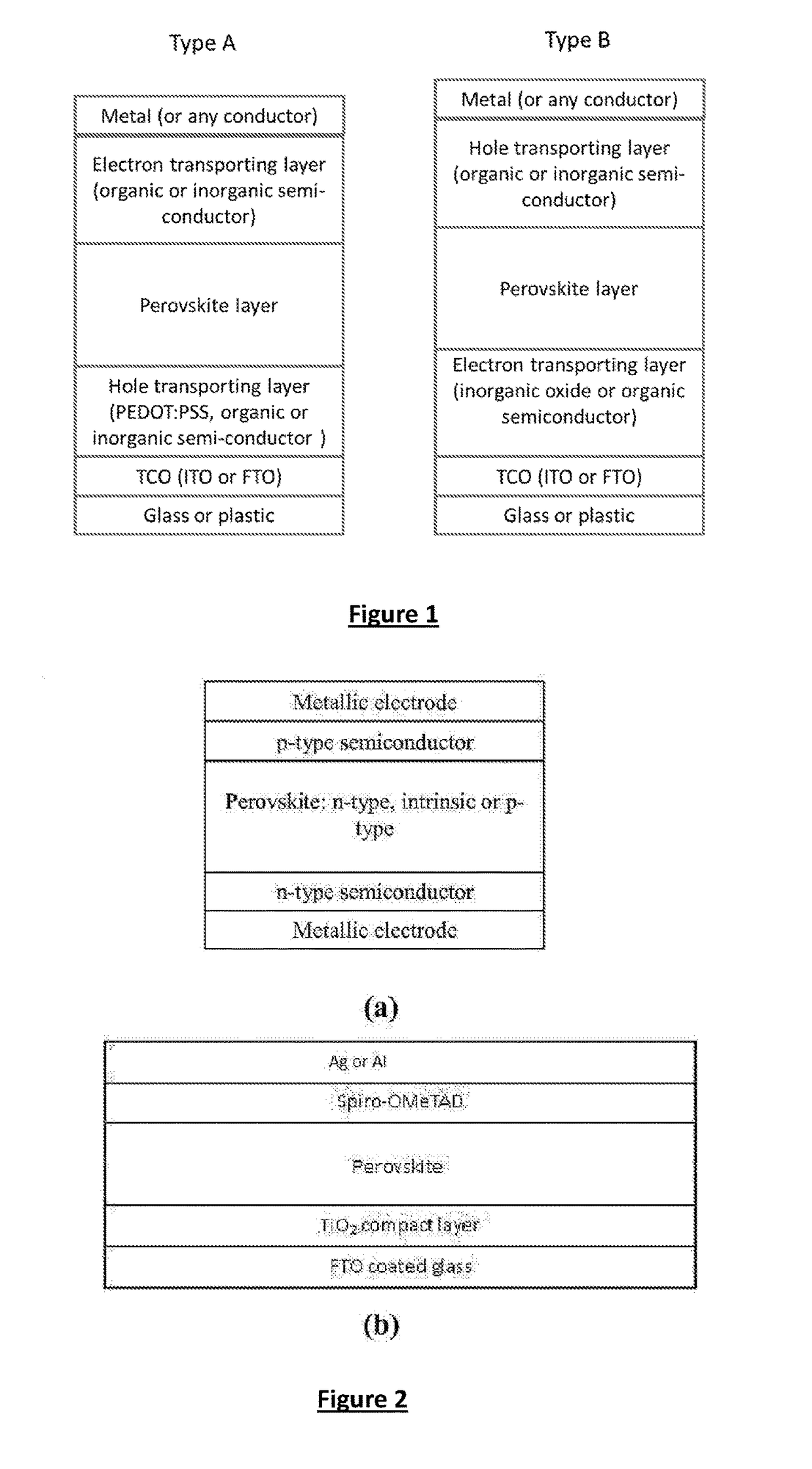

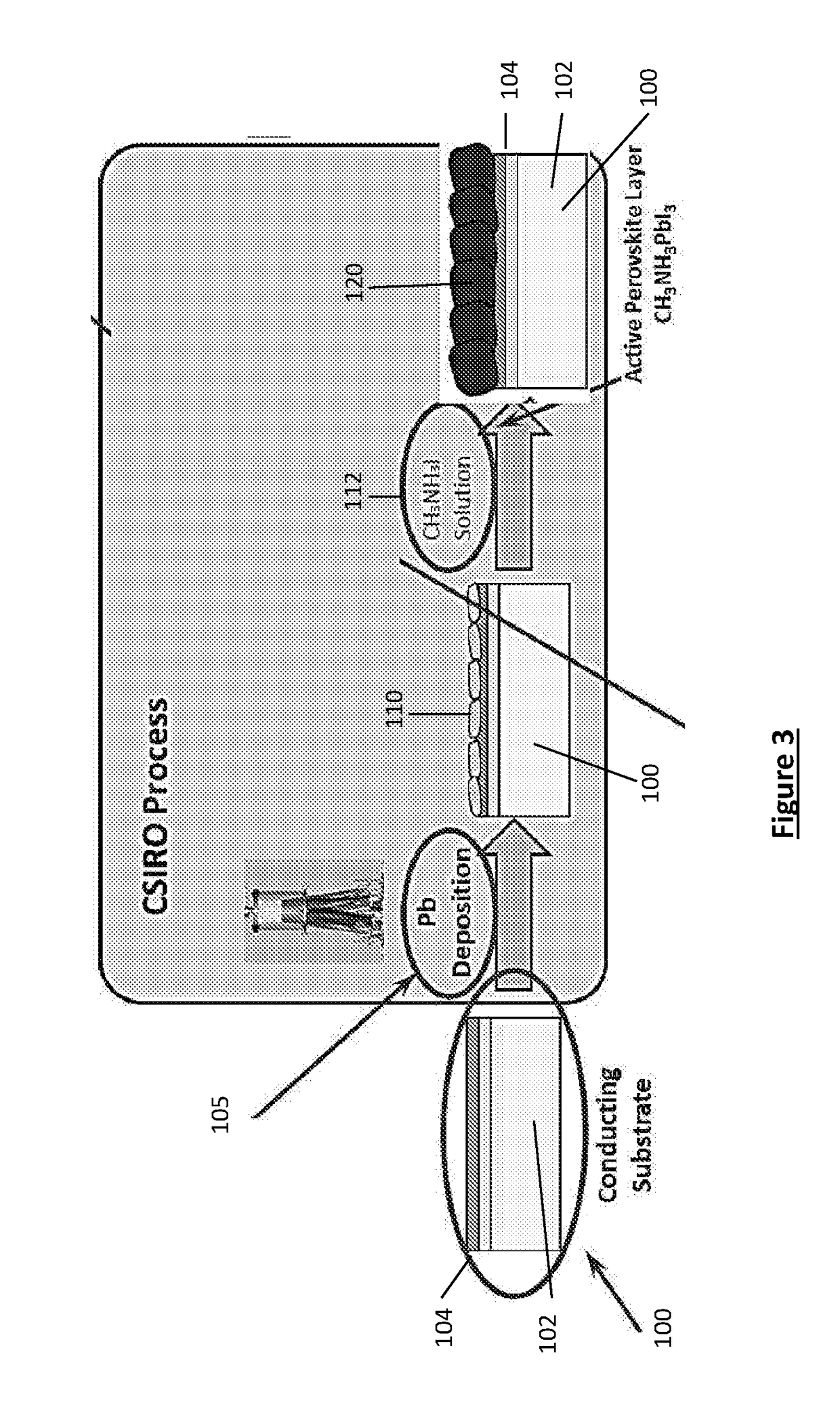

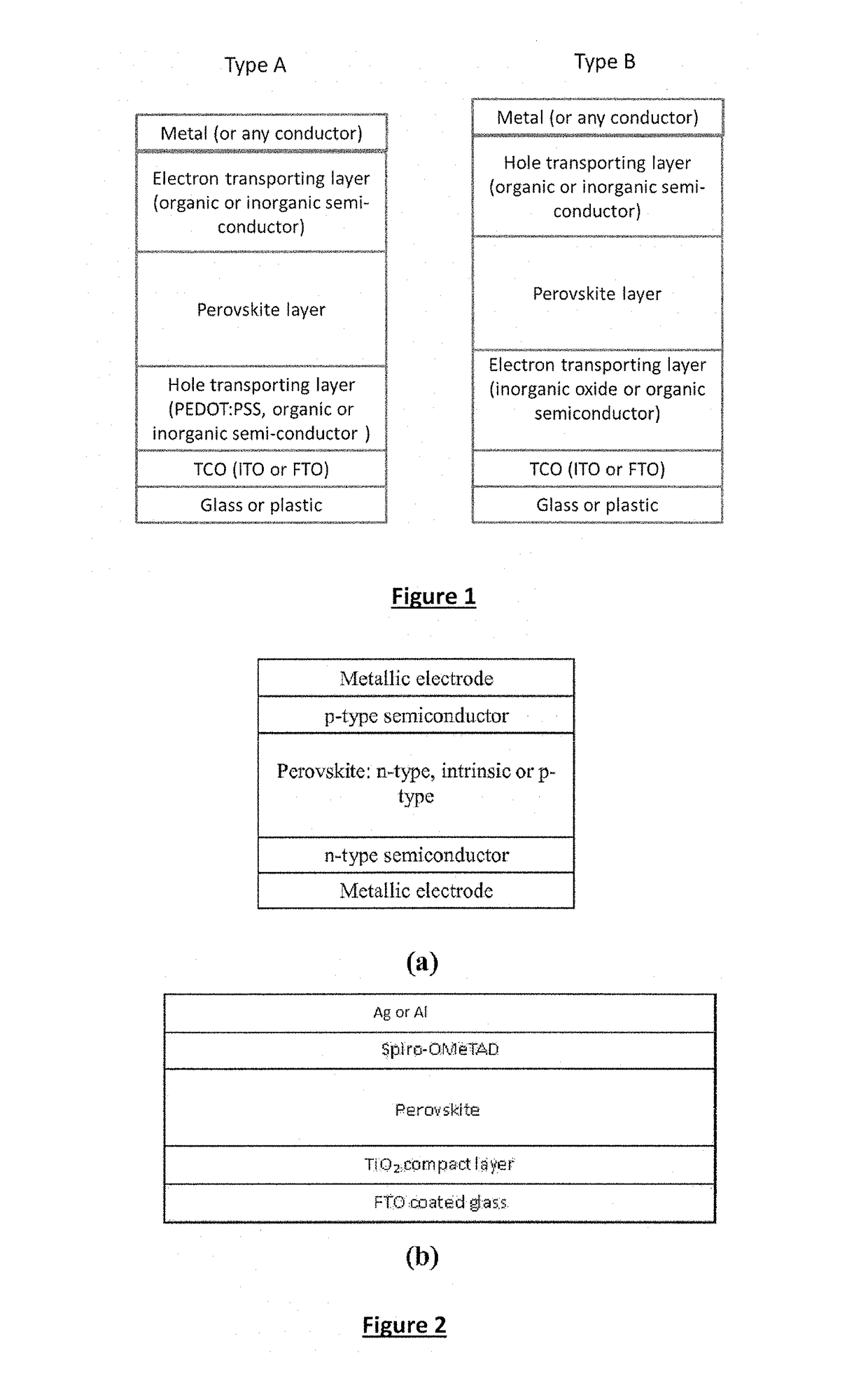

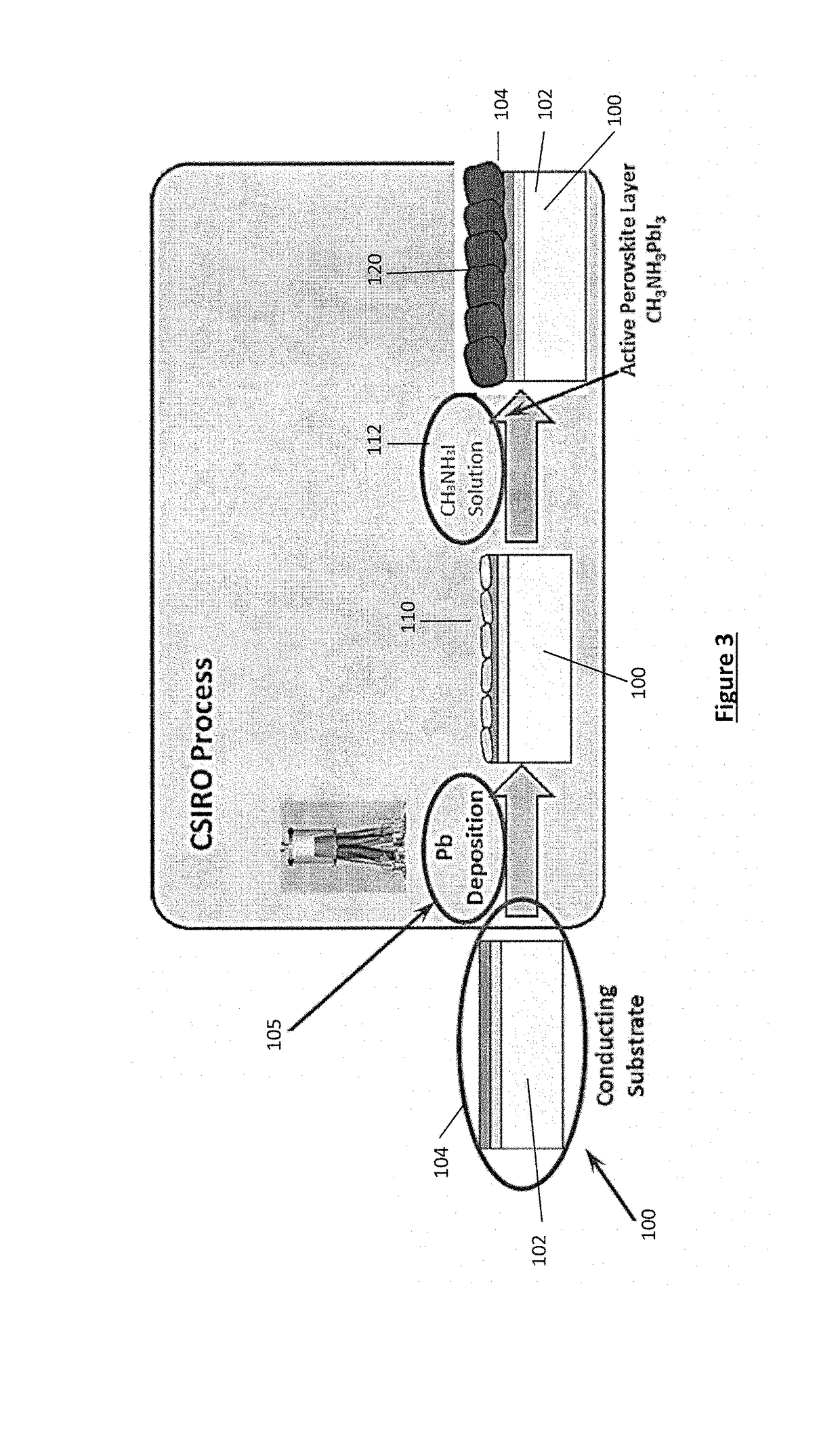

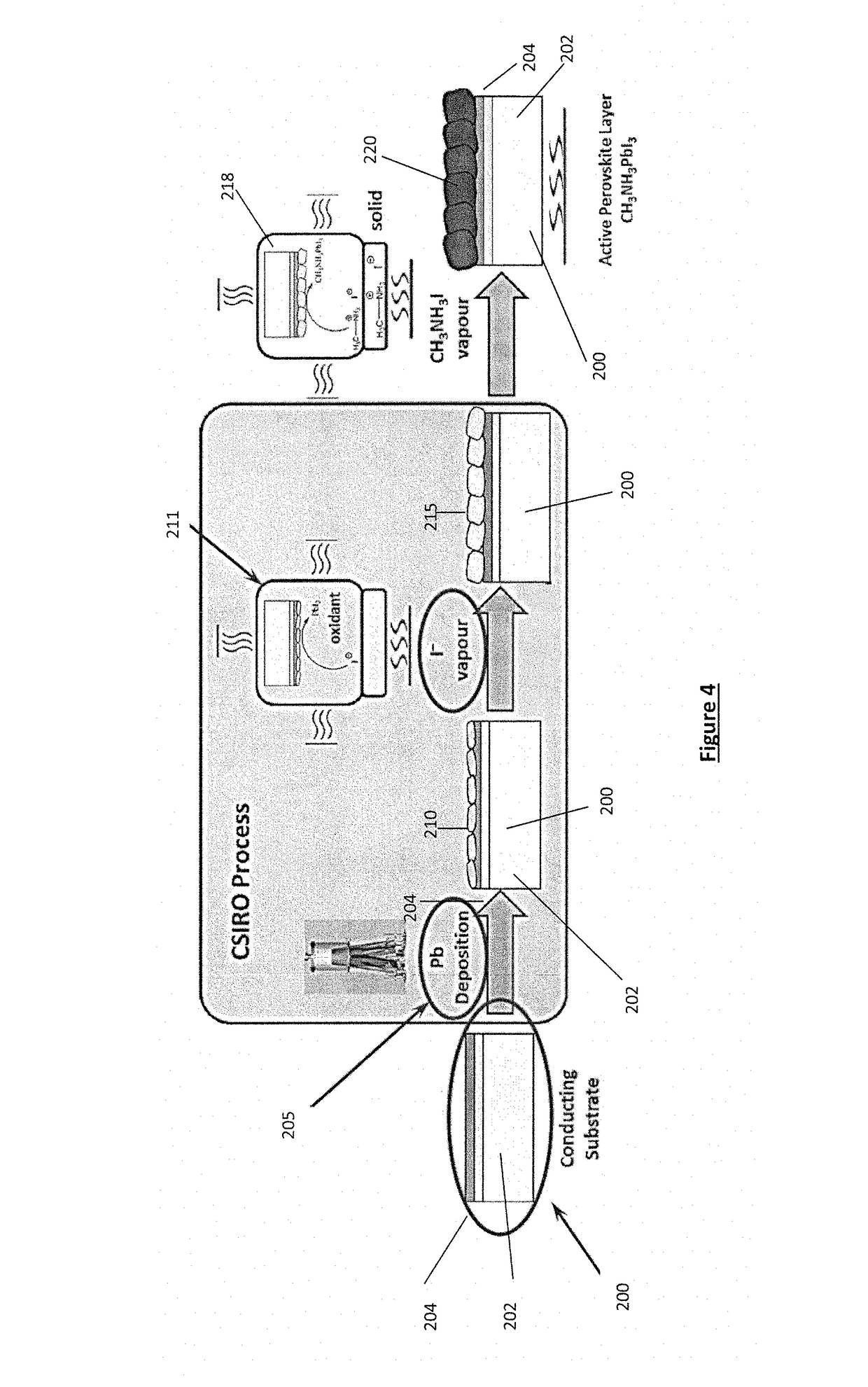

Process of forming a photoactive layer of an optoelectronic device

ActiveUS20180005764A1Monitor qualityImprove uniformityLight-sensitive devicesSolid-state devicesOptoelectronicsMetal

A process of forming a thin film photoactive layer of an optoelectronic device comprising: providing a substrate having a surface comprising or coated with a metal M selected from at least one of Pb, Sn, Ge, Si, Ti, Bi, or In; and converting the metal surface or metal coating of the substrate to a perovskite layer.

