Patents

Literature

34results about How to "Avoid oxygenation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat-resisting steel flux-cored wire

InactiveCN101450425ASimple welding processImproved arc stabilityArc welding apparatusWelding/cutting media/materialsFerrochromeRutile

The invention discloses a flux cored wire for heat resistant steel. Flux cored powder of the flux cored wire is formed by mixing the following components by weight percentage: 21 to 23 percent of rutile, 1.5 to 2.5 percent of aedelforsite, 19 to 21 percent of silicon-manganese alloy, 8.5 to 10.5 percent of ferrous powder, 1.5 to 2.5 percent of nickel powder, 2.5 to 3.5 percent of cryolite, 7 to 9 percent of feldspar, 13 to 14 percent of ferrochrome, 6 to 7 percent of ferromolybdenum, 6 to 7 percent of mid-carbon ferromanganese, 2.5 to 4.5 percent of magnesite, 6 to 7.5 percent of quartz, 0.5 to 2 percent of fluorite, 1.5 to 3 percent of aluminum-magnesium alloy and 0.5 to 2 percent of ferrotitanium. During the welding, the flux cored wire not only uses CO2 to protect shielded welding, but also has the advantages of small splash, easy slag removal, stable electric arc burning, and spray transfer as a droplet transfer form.

Owner:NINGBO LONGXING WELDING CUTTING TECH STOCK

Titaniferous stainless steel electroslag remelting casting powder

The invention discloses titaniferous stainless steel electroslag remelting casting powder which is prepared from the raw materials in parts by weight as follows: 46.0-50.0 parts of fluorite, 20.0-24.0 parts of alumina powder, 18.5-22.5 parts of lime, 3.5-5.5 parts of fused magnesite, 2.0-4.0 parts of titanium dioxide as well as other components: 0.0-0.6 part of SiO2, 18.0-22.0 parts of CaO, 20.0-24.0 parts of Al2O3, 4.2-5.8 parts of MgO, 2.0-4.0 parts of TiO2, 45.0-51.0 parts of CaF2, less than 0.03 part of S and less than 0.03 part of C. Slag is formed by the casting powder according to strict quality control standard so as to ensure that the impurity content is low, the purity is high and the slag is dry and free from moisture. In the electroslag remelting process, desulfuration and deoxygenation effects are enhanced, the resistivity is improved, and the casting powder is free from cutoff in arcing, good in lubrication and relatively easy to popularize and apply.

