Method for semi-continuously preparing TiAl base alloy automobile air valve and components with similar shape

A semi-continuous, alloy-based technology, which is applied in the field of preparation of automobile air valves and parts with similar shapes, can solve the problems of high smelting cost, difficulty in forming automobile air valves, difficult alloy liquid and high casting superheat, and improve production efficiency , prevent oxygenation, control the effect of interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

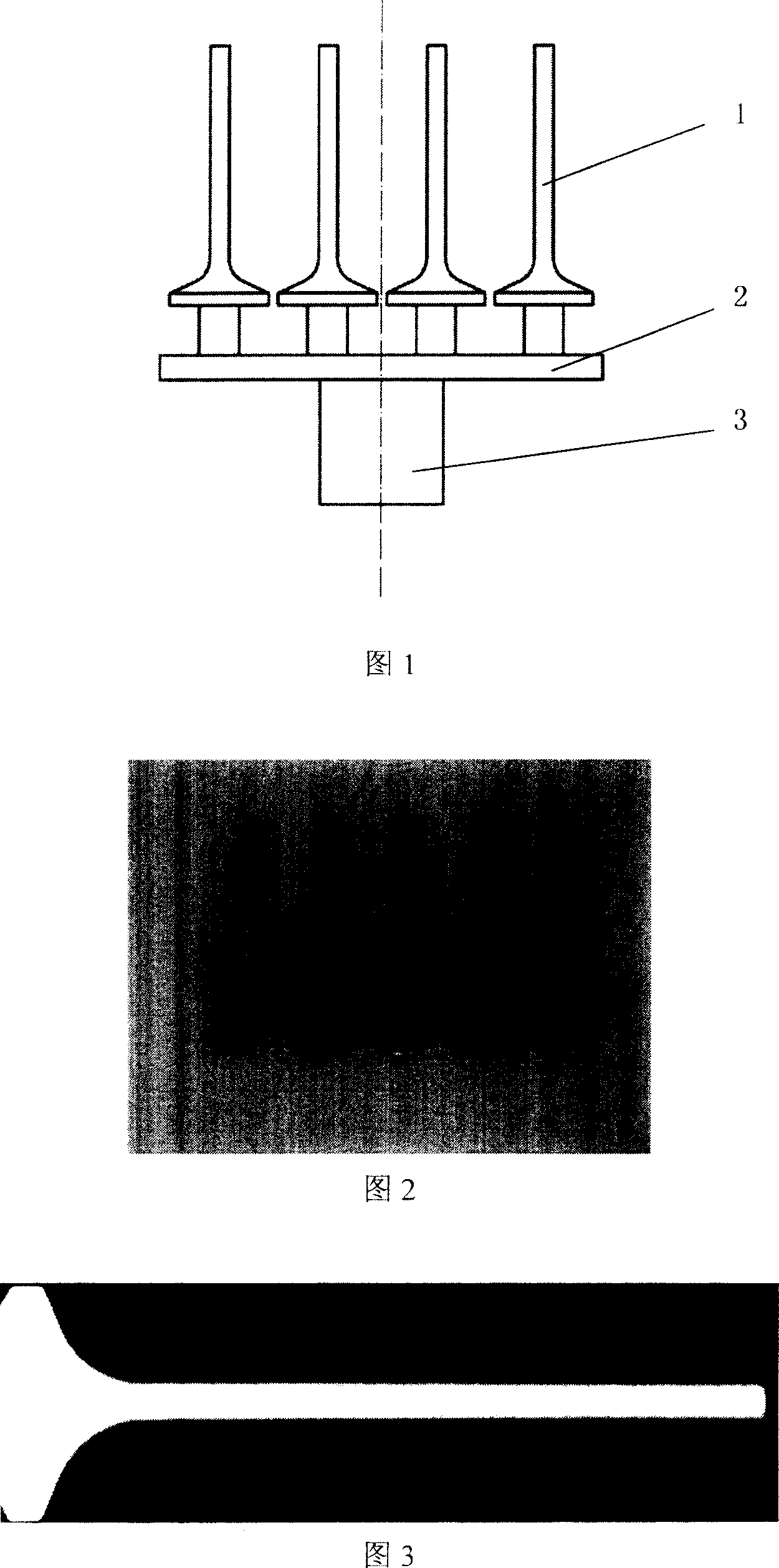

[0027] The semi-continuous suction casting of titanium-aluminum-based alloy automobile valves and parts of similar shapes adopts the method shown in Figure 1. Of course, it is not limited to this. The TiAlB valve is suction-cast on a 50kg vacuum suction casting furnace. The composition is shown in Table 1. The suction casting process for:

[0028] 1. Raw materials are sponge Ti, industrial pure Al, TiB 2 ;

[0029] 2. Put the above raw materials into a CaO crucible for vacuum induction melting;