Owner:COMMONWEALTH SCI & IND RES ORG

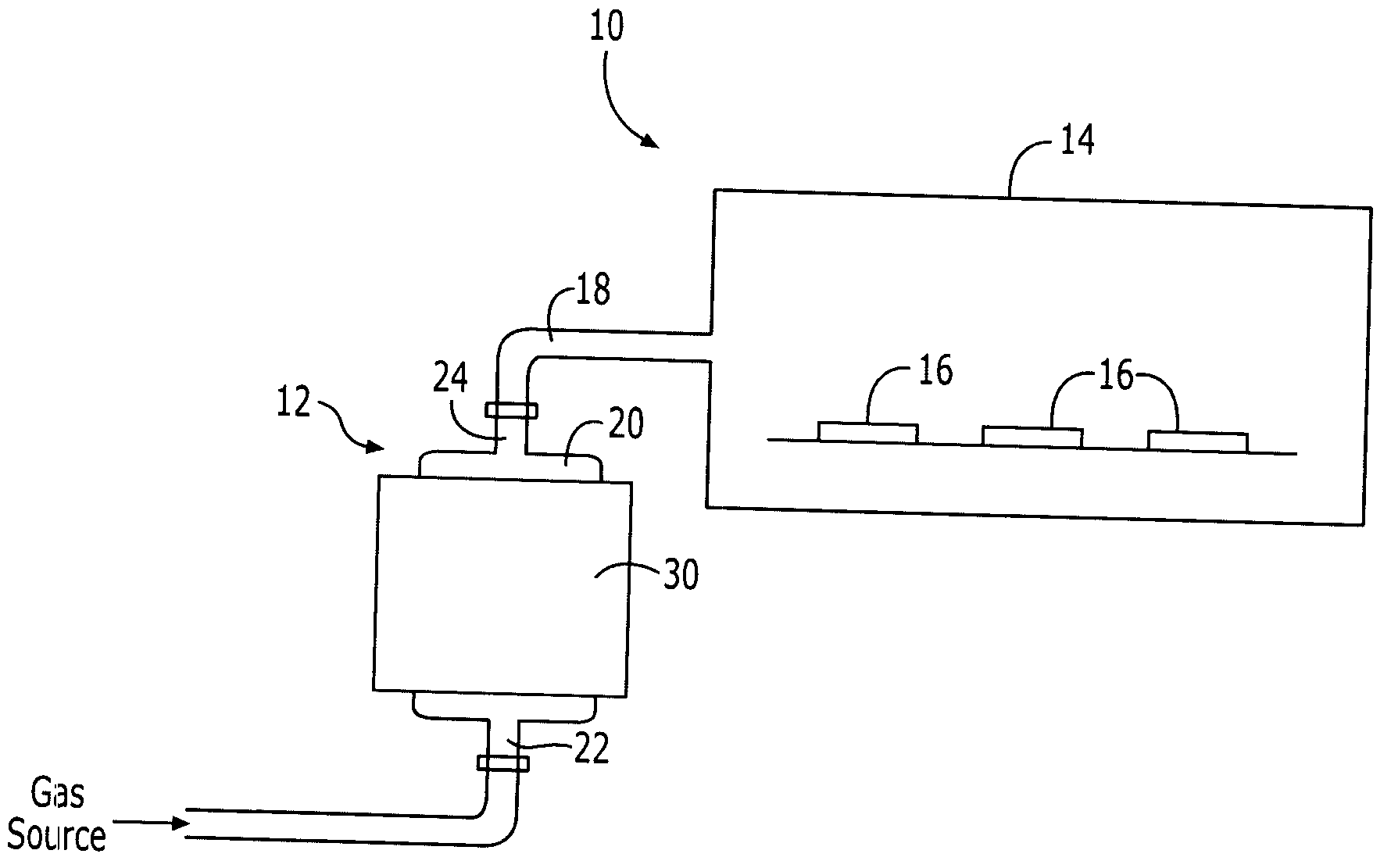

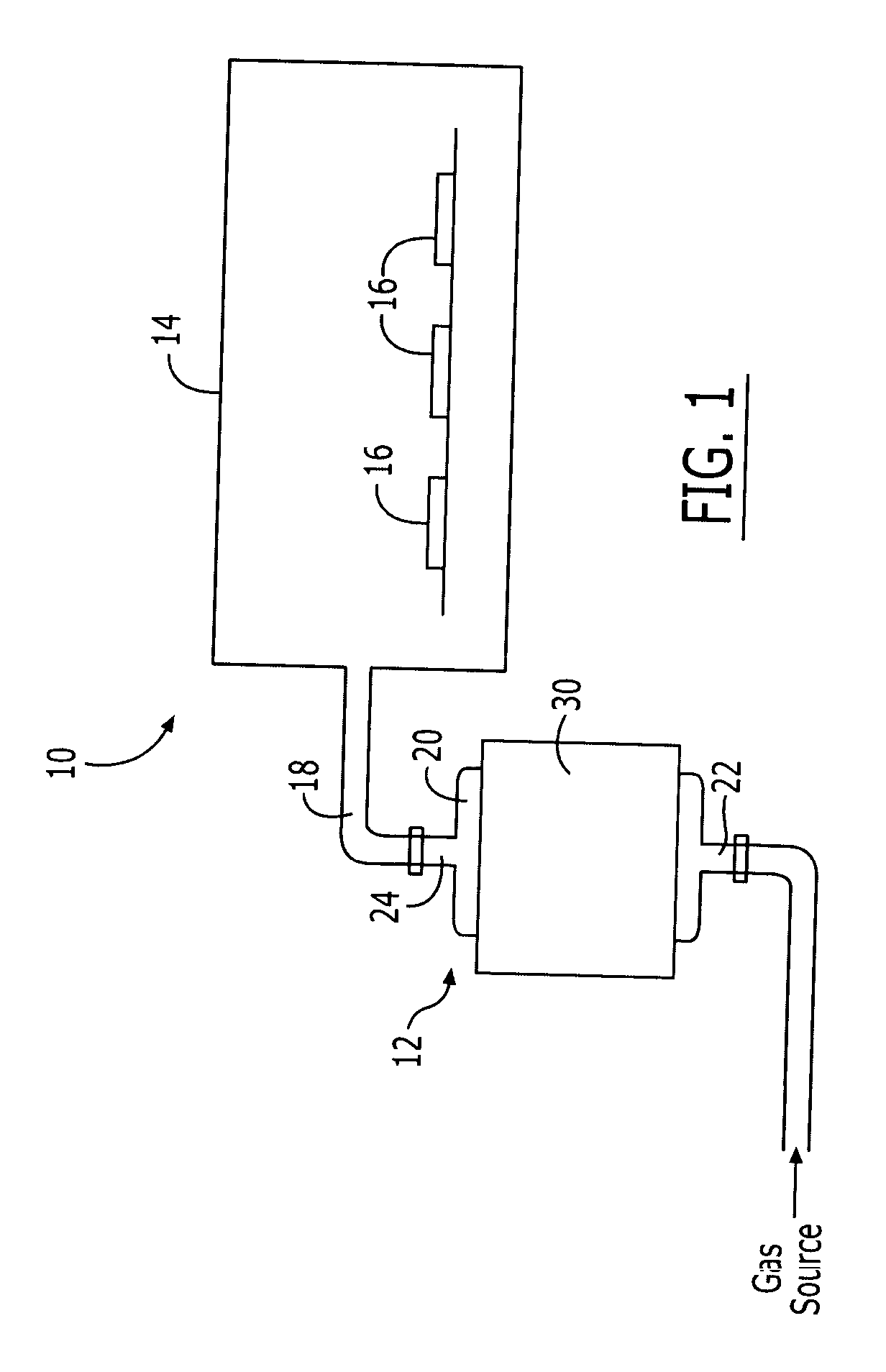

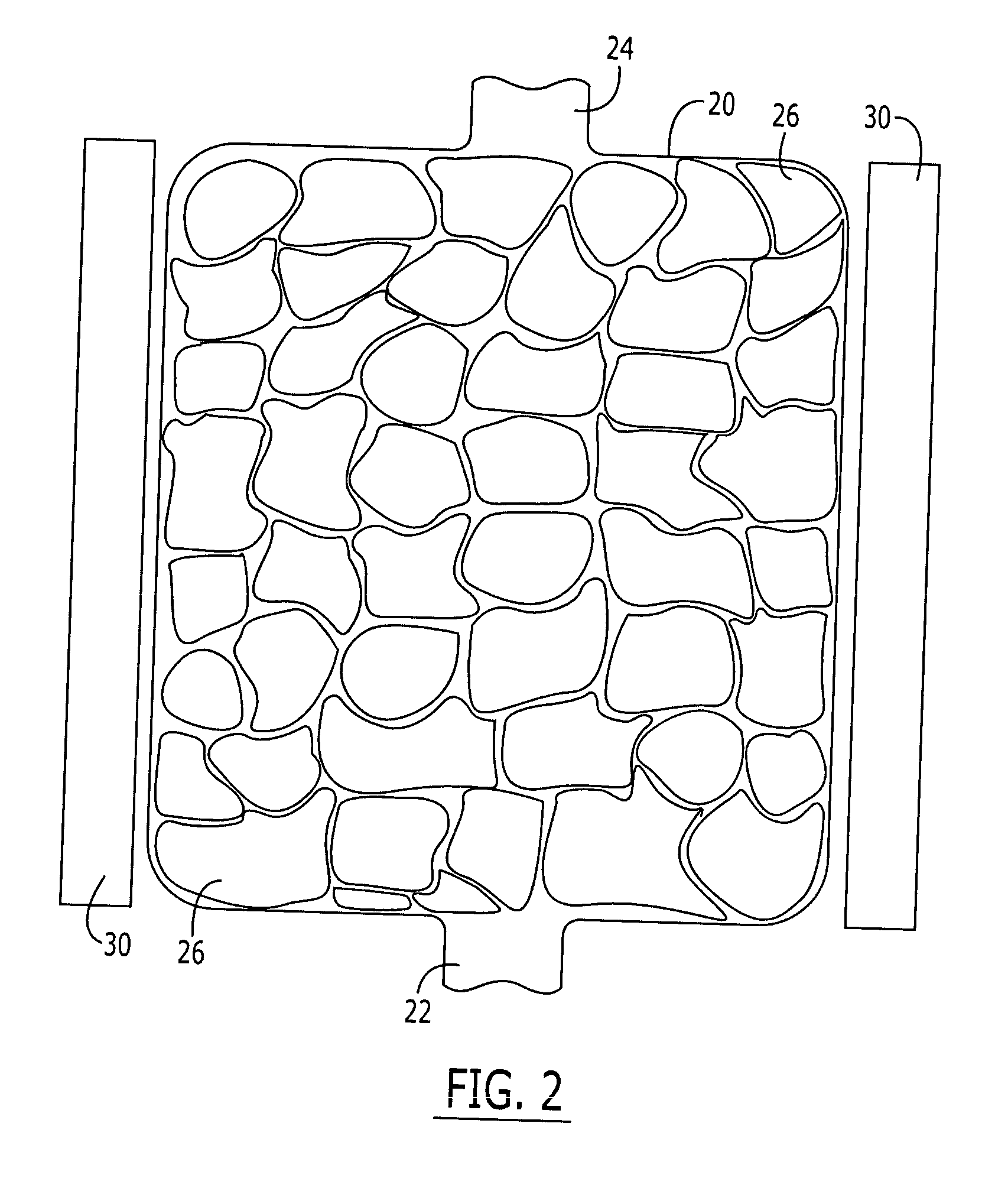

Gettering filter and associated method for removing oxygen from a gas

InactiveUS20050053535A1Improve efficiency and yieldReduce in quantityOxygen/ozone/oxide/hydroxideDispersed particle separationOxygenMoisture

A method and apparatus are provided for removing oxygen and moisture from a gas such that wafers subsequently exposed to the gas develop less haze. The apparatus includes a process chamber for receiving a wafer. The apparatus also includes a gettering filter in fluid communication with the process chamber for removing oxygen from a gas that passes through the gettering filter in route to the process chamber. The gettering filter includes a vessel and a plurality of pieces of an oxidizable material disposed within the vessel. The oxidizable material is selected to oxidize upon exposure to oxygen in the gas such that the gas exiting the vessel has less oxygen than the gas entering the vessel. The oxidizable material may also be selected such that the resulting oxide layer is etchable upon exposure to an etchant, thereby permitting the gettering filter to be regenerated.

Owner:SEH AMERICA

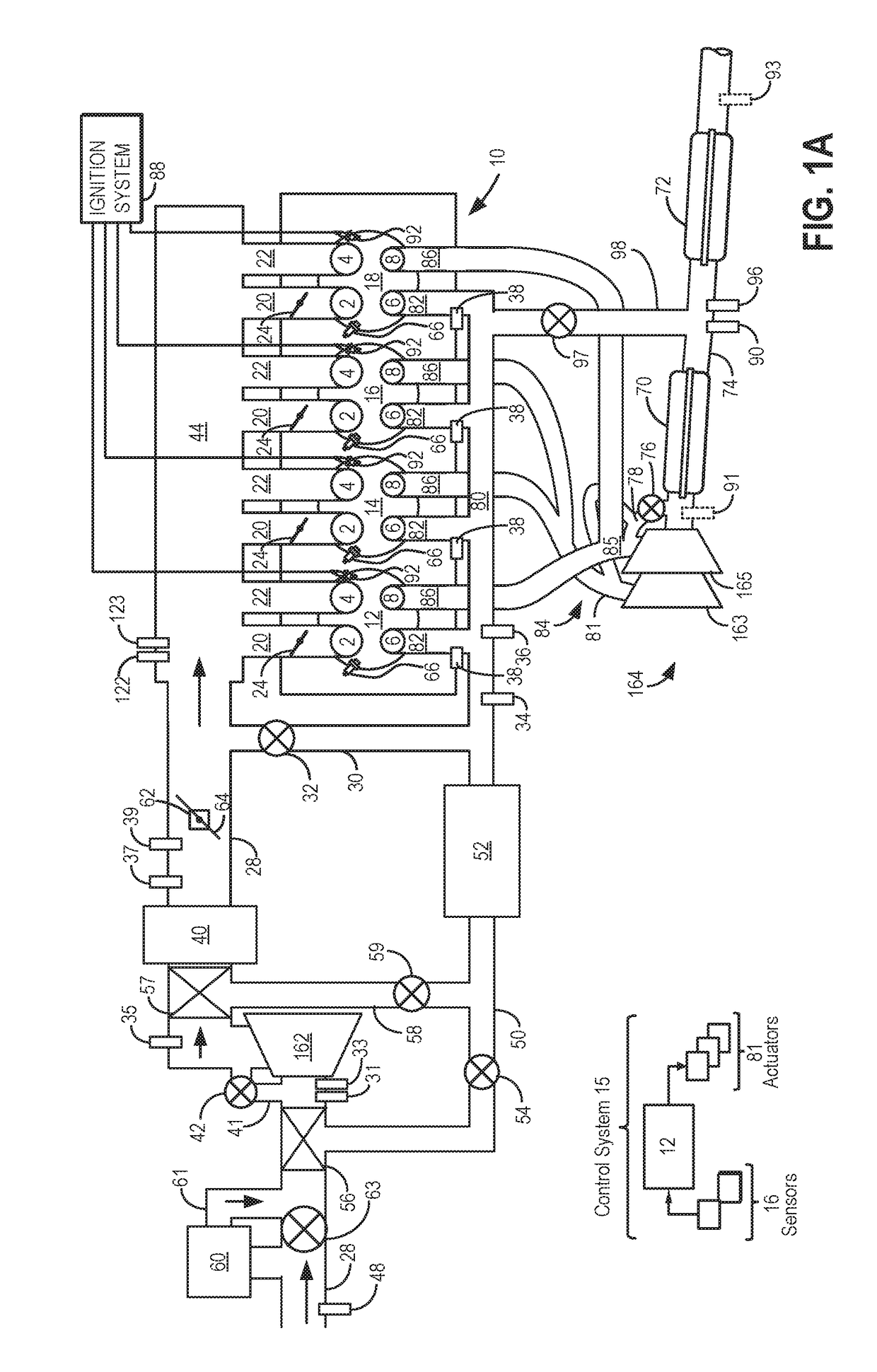

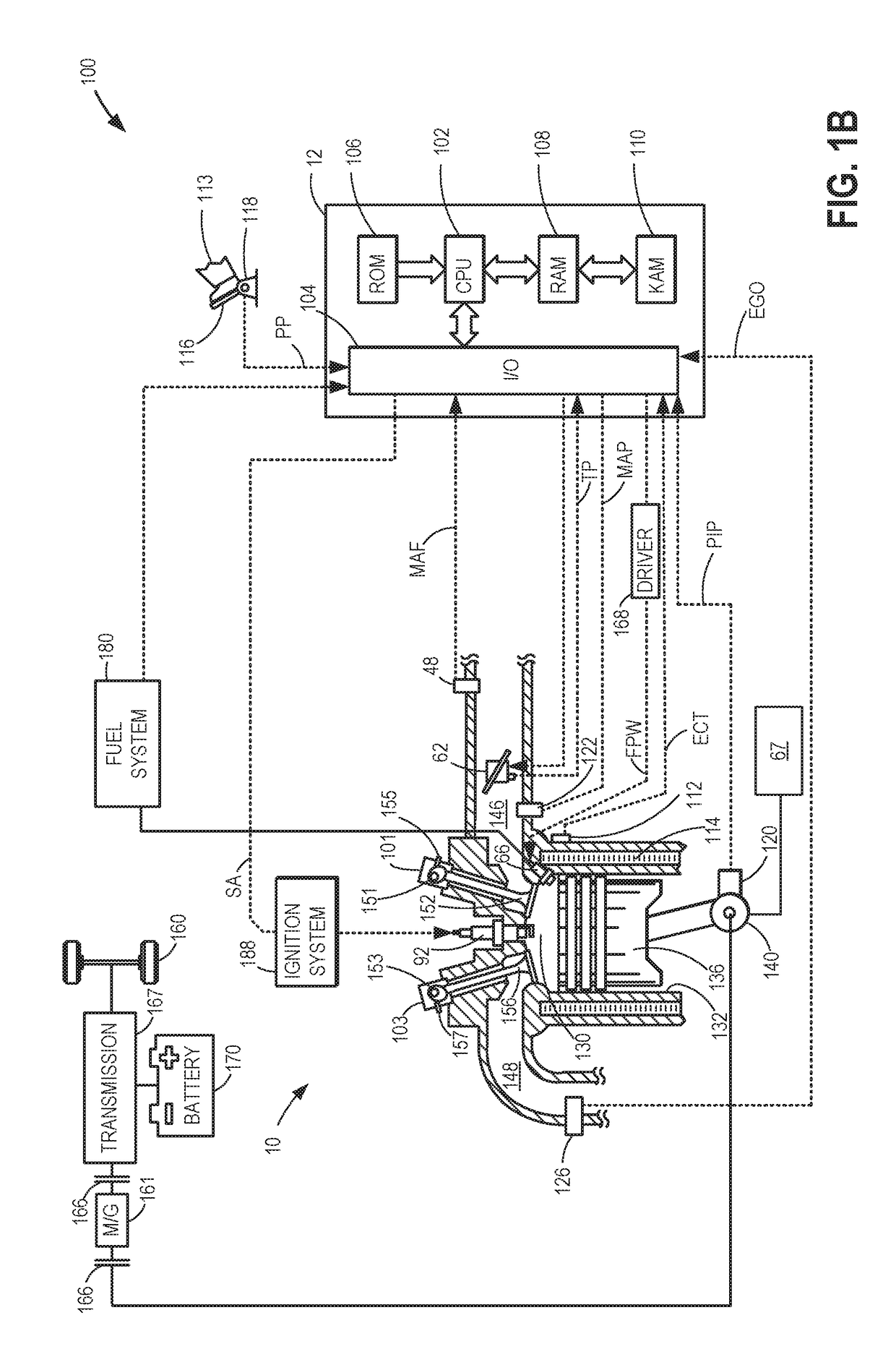

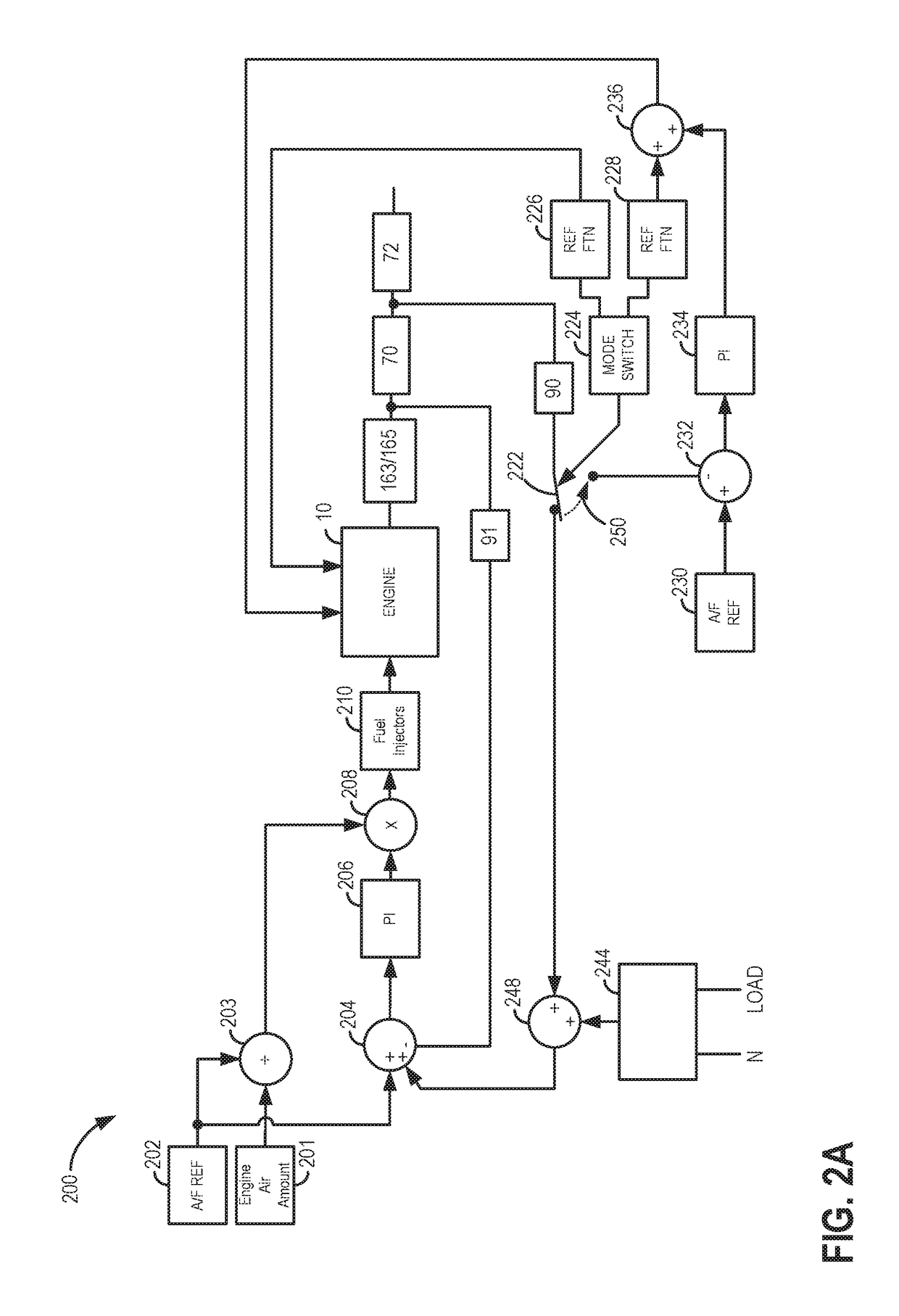

Systems and methods for a split exhaust engine system

InactiveUS10190507B2Increase engine power densityReduce knockingElectrical controlInternal combustion piston enginesExhaust valveExhaust gas recirculation

Methods and systems are provided for operating a split exhaust engine system that provides blowthrough air and exhaust gas recirculation to an intake passage via a first exhaust manifold and exhaust gas to an exhaust passage via a second exhaust manifold. In one example, one or more valves of a set of first exhaust valves coupled to the second exhaust manifold may be deactivated in response to select engine operating conditions, while maintaining active all valves of a set of second exhaust valves coupled to the first exhaust manifold. The select engine operating conditions may include one or more of a deceleration fuel shut-off condition, a part throttle condition, and a cold start condition.