Owner:HENAN XIBAO METALLURGICAL MATERIALS GROUP

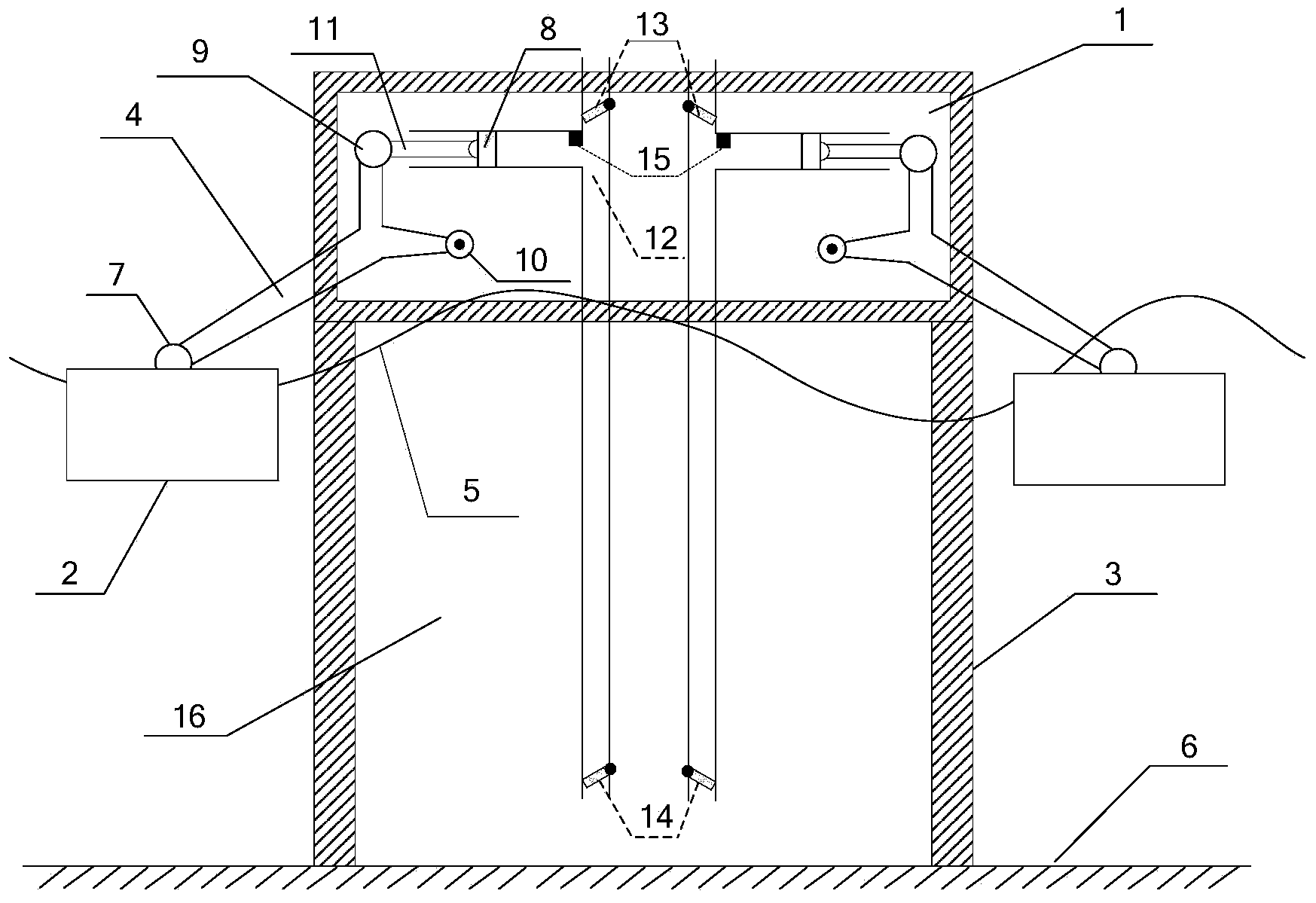

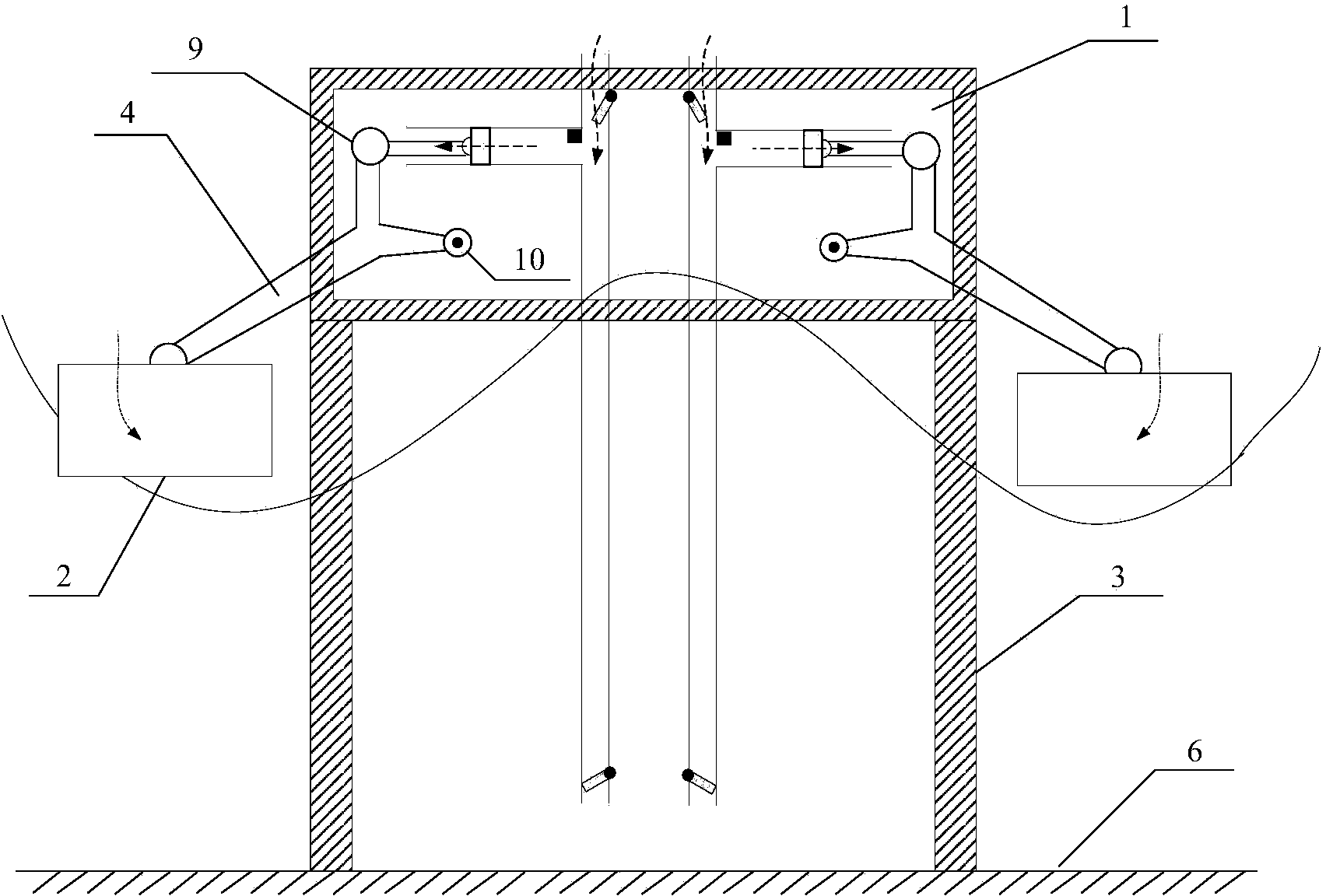

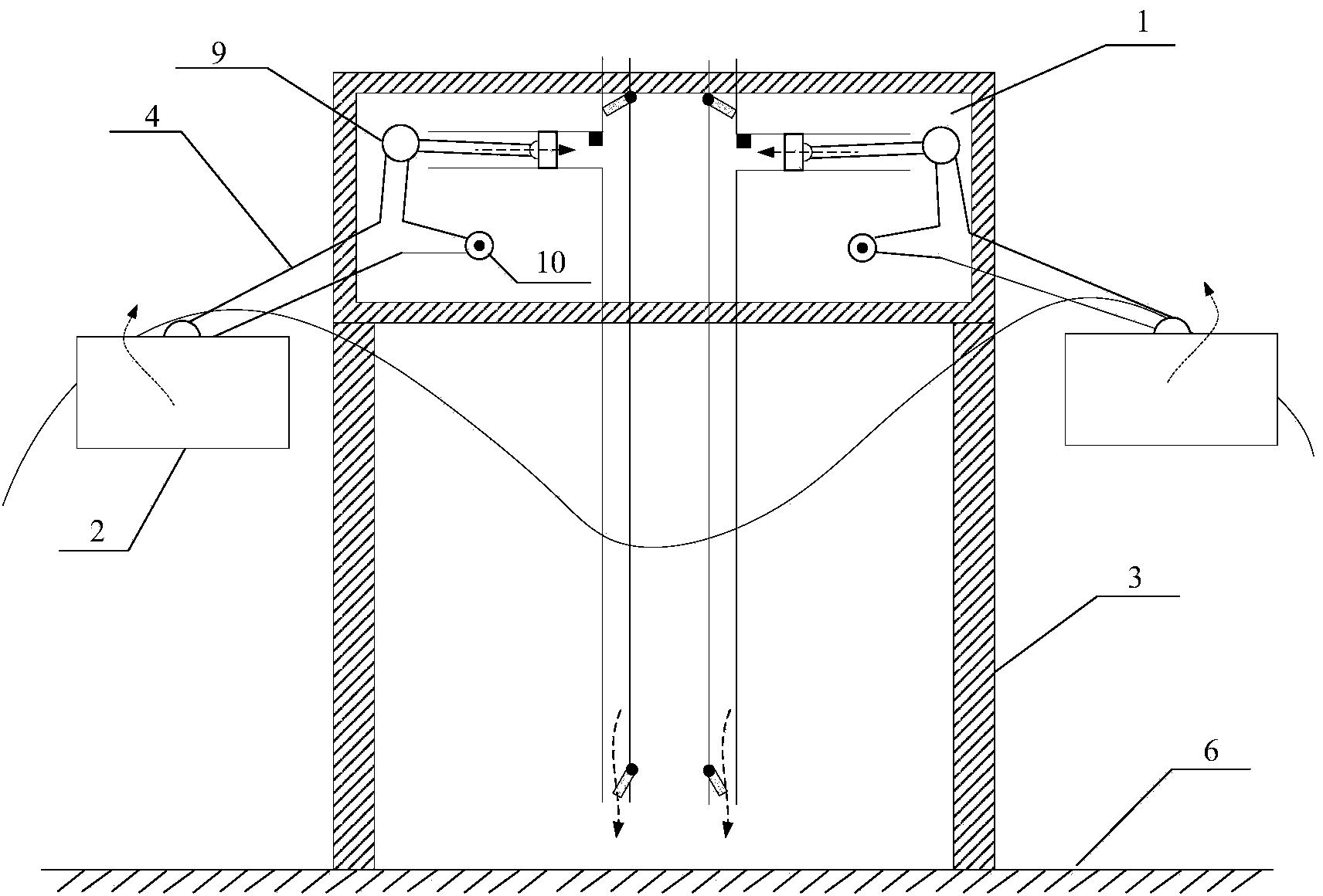

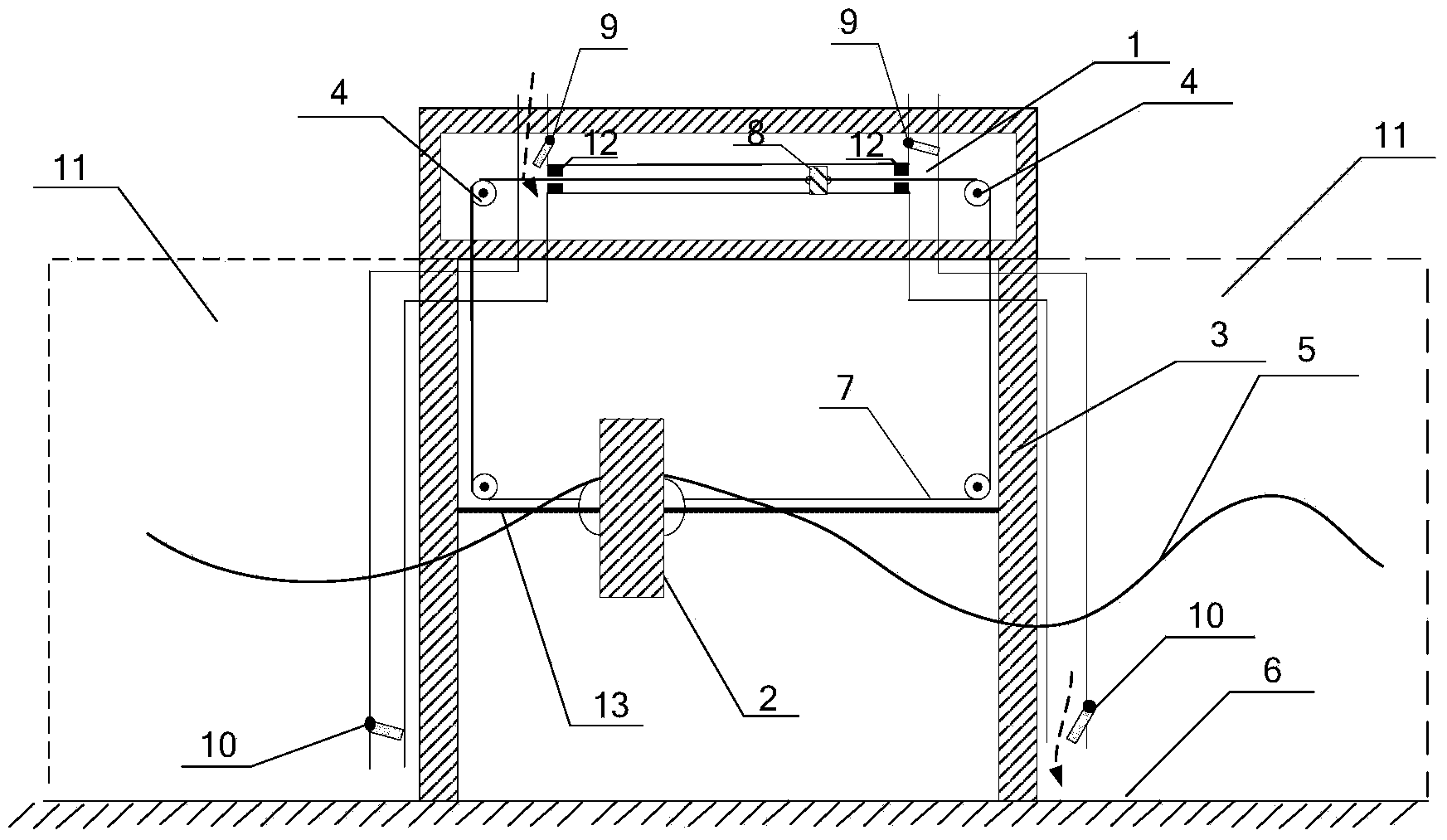

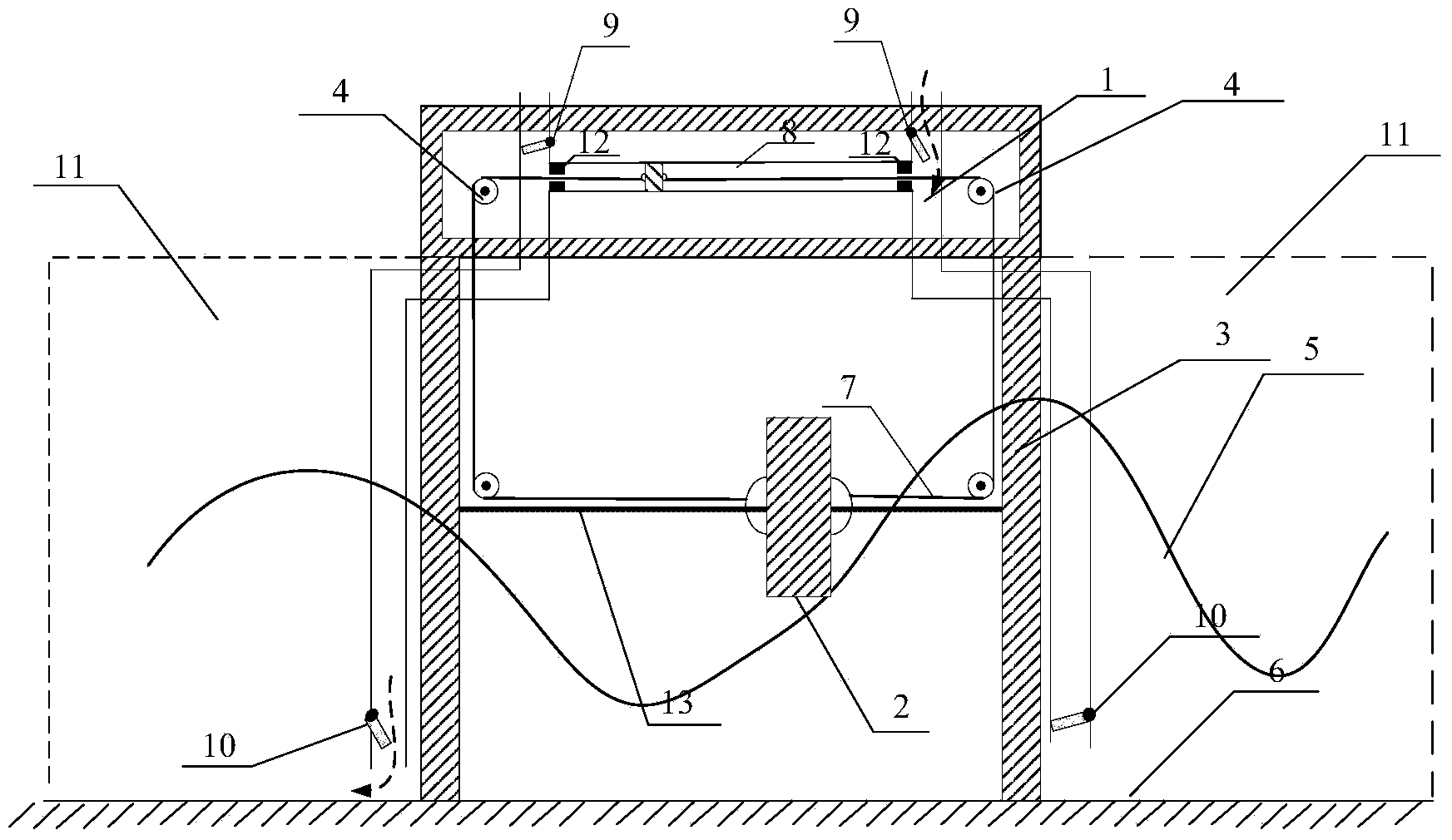

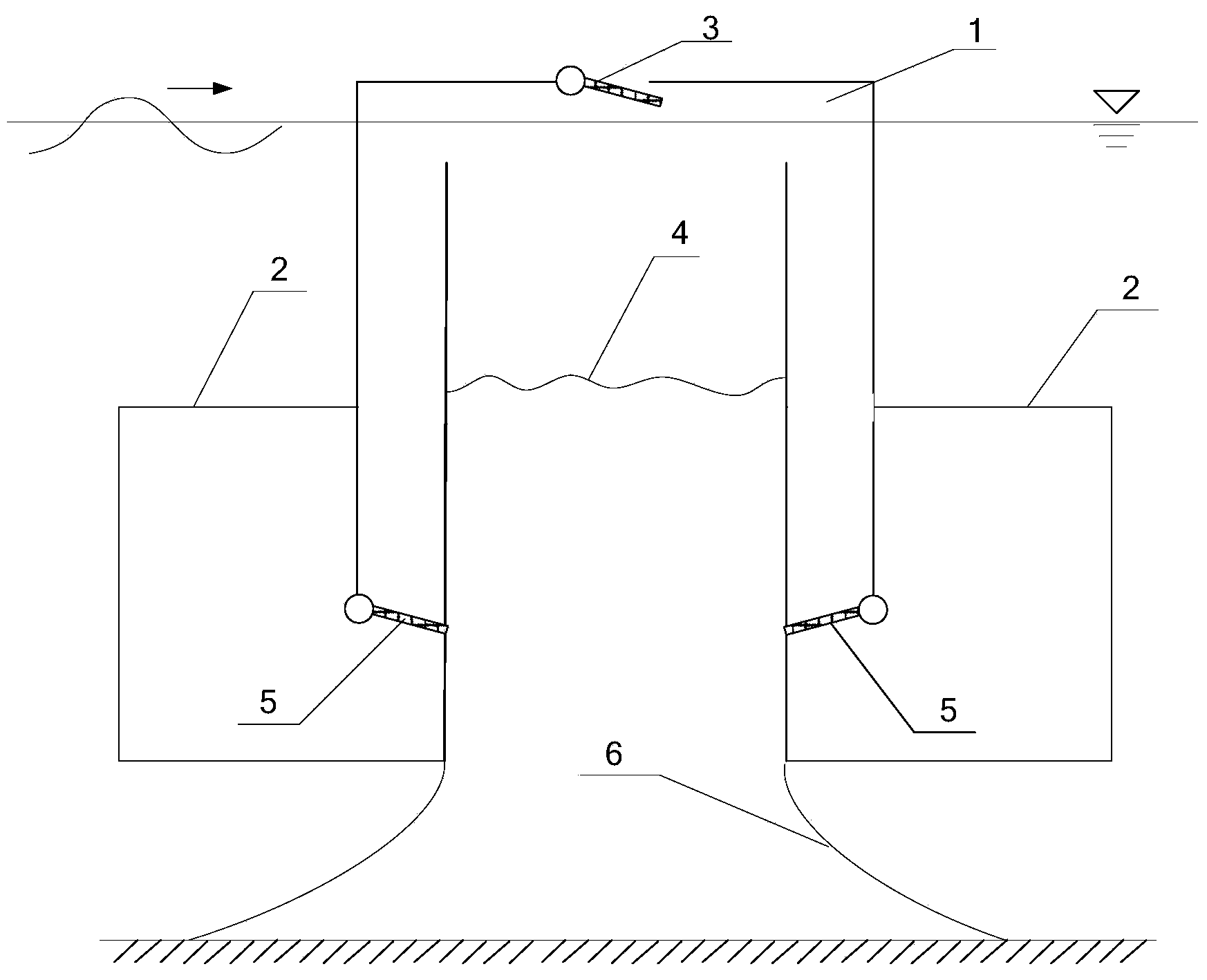

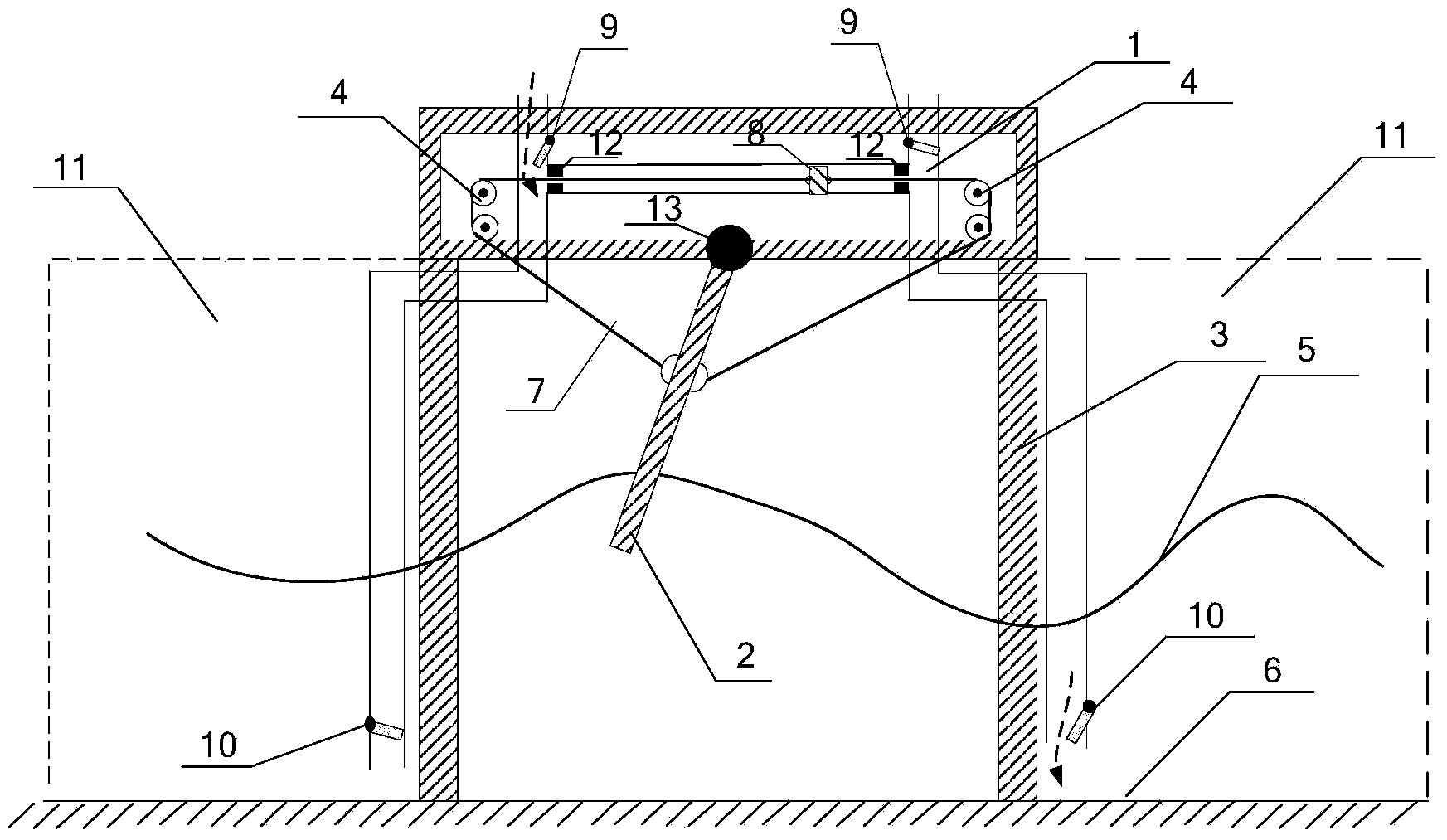

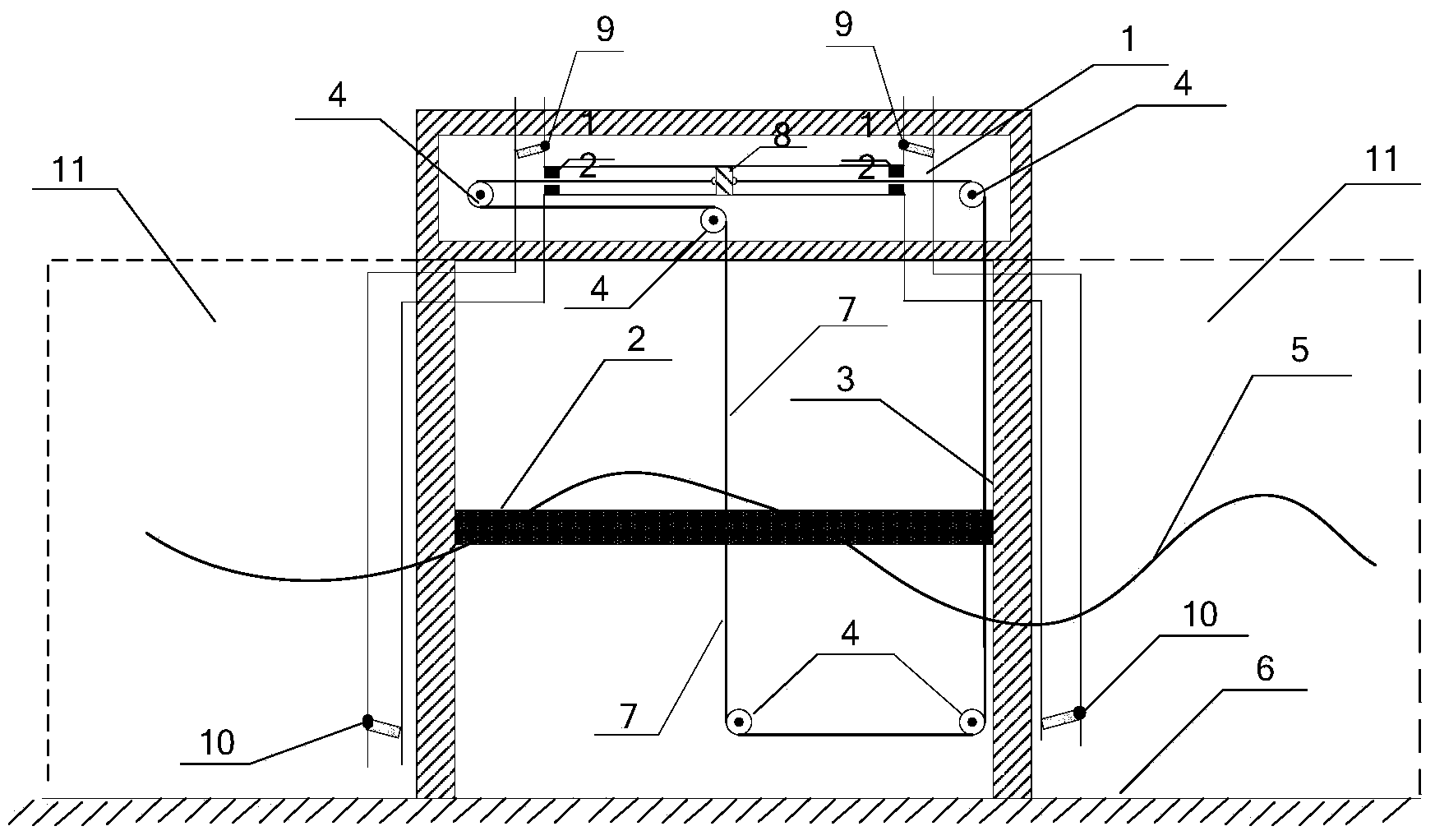

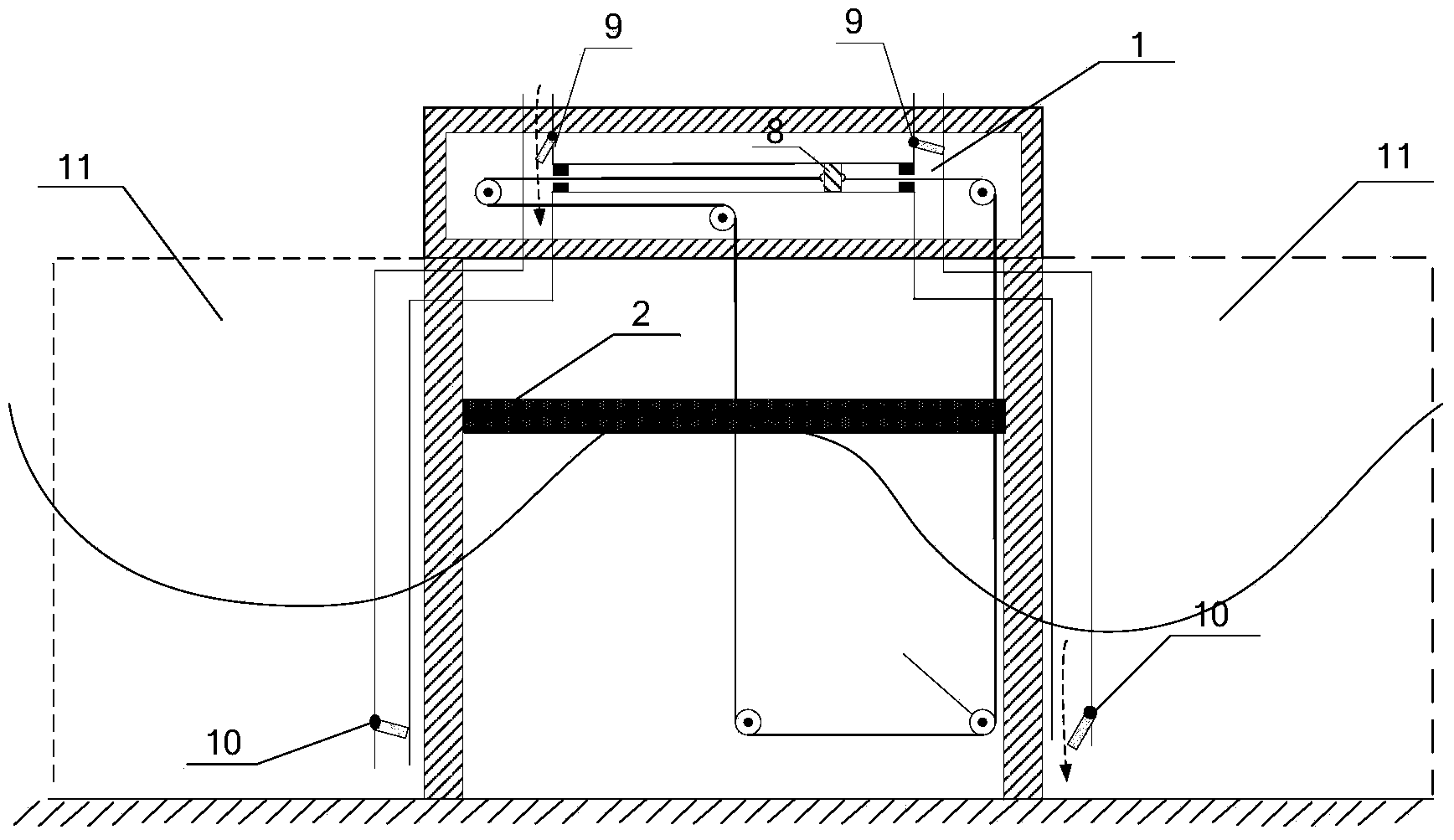

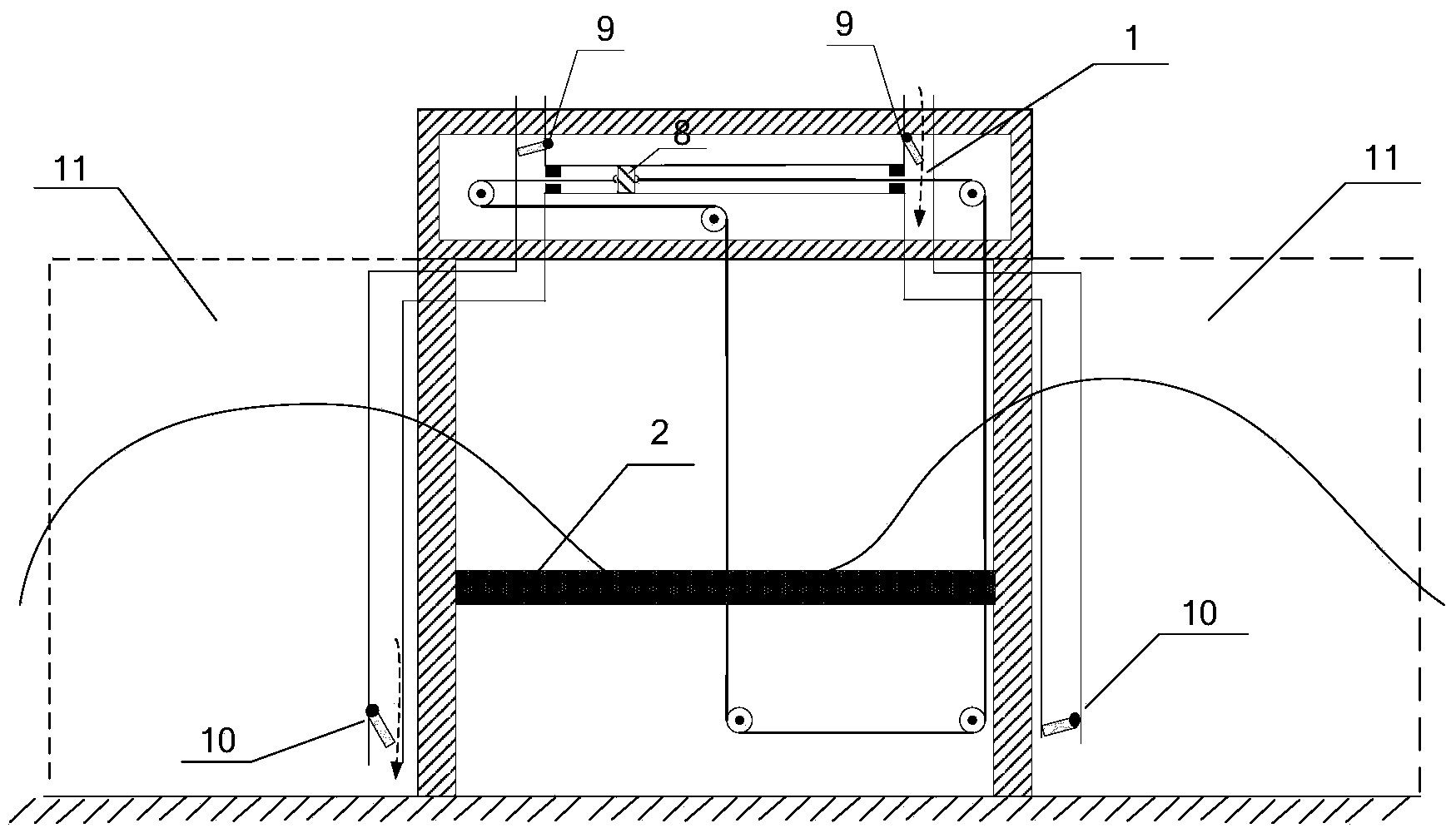

Wave energy oxygen supply device using multiple floaters

InactiveCN104234923AEffective combinationAvoid oxygenationMachines/enginesEngine componentsAir compressionOcean bottom

