Packaging device for reactive metal powder for 3D printing

An active metal, 3D printing technology, applied in packaging, packaging by pressurization/gasification, etc., can solve the problems of increased oxygen content required for purity, moisture absorption and agglomeration of powder, and easy to be polluted by oxygen, so as to reduce external impurities. Mixed, solve the problem of oxygenation, avoid the effect of moisture absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

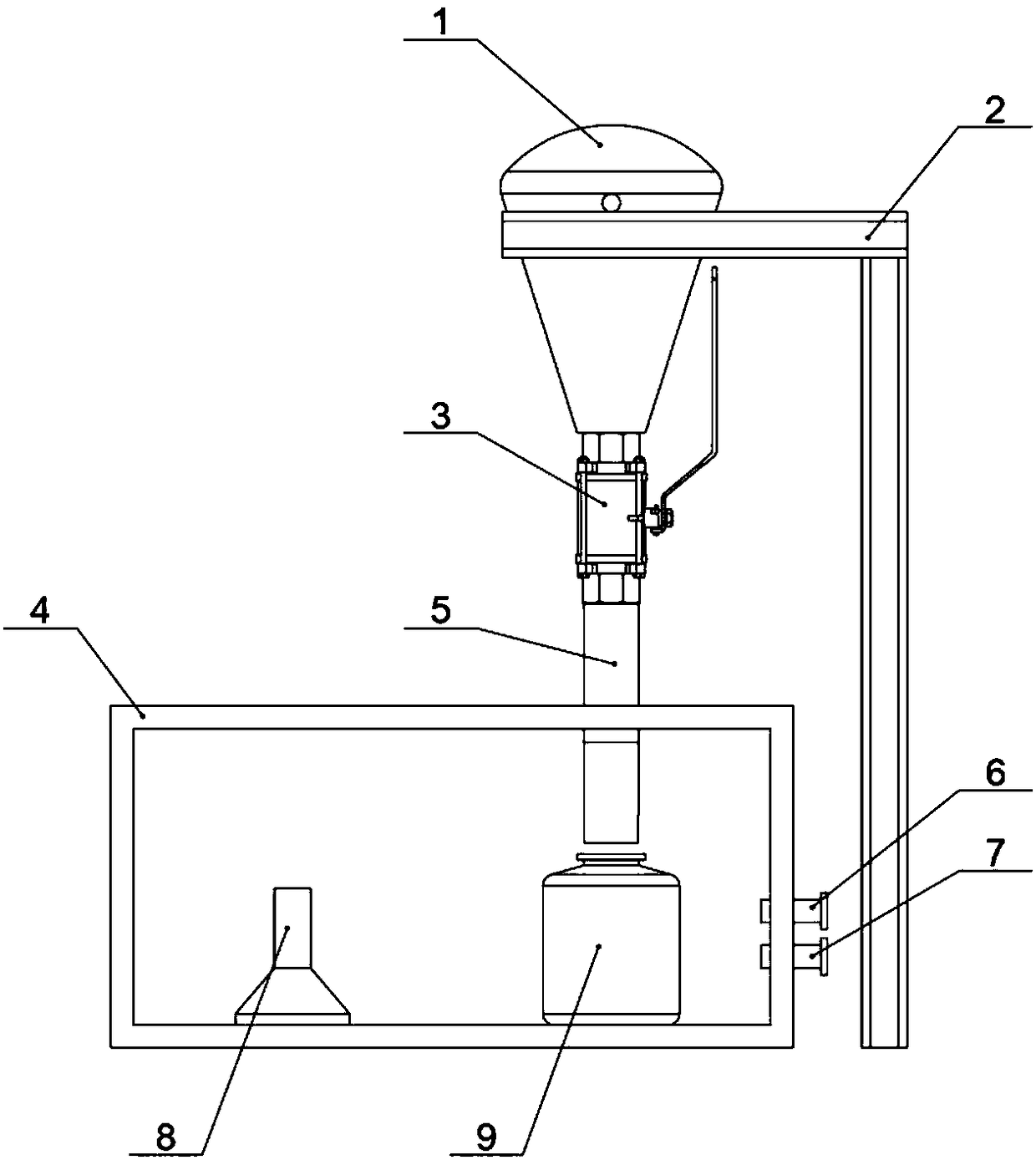

[0023] A packaging device for active metal powder for 3D printing, including a collection tank 1, a tank bracket 2, a feed ball valve 3, a glove box 4, a stainless steel pipe 5, an exhaust valve 6, an air intake valve 7, and an electromagnetic induction sealer 8 and barrel 9. The collecting tank 1 filled with metal powder is placed upside down on the tank bracket 2, the mouth of the collecting tank 1 is connected to the feed ball valve 3, the lower end of the feed ball valve 3 is connected to the stainless steel pipe 5, and the stainless steel pipe 5 is connected to the inside of the glove box 4 , through the feeding ball valve 3 to control the feeding amount of the powder, the glove box 4 is equipped with an exhaust valve 6 and an intake valve 7, and the glove box 4 is vacuumed and filled with argon through the exhaust valve 6 and the intake valve 7. Exhaust and inflate; the electromagnetic induction sealer 8 is located in the glove box 4, the lower end of the stainless steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com