Owner:FORD GLOBAL TECH LLC

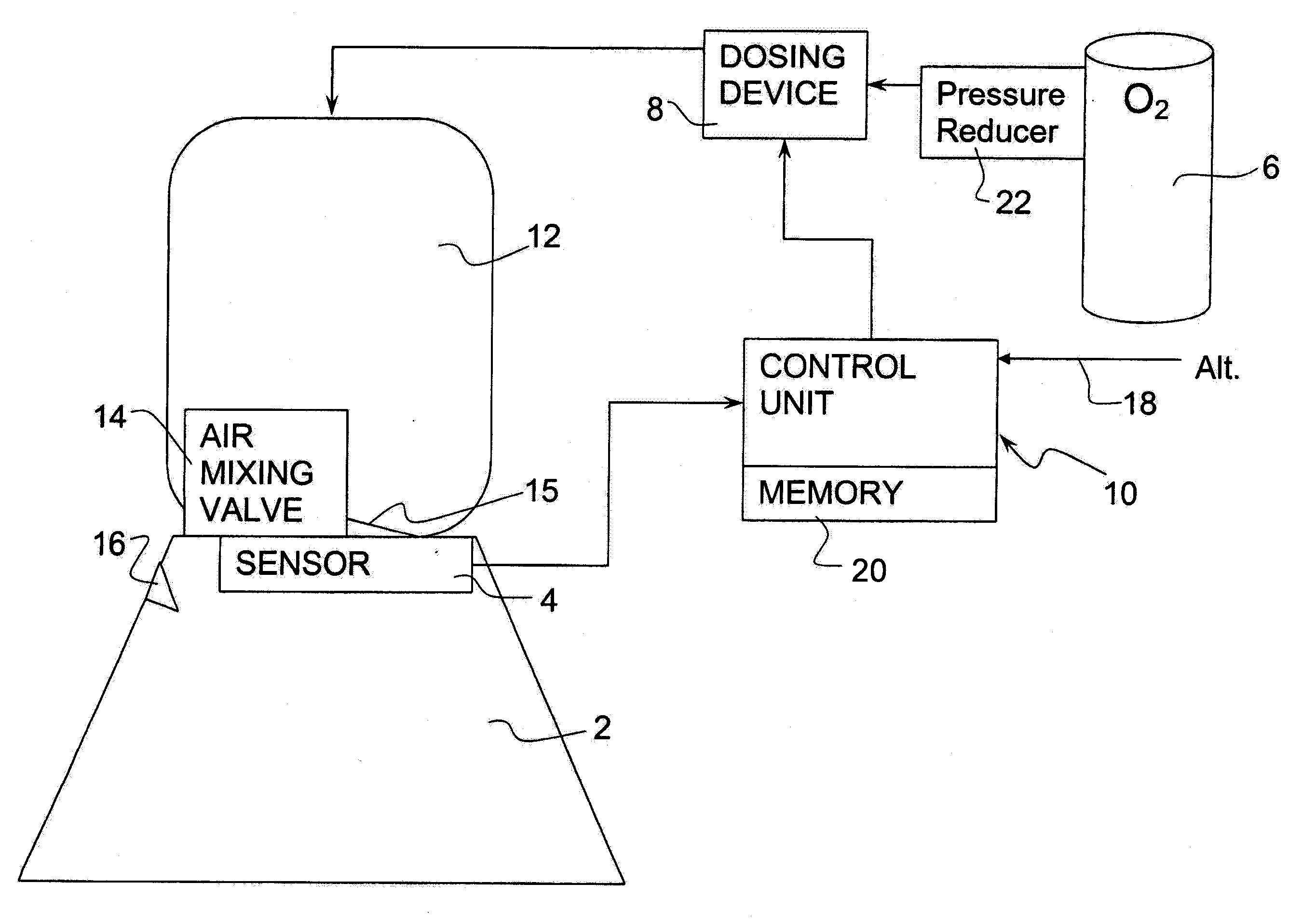

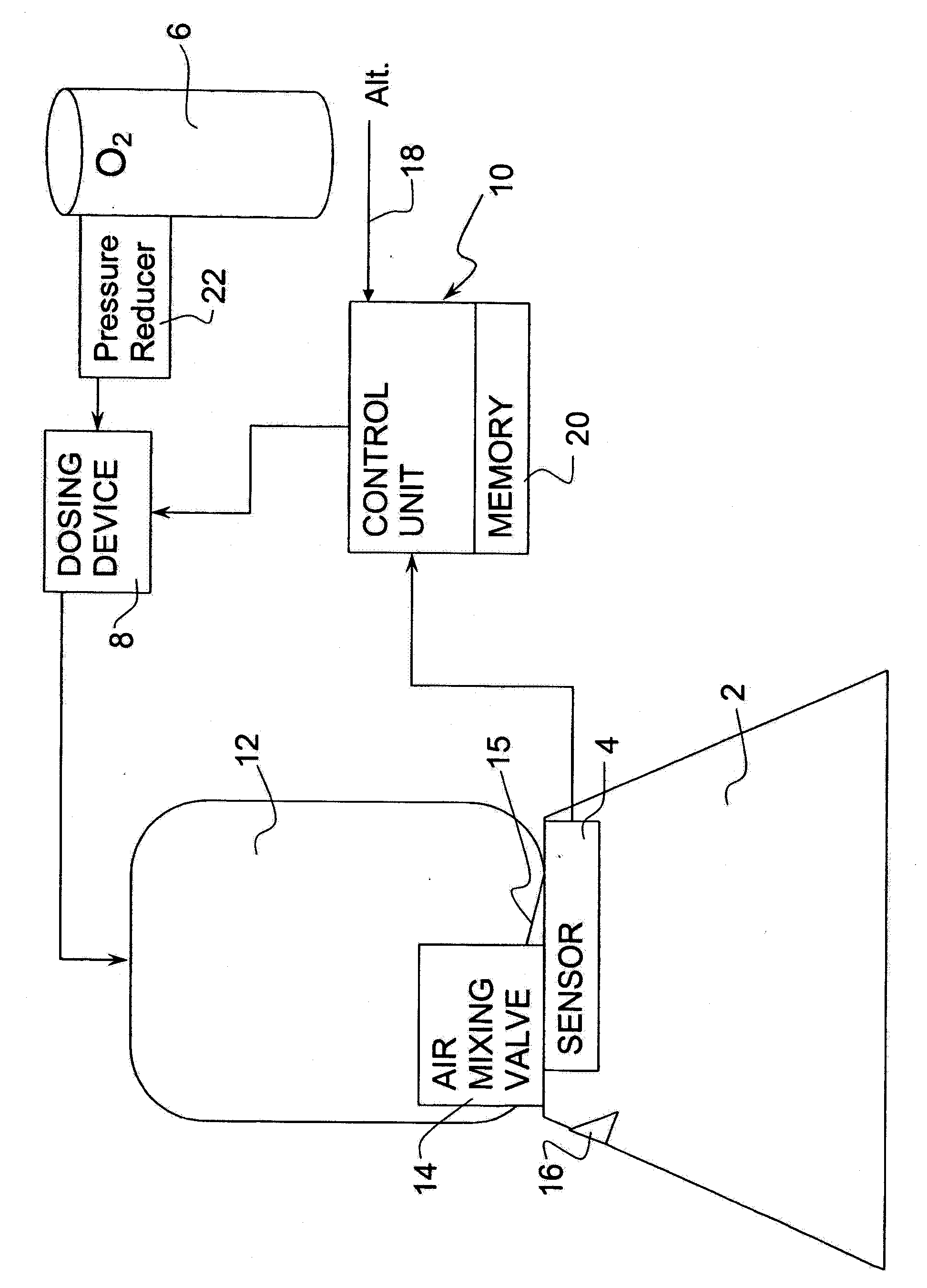

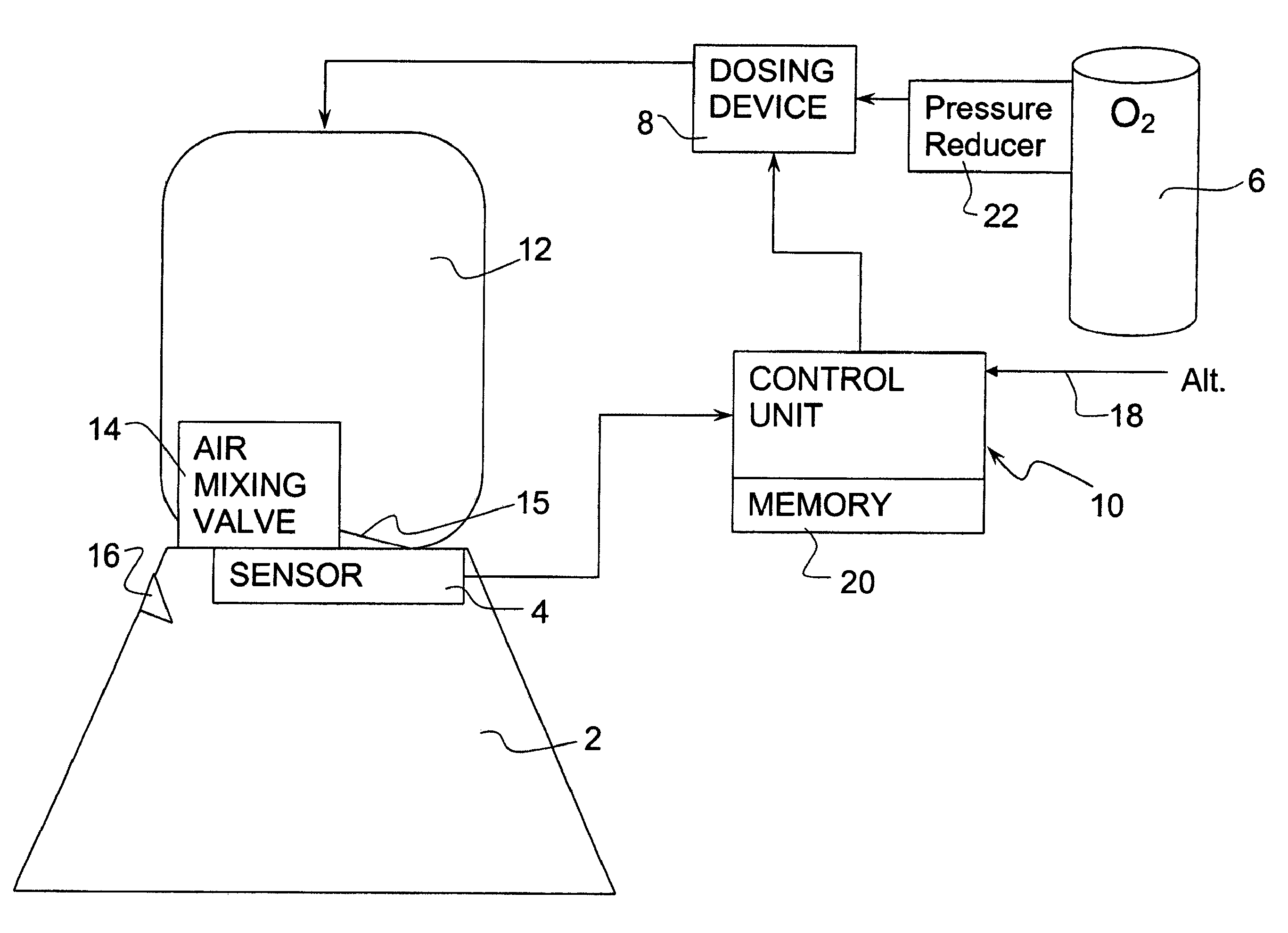

Emergency oxygen system for aircraft passengers

InactiveUS20090014003A1Reduce the amount of oxygenLess oxygenOperating means/releasing devices for valvesRespiratory masksJet aeroplaneOxygen system

An emergency oxygen system is provided for aircraft passengers. The system includes at least one oxygen mask (2), with a sensor (4) for detecting at least one breathing characteristic value of a passenger using this oxygen mask (2). A control unit (10) individually determines the oxygen requirement of the passenger on account of the detected breathing characteristic value. A dosing device (8) is actuated by the control unit (10). The dosing device (8) supplies an oxygen quantity corresponding to the determined oxygen requirement, to the oxygen mask (2).

Owner:BE AEROSPACE SYST

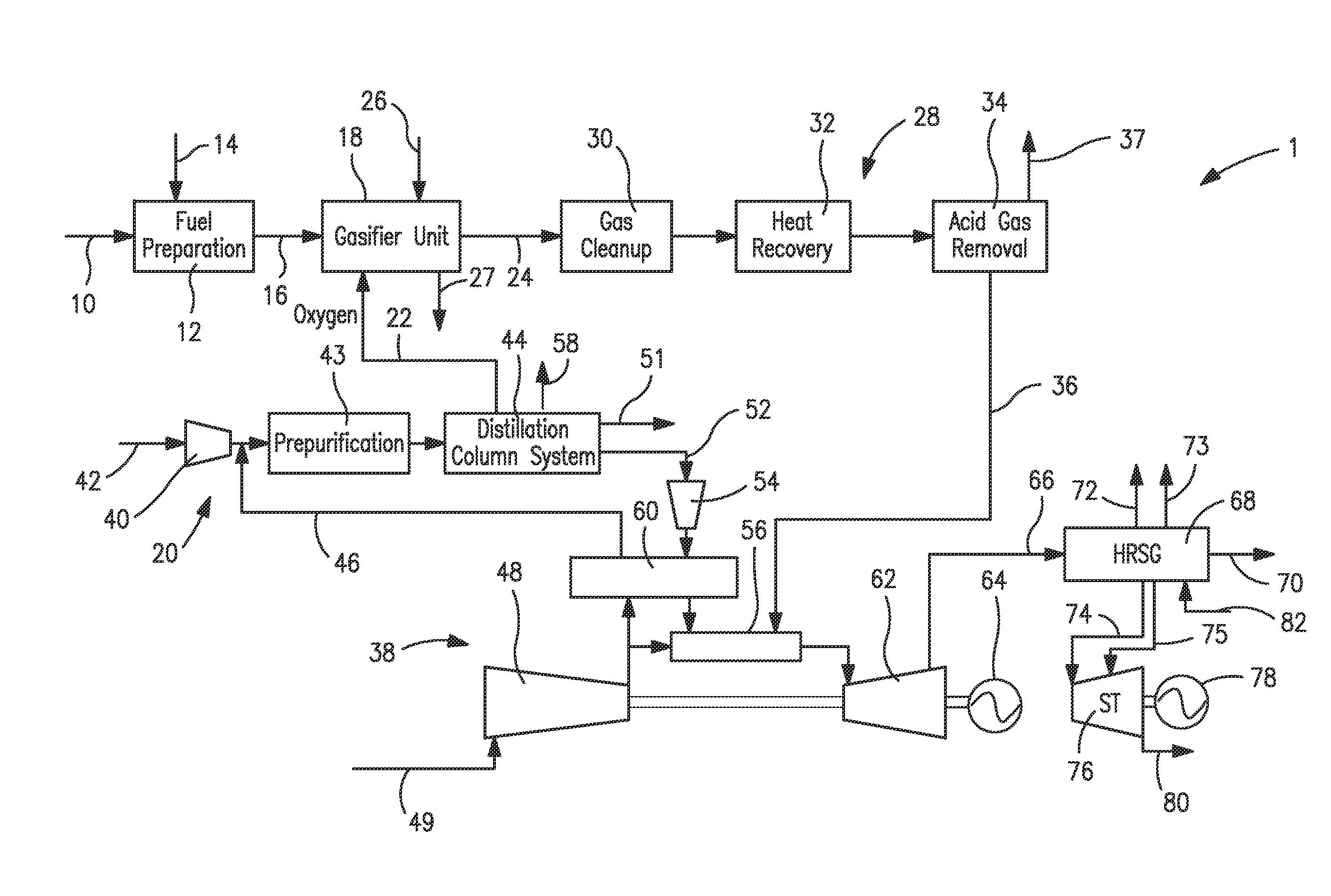

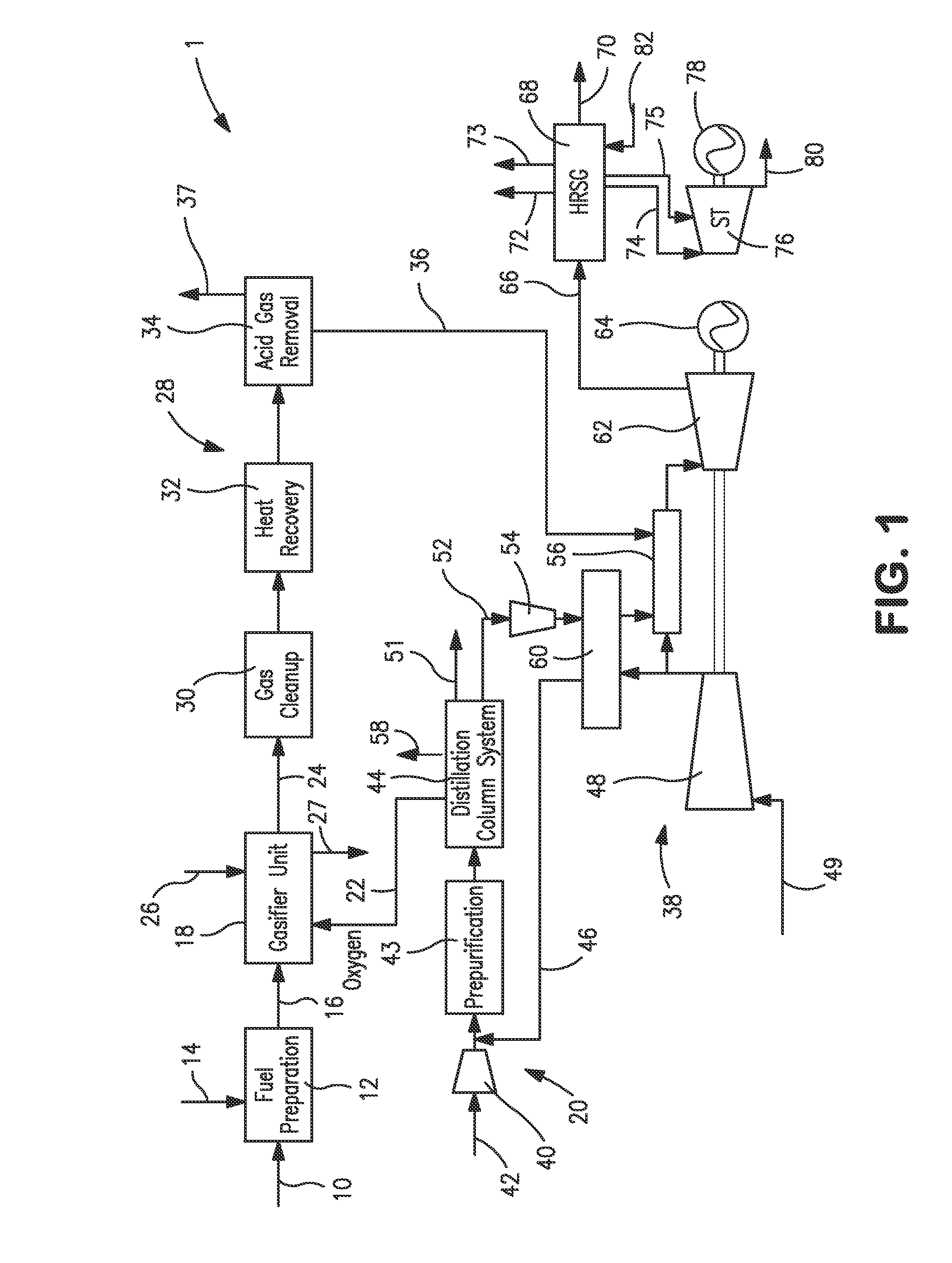

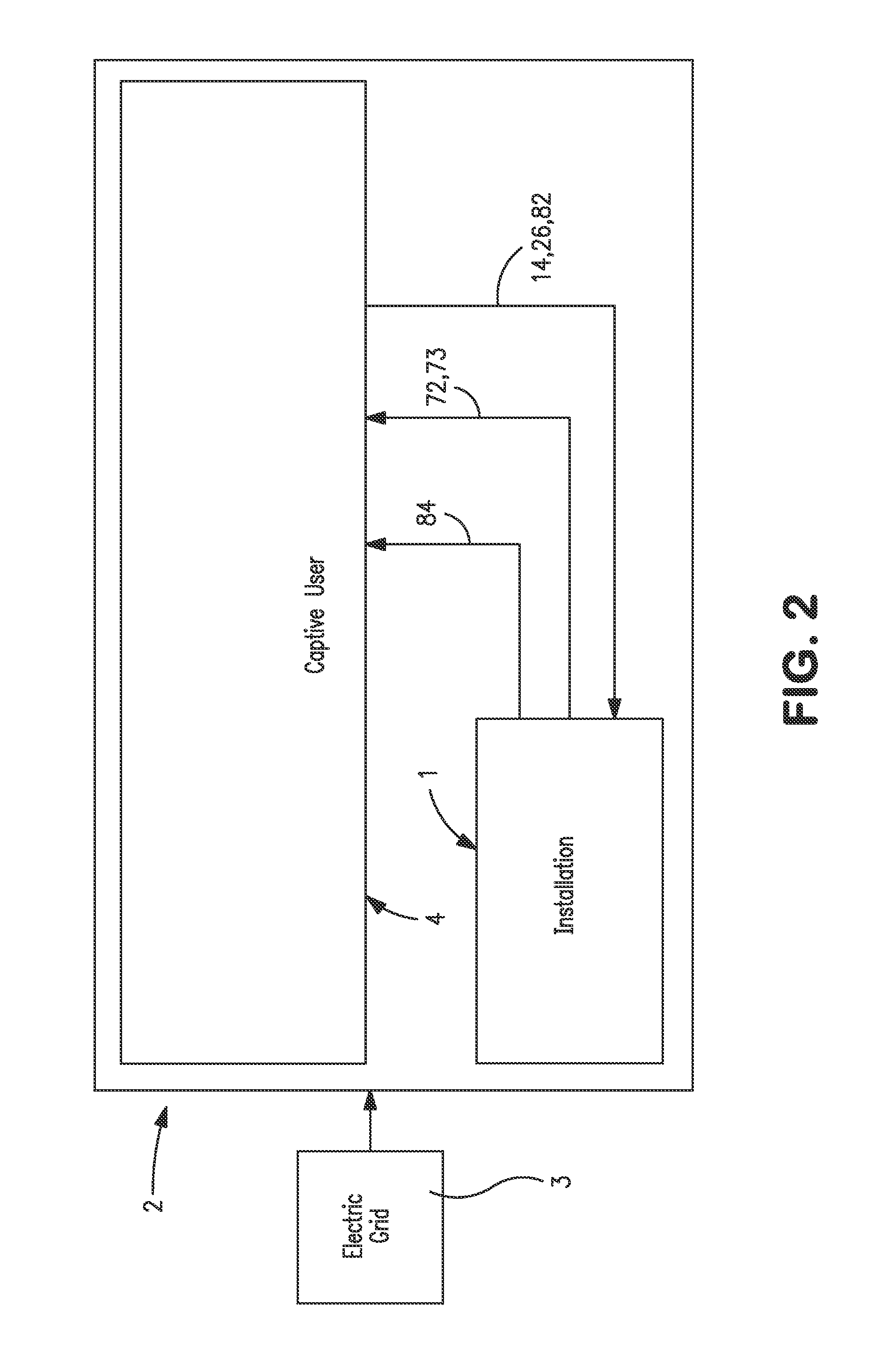

Combined gasification and power generation

InactiveUS20140130509A1Low efficiencyMost efficientGas turbine plantsSteam engine plantsGas compressorNitrogen

A combined gasification and electric power generation method wherein between 30.0 and 60.0 percent of the compressed air required by an air separation unit supplying oxygen to a gasifier and nitrogen to gas turbine(s) is extracted from a compressor of the gas turbine(s). An installation, including the gas turbine(s), the air separation unit, a gasifier and a gas conditioning system for producing gas turbine fuel, has a design point of ambient temperature and pressure and net power output for producing the electric power required by a captive user. The gas turbine(s), at the design point, have a capacity to compress air from the compressor thereof, at a rate between 4.8 and 6.0 times the total molar flow rate of air required by the air separation unit and the compressor of the gas turbine(s) is operated at no less than 90.0 percent of its capacity at the design point.