The invention belongs to the fields of renewable energy technologies and aquaculture devices, and particularly relates to a wave energy oxygen supply device using multiple floaters. The wave energy oxygen supply device comprises an air compression pipeline, floaters, an upright post, a rotating shaft, a connecting rod, a piston, an air one-way valve, an underground one-way valve and a fish-farming room. The wave energy oxygen supply device is characterized in that the overall device is installed on a seafloor foundation through the upright post; an airtight cabin is arranged above the upright post; the air compression pipeline and the piston are arranged inside the airtight cabin; the floaters are respectively distributed on two sides of the device, and are connected with the piston through internal connecting rods, external connecting rods and hinge shafts; the fish-farming room is arranged below the device, and is communicated with the oxygen supply device through the air compression pipeline. The wave energy oxygen supply device disclosed by the invention is capable of driving flowing of air in the air compression pipeline by using the change of floater elevation caused in the wave transmitting process, and supplying oxygen to the fish-farming room, and has the advantages of being high in reliability, and easy to manufacture, install and move.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

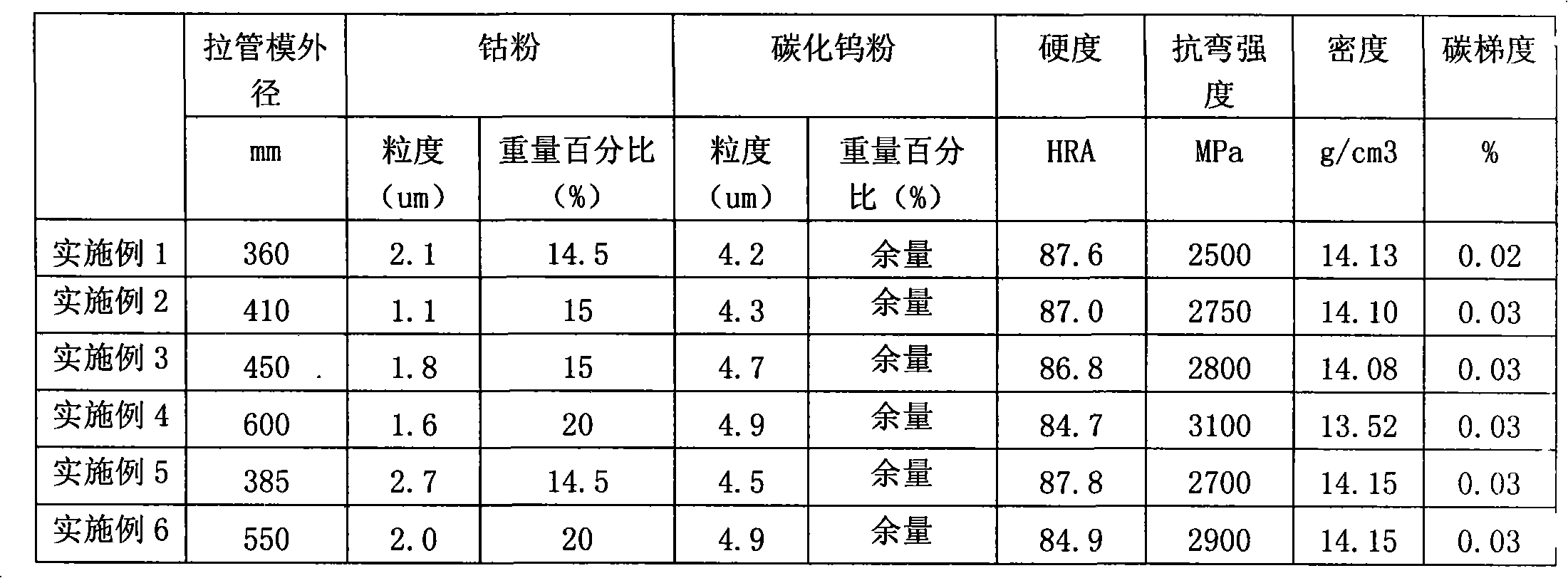

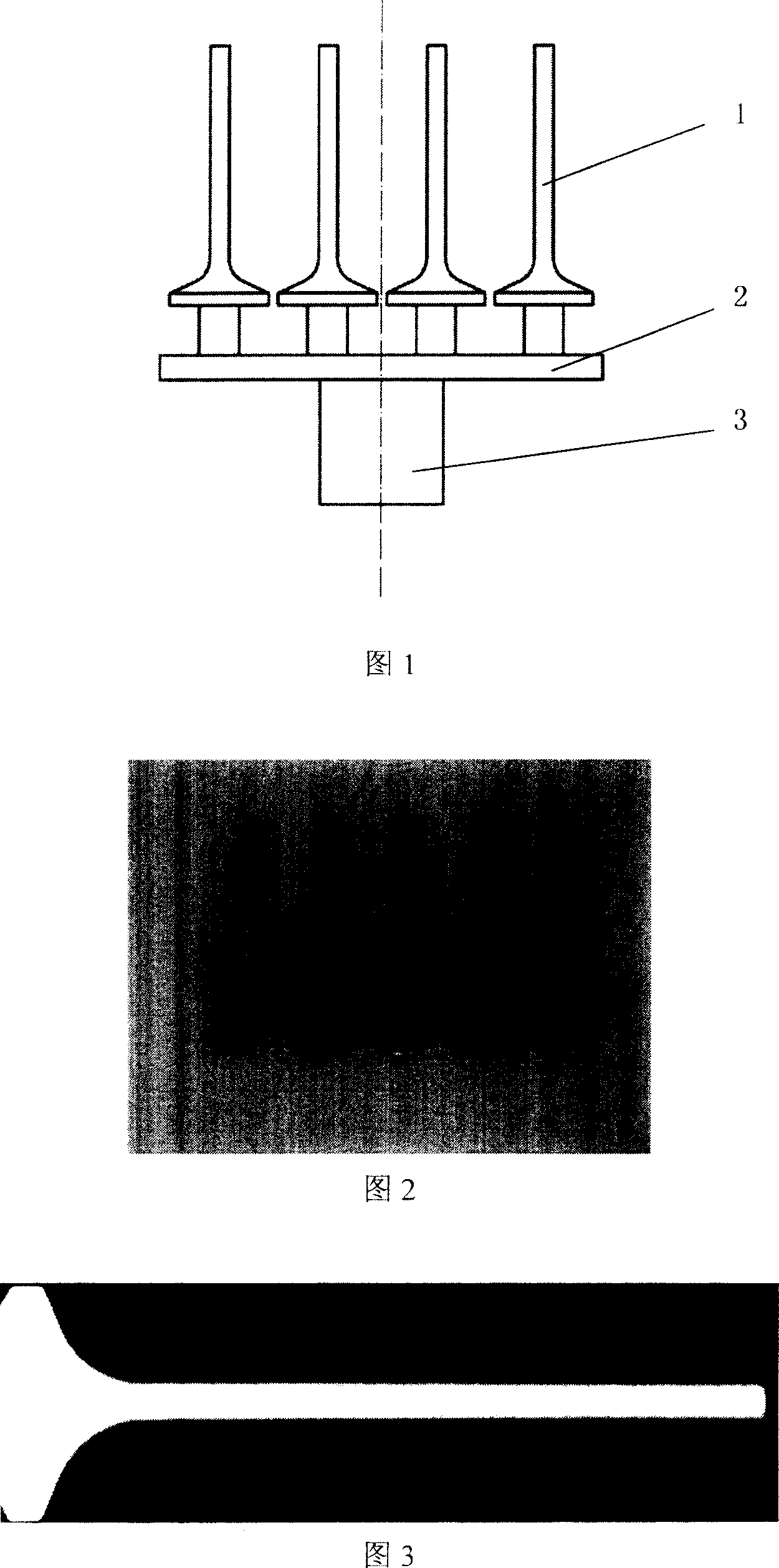

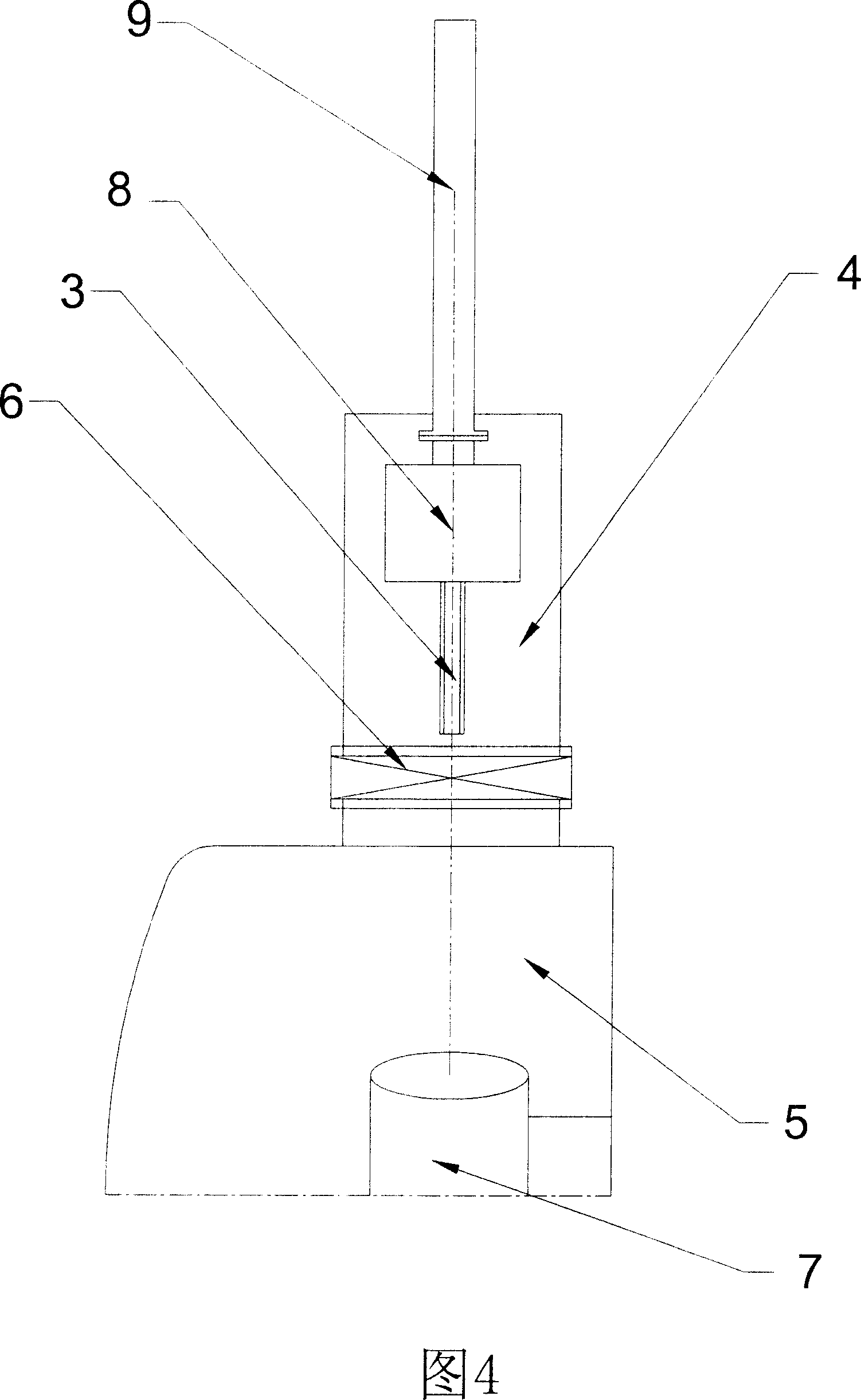

Hard alloy large pipe drawing mold and preparation method

InactiveCN101892408AHigh product strengthGuaranteed hardness and wear resistanceDrawing profiling toolsWaxCemented carbide

The invention provides a hard alloy large pipe drawing mold and a preparation method. The hard alloy large pipe drawing mold comprises the following raw material ingredients in percentage by weight: 14 to 20 percent of cobalt with a particle size of 1.0 to 3.0mu m, and the balance of tungsten carbide with a particle size of 4 to 5mu m. The preparation method comprises: raw material preparation, wet milling, drying, pressing, forming agent removal and sintering, wherein in the drying step, wax or butadiene rubber is used as the forming agent; the drying with the wax as the forming agent is spray drying; the forming agent remove is performed in a dewaxing and sintering integrated furnace or bell-type furnace; and the sintering is pressure sintering, and during the sintering, the temperature is raised within 11 to 13 hours till a liquid phase of the product appears, then about 40 mbars of high-purity argon is introduced into the furnace till the final sintering temperature of 1,390 to 1,400 DEG C, the temperature is kept for 50 to 60 minutes, then about 50 to 60 bars of high-purity argon is introduced, the temperature is kept continuously for 50 to 60 minutes, and the product is cooled to room temperature. The Rockwell hardness of the hard alloy large pipe drawing mold of the invention is more than or equal to 83HRA, the bending strength of the hard alloy large pipe drawing mold is more than or equal to 2,200MPa, and the density of the hard alloy large pipe drawing mold is 13.40 to 14.20g / cm<3>. And the hard alloy large pipe drawing mold has the advantages of high hardness, high wear resistance, uniform product performance, fragmentation resistance and long service life.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Vanadium aluminum titanium intermediate alloy used for manufacturing high vanadium titanium alloy material and preparation method thereof

The invention provides a preparation method of vanadium aluminum titanium alloy, and relates to a preparation method of high vanadium titanium material. The preparation method of the vanadium aluminum titanium alloy is characterized in that the preparation process is that firstly, a metallothermic reduction method is adopted and aluminum is taken as a reducing agent to reduce vanadium pentoxide and titanium dioxide, so as to prepare one-step vanadium aluminum titanium alloy; and then the well-prepared one-step vanadium aluminum titanium alloy is crushed and secondarily refined in a vacuum medium frequency induction furnace, and the final product of the vanadium aluminum titanium alloy is obtained. According to the method provided by the invention, the metallothermic reduction method (one-step method) is adopted and the aluminum is taken as the reducing agent to prepare the vanadium aluminum titanium alloy, then the vanadium aluminum titanium alloy is melted in the vacuum induction melting furnace and crushed, and finally a product of the aluminum titanium alloy is obtained. By adopting the method, the problem of high oxygen content of traditional Al-V85 alloy is solved, and the vanadium aluminum titanium alloy with relatively low oxygen content is obtained through adding a titanium element while the proportion of aluminum to vanadium in the Al-V85 alloy is not changed, and the oxygen content of a titanium alloy ingot is successfully controlled.