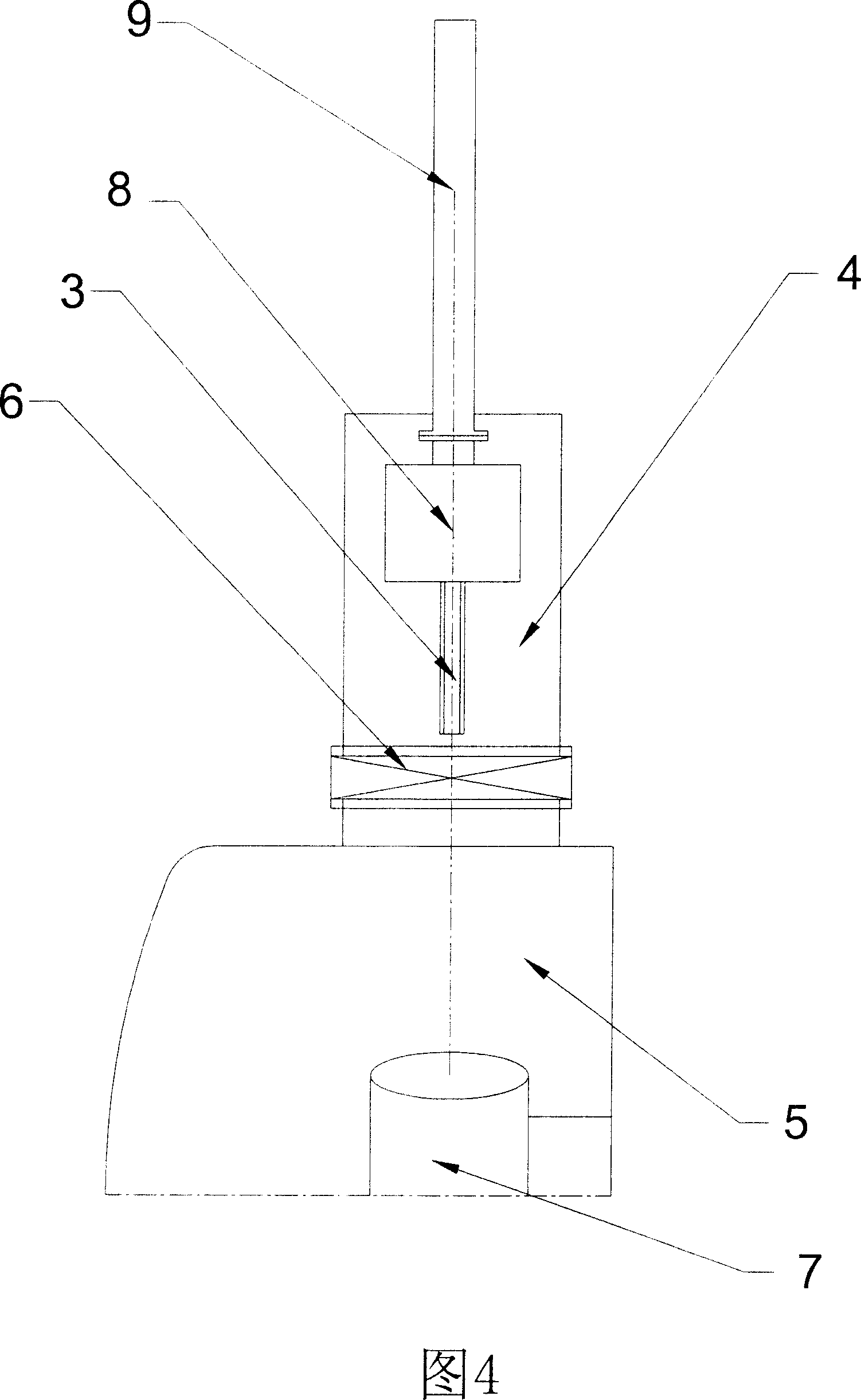

[0030] 3. The casting shell mold is composed of the air valve and other parts mold shell 1, the intermediate flow plate 2 and the suction casting pipe 3. The length direction of the air valve components is evenly distributed perpendicular to the intermediate flow plate; the preheating temperature is 50-800°C (this embodiment (300°C) shell mold is installed in the suction casting chamber, and is connected with the suction casting pipe. The combined furnace vacuumizes the melting cham...

Embodiment 2

[0038] The difference from Example 1 is that the TiAlB gas valve is suction-cast on a 50kg vacuum suction casting furnace, and the composition is shown in Table 2.

[0039] Table 2 Composition of air valve

[0040] the element

[0041] The shell mold with a preheating temperature of 300°C is installed in the suction casting chamber and is connected with the suction casting pipe. The combined furnace evacuates the melting chamber and the suction casting chamber respectively. Introduce 0.6atm argon gas to start melting the alloy. The frequency of the melting power is 3300Hz. After the melting, use infrared and contact thermocouples to measure the temperature. When the superheat reaches 120°C, insert the suction casting tube into the molten metal and turn on The valve starts suction casting. During the suction casting process, the flow control valve is used to adjust the suction casting speed. The pressure difference of vacuum suction casting is 6×10 4 Pa.

Embodiment 3

[0043] The difference from Example 1 is that the TiAlB gas valve is suction-cast on a 50kg vacuum suction casting furnace, and the composition is shown in Table 3.

[0044] Table 3 Composition of air valve

[0045] the element

[0046] The shell mold with a preheating temperature of 500°C is installed in the suction casting chamber and is connected with the suction casting pipe. The combined furnace evacuates the melting chamber and the suction casting chamber respectively. Introduce 0.5atm of argon gas to start melting the alloy. The frequency of the melting power is 3600Hz. After the melting, use infrared and contact thermocouples to measure the temperature. When the superheat reaches 120°C, insert the suction casting tube into the molten metal and open the valve. Start the suction casting. During the suction casting process, adjust the suction casting speed through the flow control valve. The pressure difference of the vacuum suction casting is 5×10 4 Pa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com