Owner:PRAXAIR TECH INC

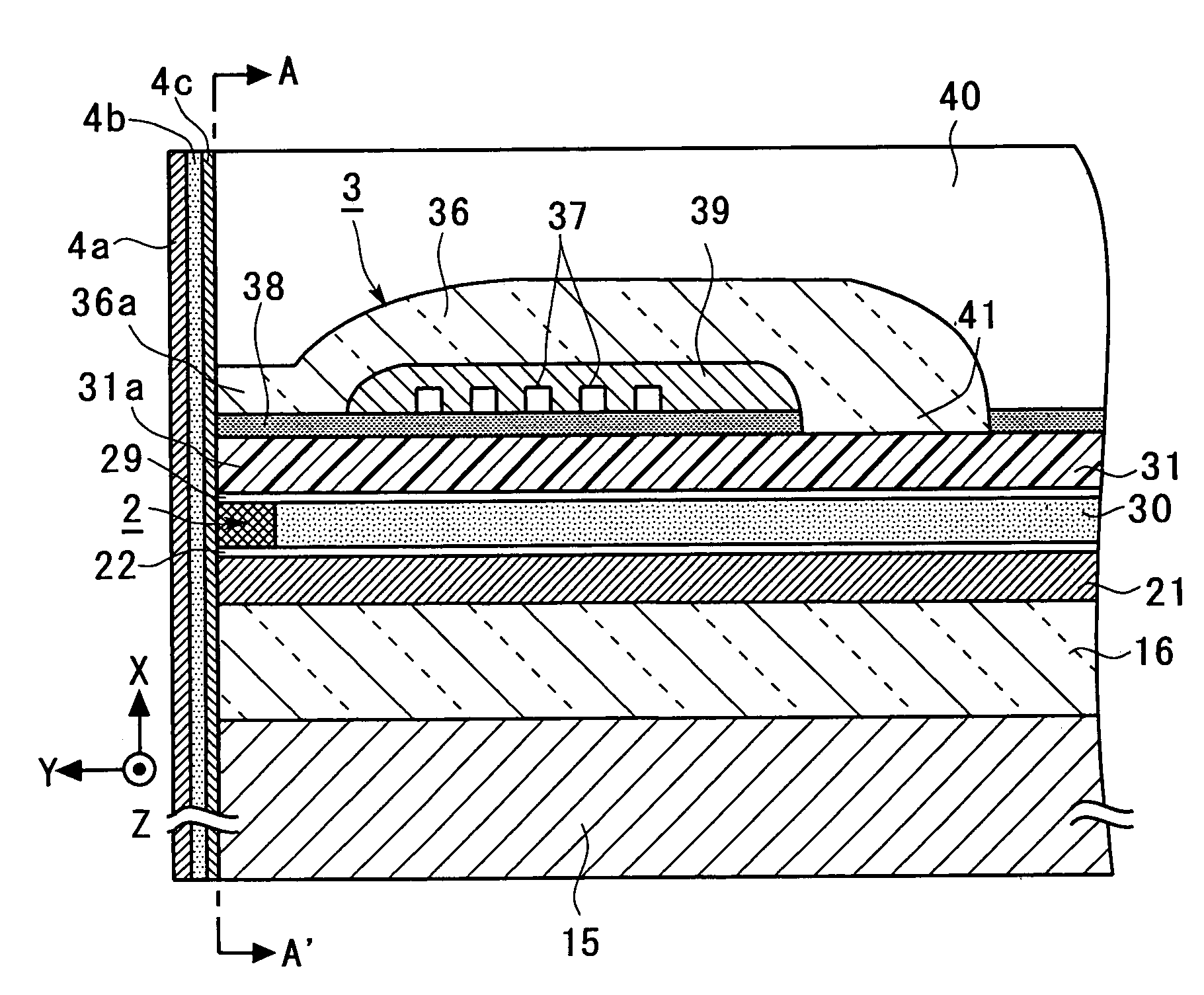

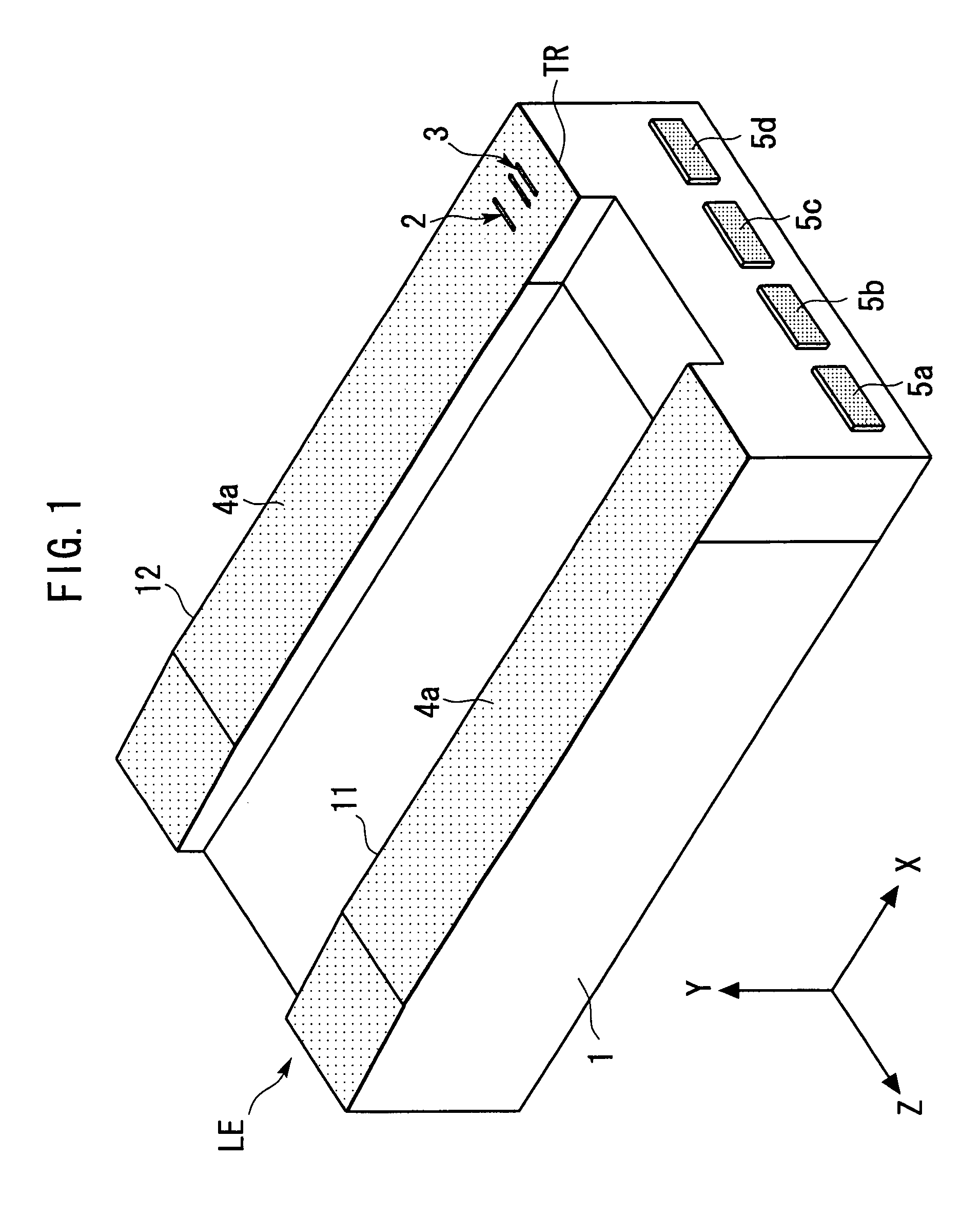

Magnetic head and method of manufacturing same, head suspension assembly and magnetic disk apparatus

ActiveUS7308751B2Improve stabilityLess variationElectrical transducersNanomagnetismTectorial membraneMagnetic reluctance

A magnetic head has less variations in the resistance of a magneto-resistive device before and after the magnetic head is left in a high temperature environment so as to have higher stability of the characteristics of the magnetic head against a high temperature environment. A TMR device includes a tunnel barrier layer made of an oxide layer. A DLC film serving as a protection film and an underlying layer therefor are formed on an end face of the TMR device on an air bearing surface side. A layer made of an oxide of a metal or an oxide of a semiconductor is formed between the underlying layer and the end face of the tunnel barrier layer on the air bearing surface side to be in contact with the end face of the tunnel barrier layer.

Owner:TDK CORP

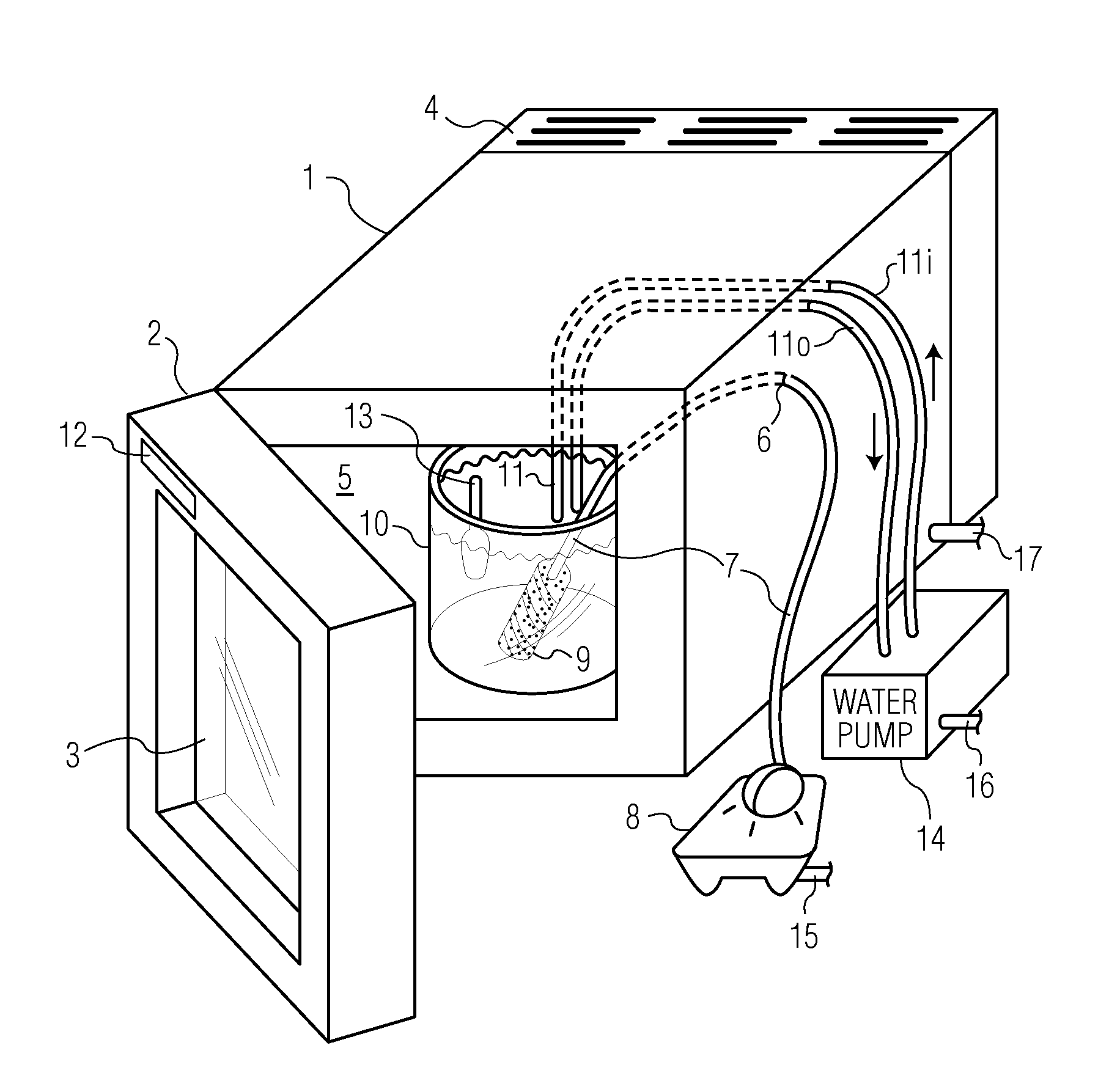

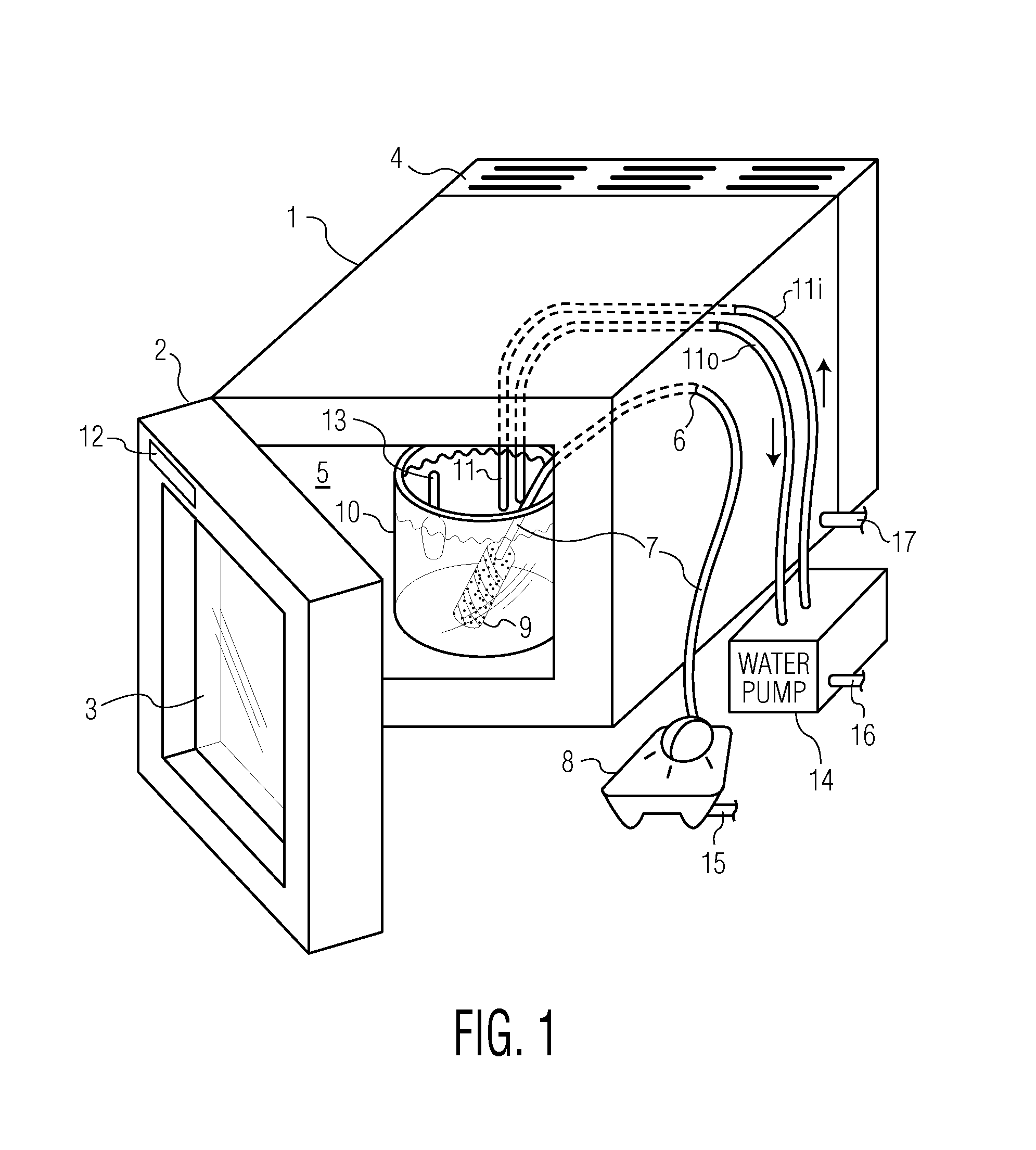

Temperature-Controllable Aquaculture Apparatus

InactiveUS20130333627A1Less oxygenReduce capacityClimate change adaptationPisciculture and aquariaAquatic speciesPotential effect

An inexpensive, easily manufactured aquaculture apparatus featuring a water temperature control feature, useful for studying the effect of water temperature changes on the viability of aquatic species. The apparatus is useful to, for example, study the potential effect of global warming and rising ocean water temperatures on various aquatic species.

Owner:POHL NAOMI

Emergency oxygen system for aircraft passengers

InactiveUS7481216B1Less oxygenLower requirementRespiratorsOperating means/releasing devices for valvesJet aeroplaneOxygen system

An emergency oxygen system is provided for aircraft passengers. The system includes at least one oxygen mask (2), with a sensor (4) for detecting at least one breathing characteristic value of a passenger using this oxygen mask (2). A control unit (10) individually determines the oxygen requirement of the passenger on account of the detected breathing characteristic value. A dosing device (8) is actuated by the control unit (10). The dosing device (8) supplies an oxygen quantity corresponding to the determined oxygen requirement, to the oxygen mask (2).