Owner:宝鸡市嘉诚稀有金属材料有限公司

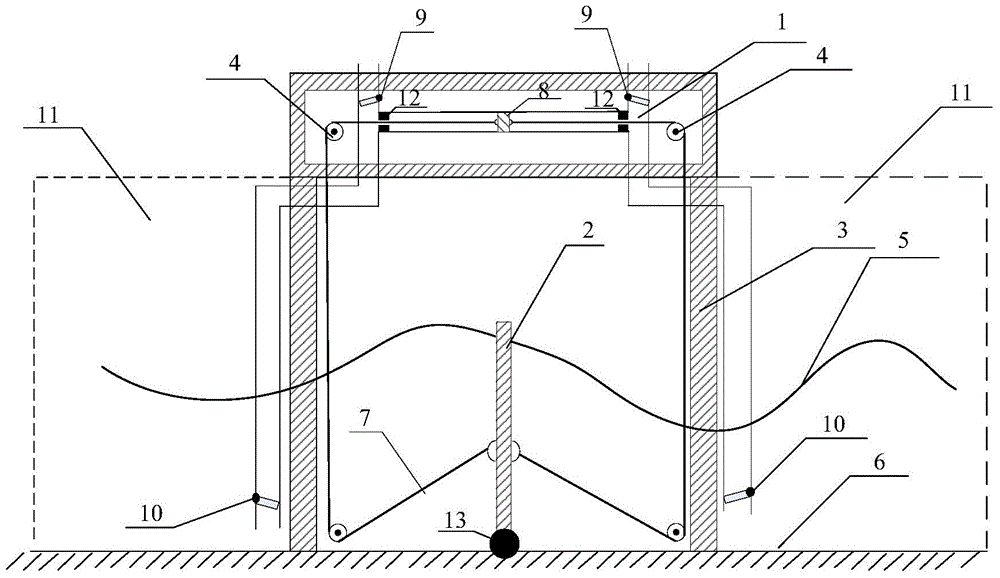

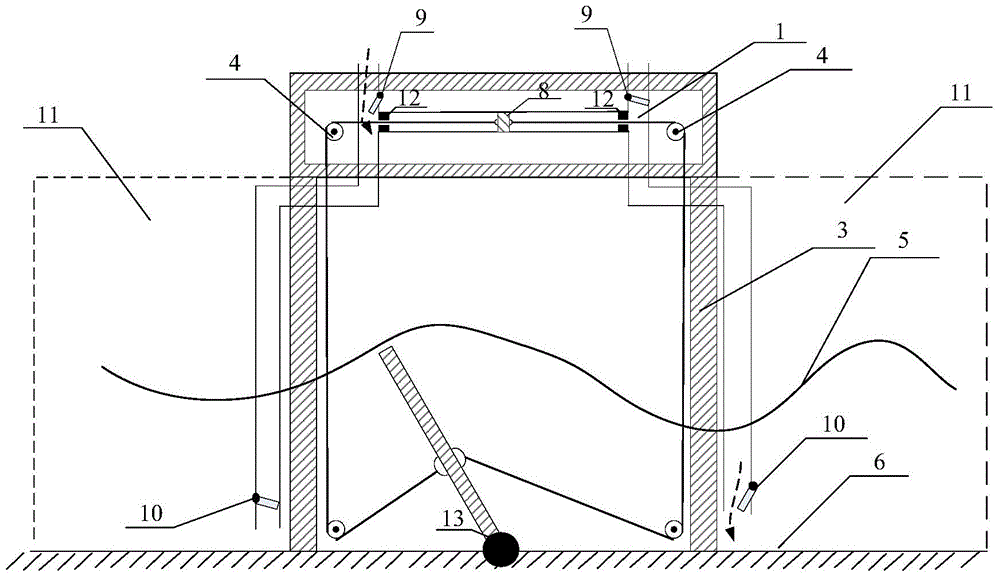

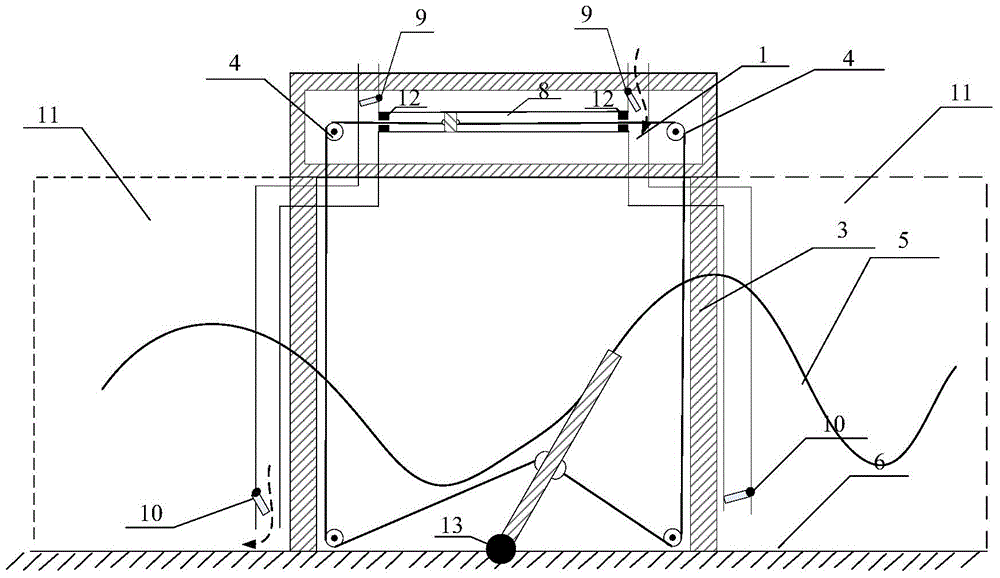

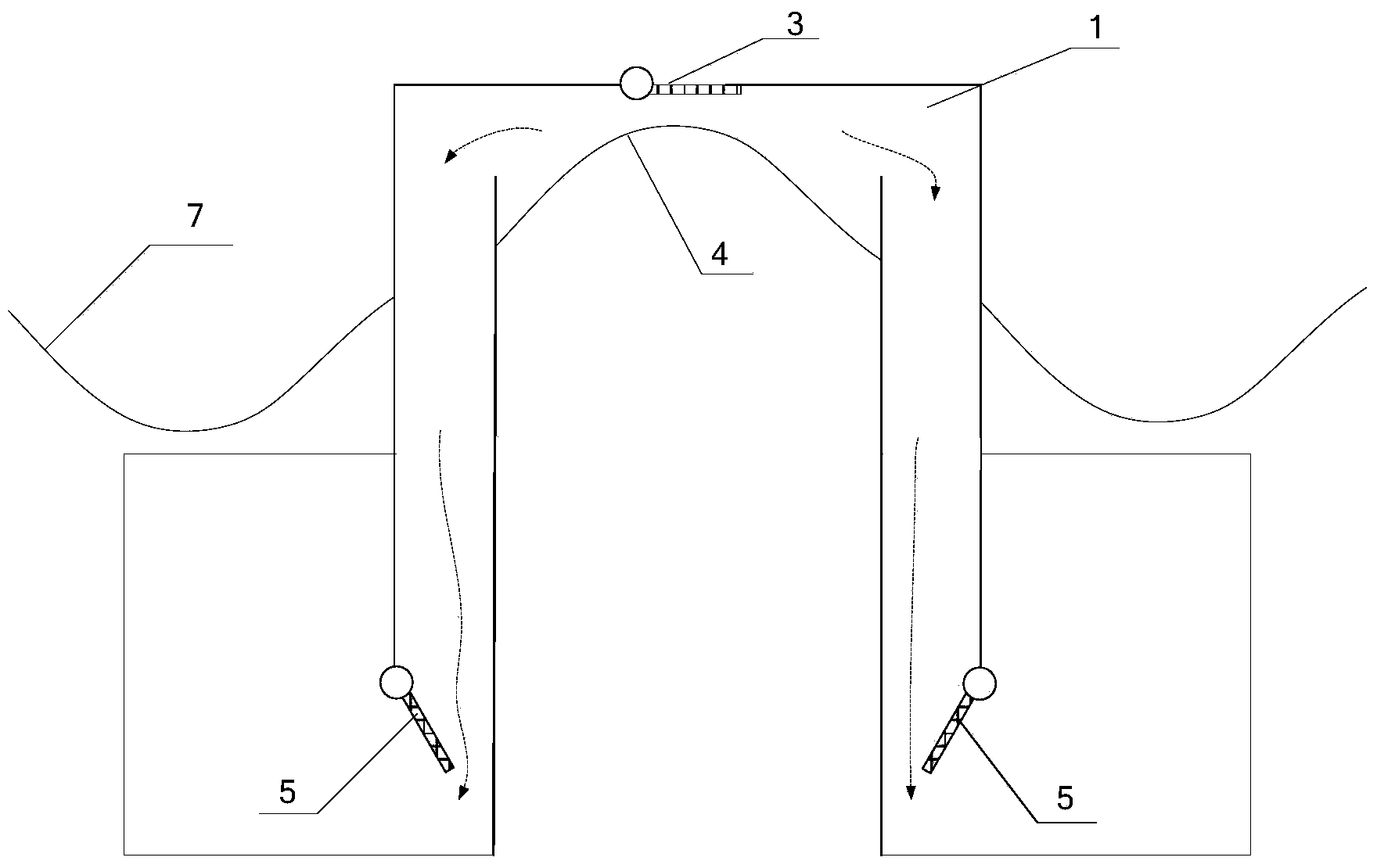

Floating type wave energy oxygen supply device utilizing buoyancy pendulum

InactiveCN104314740AEffective combinationAvoid oxygenationPisciculture and aquariaPiston pumpsOcean bottomEngineering

The invention belongs to the field of a novel renewable energy technology and an aquaculture device, and in particular relates to a floating type wave energy oxygen supply device utilizing a buoyancy pendulum. The floating type wave energy oxygen supply device comprises an air compression pipeline, a pendulum plate, upright columns, a fixed pulley, a steel cable, a piston, an air one-way valve, an underwater one-way valve, a rotating shaft and fish culture chambers. The floating type wave energy oxygen supply device is characterized in that the device is integrally arranged on a seabed foundation through the upright columns; a sealing cabin is mounted above the upright columns and is internally provided with the air compression pipeline and the piston; the rotating shaft and the pendulum plate are arranged between the two upright columns; the rotating shaft is fixed on the seabed; the pendulum plate is connected with the piston through the steel cable and the fixed pulley; the fish culture rooms are positioned at two sides of the device and are communicated with the oxygen supply device through the air compression pipeline. According to the floating type wave energy oxygen supply device, flowing of air in the air compression device is driven by utilizing the change of flow velocity of seawater along with wave transfer to supply oxygen to the fish culture rooms; the floating type wave energy oxygen supply device is relatively high reliability and easy to manufacture, mount and move.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Wave energy oxygen supply device utilizing horizontal-movement float

The invention relates to the fields of novel renewable energy technology and aquaculture equipment, and especially relates to a wave energy oxygen supply device utilizing a horizontal-movement float. The device comprises an air compression pipe, a float, columns, fixed pulleys, steel cables, a piston, air check valves, underwater check valves, a rail, and fish farming chambers. The device is characterized in that: the entire device is arranged on a seabed base; a sealed bin is arranged above the columns, the air compression pipe and the piston are arranged in the bin; the rail and the float are distributed between two columns; the two ends of the rail are respectively fixed on the columns; the float is connected with the piston through the fixed pulleys and the steel cables; the fish farming chambers are positioned on two sides of the device, and communicate with the oxygen supply device through the air compression pipe. With the design provided by the invention, air flow in the air compression pipe can be driven by the changes formed by seawater flow rate transferred through waves, and the oxygen supply of the fish farming chambers is realized. The device has high reliability, and is easy to manufacture, mount and move.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

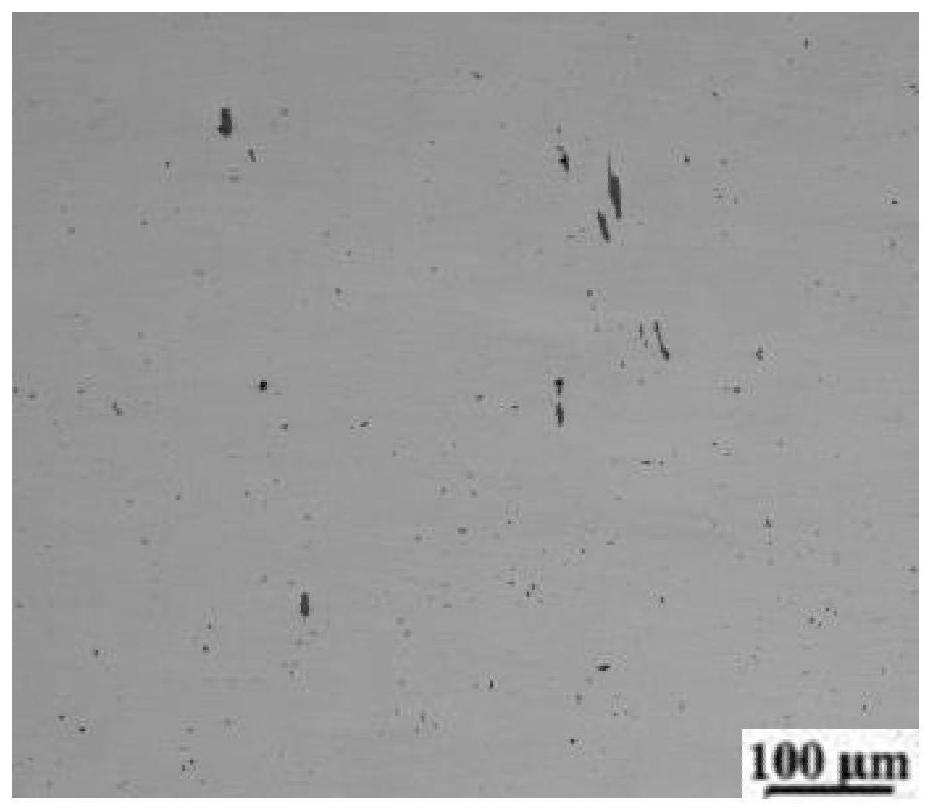

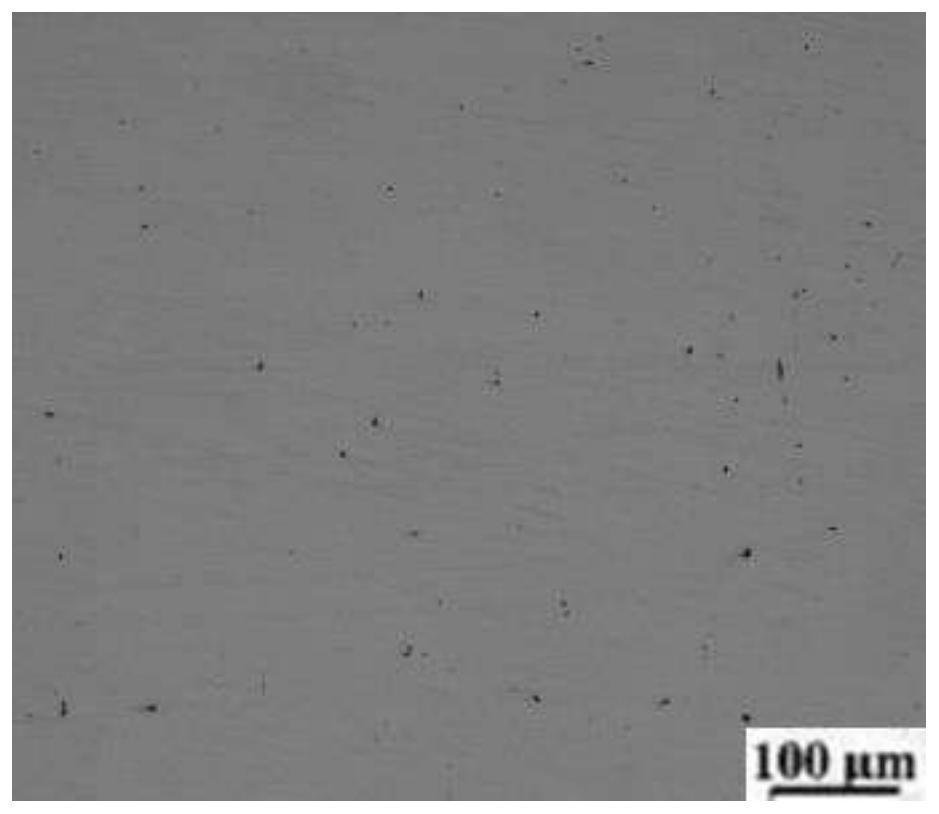

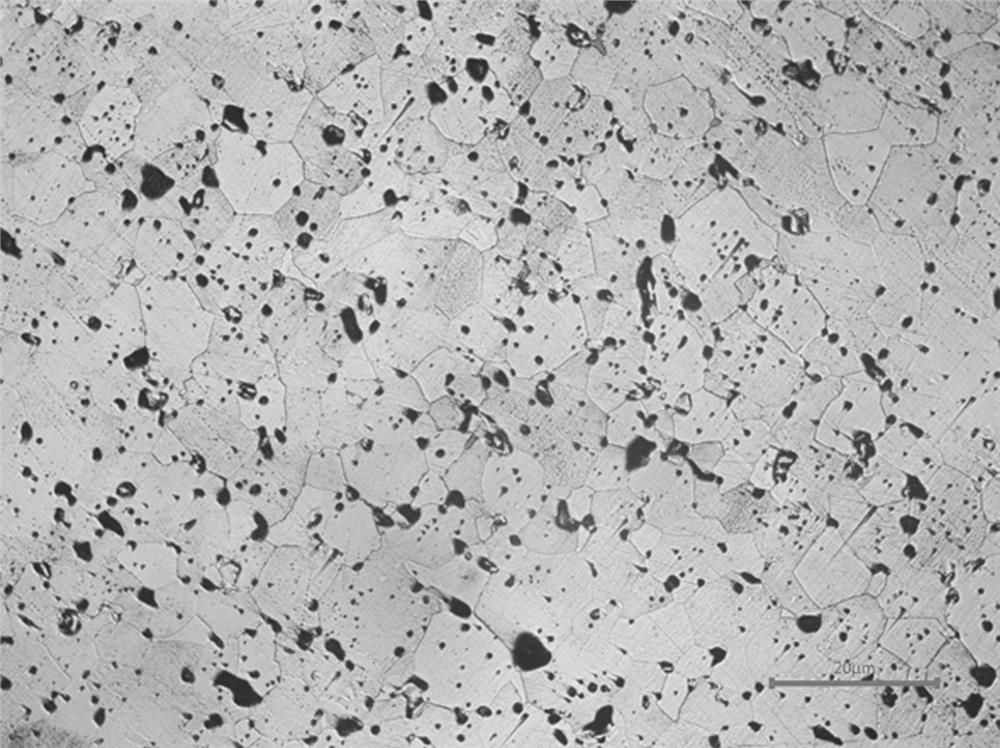

Magnesium-containing steel 45 and preparation process thereof

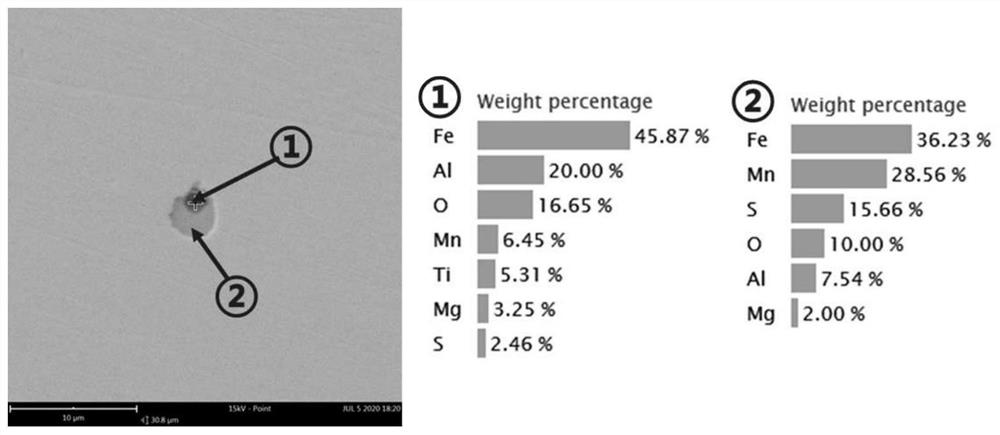

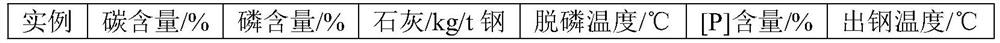

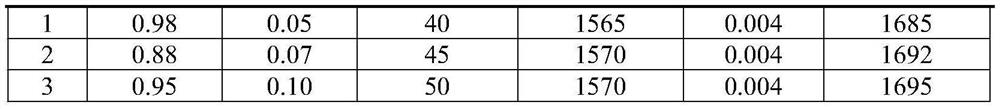

PendingCN113957338AIncreased level of controlIncrease ratingsTemperature control deviceProcess efficiency improvementOxide compositeMolten steel

The invention discloses magnesium-containing steel 45 and a preparation process thereof, and relates to the technical field of steel production. The steel 45 comprises the following chemical components of, in percentage by mass, 0.45%-0.48% of C, 0.17%-0.37% of Si, 0.65%-0.80% of Mn, less than or equal to 0.035% of P, less than or equal to 0.035% of S, 0.0005%-0.0020% of Mg, and the balance iron and inevitable impurities. On the basis of ensuring the safe production of the steel 45, the inclusion in the steel is modified by feeding a magnesium-silicon cored wire into molten steel at the final stage of refining, so that the inclusion in the steel is converted into the fine and dispersively distributed sulfide-oxide composite inclusion, the rating of the inclusion is optimized, and the comprehensive mechanical property of the steel 45 is improved.

Owner:NANJING IRON & STEEL CO LTD

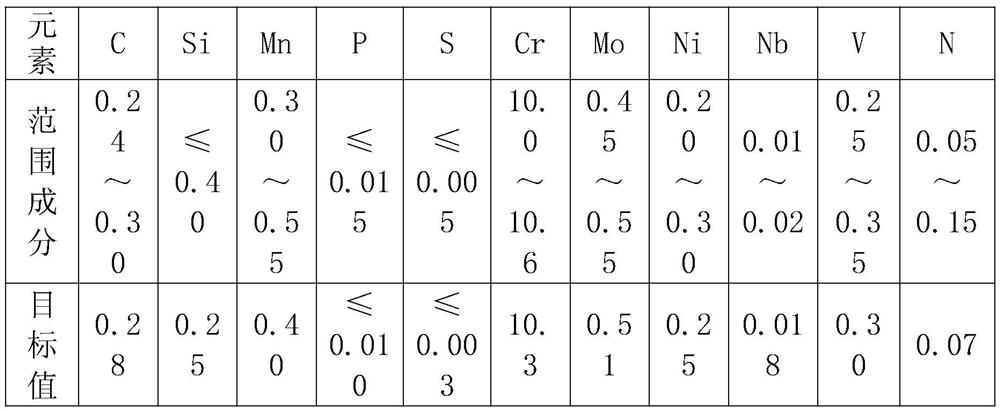

Smelting method of electrode bar base material for non-protective-atmosphere electroslag remelting of H13 steel

The invention discloses a smelting method of an electrode bar base material for non-protective-atmosphere electroslag remelting of H13 steel, and belongs to the field of ferrous metallurgy. The smelting method of the electrode bar base metal for non-protective-atmosphere electroslag remelting of the H13 steel comprises the steps of electric furnace steelmaking, LF furnace refining, VD vacuum degassing, pouring and the like. According to the smelting method, by increasing the content of [Al] in the steel, adjusting the composition of the LF slag, and adjusting a VD argon soft blowing system to be proper, the content of inclusions in the molten steel can be effectively reduced, and the cleanliness of the electrode bar base material is improved. By the adoption of the electrode bar base material prepared through the method, secondary oxidation of molten steel in the electroslag remelting process can be avoided, so that the content of oxidation-system inclusions in the H13 steel manufactured through non-protective-atmosphere electroslag remelting is reduced, and the quality of steel obtained after non-protective-atmosphere electroslag remelting is improved. The problems that an existing electrode bar base material used for non-protective-atmosphere electroslag remelting of the H13 steel is low in cleanliness and prone to secondary oxidation in the non-protective-atmosphere electroslag remelting process can be effectively solved.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

Rare earth heavy rail steel rare earth adding method and rare earth heavy rail steel

The invention provides a rare earth heavy rail steel rare earth adding method and rare earth heavy rail steel. According to the rare earth adding method, in the production of the rare earth heavy railsteel, the rare earth heavy rail steel is sequentially subjected to LF refining and VD refining until the mass fraction of oxygen in molten steel is less than or equal to 10 ppm; on the premise thatthe mass fraction of oxygen in the molten steel is less than or equal to 10 ppm, the rare earth alloy with the rare earth content of more than or equal to 99 wt% is added into the molten steel by adopting a direct input method. According to the adding method, on one hand, pure rare earth is adopted to ensure that the rare earth content is over 99%, the oxygen content in the rare-earth alloy can begreatly reduced, the rare earth can be rapidly molten into the molten steel, and oxygenation is avoided due to the fact that the rare earth is uniformly stirred for a long time; on the other hand, after the LF refining and the VD refining, the oxygen content in the molten steel of the heavy rail steel is reduced to be less than 10 ppm, so that the oxidation of dissolved oxygen in the molten steelto the rare earth is avoided, and the rare earth yield can be improved.

