Method for preparing pigment carbon black from waste and abandoned tires

A technology for pigmented carbon black and waste tires, which is applied in the direction of fibrous fillers, etc., can solve the problems of reduced oxygen content on the surface of carbon black, tires cannot be fully utilized, and high processing costs, so as to increase adsorption performance, realize full utilization, and reduce waste. The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

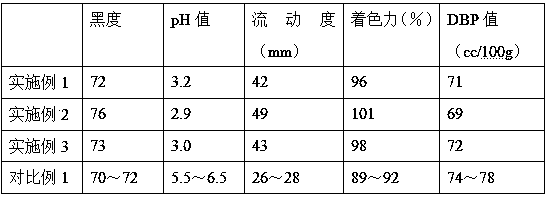

Examples

preparation example Construction

[0020] A kind of method utilizing discarded tire to prepare pigment carbon black, this preparation method comprises the steps:

[0021] (1) Wash the waste tires, crush them, pass through a 200-mesh sieve, collect the sieved particles, put the sieved particles and additives into a ball mill at 300r / min for 20-30min at a mass ratio of 7:1-3 , then add acetone with a sieved particle mass of 15-20%, ball mill at 400r / min for 45-50min, and collect the ball-milled product;

[0022] (2) Put the ball mill into the reactor, use carbon dioxide to discharge the gas in the reactor, heat up to 756-763°C for pyrolysis for 4-7 hours, then cool down to room temperature, collect the pyrolysis mixture, and dispose of the pyrolysis mixture Place it at 10-15°C for 40 minutes;

[0023] (3) After standing still, ultrasonically oscillate the pyrolysis mixture after standing with sodium hydroxide solution at a mass ratio of 1:4, put it into a container, use nitrogen protection, and then add sodium h...

example 1

[0028] Preparation of additives: Mix sodium carbonate and ferric sulfate at a mass ratio of 4:3.

[0029] Preparation of additives: Mix nitrobenzene and boric acid at a mass ratio of 7:1.

[0030] A kind of method utilizing discarded tire to prepare pigment carbon black, this preparation method comprises the steps:

[0031] (1) Wash the waste tires, crush them, pass through a 200-mesh sieve, collect the sieved particles, put the sieved particles and additives into a ball mill at 300r / min for 30min at a mass ratio of 7:3, and then add over Sieve acetone with 20% particle mass, ball mill at 400r / min for 50min, and collect the ball mill;

[0032] (2) Put the ball mill into the reactor, use carbon dioxide to discharge the gas in the reactor, heat up to 763°C for pyrolysis for 7 hours, then cool down to room temperature, collect the pyrolysis mixture, and place the pyrolysis mixture at 15°C Stand still for 40min;

[0033] (3) After standing still, ultrasonically oscillate the py...

example 2

[0038] Preparation of additives: Mix sodium carbonate and ferric sulfate at a mass ratio of 4:2.

[0039] Preparation of additives: Mix nitrobenzene and boric acid at a mass ratio of 7:1.

[0040] A kind of method utilizing discarded tire to prepare pigment carbon black, this preparation method comprises the steps:

[0041] (1) Wash the waste tires, crush them, pass through a 200-mesh sieve, collect the sieved particles, put the sieved particles and additives into a ball mill at 300r / min for 25 minutes at a mass ratio of 7:2, and then add over Sieve acetone with a particle mass of 18%, ball mill at 400r / min for 48min, and collect the ball mill;

[0042](2) Put the ball mill into the reactor, use carbon dioxide to discharge the gas in the reactor, heat up to 760°C for pyrolysis for 5 hours, then cool down to room temperature, collect the pyrolysis mixture, and place the pyrolysis mixture at 13°C Stand still for 40min;

[0043] (3) After standing still, ultrasonically oscilla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com