Owner:BE AEROSPACE SYST

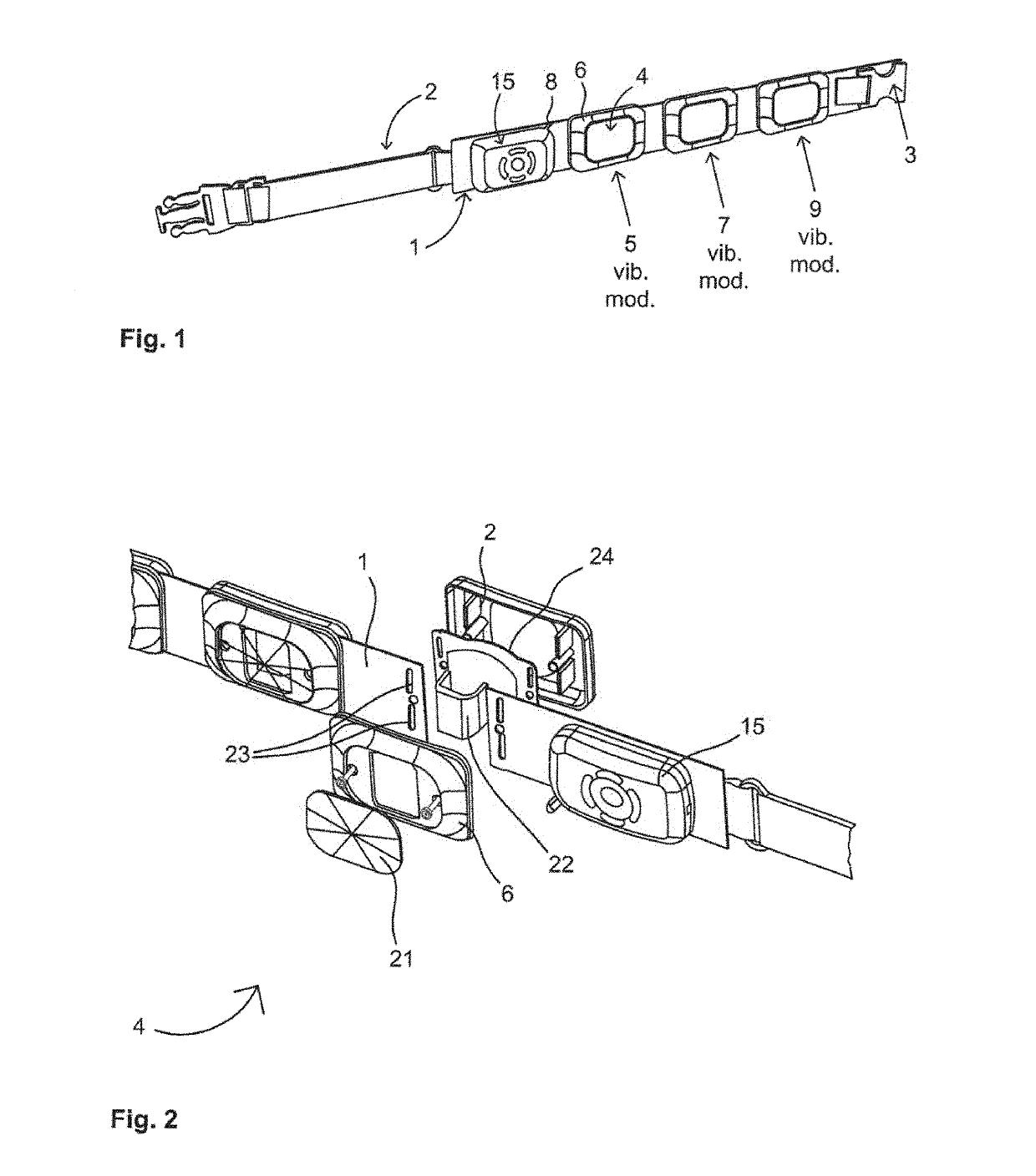

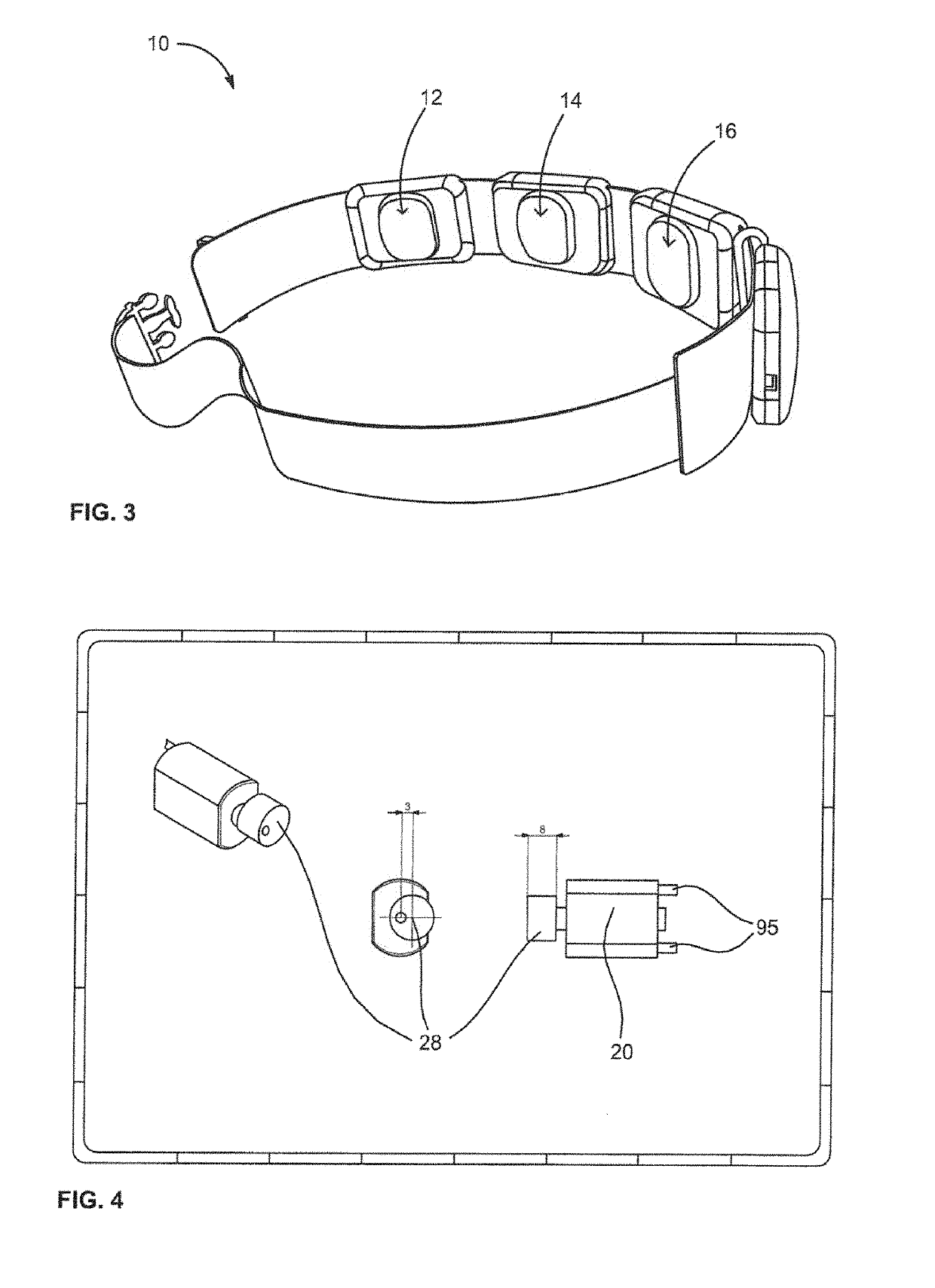

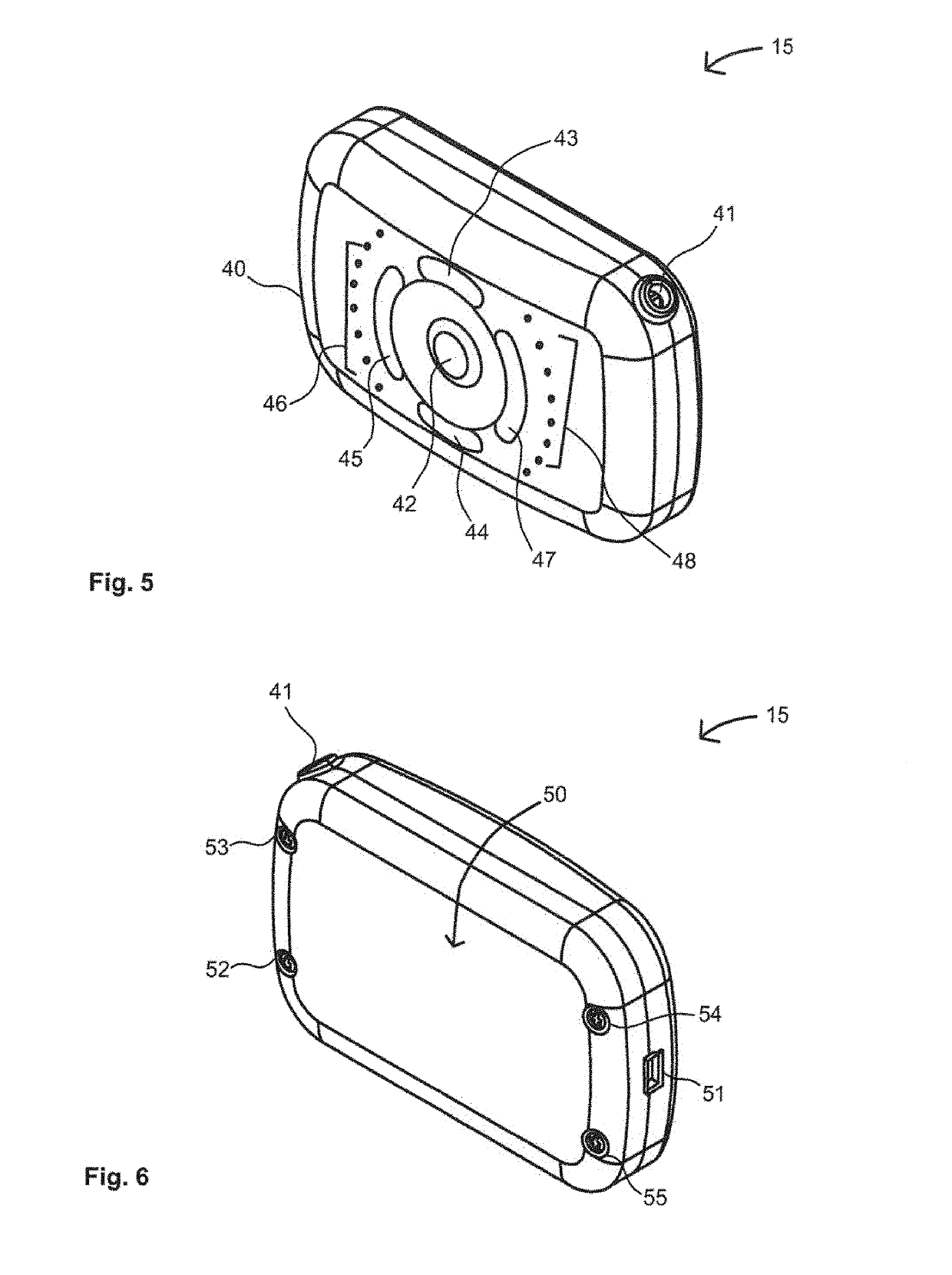

Stimulating Device

ActiveUS20190290534A1Deepen abdominalDeepen flank breathingMassage combsMassage beltsEngineeringFlywheel

The invention discloses a stimulation device comprising: a belt (10) containing at least two vibration modules (5, 7, 9), wherein each of the at least two vibration modules (5, 7, 9) comprises: a pod (4) with a casing (6, 26) and a vibration pad (24) arranged within the casing (6, 26), and a vibration motor (20) with a flywheel (28) within the housing (6, 26), a control panel (15) operating said vibration motors (20) of the at least two vibration modules (5, 7, 9); wherein the vibration motors (20) are mounted to the vibration pad (24) via at least one elastic motor housing (22). The invention further discloses the use of such a device for treating hypoventilation and respiratory depression and a method of treating hypoventilation and respiratory depression by fastening a belt (10) to the abdomen of a user and operating the belt (10), wherein the at least two vibration modules are externally applied to an abdominal region of a user to stimulate the diaphragm, to enhance pulmonary function.

Owner:SATINA MEDICAL UG HAFTUNGSBESCHRANKT

gr.9 tube billet manufacturing process

The invention discloses a Gr.9 tube billet manufacturing process, including forging, peeling, drilling and extrusion piercing, wherein the steps of extrusion piercing are: blank preparation, drilling, sheathing, heating and extrusion. The surface of the tube blank is completely covered with copper plates, so that the tube blank absorbs very little oxygen and hydrogen, and the size of the tube blank and the size of the finished tube can be controlled at the most appropriate ratio, reducing the number of processing passes. The amount of deformation is large, and the grains are more fully broken. Compared with the cross-rolling piercing, the deformation of each part is more uniform, which makes the metal plasticity better and is more conducive to processing. There is almost no surface oxidation, and the surface treatment is reduced to improve the product yield.

Owner:浙江五环钛业股份有限公司

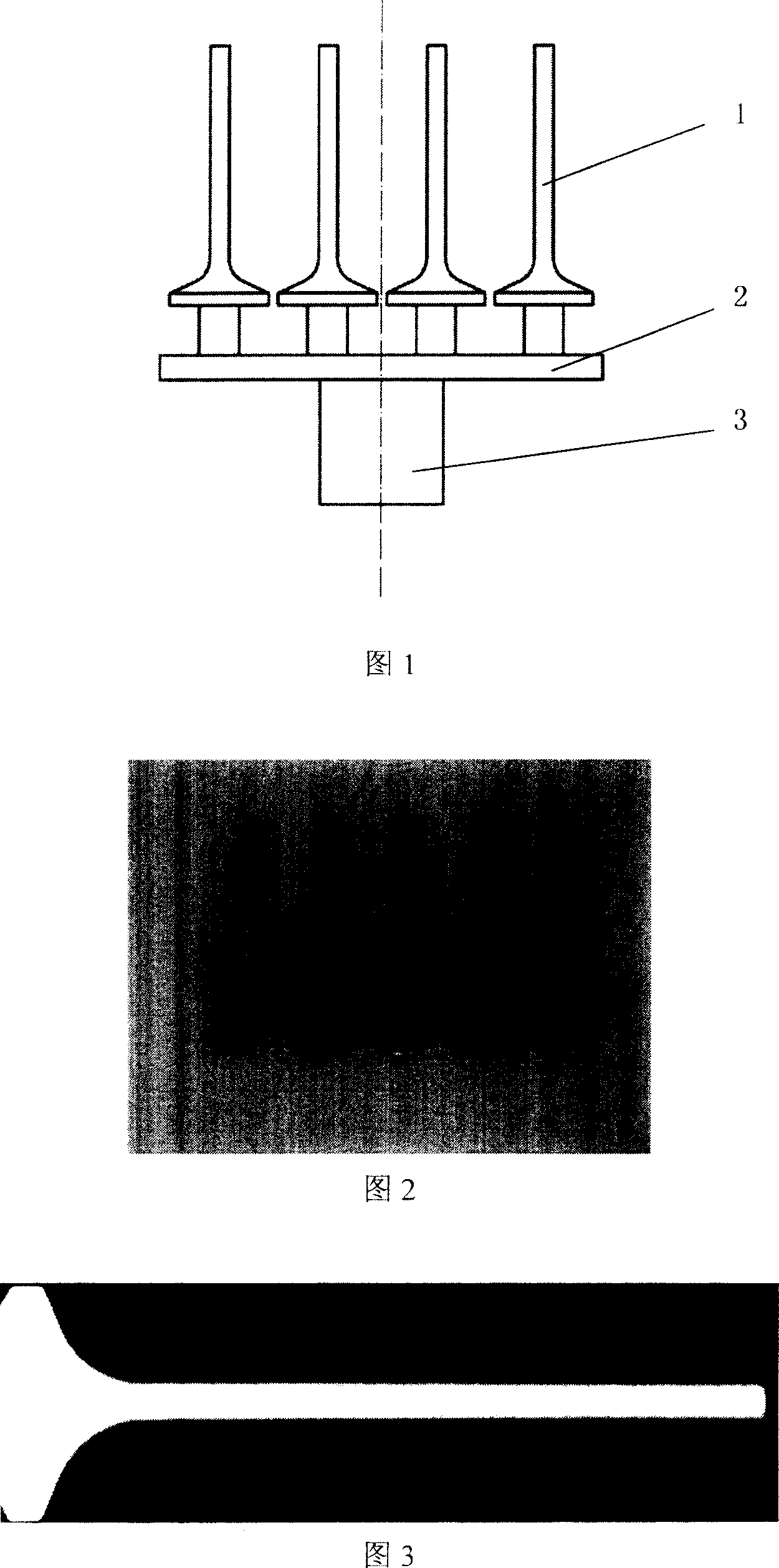

Method for semi-continuously preparing TiAl base alloy automobile air valve and components with similar shape

The present invention relates to preparative technique for automobile air valve and parts of similar shape, specifically speaking, the present invention is a semi-continuous method for preparing TiA1-based alloy automobile air valve and parts of similar shape. The present invention adopts the method of vacuum pouring after semi-continuous induction melting in a vacuum pouring furnace: take the spongy titanium, industrial pure aluminum and other alloy elements as the raw materials and adopt a CaO formed ceramic pot for vacuum induction melting; the cast shell mold consists of part mold shell such as air valve, etc., intermediate flow trays and a vacuum pouring pipe; the intermediate flow trays are evenly distributed in the lengthwise direction of the air valve part; the technique parameters of the vacuum pouring are that the shell mold temperature is between 50 to 800 Celsius degrees and the vacuum pouring pressure difference is2.0 multiplied by 104-7.0 multiplied by 104Pa. The present invention can semi-continuously produce parts which have complicated shapes and are hard to be formed with high-melting point, high-activity Ti A1-based materials and the cost is low; in addition, the produced automobile air valve boasts of excellent internal quality and stable casting performance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

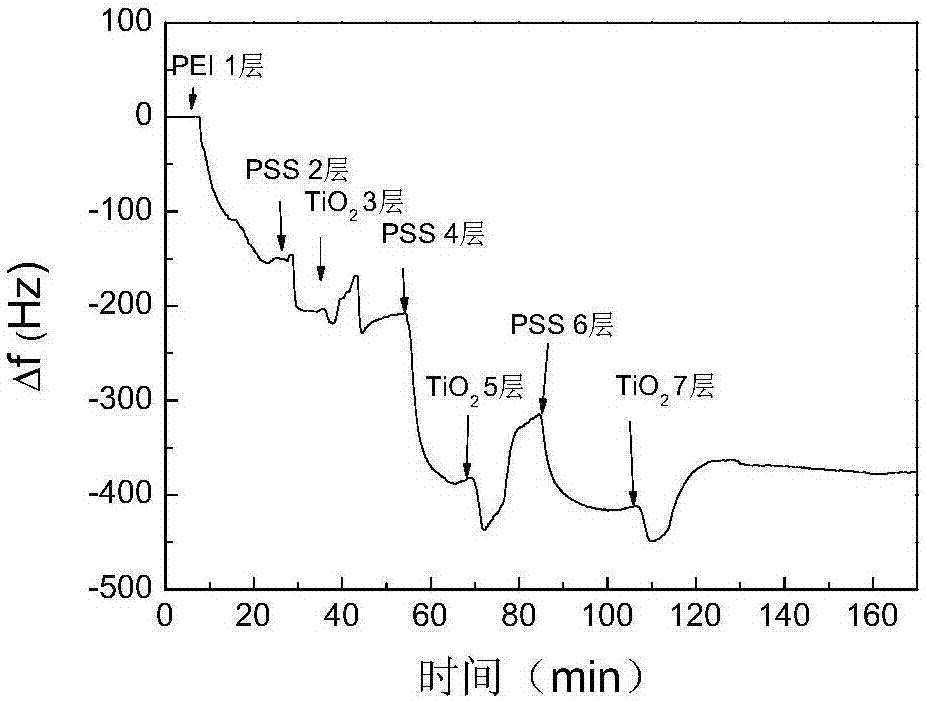

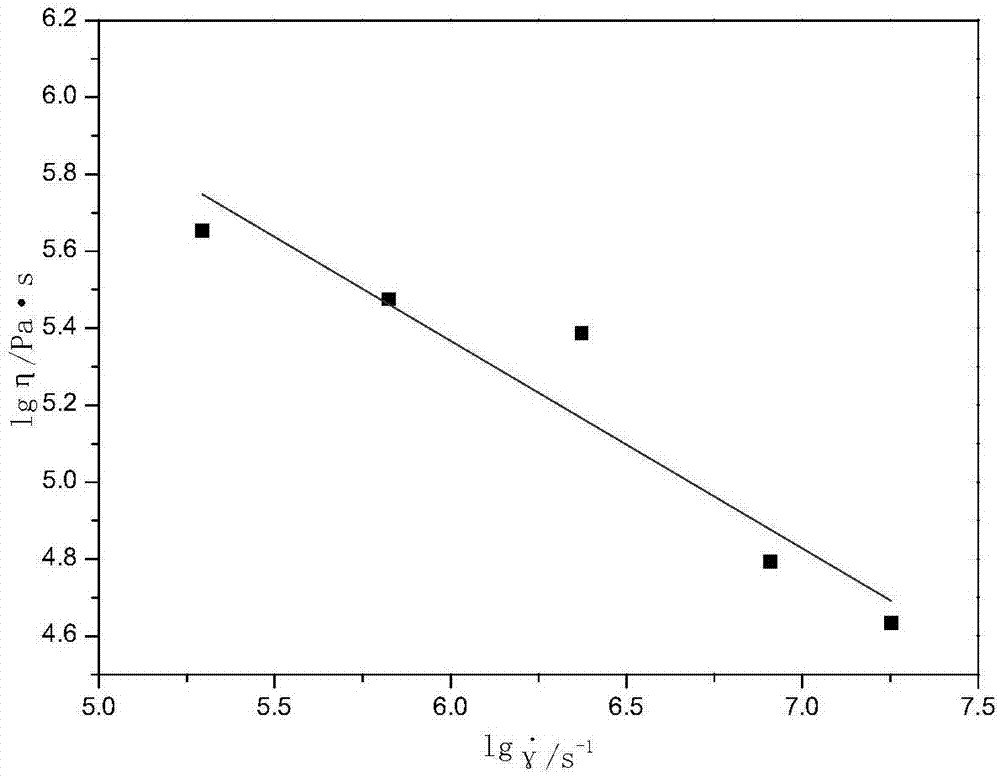

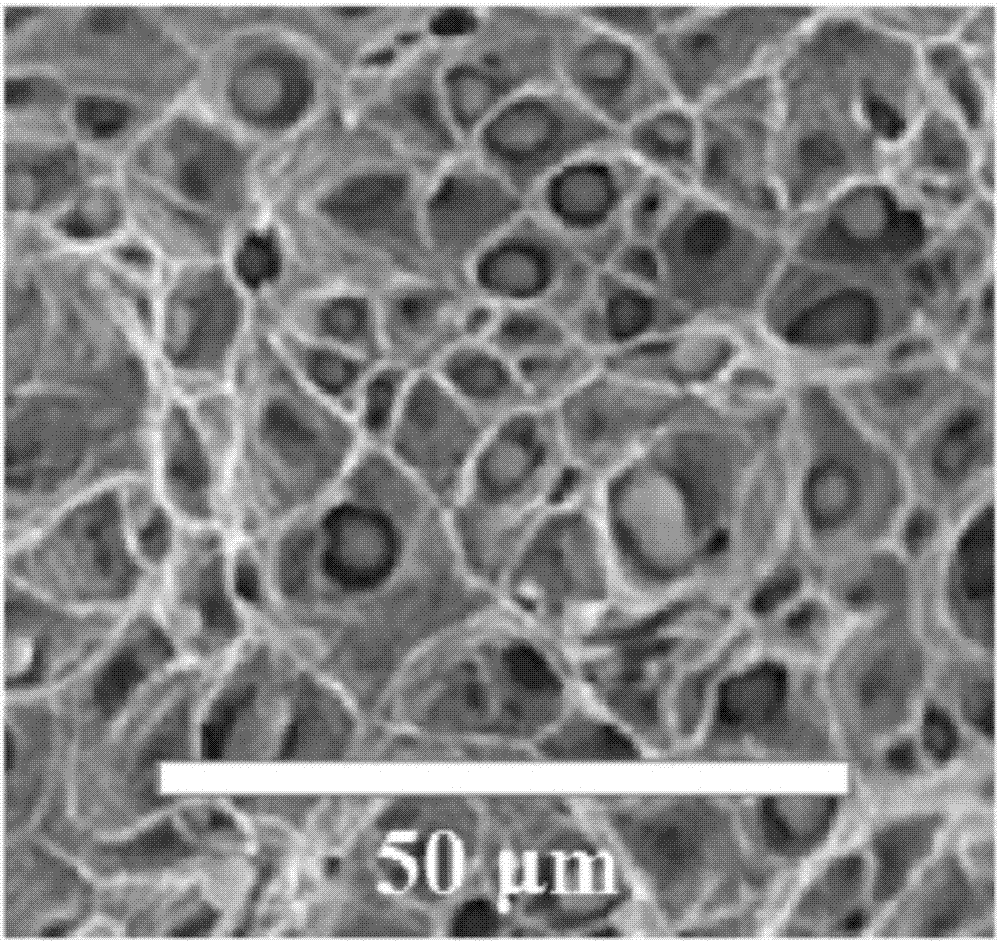

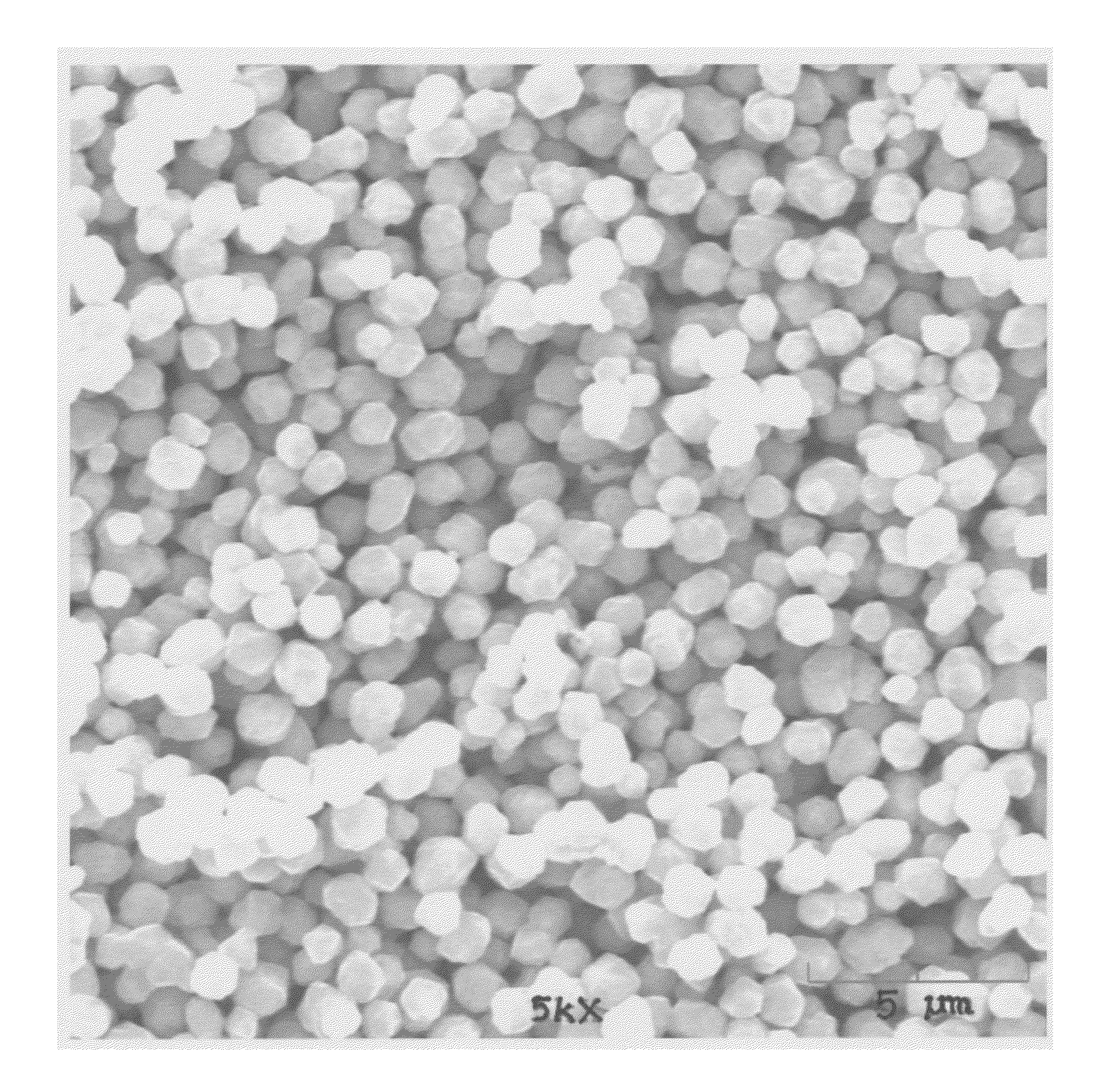

Titanium alloy powder injection molding special material and preparation method thereof

ActiveCN107081424AReduce surface roughnessHelp adsorptionTransportation and packagingMetal-working apparatusPolyelectrolyteTitanium alloy

The invention belongs to the field of polymer binder materials and powder metallurgy, and particularly relates to a titanium alloy powder injection molding special material and a preparation method thereof. Only surface modification of coarse titanium or titanium alloy powder is required, a simple layer-by-layer self-assembling technology is adopted, titanium dioxide particles and a polyelectrolyte are led into the surfaces of existing coarse titanium or titanium alloy powder particles, and accordingly coarse titanium or titanium alloy powder particles of a core-shell structure can be obtained by means of preparation; and then a titanium alloy product which is low in cost, shrinking percentage and sintering density and is of a porous structure can be prepared by mixing with a polymer binder, powder injection molding, catalytic debinding and vacuum sintering.