Owner:BAOTOU IRON & STEEL GRP

Novel ecological fishing tank utilizing wave energy

InactiveCN104041442AEffective combinationAvoid oxygenationClimate change adaptationAgricultural fishingRenewable energy technologyInlet valve

The invention belongs to the fields of a novel renewable energy technology and aquaculture devices, and particularly relates to a novel ecological fishing tank utilizing wave energy. The novel ecological fishing tank utilizing wave energy comprises an air chamber, fish culture chambers, a one-way air inlet valve, one-way air outlet valves and an anchor chain. The fish culture chambers are located on the two sides of the ecological fishing tank and are communicated with the two sides of the ecological fishing tank through the one-way air outlet valves. The fishing tank is integrally fixed to the seabed through the mode that the anchor chain is connected with a high holding power anchor. The air chamber is arranged at the upper portion of the fishing tank. The one-way air inlet valve is arranged at the top of the air chamber. The novel ecological fishing tank utilizing wave energy is characterized in that the water level in the air chamber in the fishing tank changes along with transmission of wave, air in the air chamber is compressed through changes of the water level and is driven to flow, and oxygen is transmitted to the fish culture chambers communicated with the fishing tank. According to the novel ecological fishing tank utilizing wave energy, because the water level in a tank body changes in the wave transmission process, the compressed air in the air chamber is driven to flow, and oxygen is transmitted to the fish culture chambers. The novel ecological fishing tank utilizing wave energy has higher reliability and is easy to manufacture, install and move.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

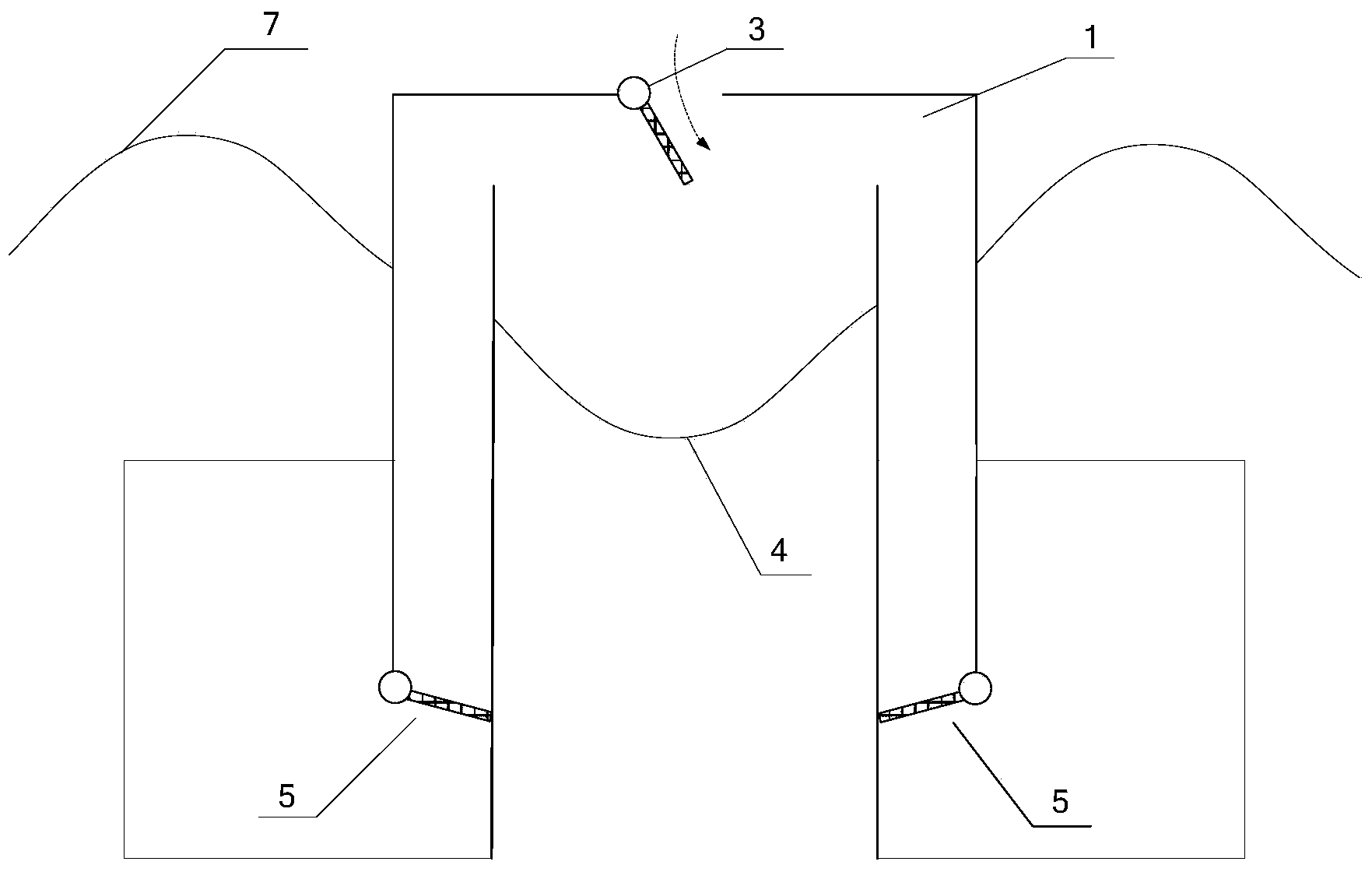

Floating wave energy oxygen supply device using gravity pendulum

InactiveCN104335964AEffective combinationAvoid oxygenationPisciculture and aquariaOcean bottomEngineering

The invention belongs to the field of novel renewable energy technologies and aquaculture devices, and particularly relates to a floating wave energy oxygen supply device using a gravity pendulum. The floating wave energy oxygen supply device comprises air compressing pipes, a pendulum plate, upright posts, fixed pulleys, a steel cable, a piston, air one-way valves, underwater one-way valves, a rotating shaft and fish raising chambers. The floating wave energy oxygen supply device is characterized in that the whole floating wave energy oxygen supply device is installed on a sea foundation through the upright posts; a closed cabin is installed above the upright posts; the air compressing pipes and the piston are installed inside the cabin; the rotating shaft and the pendulum plate are installed between the two upright posts; the rotating shaft is fixed on a bottom plate of a power-generating cabin; the pendulum plate is connected with the piston through the steel cable and the fixed pulleys; the fish raising chambers are positioned on two sides of the floating wave energy oxygen supply device, and are communicated with the oxygen supply device through the air compressing pipes. Through design of the floating wave energy oxygen supply device, by virtue of change of seawater flow rate along with transmission of wave, air in the air compressing pipes can be driven to flow and oxygen is supplied for the fish raising chamber, the floating wave energy oxygen supply device has relatively high reliability and is easy to manufacture, install and move.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

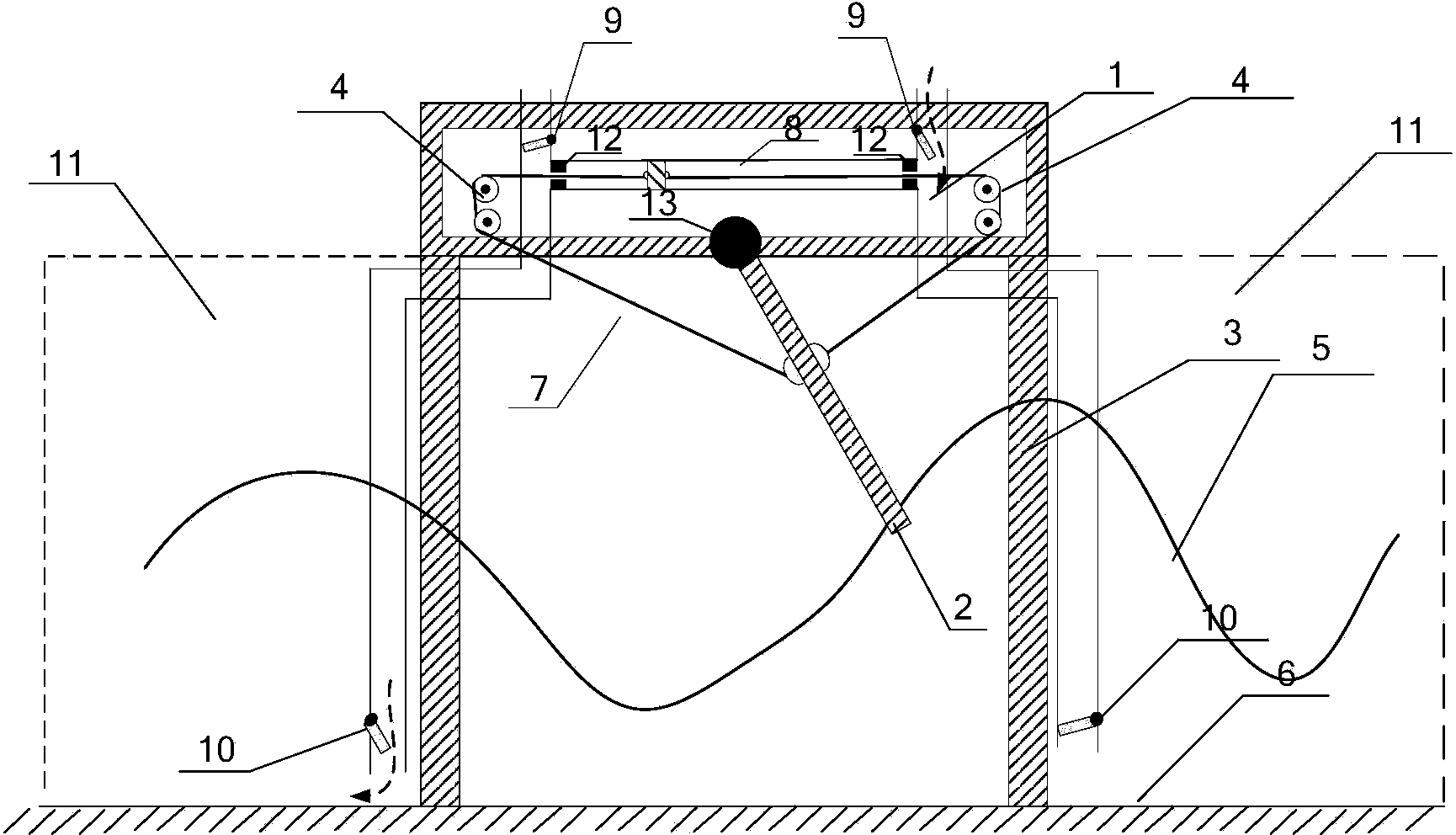

Method for preparing pigment carbon black from waste and abandoned tires

InactiveCN108384287AAchieve full utilizationReduce manufacturing costPigmenting treatmentChemistryCarbon black

The invention relates to a method for preparing pigment carbon black from waste and abandoned tires, and belongs to the technical field of waste reutilization. The waste and abandoned tires are used as raw materials to be subjected to mixed ball milling and pyrolysis with auxiliary agents; then, obtained materials are mixed with a sodium hydroxide solution and glacial acetic acid; next, mixed reaction is performed with dimethylformamide, tyrosine and the like; finally, low-temperature oxidization is performed, so that the pigment carbon black is prepared. The method has the advantages that thewaste and abandoned tires are sufficiently utilized; the environment pollution and the resource waste are avoided; the problem of reduction of oxygen content on the surface of the carbon black duringthe high-temperature oxidization on the carbon black is also solved, so that the oxidization can be performed at low temperature.

Owner:雷春生

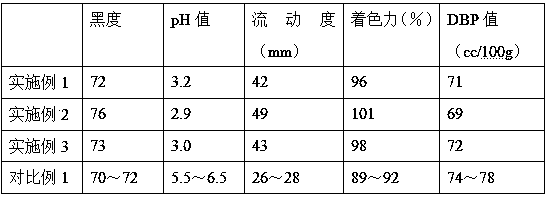

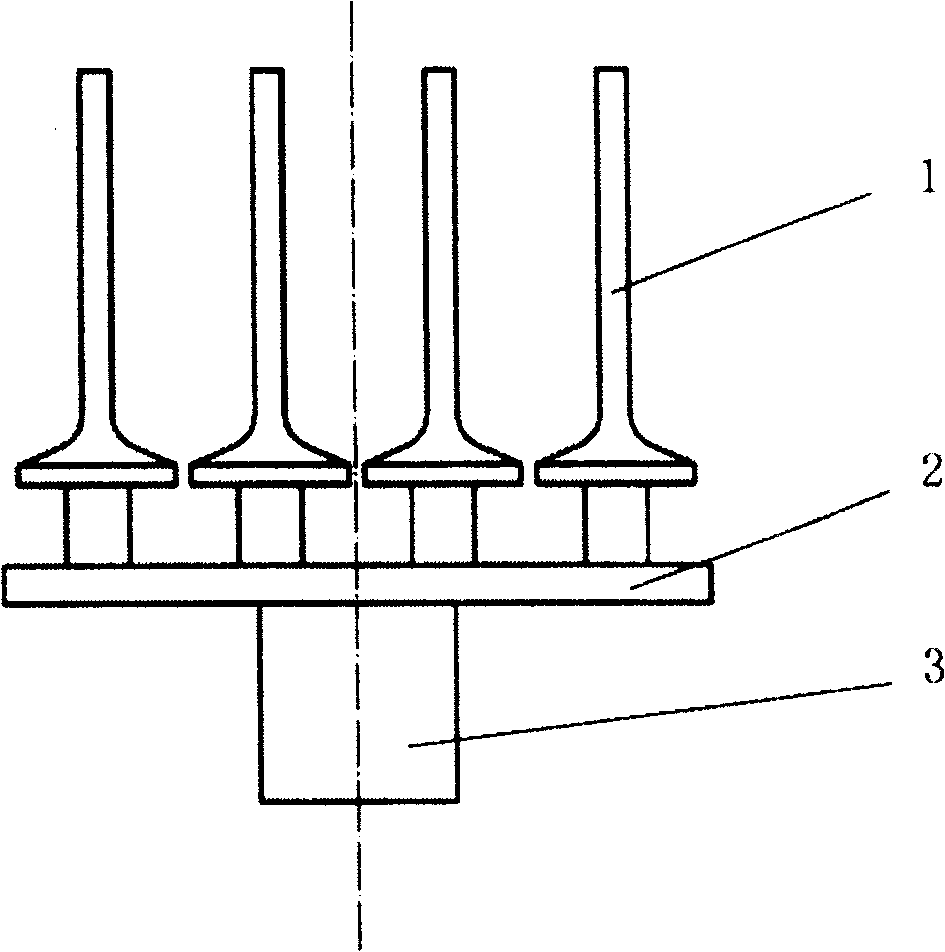

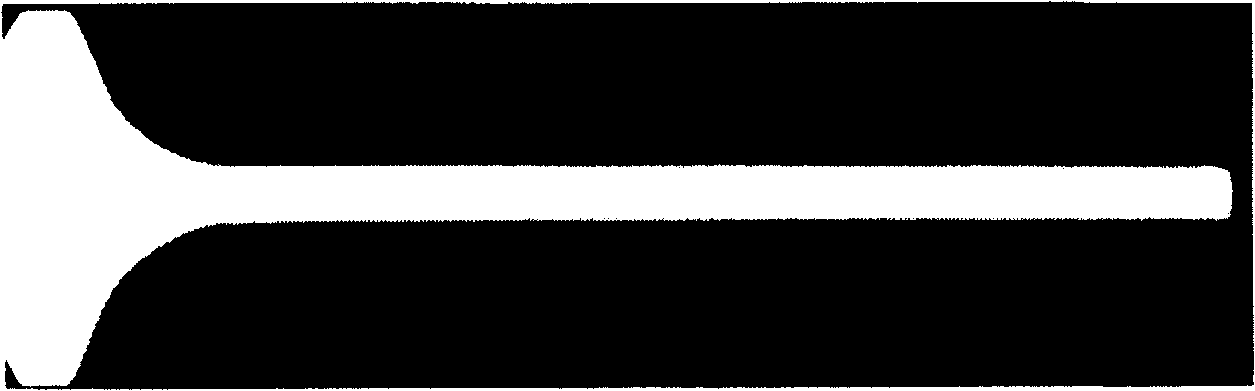

Method for semi-continuously preparing TiAl base alloy automobile air valve and components with similar shape

The present invention relates to preparative technique for automobile air valve and parts of similar shape, specifically speaking, the present invention is a semi-continuous method for preparing TiA1-based alloy automobile air valve and parts of similar shape. The present invention adopts the method of vacuum pouring after semi-continuous induction melting in a vacuum pouring furnace: take the spongy titanium, industrial pure aluminum and other alloy elements as the raw materials and adopt a CaO formed ceramic pot for vacuum induction melting; the cast shell mold consists of part mold shell such as air valve, etc., intermediate flow trays and a vacuum pouring pipe; the intermediate flow trays are evenly distributed in the lengthwise direction of the air valve part; the technique parameters of the vacuum pouring are that the shell mold temperature is between 50 to 800 Celsius degrees and the vacuum pouring pressure difference is2.0 multiplied by 104-7.0 multiplied by 104Pa. The present invention can semi-continuously produce parts which have complicated shapes and are hard to be formed with high-melting point, high-activity Ti A1-based materials and the cost is low; in addition, the produced automobile air valve boasts of excellent internal quality and stable casting performance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Rolling preparation method for large-specification molybdenum-niobium alloy target material

PendingCN113637945AGuaranteed purityTightly boundVacuum evaporation coatingSputtering coatingNiobium alloyHot isostatic pressing

The invention relates to a rolling preparation method for a large-specification molybdenum-niobium alloy target material. The method specifically comprises the following steps that raw material powder of the target material alloy is uniformly mixed, cold isostatic pressing, hot isostatic pressing, rolling with a sheath, and then leveling and annealing are performed, the sheath is removed, and the mixture is machined to a specified size, wherein a cogging temperature of rolling with the sheath is 1400 DEG C-1450 DEG C, and the pass deformation quantity is 20%-30%, and cooling and rolling are performed until a final rolling temperature is 1250 DEG C. According to the method, a molybdenum-niobium target blank can be rolled and produced, according to the equipment size, the large-specification size can be achieved, the long-strip target material with the size of 2000 mm or above can be rolled, and compared with a sintered target material, the rolled target material is high in density and can reach the theoretical density.

Owner:ACHEMETAL TUNGSTEN & MOLYBDENUM

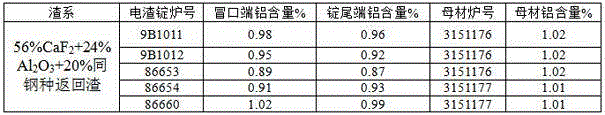

Electroslag re-melting process for controlling aluminum uniformity of high-aluminum steel

The invention relates to an electroslag re-melting process for controlling aluminum uniformity of high-aluminum steel. The electroslag re-melting process is characterized in that a binary slag system is adopted, wherein parts of CaF2 and Al2O3 are replaced by returned slag of the same steel type. During slag melting, aluminum powder which accounts for 2%-4% of the slag is added to remove unstable oxides in the slag. Aluminum burning loss is severe because of large current fluctuation in first two hours of a re-melting initial stage, the aluminum powder is added to regulate aluminum in electrode blank until the aluminum amount exceeds upper limit of a range by 0.1%, and then, aluminum powder is added according to component upper limit for deoxidation. A melting rate (kg / h) during the electroslag re-melting process is equal to (0.75-0.85)*an average diameter (mm) of a crystallizer, so that surface smooth of an electroslag ingot can be guaranteed, and surfaces pits and insufficient steel-slag separation are avoided.

