A high-nitrogen steel consumable electrode for pressurized electroslag remelting and its preparation method

A technology of consumable electrode and pressurized slag, which is applied in the smelting field of high nitrogen steel, can solve the problems of oxygenation of molten steel, excessive Si content, uneven distribution of nitrogen content, etc., to improve composition distribution and increase outer diameter. Size, the effect of avoiding the oxygenation of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The embodiment of the present invention also proposes a method for preparing a consumable electrode for pressurized electroslag remelting high nitrogen steel, comprising the following steps:

[0048] Step S1. Determine the nitrogen content of the consumable electrode base material according to the chemical composition of the designed steel type, and determine the core cladding according to the target weight of the designed steel type, the nitrogen content of the designed steel type, and the nitrogen content of the consumable electrode base material The amount of nitrided alloy in the tube and prepare the nitrided alloy.

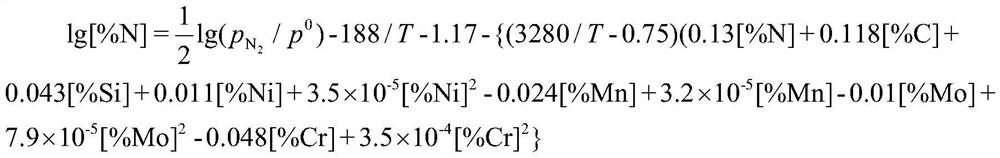

[0049] Specifically, according to the chemical composition of the designed steel, determine the nitrogen content of the consumable electrode base material, including: according to the chemical composition of the designed steel, determine the limit nitrogen content of the designed steel under normal pressure, according to the designed steel Determine th...

Embodiment 1

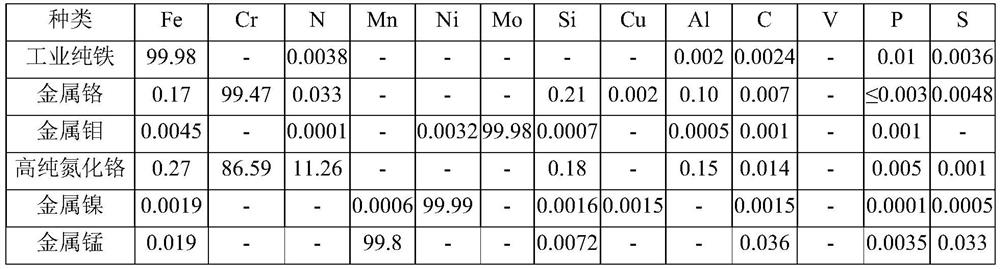

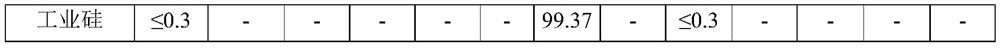

[0066] Prepare 250kg of design steel grade 18Cr20Mn2Ni1Mo0.3Si1N, its composition (wt.%) is shown in Table 1.

[0067] Table 1 Composition of design steel grade 18Cr20Mn2Ni1Mo0.3Si1N

[0068] Element type C mn Cr Si Ni Mo N P S Fe Component range ≤0.05 18~22 16.5~19.8 ≤0.3 ≤2.1 ≤1 0.95~1.05 ≤0.03 ≤0.01 margin target ingredient 0.05 20 18 0.3 2 1 1 0.03 0.01 margin

[0069] Step S1, according to the chemical composition of the designed steel grade, determine the limit nitrogen content [%N]=0.988 of the designed steel grade 18Cr20Mn2Ni1Mo0.3Si1N at 1520°C and 0.07MPa nitrogen partial pressure, according to the limit of the designed steel grade under this pressure Nitrogen content and empirical correction value, it is determined that the nitrogen content of the consumable electrode base material is 0.988%×0.7=0.642%. According to the target weight of the designed steel grade, the nitrogen content of the designed steel ...

Embodiment 2

[0095] 200kg of design steel grade 21Cr23Mn2.5Ni1Mo0.5Si1.6N was prepared, and its composition (wt.%) is shown in Table 6.

[0096] Table 6 Composition of Design Steel Type 21Cr23Mn2.5Ni1Mo0.5Si1.6N

[0097]

[0098]

[0099] Step S1, according to the chemical composition of the designed steel, determine the limit nitrogen content of the designed steel 21Cr23Mn2.5Ni1Mo0.5Si1.6N at 1510°C and 0.07MPa nitrogen partial pressure [%N]=1.635, according to the designed steel here Based on the limit nitrogen content under pressure and the empirical correction value, it is determined that the nitrogen content of the base material of the consumable electrode is 1.635%×0.7=1.063%. According to the target weight of the designed steel grade, the nitrogen content of the designed steel grade, the nitrogen content of the consumable electrode base metal and the recovery rate of nitrogen in the chromium nitride, the nitrogen content provided by the nitrided alloy is (1.6-1.063) / 0.80×100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com