Owner:CHANGZHOU UNIV

Copper alloy particle synthesis

Owner:ENERGETIC MATERIALS

Magnetic head and method of manufacturing same, head suspension assembly and magnetic disk apparatus

ActiveUS20070163103A1Improve stabilityLess variationElectrical transducersNanomagnetismTectorial membraneMagnetic reluctance

A magnetic head has less variations in the resistance of a magneto-resistive device before and after the magnetic head is left in a high temperature environment so as to have higher stability of the characteristics of the magnetic head against a high temperature environment. A TMR device includes a tunnel barrier layer made of an oxide layer. A DLC film serving as a protection film and an underlying layer therefor are formed on an end face of the TMR device on an air bearing surface side. A layer made of an oxide of a metal or an oxide of a semiconductor is formed between the underlying layer and the end face of the tunnel barrier layer on the air bearing surface side to be in contact with the end face of the tunnel barrier layer.

Owner:TDK CORPARATION

Pyrolysis methods and ovens therefor

InactiveUS8246757B2Less oxygenDisassociating organic materialsMechanical conveying coke ovensDirect heating destructive distillationSufficient timeWater vapor

Pyrolysis methods for disassociating an organic mass, or coating from an article, by placing the article in an air tight processing chamber, circulating a gaseous mixture of ambient air and at least 40% water vapor from an opening, through the processing chamber and out of an exhaust port, and maintaining the processing chamber at a temperature above 650 degrees Fahrenheit for a sufficient time to disassociate the organic material. A batch oven and a continuous processing oven including entrance and exit air closures that utilize the pyrolysis methods are described.

Owner:NOWACK WILLIAM C

Process of forming a photoactive layer of an optoelectronic device

ActiveUS10157710B2Improve uniformityPromote conversionLight-sensitive devicesSolid-state devicesMetal coatingOptoelectronics

A process of forming a thin film photoactive layer of an optoelectronic device comprising: providing a substrate having a surface comprising or coated with a metal M selected from at least one of Pb, Sn, Ge, Si, Ti, Bi, or In; and converting the metal surface or metal coating of the substrate to a perovskite layer.

Owner:COMMONWEALTH SCI & IND RES ORG

Method for preparing low nickel content ternary TiNiHf shape memory alloy sheet material

The invention relates to a technology for preparing a TiNi-based shape memory alloy sheet, in particular to a method for preparing a low-nickel binary TiNi and ternary TiNiHf shape memory alloy sheet.The technology takes titanium sponge, electrolytic nickel and a hafnium sheet as raw materials, and adopts a ceramic crucible which is formed by CaO to carry out vacuum induction melting, and the power frequency for melting is controlled to between 2,000 and 5,000 Hz and the superheat degree of an alloy liquid is controlled to between 50 and 180 DEG C under the condition of casting; static liquidforging press is adopted for modification of cast ingot tissues; forged ingots are slivered along the vertical direction from the intermediate part, and forged cracks caused by secondary hole shrinkage are completely eliminated; the forged ingots after elimination of the surface defects are forged at a temperature of between 840 and 900 DEG C; and unilateral rolling is adopted. The technology cangreatly improve the finished product rate of the low-nickel binary TiNi and ternary TiNiHf shape memory alloy sheet; and the alloy sheet prepared has superior internal quality, mechanical property and stable phase transition temperature.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

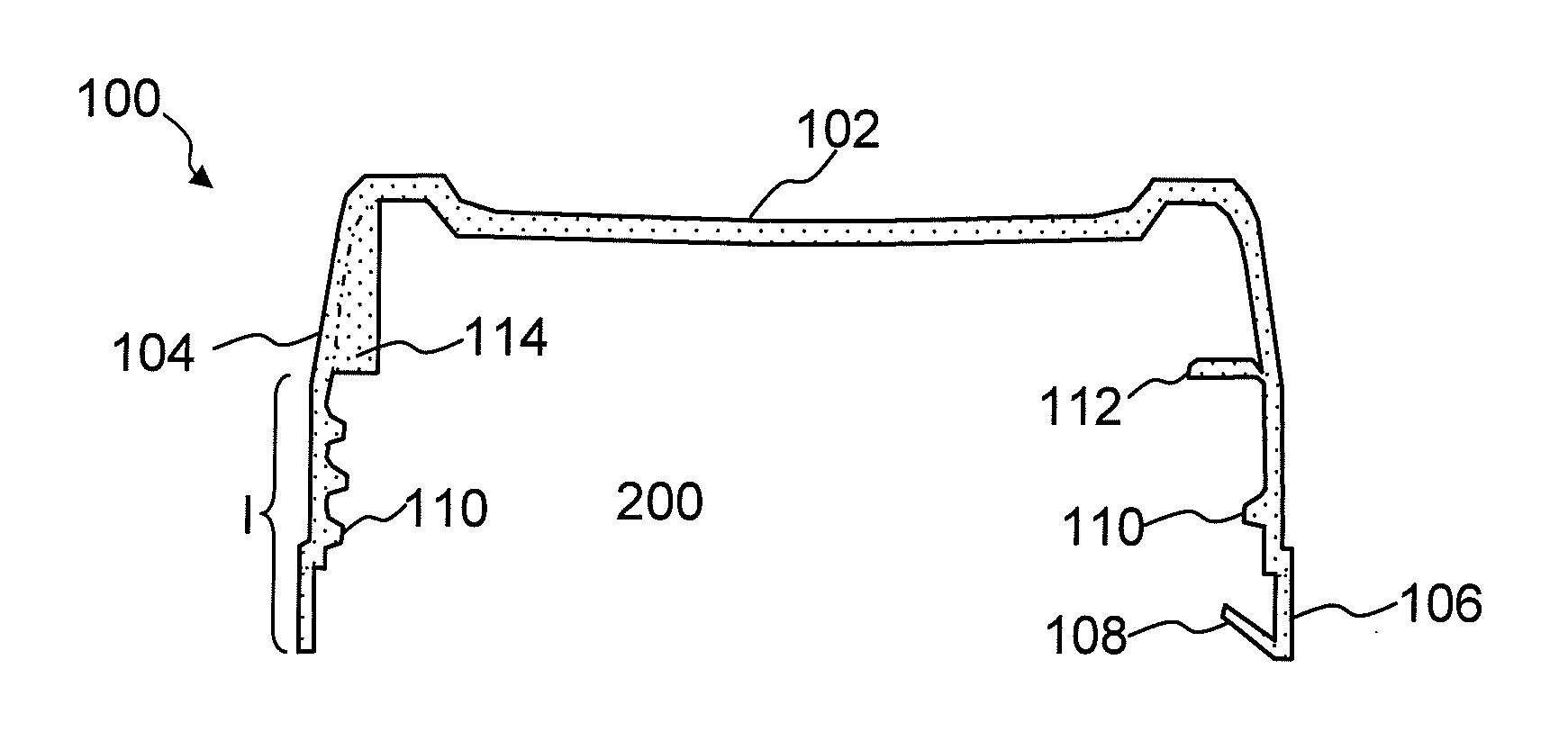

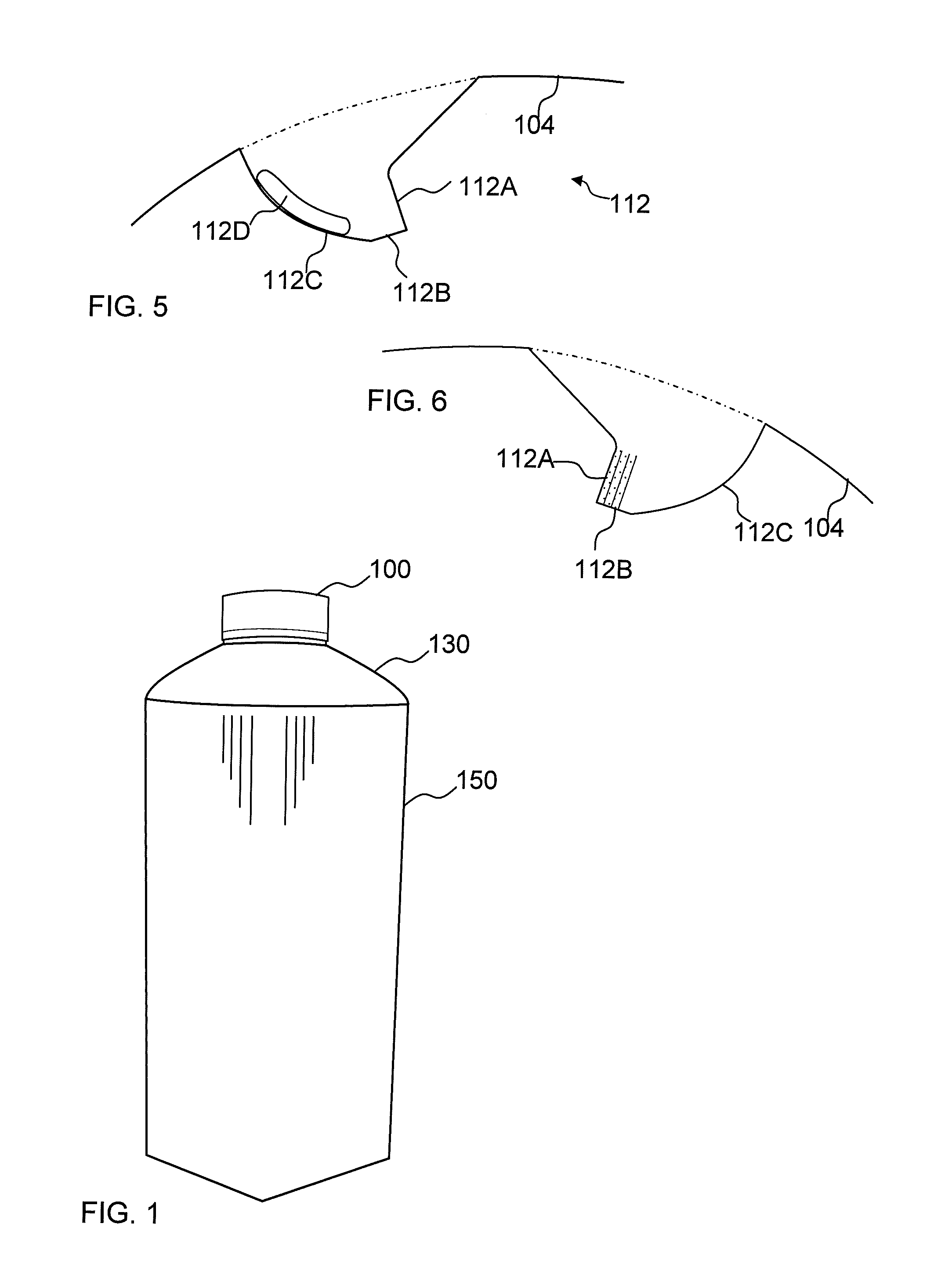

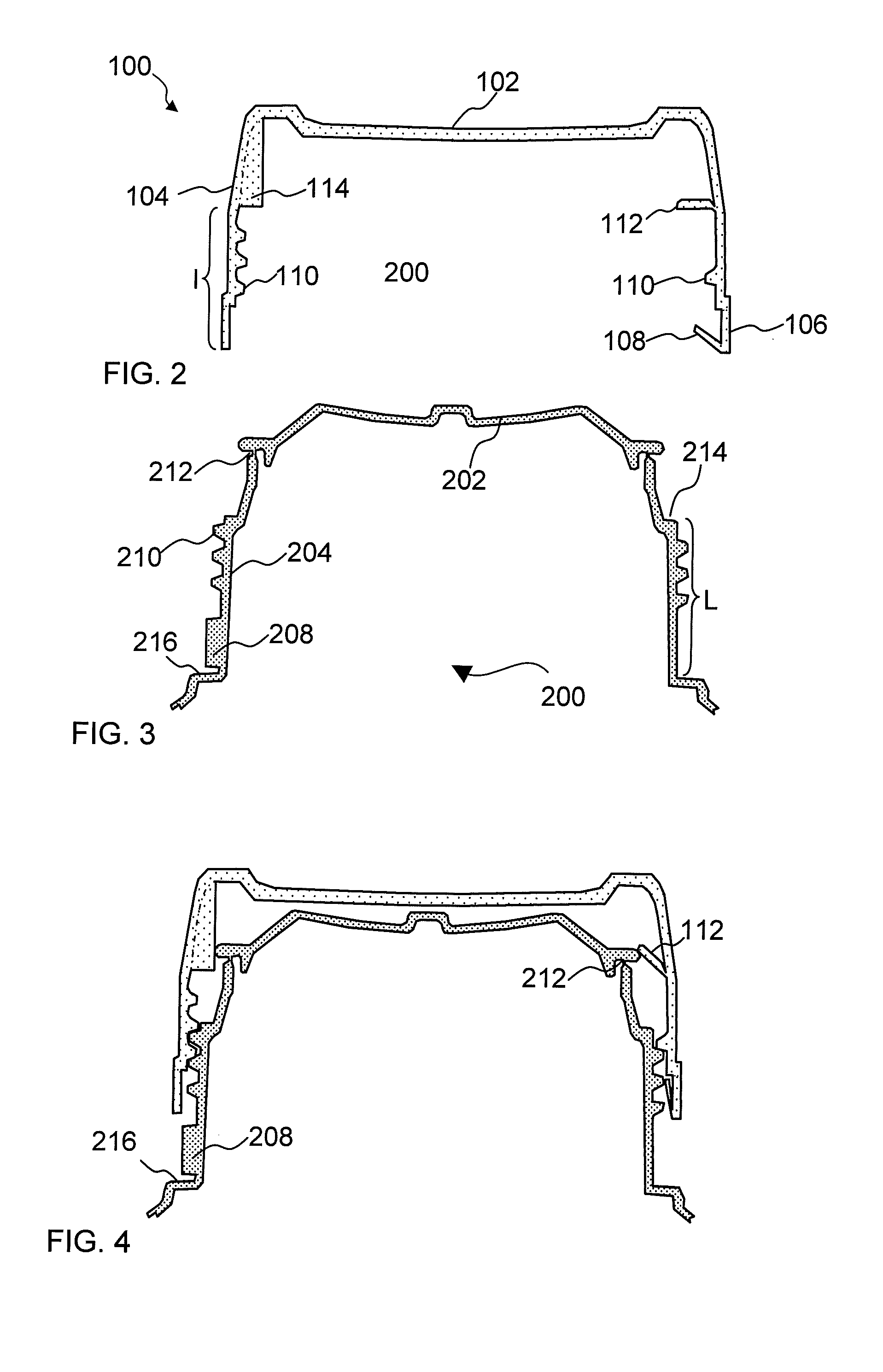

A cap with a cutting element

InactiveUS20160152386A1Facilitates initial arrangementSufficient operationCapsDecorative coversEngineeringMechanical engineering

A cap arranged to interact with a spout has a top portion, a sidewall portion depending from the top portion and formed in one piece therewith. The sidewall portion has an interior threading arranged to interact with exterior threading of the neck during an opening operation and during a closing operation. The cap further has a tamper evidence, which is removably attached to the sidewall portion having cutting elements with a first end hingedly attached to the sidewall portion and a free end portion arranged to interact with a membrane portion of the spout. The hinged attachment allows for the cutting element to pivot in an axial direction. Further, the free end portion has a blunt tip and a comparatively sharper cutting edge on a lateral side of the free end portion.