Owner:ZHONGYUAN SPECIAL STEEL

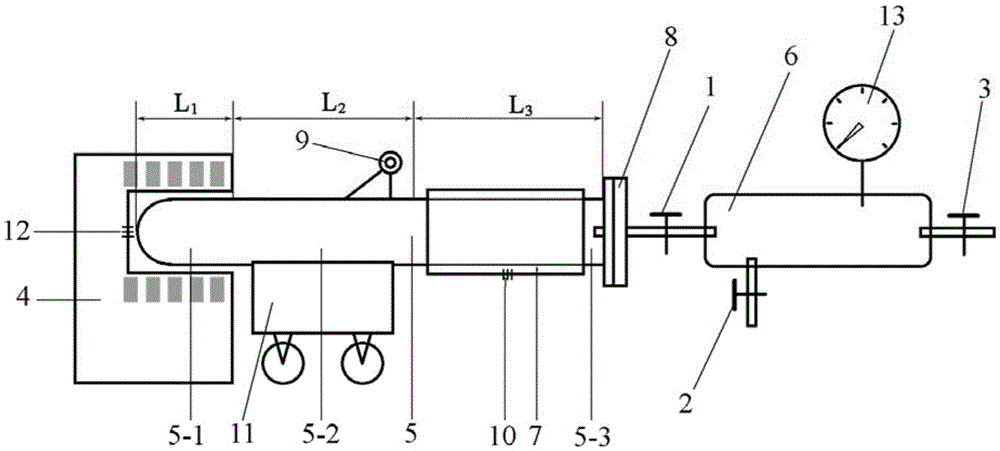

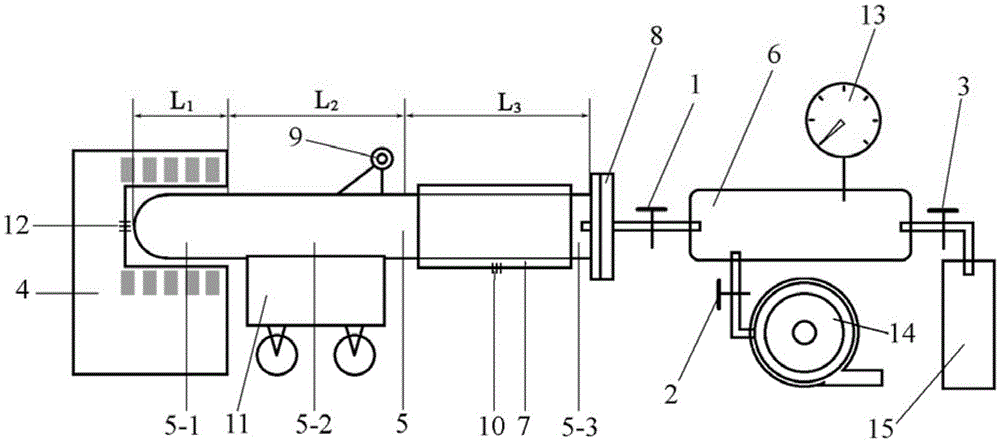

Multi-sectional hydrogenation dehydrogenation furnace and manufacturing method of low-oxygen-content titanium powder

The invention provides a multi-sectional hydrogenation dehydrogenation furnace which comprises a heating furnace, a reactor, a gas storage tank, a cooling device and a movable support, wherein the heating furnace and the reactor are horizontally placed. The reactor is a cylinder with two closed ends and formed by sequentially jointing a heating part section, a middle part section and a cooling part section, a material feeding and discharging port is formed in the end of the cooling part section and provided with a sealing cover, and a gas inflow and outflow port is formed in the sealing cover or the cylinder. The cooling device is provided with a first thermoelectric couple. The heating furnace is provided with a second thermoelectric couple. The gas storage tank is provided with a pressure gauge, a reactor joint, a vacuumizing joint and a hydrogen source joint. The reactor is installed on the movable support. The heating part section of the reactor is located in a hearth of the heating furnace. The cooling device is installed on the cooling part section of the reactor. The reactor joint on the gas storage tank is communicated with the gas inflow and outflow port of the reactor through a pipe. The invention further provides a manufacturing method of low-oxygen-content titanium powder. The oxygen content of the titanium powder manufactured through the method does not exceed 0.1wt%.

Owner:SICHUAN UNIV

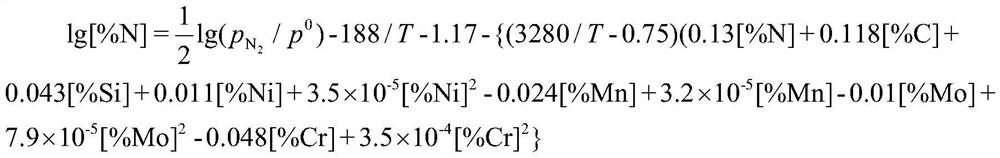

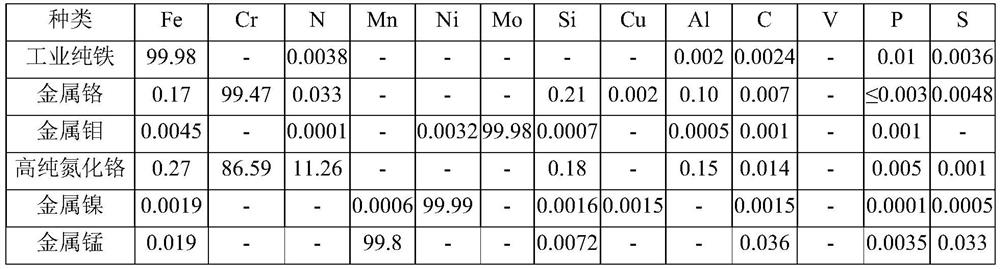

Nitrogen-filling electroslag process for cavity of nitrogen-containing steel hollow blank

The invention particularly relates to a nitrogen-filling electroslag process for a cavity of a nitrogen-containing steel hollow blank, which is different from a common process in which nitrogen is added into an electrode blank of nitrogen-containing steel and then electroslag is carried out. The process is characterized in that nitrogen is not added during smelting of an electrode blank, a nitrogen-free hollow electrode blank is adopted, nitrogen is injected from a reserved hole during electroslag, nitrogen is added into steel through the physical and chemical reaction of nitrogen and steel slag, the nitrogen flow is controlled according to the nitrogen content of different steel types, and alloying of the nitrogen element is completed in the electroslag remelting process. The process can be applied to common electroslag equipment only, and a special pressurizing electroslag furnace high in price does not need to be arranged. Due to the fact that the blank is a hollow blank, the hot spot is not in the center of a molten pool, the shape of an electroslag molten pool is greatly improved, the molten pool tends to be in a flat state, the consistency of internal and external crystalline states of an ingot is higher, redundant nitrogen overflows from the periphery to form a protective atmosphere, oxygen increasing and hydrogen increasing of molten steel are avoided, the alloying target of the nitrogen element can be easily achieved, and the quality of the electroslag ingot can be improved.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Method for preparing low nickel content ternary TiNiHf shape memory alloy sheet material

The invention relates to a technology for preparing a TiNi-based shape memory alloy sheet, in particular to a method for preparing a low-nickel binary TiNi and ternary TiNiHf shape memory alloy sheet.The technology takes titanium sponge, electrolytic nickel and a hafnium sheet as raw materials, and adopts a ceramic crucible which is formed by CaO to carry out vacuum induction melting, and the power frequency for melting is controlled to between 2,000 and 5,000 Hz and the superheat degree of an alloy liquid is controlled to between 50 and 180 DEG C under the condition of casting; static liquidforging press is adopted for modification of cast ingot tissues; forged ingots are slivered along the vertical direction from the intermediate part, and forged cracks caused by secondary hole shrinkage are completely eliminated; the forged ingots after elimination of the surface defects are forged at a temperature of between 840 and 900 DEG C; and unilateral rolling is adopted. The technology cangreatly improve the finished product rate of the low-nickel binary TiNi and ternary TiNiHf shape memory alloy sheet; and the alloy sheet prepared has superior internal quality, mechanical property and stable phase transition temperature.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

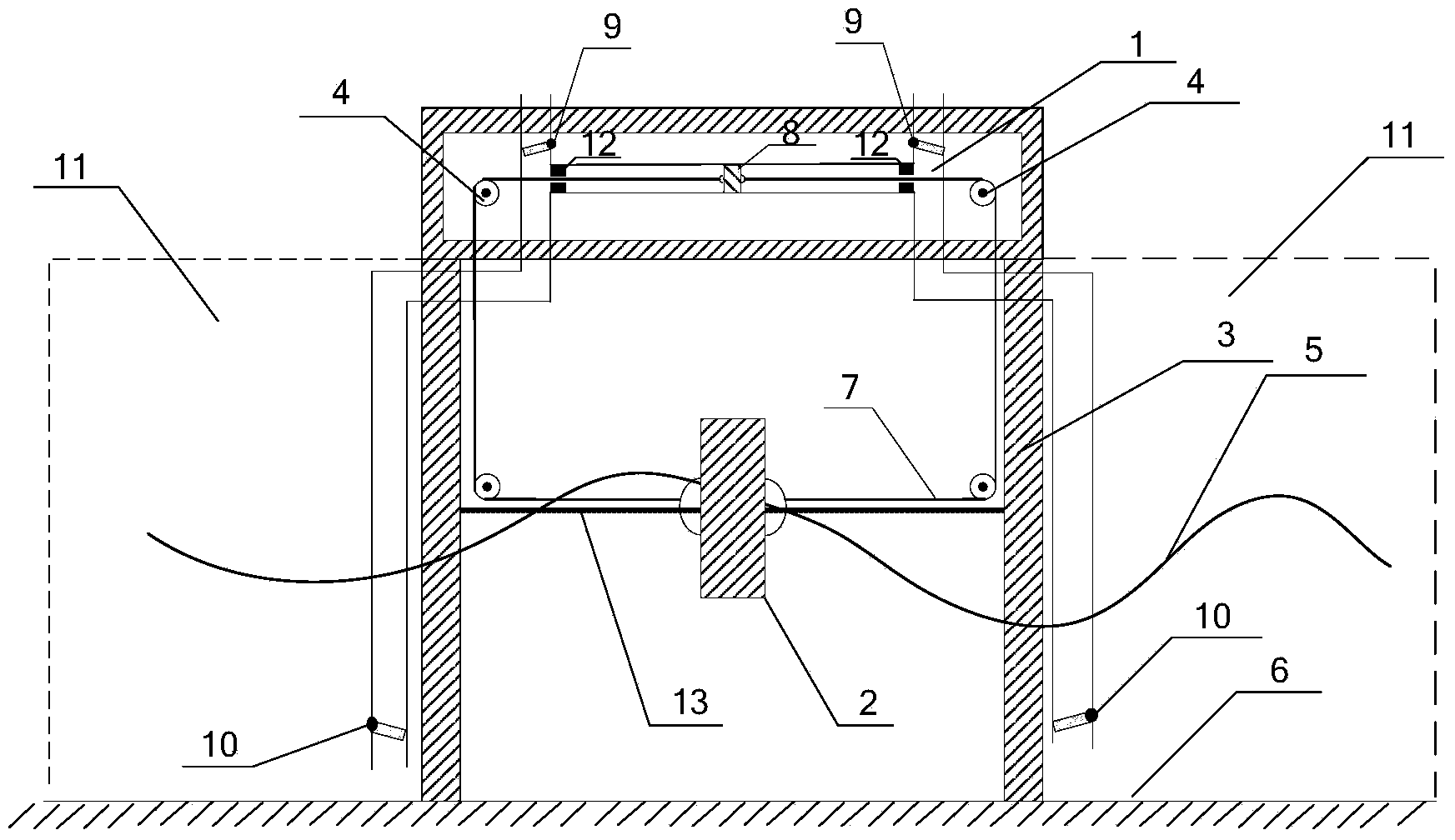

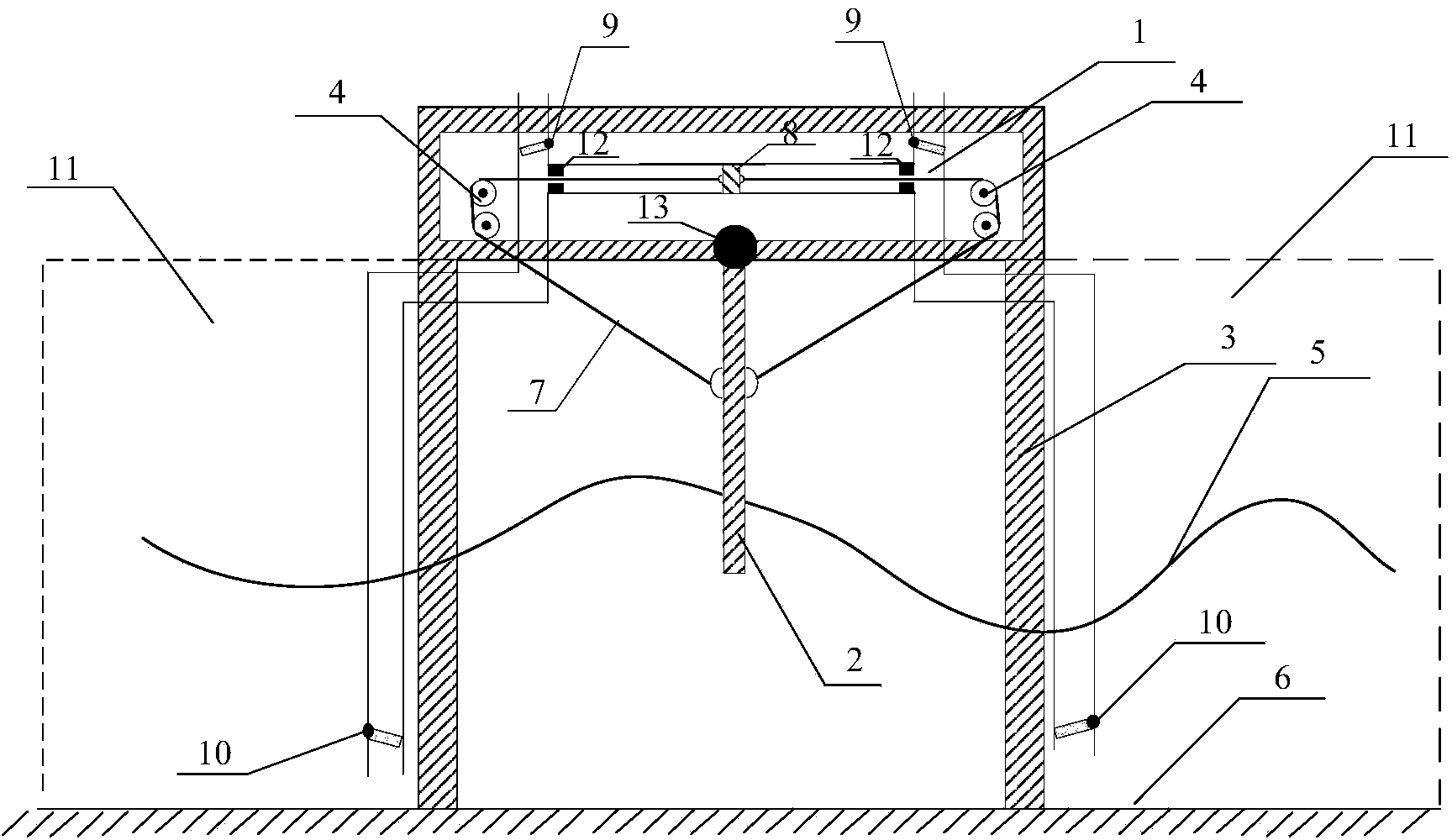

Oscillating float type wave energy oxygen supply device

InactiveCN104335962AEffective combinationAvoid oxygenationPisciculture and aquariaMachines/enginesOcean bottomAir compression

The invention belongs to the field of novel renewable energy technologies and aquaculture devices and particularly relates to an oscillating float type wave energy oxygen supply device. The oscillating float type wave energy oxygen supply device comprises an air compression pipeline, a float, vertical piles, a fixed pulley, a steel cable, a piston, an air check valve, an underwater check valve and fish culture chambers and is characterized in that the whole device is placed on a seabed foundation through the vertical piles; a sealed cabin is mounted above the vertical piles, and the air compression pipeline and the piston are mounted in the cabin; the float is distributed between two vertical piles and is connected with the piston through the steel cable and the fixed pulley; the fish culture chambers are positioned on the two sides of the device and are communicated with an oxygen supply device through the air compression pipeline. According to the design, air in the air compression pipeline can be driven to flow through the utilization of the elevation variation of the float in the wave transferring process, and oxygen is supplied to the fish culture chambers. The device has high reliability and is easy to manufacture, mount and move.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Cast steel riser covering agent as well as preparation and using method thereof

The invention belongs to the field of metallurgy, and relates to a cast steel riser covering agent as well as a preparation and using method thereof. The cast steel riser covering agent comprises thefollowing components of, with the total mass units being 100 parts, 15-40 parts of aluminum electrolysis waste cathode carbon block, 10-35 parts of dolomite, 10-25 parts of vermiculite, and 20-40 parts of aluminum electrolysis waste silicon carbide-silicon nitride bricks. During preparing, firstly, crushing and grinding the dried raw materials, wherein the particle size is not more than 2 mm; weighing the raw materials according to the composition quality of the raw materials, uniformly stirring, and drying to obtain the cast steel riser covering agent. During using, a steel ladle is added into the cast steel riser covering agent to form a slag layer, so that the thickness of the slag layer is 6-8 cm, the liquid surface of the steel ladle does not leak red, and the slag layer is not crusted. By using the cast steel riser covering agent, the heat loss at the top of the riser can be solved, the solidification speed of molten steel in the riser can be prolonged, the feeding capacity of the molten steel in the riser is improved, the process yield of the casting is guaranteed, the height of the riser is reduced, the molten steel is saved, and finally the cost is reduced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

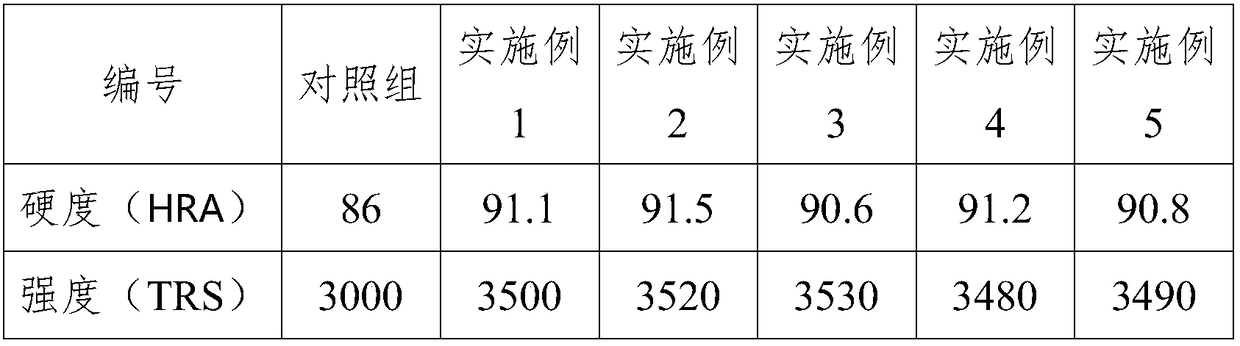

Hard alloy holding-up hammer dewaxing sintering method

PendingCN114178530AAccelerated exclusionUniform sizeTurbinesOther manufacturing equipments/toolsCemented carbideUltimate tensile strength

The invention discloses a hard alloy holding-up hammer dewaxing and sintering method which sequentially comprises the following steps: carrying out hydrogen dewaxing before 450 DEG C, filling argon between 450 DEG C and 600 DEG C to carry out negative-pressure dewaxing, then heating from 600 DEG C to 1250 DEG C to carry out vacuum sintering, filling argon to carry out pressure sintering from 1250 DEG C to 1415 DEG C, and carrying out vacuum sintering after the temperature is raised from 600 DEG C to 1250 DEG C; and finally preserving heat for 60 minutes, and then cooling to room temperature. The method has the advantages that the dewaxing mode that positive-pressure hydrogen dewaxing and negative-pressure argon dewaxing are matched is adopted, the dewaxing time is shortened to be within 2 days from original 5 days, argon is added into the sintering furnace in the sintering process, it is guaranteed that no gap defect exists in a product, and the product strength is improved.

Owner:ZHEJIANG HENGCHENG CEMENTED CARBIDE

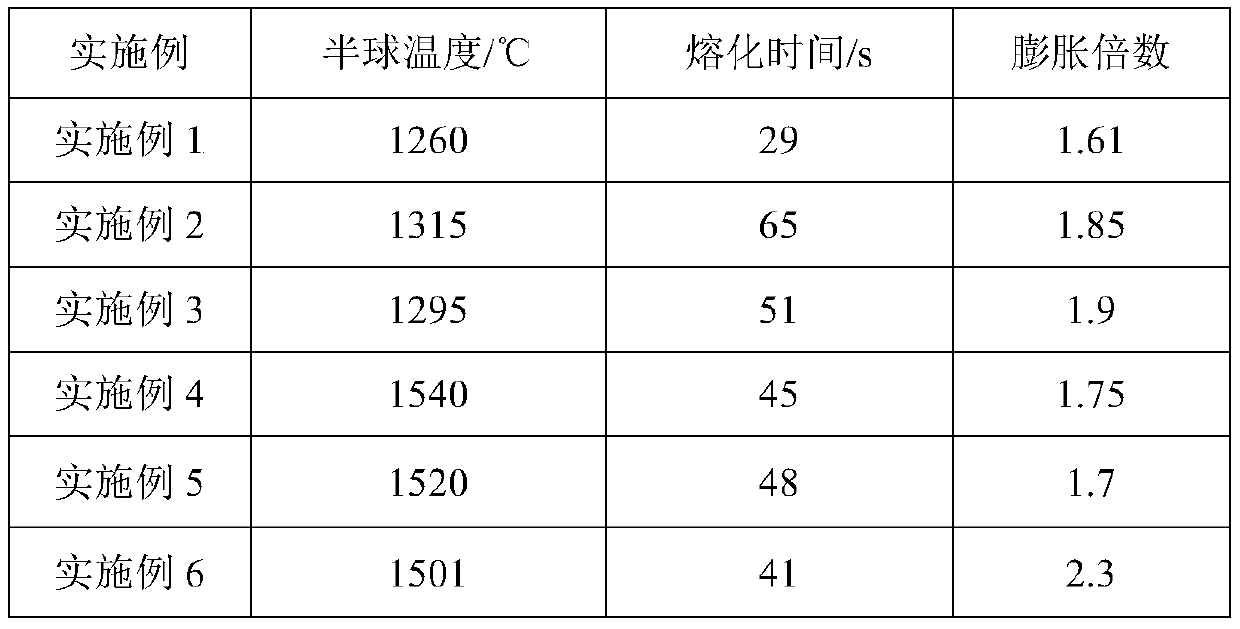

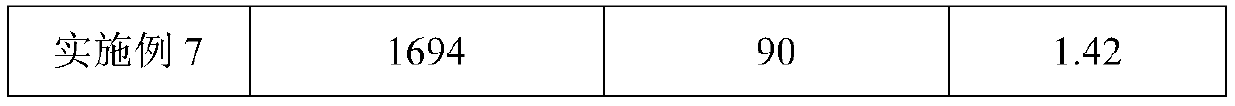

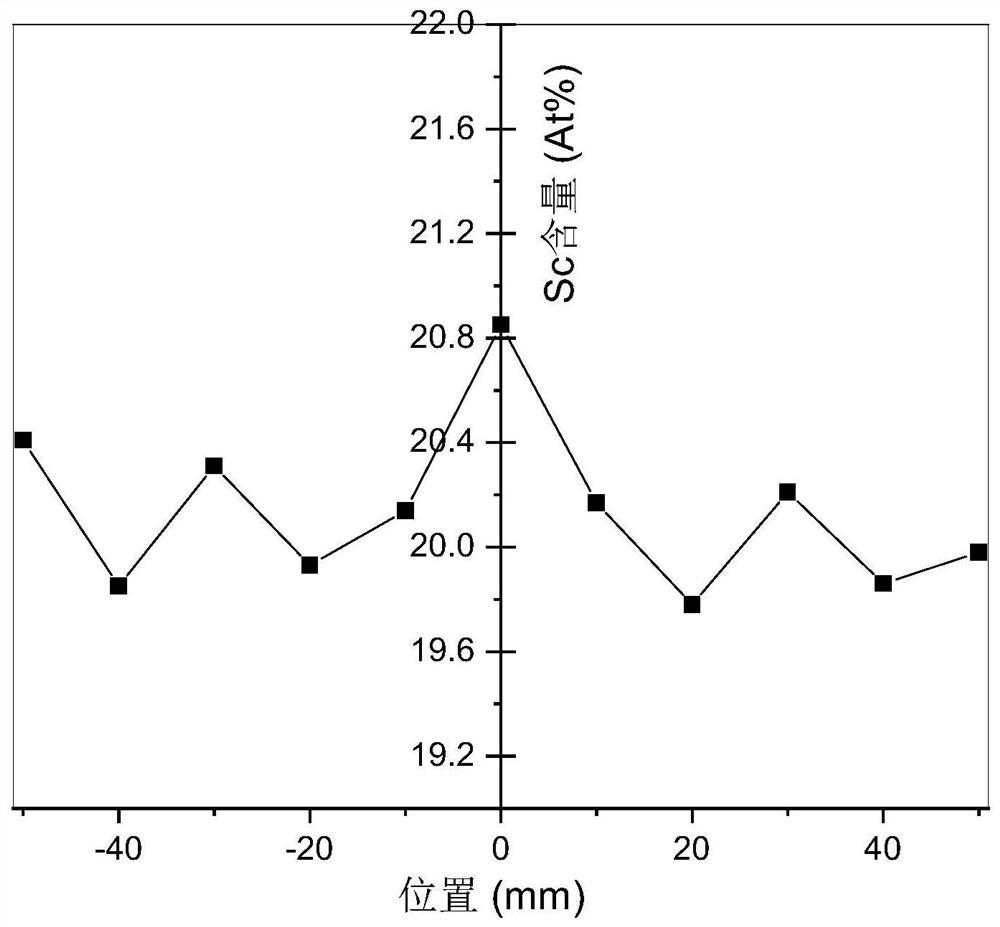

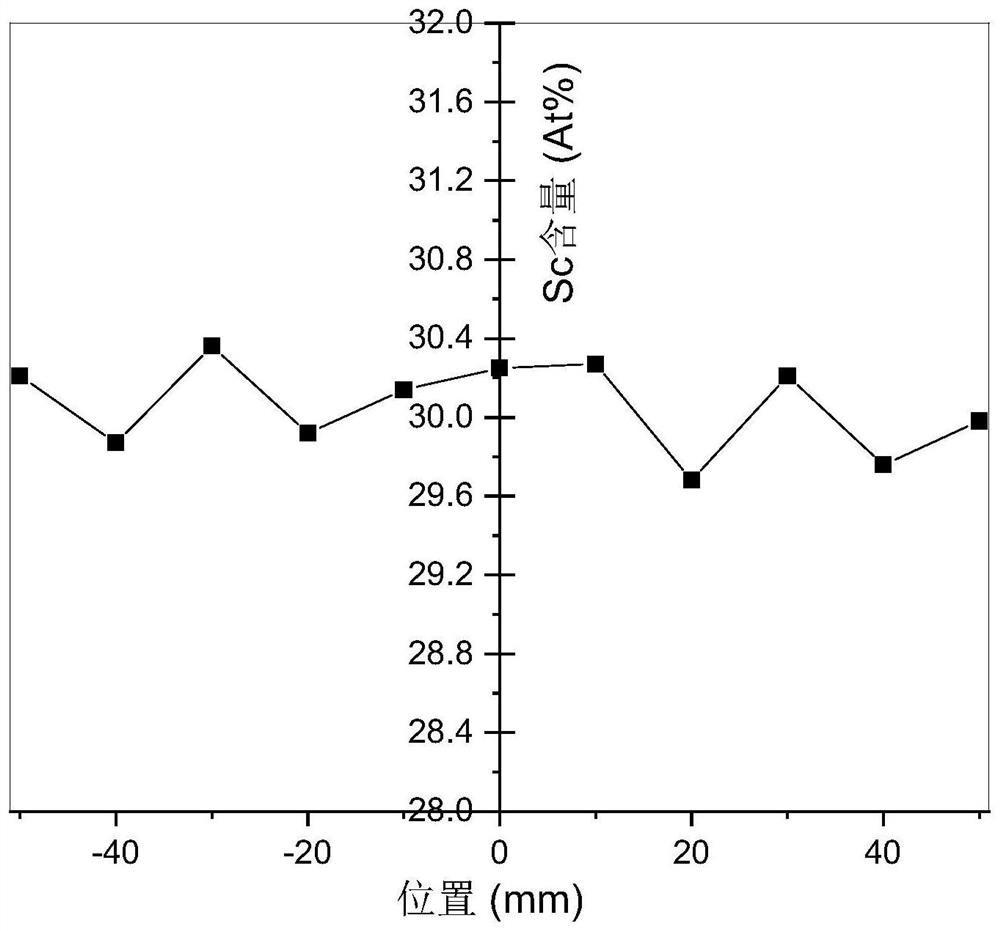

Preparation method and application of aluminum-scandium alloy sputtering target

PendingCN113373414AUniform compositionHigh densityVacuum evaporation coatingSputtering coatingAlloyAluminium

The invention provides a preparation method and application of an aluminum-scandium alloy sputtering target. The content of Sc is 8at%-53at%, the density is greater than 99%, the sum of the mass percentages of Al and Sc elements is greater than 99.9%, the oxygen content is less than 50ppm, and the aluminum-scandium alloy sputtering target is suitable for sputtering for forming a piezoelectric material film. The process is adjusted according to different Sc contents, the operation is simple, the oxygen content is low, the density is high, the components are uniform, and the segregation phenomenon is avoided.

Owner:HUNAN ORIENTAL SCANDIUM

Manufacturing process of hard alloy replaceable tool

InactiveCN109097655AHigh hardnessImprove toughnessTransportation and packagingMetal-working apparatusSlurryInjection moulding

The invention relates to the technical field of tool manufacturing, in particular to a manufacturing process of a hard alloy replaceable tool. The manufacturing process of a carbide replaceable tool comprises the following steps that preparing the raw materials, adding the raw materials to the an agitating ball mill, adding anhydrous ethanol, stirring and grinding for 4 hours to obtain a slurry; drying the slurry, sieving, and then adding the fully refined paraffin and stirring well to obtain a pellet, and then the pellet after adding zinc stearate, molding, extrusion, and injection molding; placing the formed blank in a vacuum sintering integrated furnace, and introducing argon gas, followed by sintering; and sintering the blank on a lathe. After the initial processing of the tool, the quenching heat treatment is performed after the initial processing, and the blank after the quenching and heat treatment is finished on the grinding machine, and then nano WC-Co super-hard composite coating is sprayed on the surface of the tool by using the electric spark surface cladding device. The manufacturing process of the hard alloy replaceable tool has high hardness, good toughness, stable quality, is not easy to be broken, and has simple process and is suitable for industrial production.

Owner:MAANSHAN HENGLIDA MACHINE BLADE

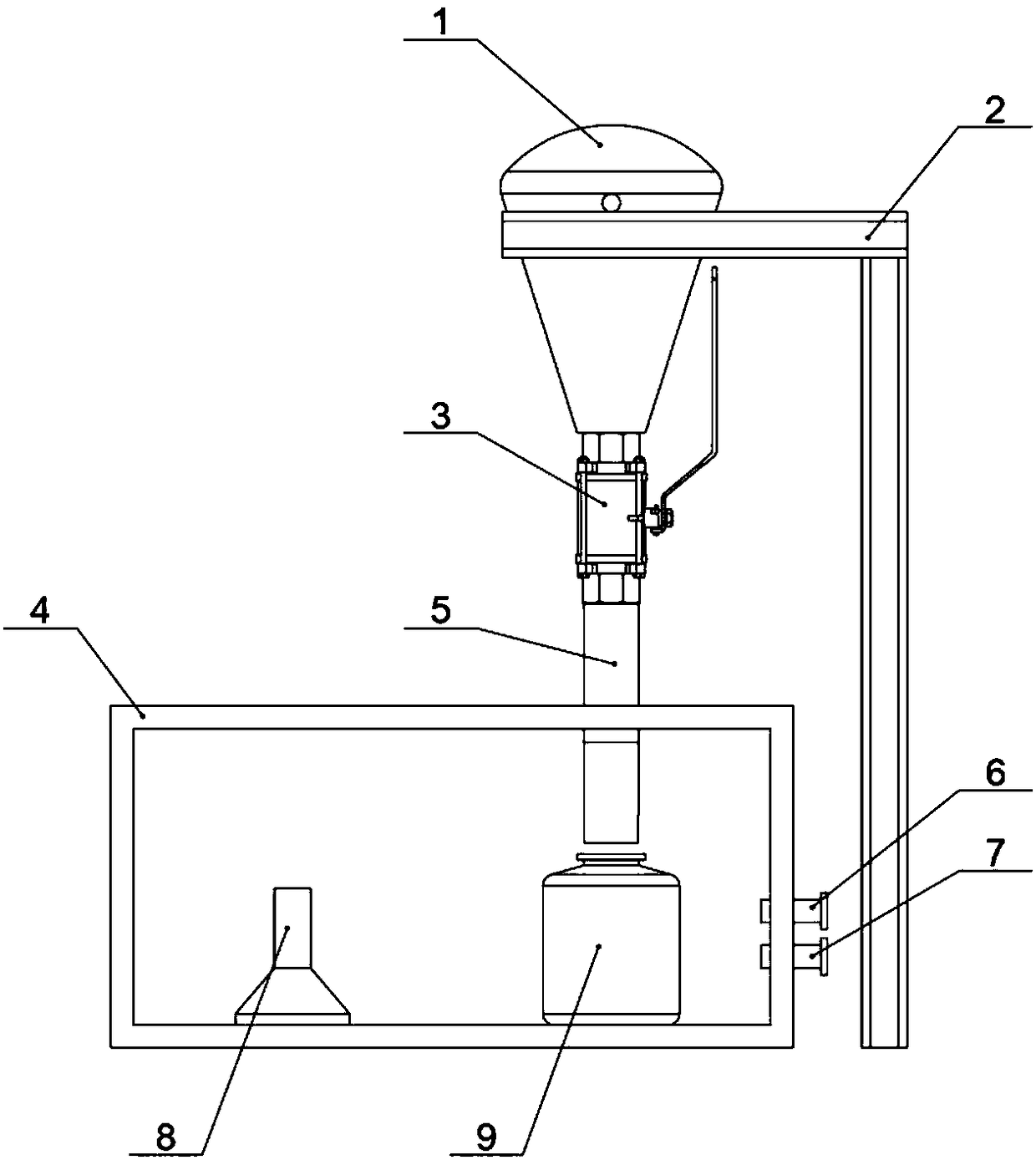

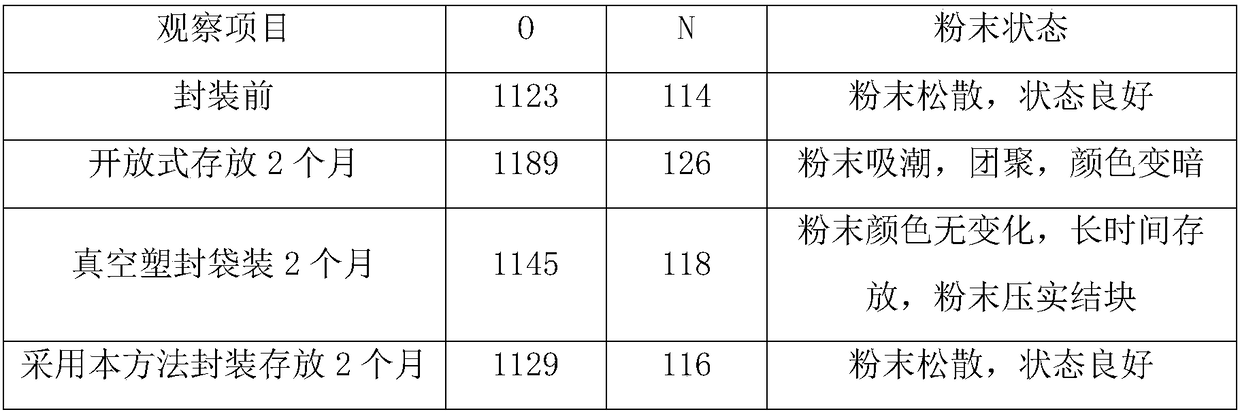

Packaging device for reactive metal powder for 3D printing

PendingCN108438316AImprove sealingPrevent moisture absorptionPackaging by pressurising/gasifyingExhaust valveVacuum extraction

The invention discloses a packaging device for reactive metal powder for 3D printing and belongs to the technical field of powder packaging. The device comprises a material collection tank, a materialtank support, a feeding ball valve, a glove box, a stainless steel pipe, an exhaust valve, a gas inlet valve and the like. The material collection tank stands upside down on the material tank support. A tank opening is connected with the feeding ball valve. The lower end of the feeding ball valve is connected with the stainless steel pipe. The stainless steel pipe communicates with the interior of the glove box. When the packaging device is used, firstly, the device is mounted, the glove box is opened, and a packaging barrel is put into the glove box; in the vacuum extraction and argon gas charging process, exhaust and inflation of the glove box are achieved through the exhaust valve and the gas inlet valve; powder feeding is conducted through the feeding ball valve (3); and finally, opening sealing is conducted through an electro-magnetic induction opening sealer (8). The packaging device has the beneficial effects that good sealing performance is achieved; and the problems that powder absorbs moisture and is oxygenated and contaminated by impurities due to manual powder feeding are avoided.

Owner:中航迈特增材制造(固安)有限公司

Method for semi-continuously preparing TiAl base alloy automobile air valve and components with similar shape

The present invention relates to preparative technique for automobile air valve and parts of similar shape, specifically speaking, the present invention is a semi-continuous method for preparing TiA1-based alloy automobile air valve and parts of similar shape. The present invention adopts the method of vacuum pouring after semi-continuous induction melting in a vacuum pouring furnace: take the spongy titanium, industrial pure aluminum and other alloy elements as the raw materials and adopt a CaO formed ceramic pot for vacuum induction melting; the cast shell mold consists of part mold shell such as air valve, etc., intermediate flow trays and a vacuum pouring pipe; the intermediate flow trays are evenly distributed in the lengthwise direction of the air valve part; the technique parameters of the vacuum pouring are that the shell mold temperature is between 50 to 800 Celsius degrees and the vacuum pouring pressure difference is2.0 multiplied by 104-7.0 multiplied by 104Pa. The present invention can semi-continuously produce parts which have complicated shapes and are hard to be formed with high-melting point, high-activity Ti A1-based materials and the cost is low; in addition, the produced automobile air valve boasts of excellent internal quality and stable casting performance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