Owner:TETRA LAVAL HLDG & FINANCE SA

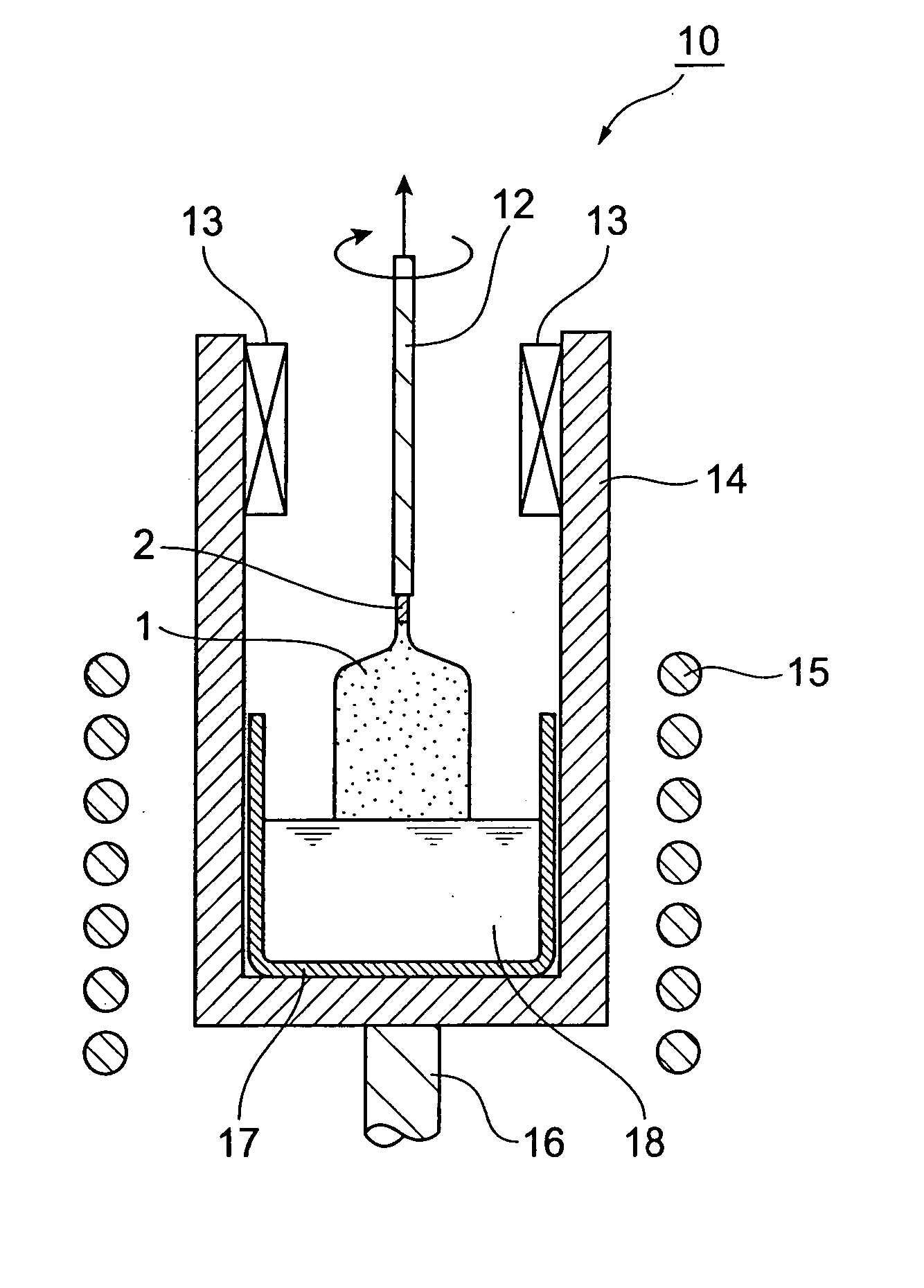

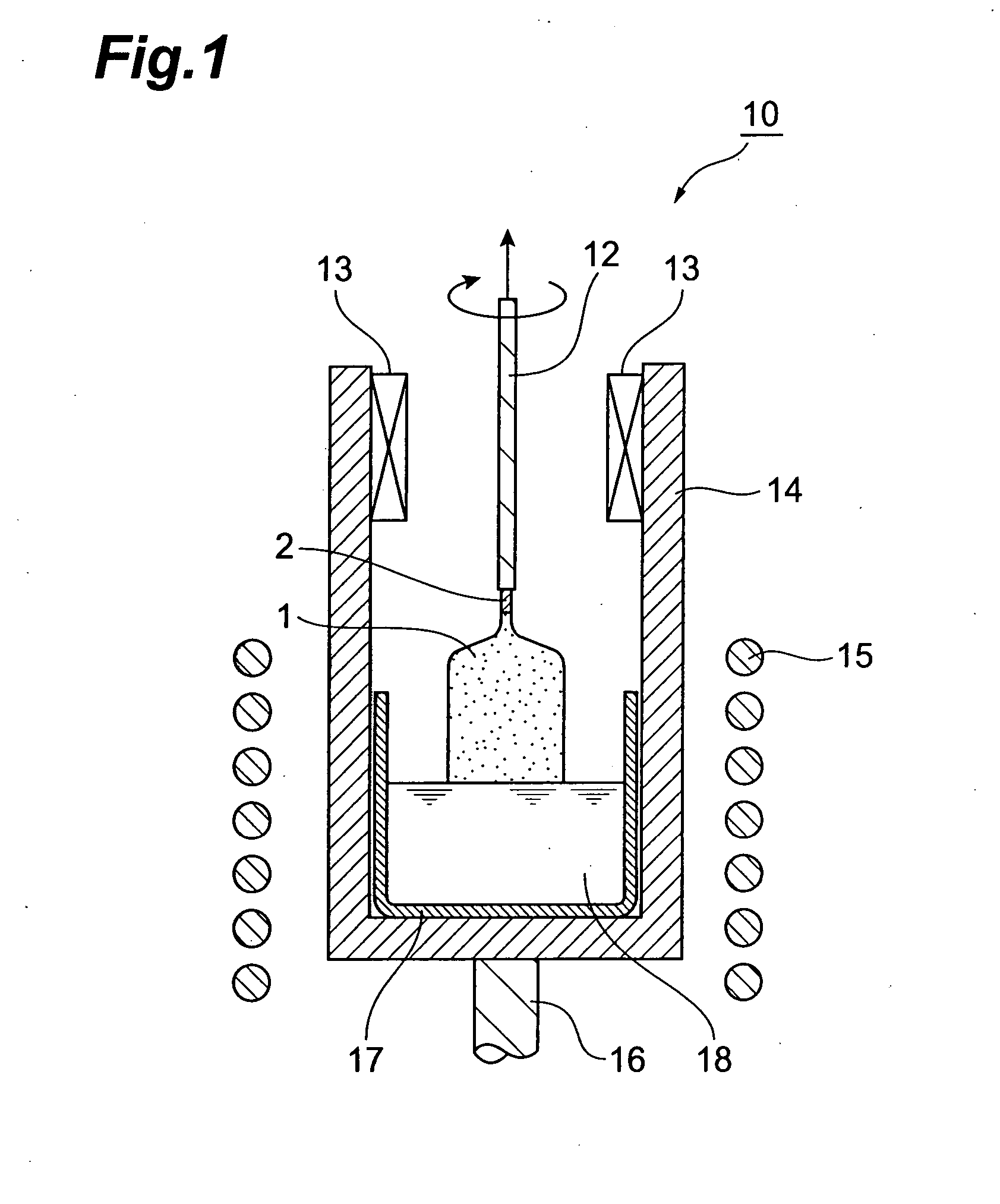

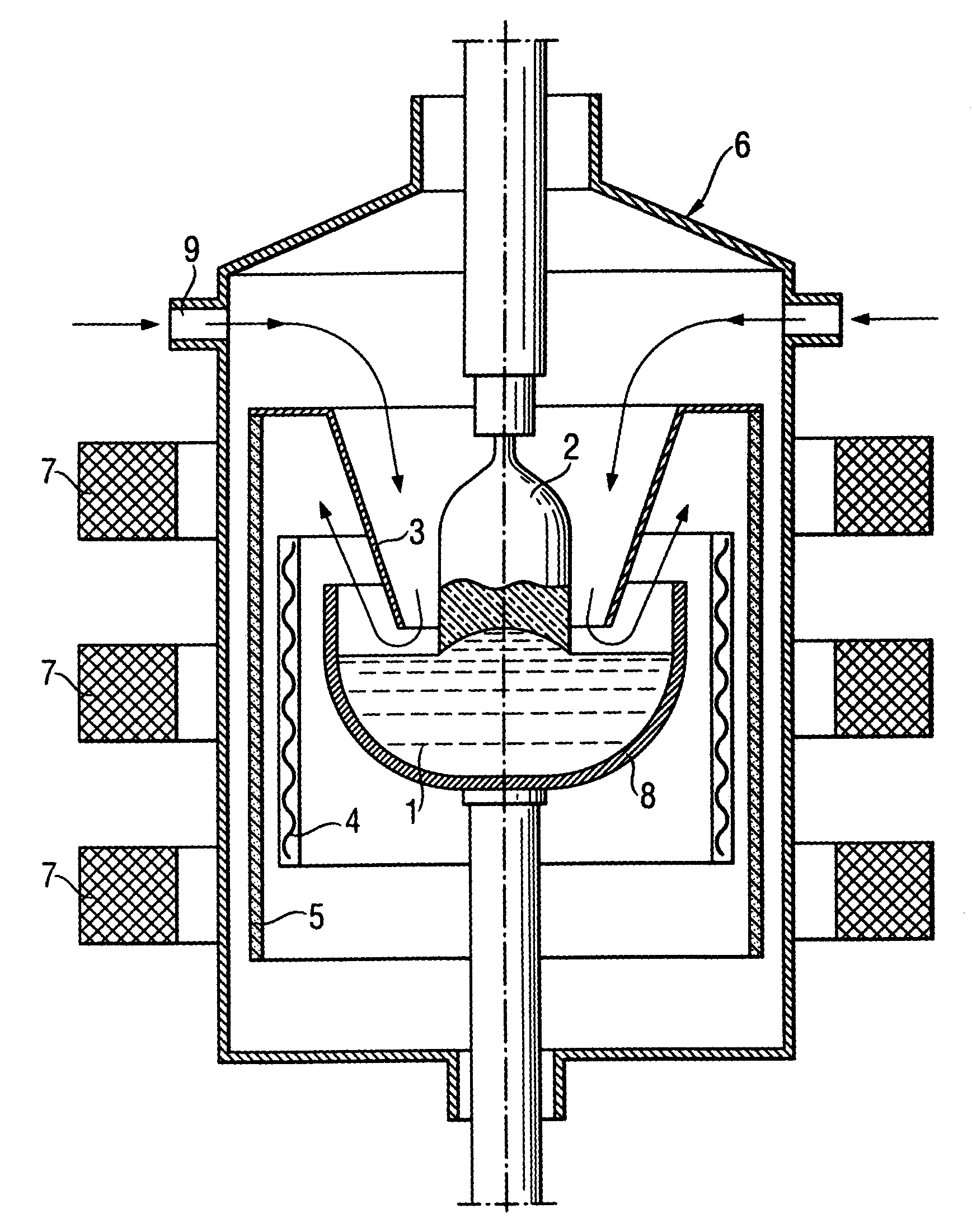

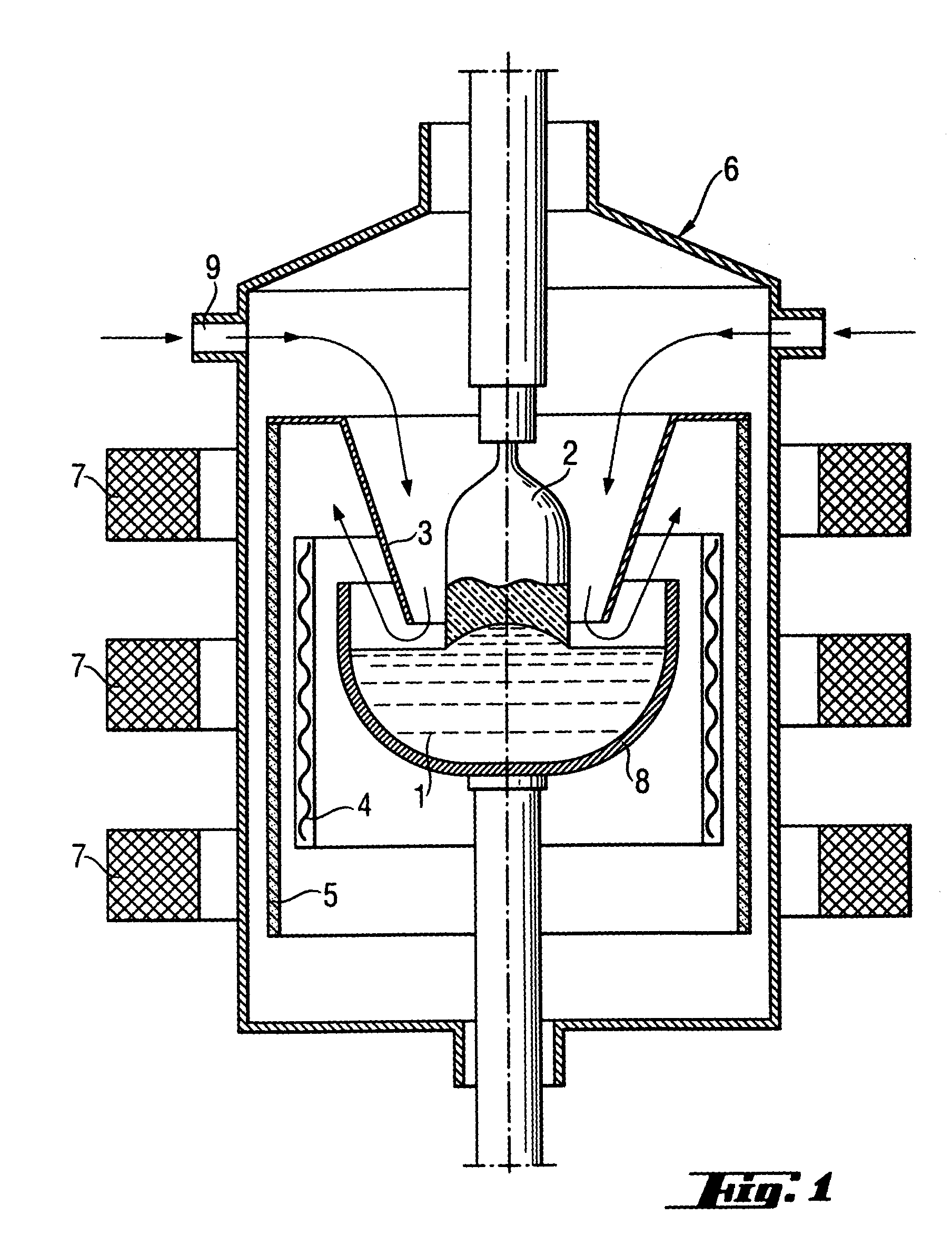

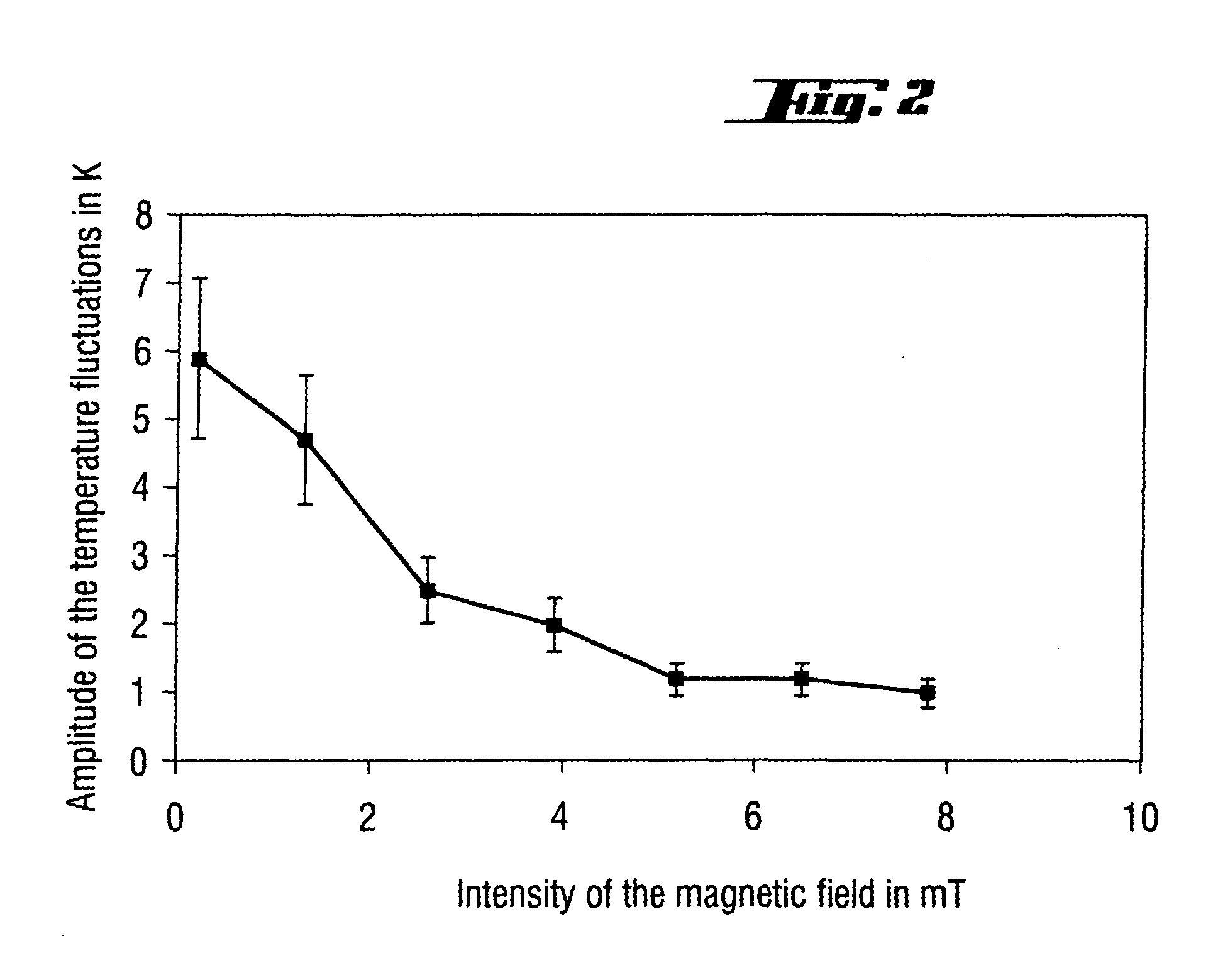

Process and apparatus for producing a silicon single crystal

InactiveUS7771530B2Increase productionIncrease ratingsPolycrystalline material growthBy pulling from meltCrucibleSingle crystal

A process for producing a silicon single crystal is by pulling the single crystal from a silicon melt which is contained in a crucible with a diameter of at least 450 mm, above which a heat shield is arranged. The single crystal being pulled has a diameter of at least 200 mm. The silicon melt is exposed to the influence of a traveling magnetic field which exerts a substantially vertically oriented force on the melt in the region of the crucible wall. There is also an apparatus which is suitable for carrying out the process.