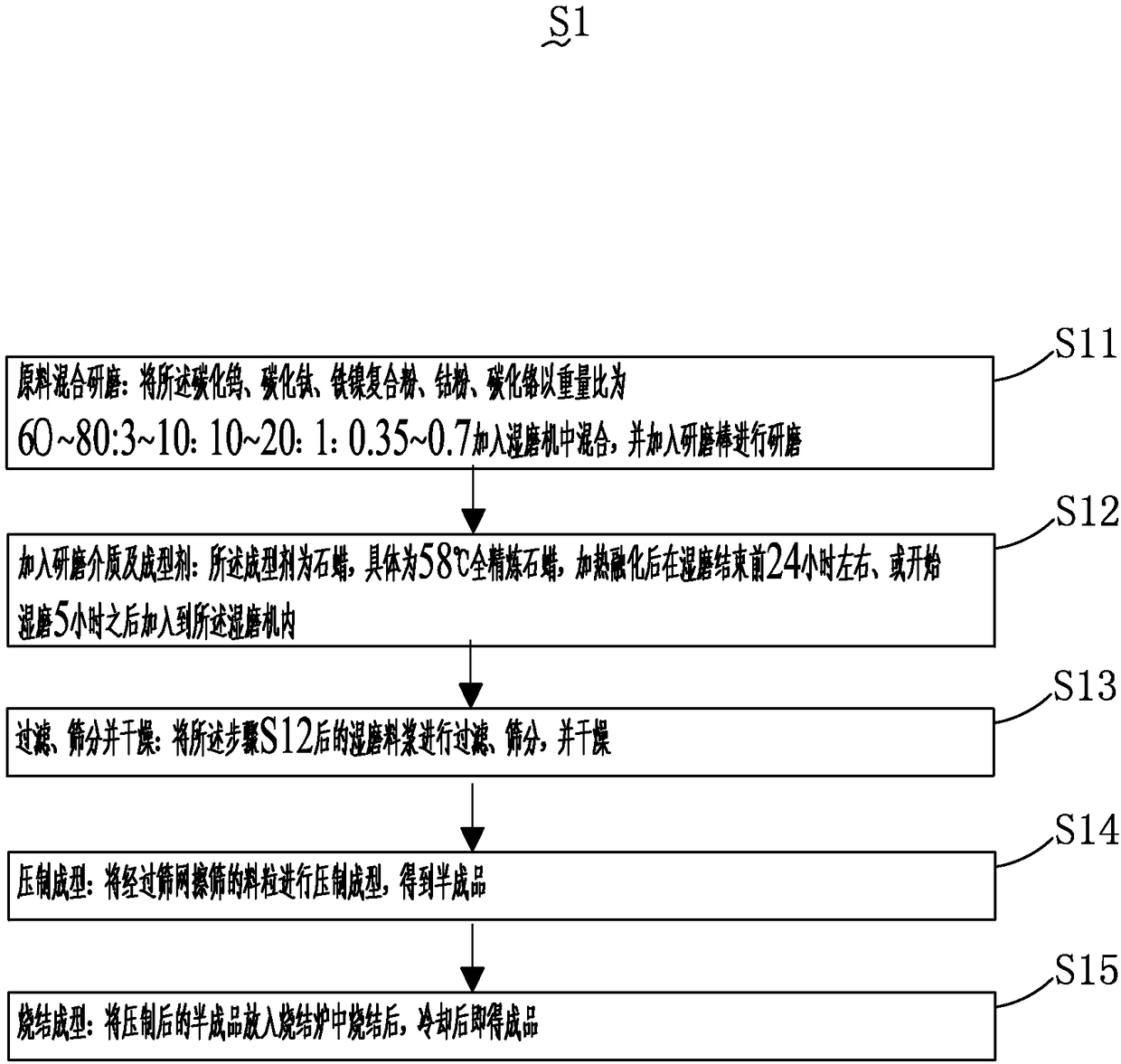

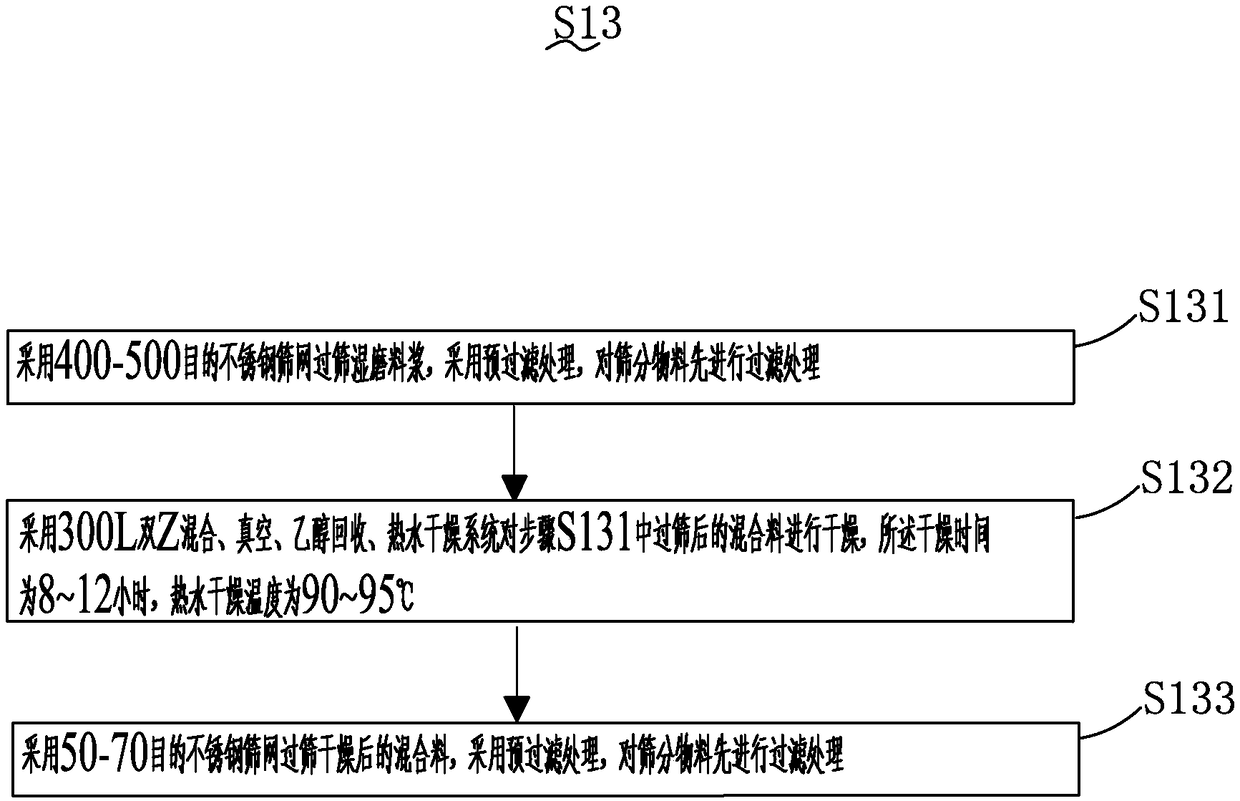

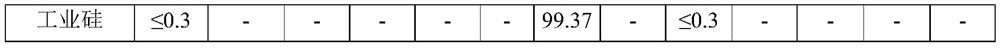

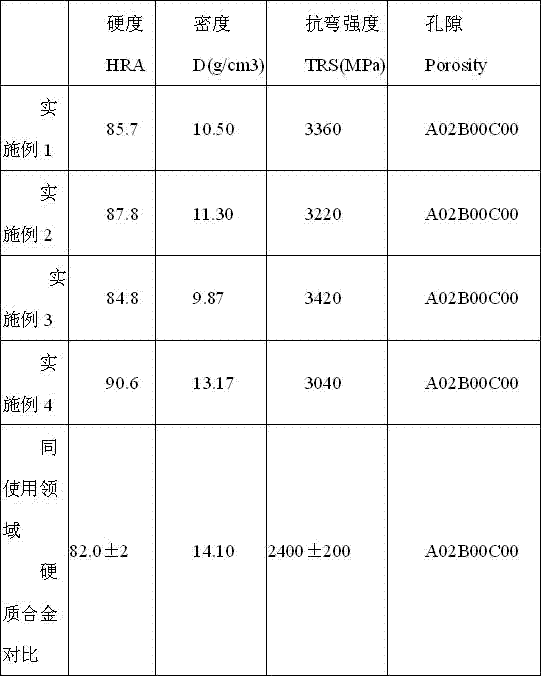

Cemented carbide with iron-nickel substituting cobalt and titanium substituting part of tungsten and its production process

The invention provides a novel hard alloy with iron and nickel replacing cobalt and titanium replacing part of tungsten and a production technology of the novel hard alloy. The novel hard alloy with the iron and the nickel replacing the cobalt and the titanium replacing part of the tungsten is a hard alloy prepared from raw materials including tungsten carbide, titanium carbide, iron and nickel composite powder, cobalt powder and chromium carbide with the weight ratio being (60-80):(3-10):(10-20):1:(0.35-0.7). By means of the novel hard alloy with the iron and the nickel replacing the cobalt and the titanium replacing part of the tungsten, a novel hard alloy material with iron and nickel replacing cobalt and titanium replacing part of tungsten is adopted, the problems that the price of cobalt stays at a high level and tungsten and cobalt resources are less and less are solved, environment pollution is reduced through the production technology, and the problem of potential safety hazards is solved; and meanwhile, the pressing forming performance of the hard alloy and the quality of the hard alloy material are ensured, and a wide and long-range application prospect is achieved.

Owner:ZHUZHOU SANXIN HARD ALLOY PRODN CO LTD

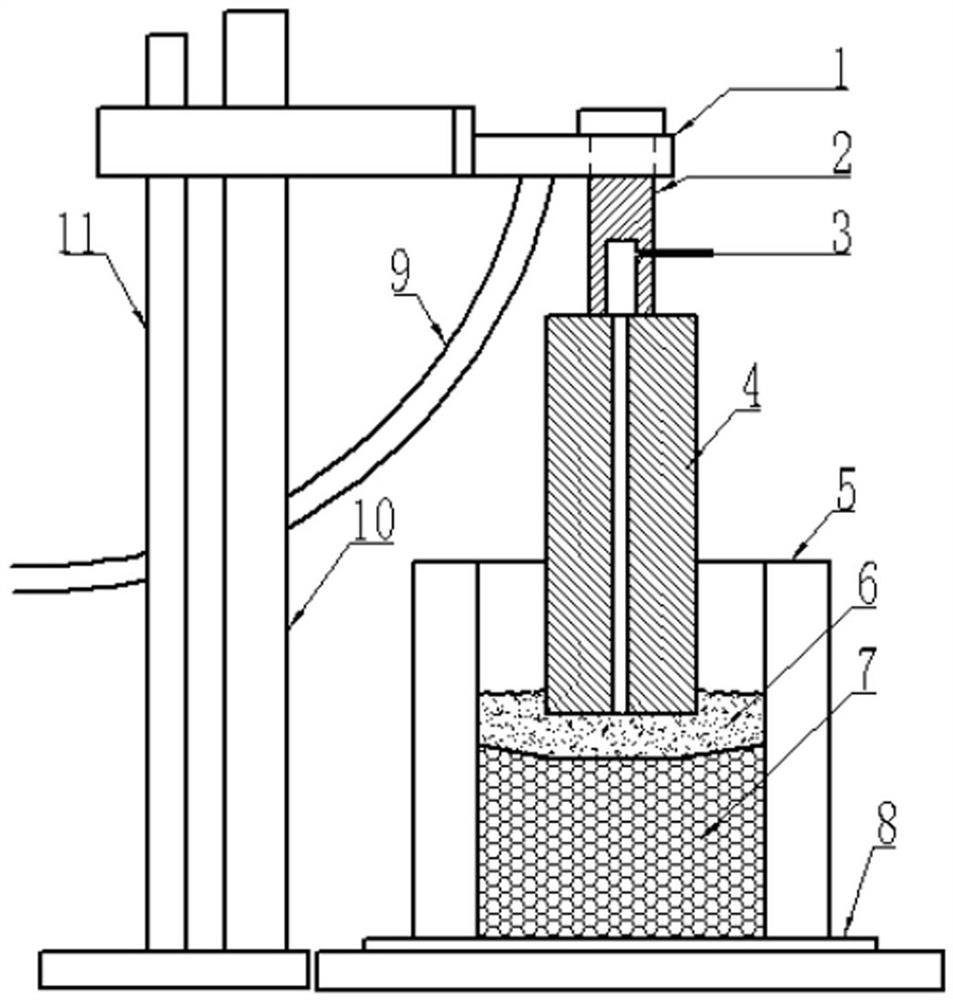

A high-nitrogen steel consumable electrode for pressurized electroslag remelting and its preparation method

ActiveCN113106265BPrevent leakageAvoid oxygenationIncreasing energy efficiencySlag (welding)Molten steel

One aspect of the present invention provides a consumable electrode for pressurized electroslag remelting high-nitrogen steel, which includes a base material of the consumable electrode and at least two cored tubes embedded in the base material of the consumable electrode; the cored tube includes The iron pipe and the nitride alloy filled in the iron pipe, the first end of the cored pipe is located at the end where the consumable electrode base material is inserted into the slag pool, and the second end of the cored tube is located at the end where the consumable electrode base material is away from the slag pool one end. It avoids the leakage of nitrided alloy in the process of electroslag remelting, and improves the composition distribution from the core to the edge of the remelted steel ingot. Another aspect of the present invention provides a method for preparing a consumable electrode for pressurized electroslag remelting high-nitrogen steel, which avoids the oxygenation of molten steel caused by welding, and has a simple preparation process and low cost.

Owner:NORTHEASTERN UNIV LIAONING

Heat-resisting steel flux-cored wire

InactiveCN101450425BSimple welding processImproved arc stabilityArc welding apparatusWelding/cutting media/materialsFerrochromeRutile

Owner:NINGBO LONGXING WELDING CUTTING TECH STOCK

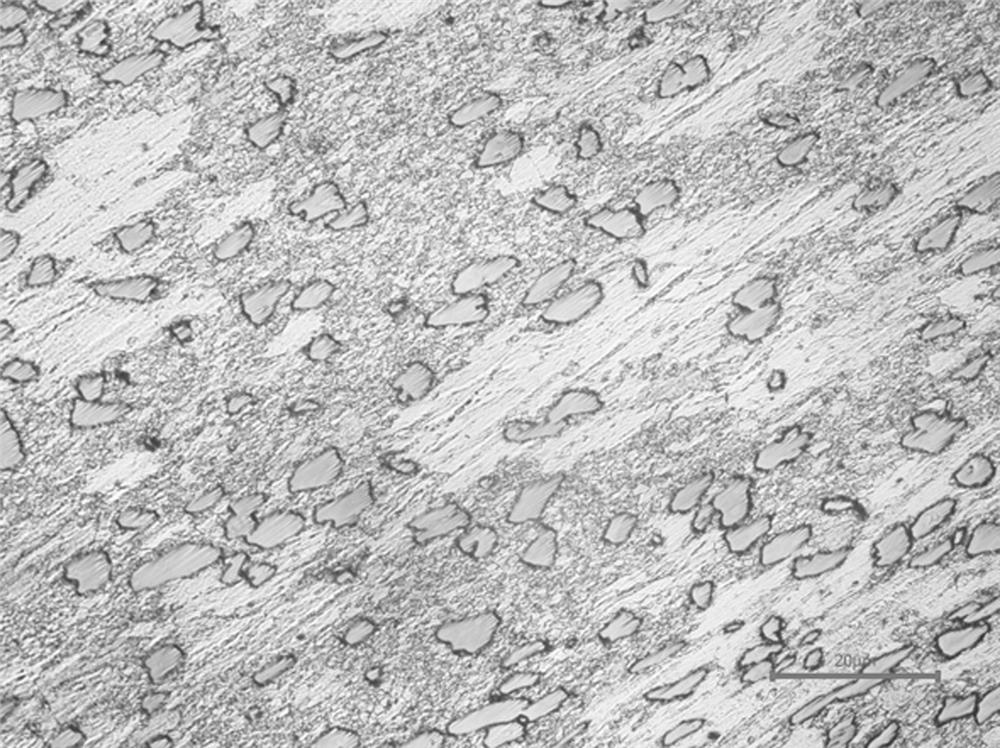

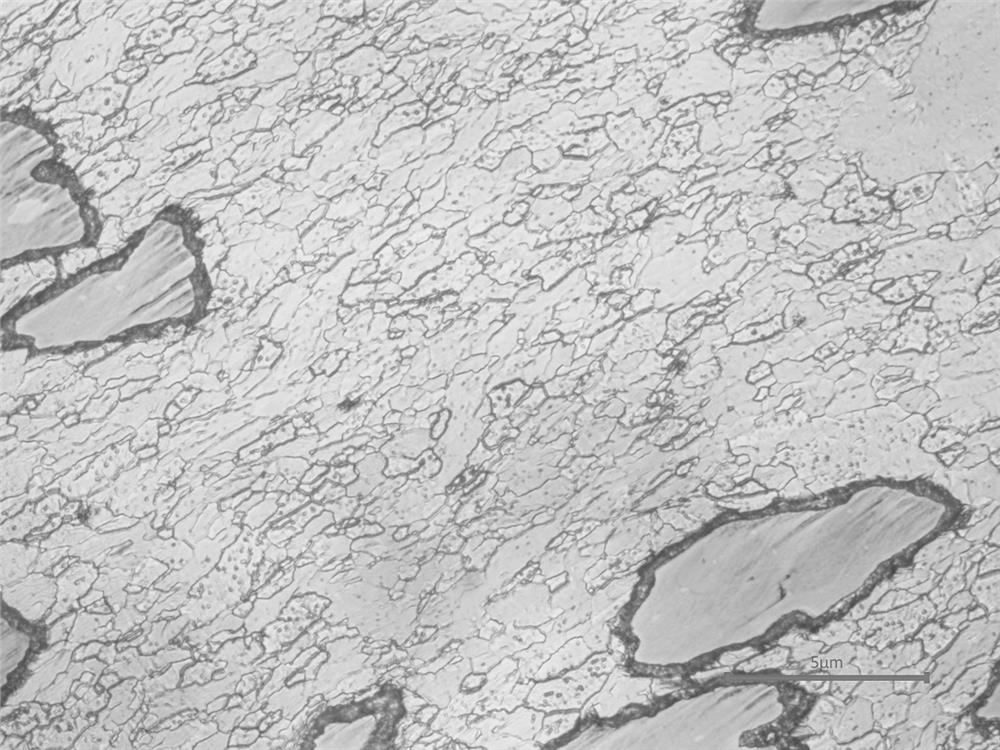

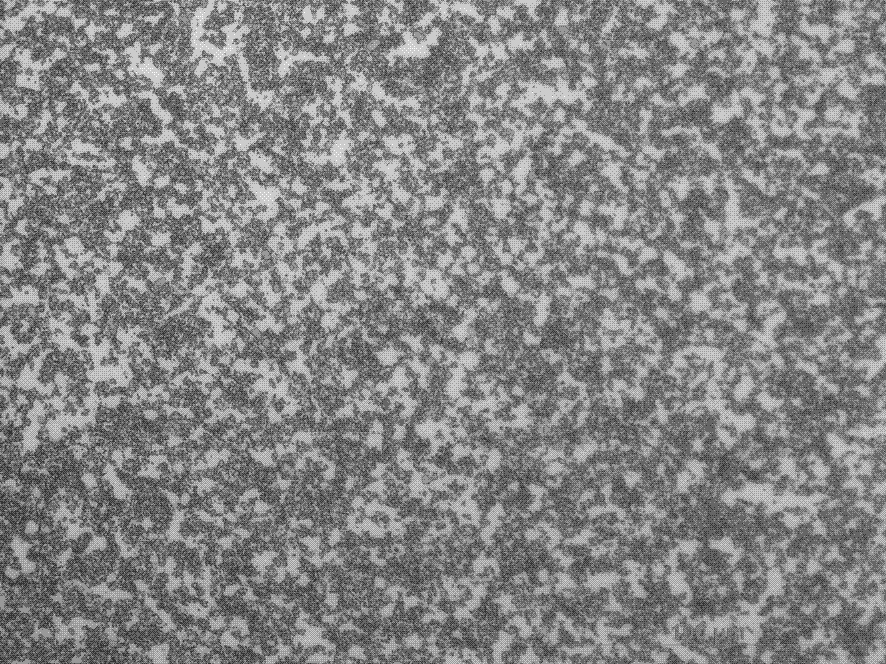

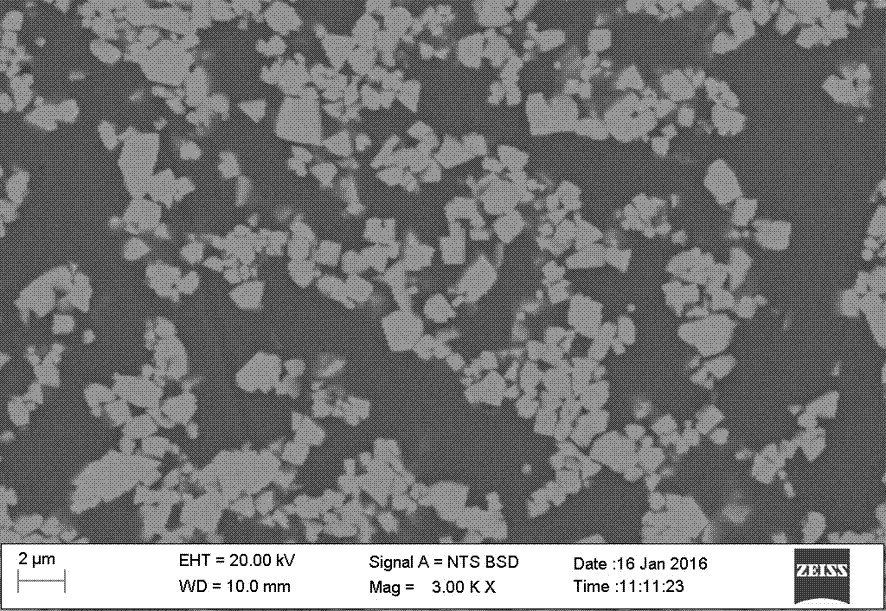

A kind of steel-bonded hard alloy and preparation method thereof

ActiveCN106086575BFully integratedImprove uniformityTransportation and packagingMetal-working apparatusPorosityWear resistant

A steel-bonded hard alloy, with WC as the hard phase and Fe as the binder phase, the weight percentage distribution ratio of each component in the alloy is: WC 40‑80%, Fe 15%‑55%, Cr3C2 0.5%‑ 4%, carbon black 0.1%‑0.5% and WB 0.5%‑5%. The preparation method includes batching-wet grinding-spray drying-compression molding-sintering-heat treatment and the like. The prepared cemented carbide has low porosity, excellent wear resistance, corrosion resistance, impact resistance and high strength and toughness. The bending strength can reach more than 4000N / mm2, which exceeds 10% of cemented carbide with the same binder phase content in some application fields. %‑30%. The raw materials required by the alloy of the present invention are cost-effective, and the preparation method meets the requirements of industrial mass production, which greatly expands the application scope of steel-bonded hard alloys, and can meet the wear resistance and toughness requirements of mold materials, wear-resistant parts and mining tools, etc. Both are used in high industrial fields.

Owner:LUOYANG GOLDEN EGRET GEOTOOLS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com