Owner:SILTRONIC AG

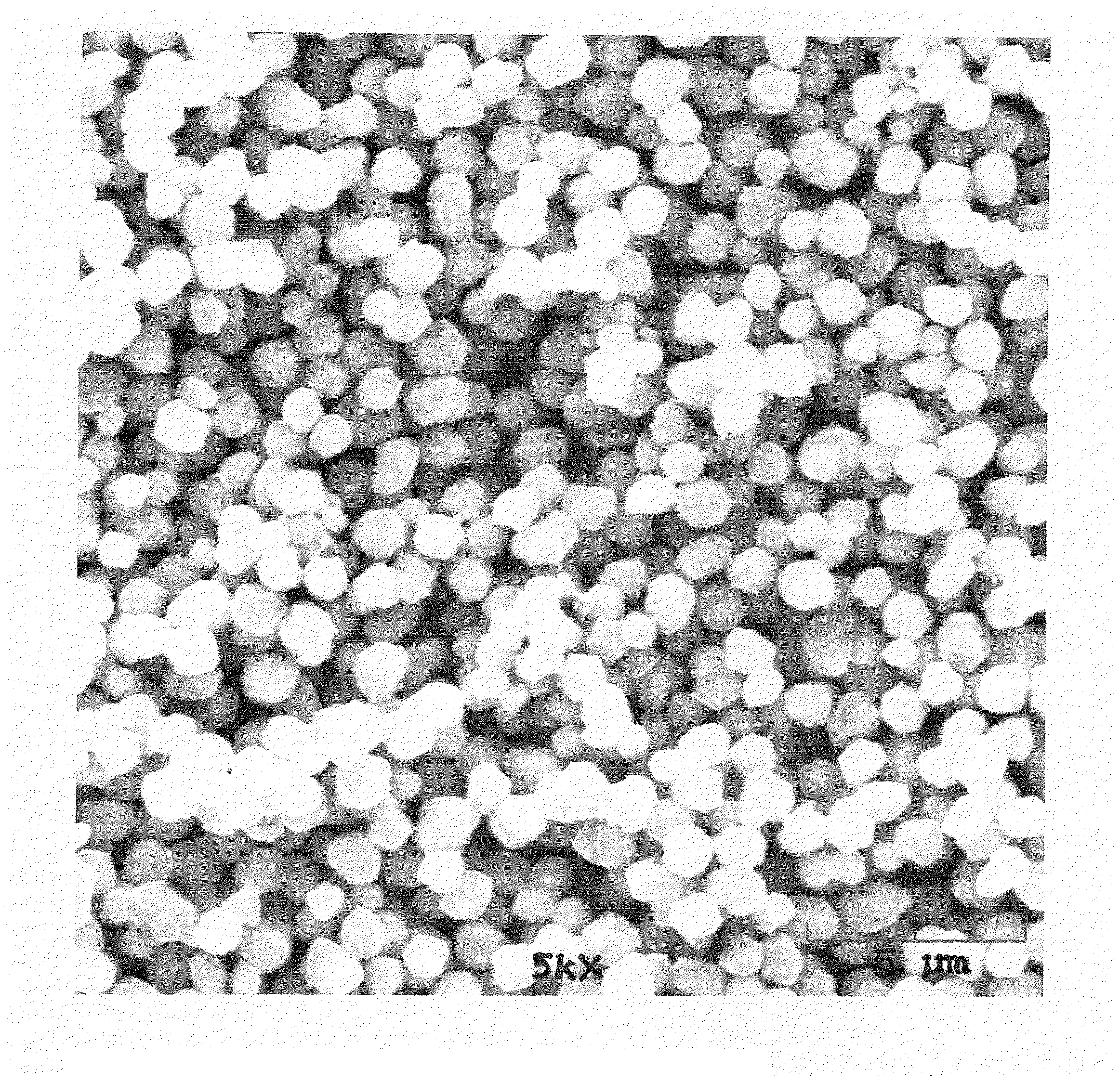

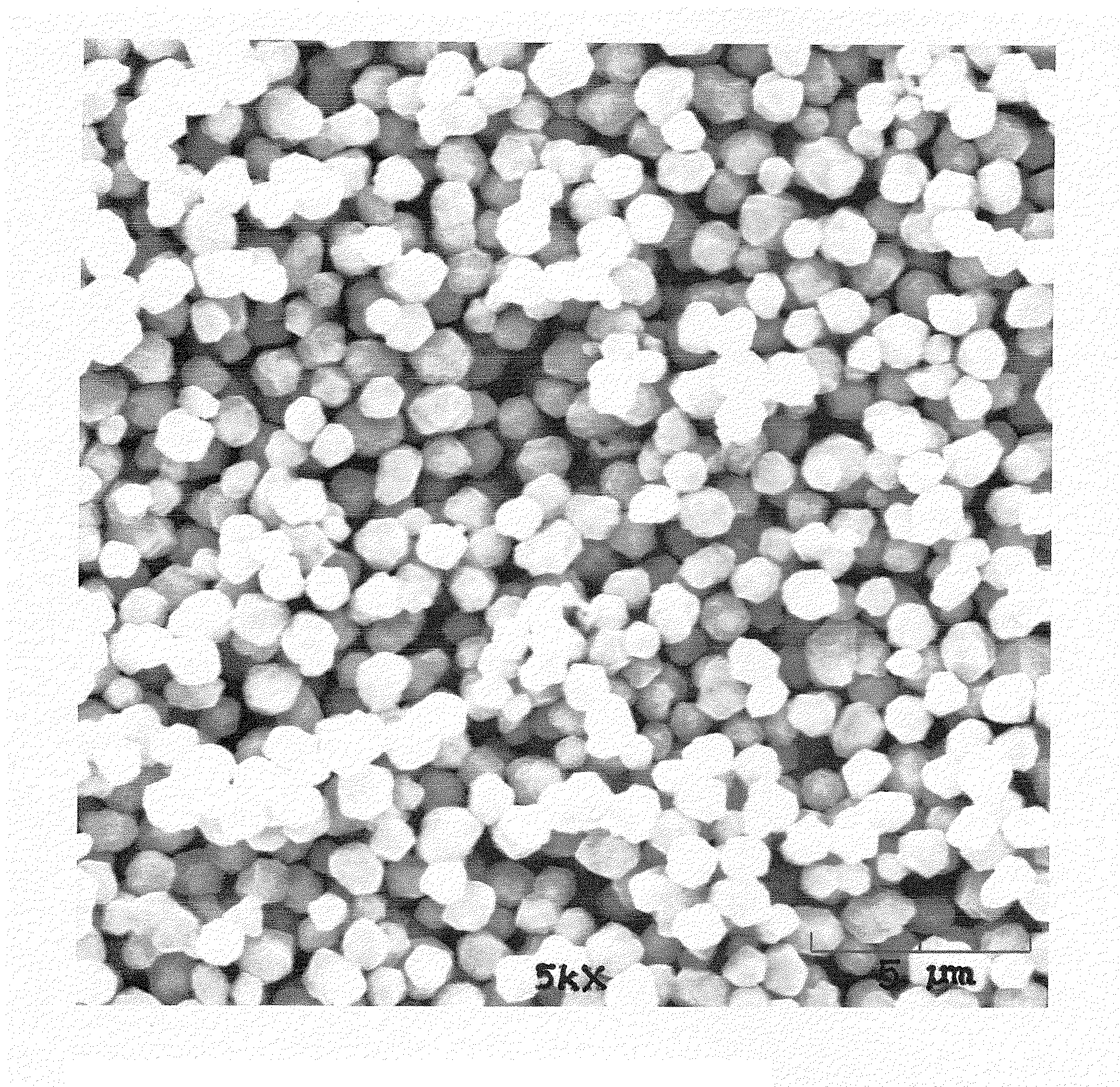

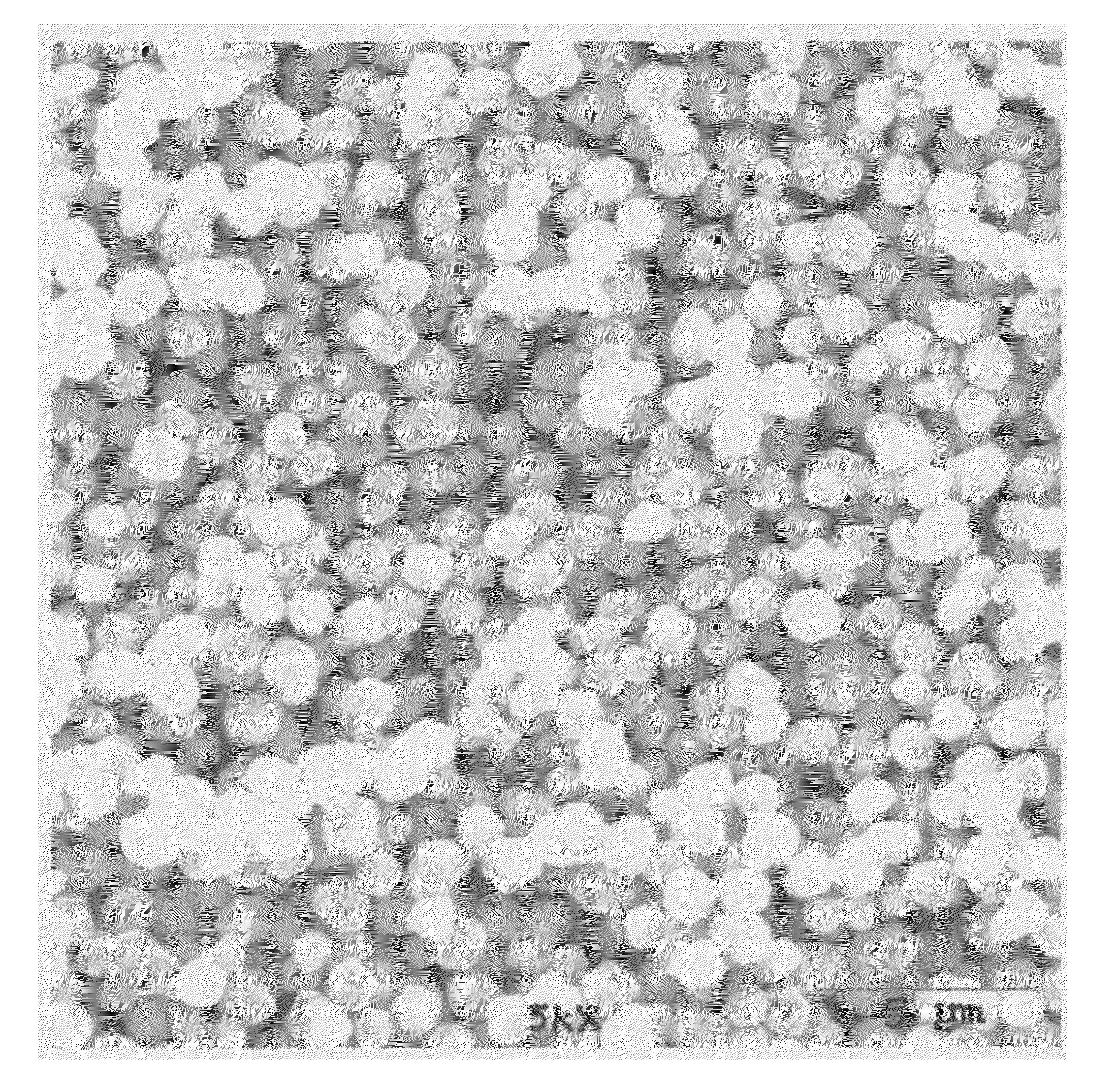

Copper alloy particle synthesis

InactiveUS8313551B1Tighter particle size distributionSmall particle size distribution rangeNickelZinc

The present invention provides a novel process for synthesis of a copper-alloy particle with improved grain boundary properties. The process comprises the steps of: forming a solution from an alcoholic agent and a branched dispersing agent; forming a reaction mixture with the solution and a copper precursor and optionally a nickel precursor; heating the reaction mixture; cooling the reaction mixture; adding an additional amount of copper precursor and at least one precursor selected from the group consisting of: nickel, zinc, and bismuth; heating the reaction mixture; and maintaining the reaction mixture for a time sufficient to reduce the reaction mixture to copper-alloy particles.

Owner:ENERGETIC MATERIALS

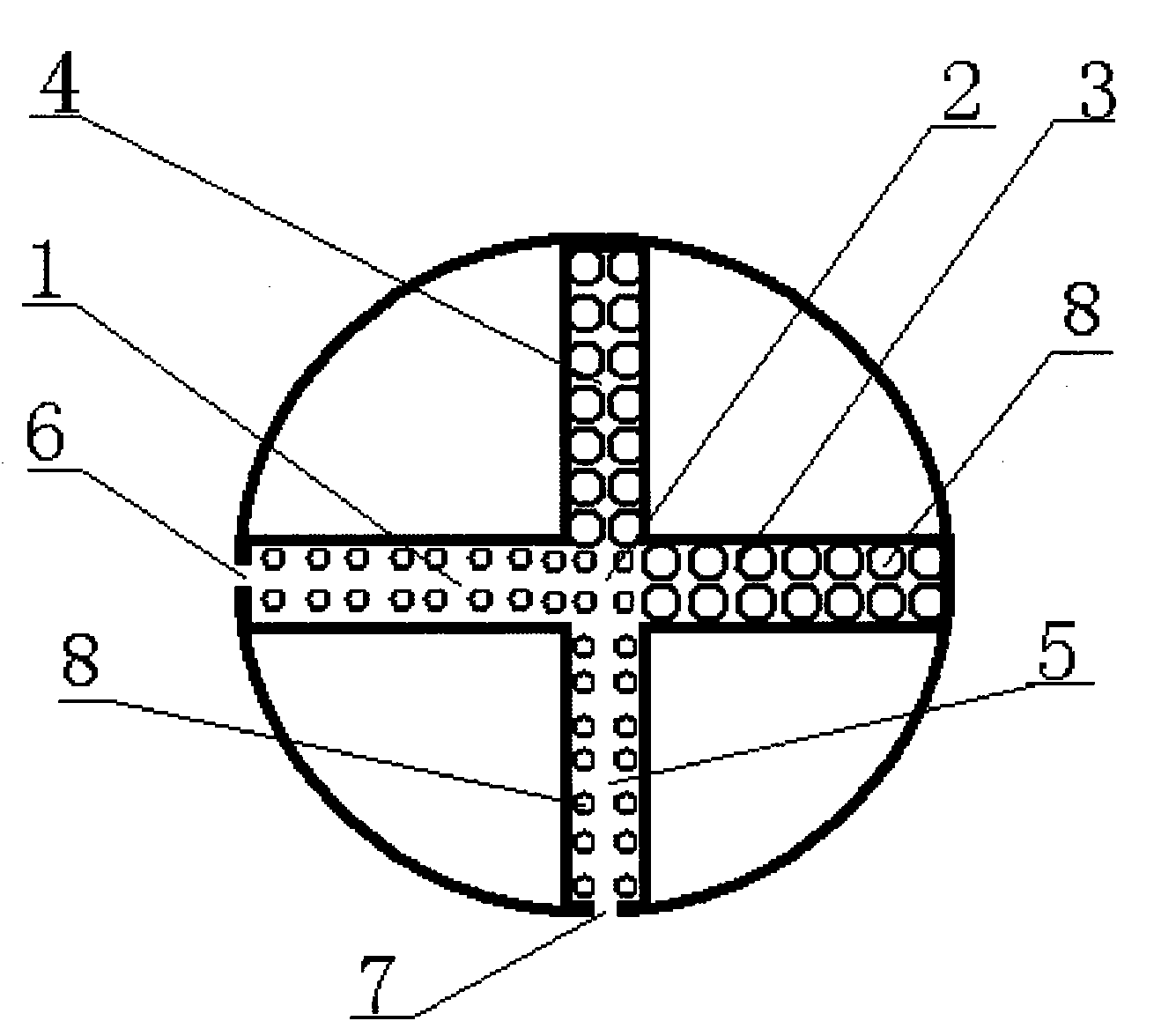

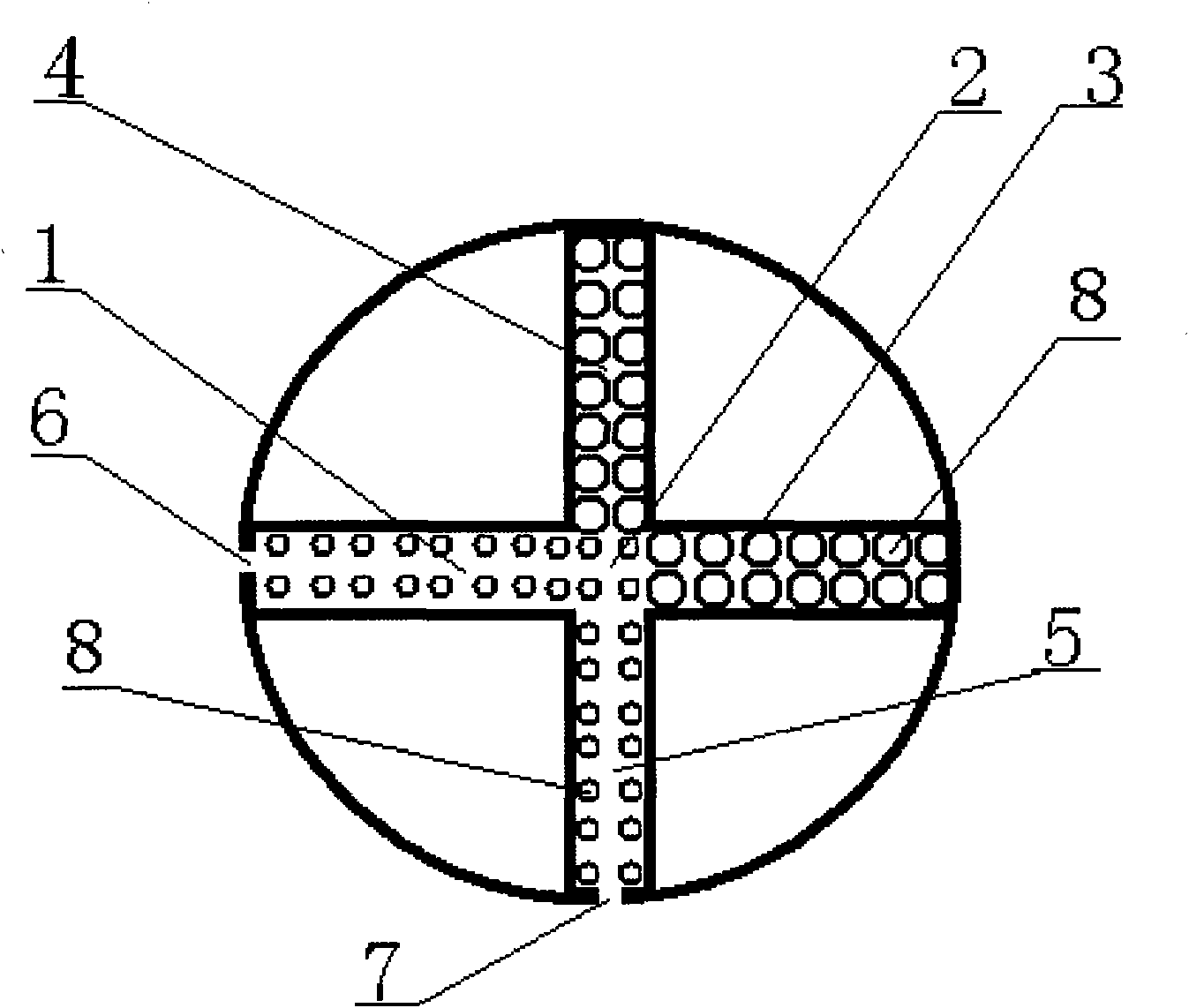

Oxygen replenishment plate of straw gasification furnace

The invention relates to an oxygen replenishment plate of a straw gasification furnace. The layout of the oxygen replenishment plate is hollow cross, the oxygen replenishment plate is divided into five combustion zones of a left zone, a middle zone, a right zone, an upper zone and a lower zone, and the size of oxygen replenishment holes are determined according to wind speed, thereby achieving the purpose of uniform oxygen supply and further avoiding the phenomena of burning out and partial burning.

Owner:陈荣均

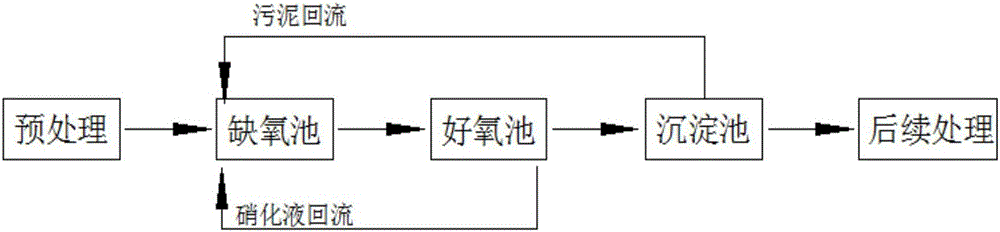

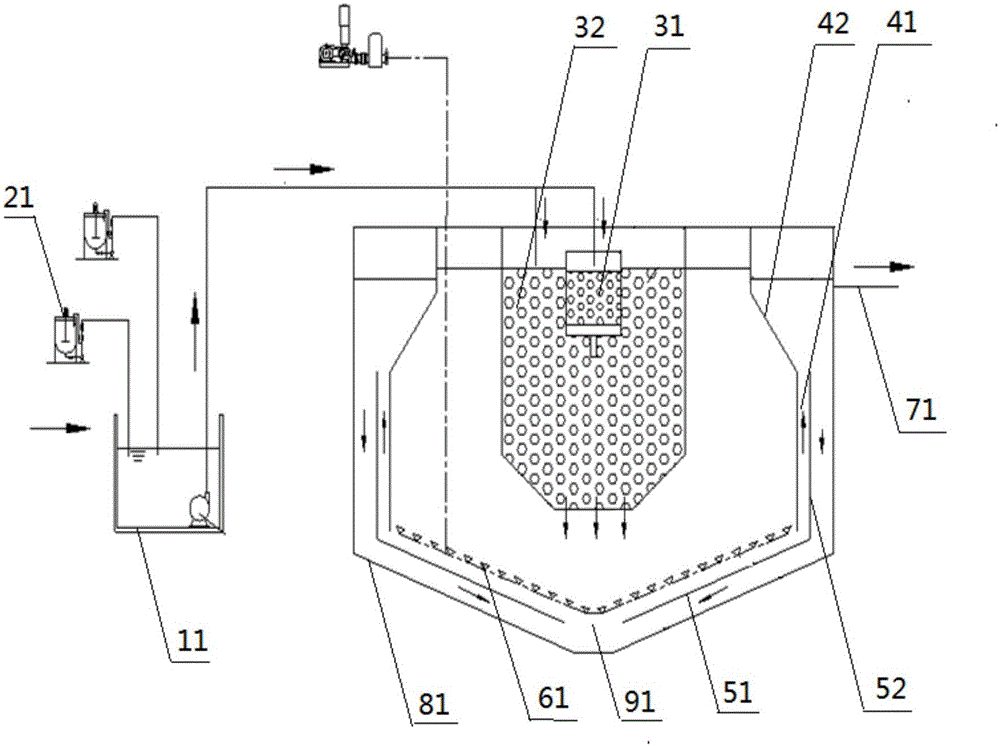

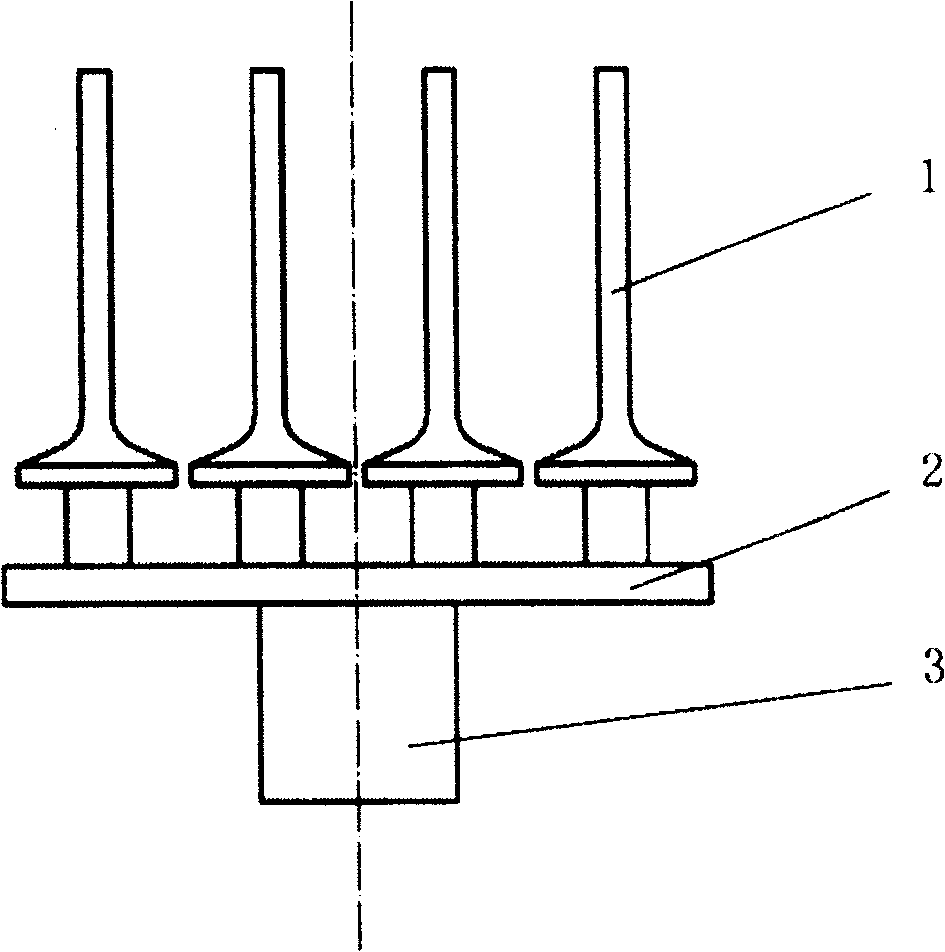

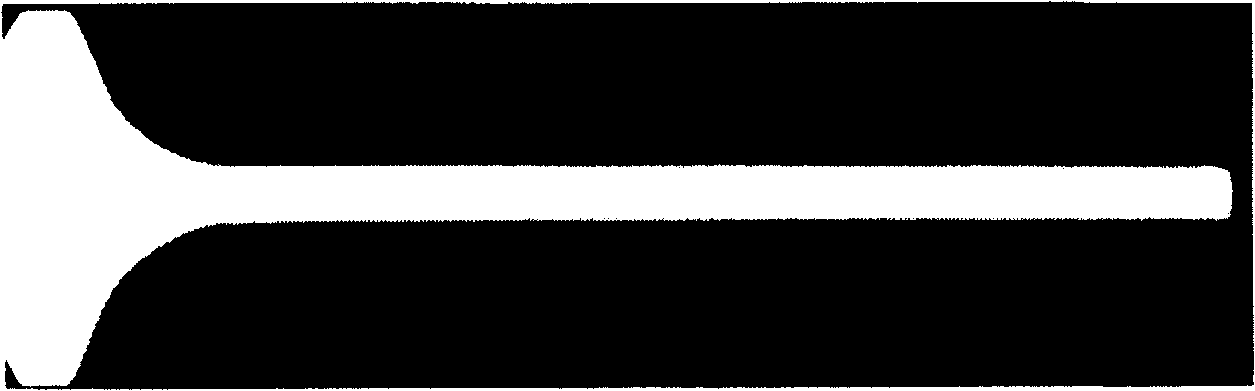

Treatment device and method for high ammonia-nitrogen wastewater

PendingCN106587351ASimple processReduce processing costsWater contaminantsBiological treatment apparatusSewageAmmonia nitrogen

The invention provides a treatment device and method for high ammonia-nitrogen wastewater. The treatment device comprises an adjustment pool, chemical feeding units, a tank, a first container, a second container, a first separating piece, a second separating piece and an aeration module, wherein the chemical feeding units are used for adjusting the PH value of the wastewater; an opening is formed in the upper portion of the tank; the first container is arranged in the tank and located in the second container, an opening is formed in the bottom of the first container, and a separating net is arranged in the opening; padding is arranged in the first container; wastewater output by the adjustment pool is sent into the first container; the second container is arranged in the tank, an opening is formed in the bottom of the second container, and a separating net is arranged in the opening; padding is arranged in the second container; wastewater output by the adjustment pool is sent into the second container; the first separating piece and the second separating piece are arranged in the portion, outside the second container, of the tank from top to bottom; the upper portion of the first separating piece is inclined, and the horizontal distance between the first separating piece and the inner wall of the tank is decreased from top to bottom; the top end of the second separating piece is lower than the first separating piece; the second separating piece is provided with an opening; and the aeration module is arranged under the second container. The treatment device and method for the high ammonia-nitrogen wastewater have the advantages of efficient operation, good application prospects and the like.

Owner:FOCUSED PHOTONICS

Method for semi-continuously preparing TiAl base alloy automobile air valve and components with similar shape

The present invention relates to preparative technique for automobile air valve and parts of similar shape, specifically speaking, the present invention is a semi-continuous method for preparing TiA1-based alloy automobile air valve and parts of similar shape. The present invention adopts the method of vacuum pouring after semi-continuous induction melting in a vacuum pouring furnace: take the spongy titanium, industrial pure aluminum and other alloy elements as the raw materials and adopt a CaO formed ceramic pot for vacuum induction melting; the cast shell mold consists of part mold shell such as air valve, etc., intermediate flow trays and a vacuum pouring pipe; the intermediate flow trays are evenly distributed in the lengthwise direction of the air valve part; the technique parameters of the vacuum pouring are that the shell mold temperature is between 50 to 800 Celsius degrees and the vacuum pouring pressure difference is2.0 multiplied by 104-7.0 multiplied by 104Pa. The present invention can semi-continuously produce parts which have complicated shapes and are hard to be formed with high-melting point, high-activity Ti A1-based materials and the cost is low; in addition, the produced automobile air valve boasts of excellent internal quality and stable casting performance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com