Method and device for regenerating circular wash oil during rich oil debenzolization of gas purification

An oil-washing and oil-enriching technology, used in combustible gas purification, combustible gas purification/transformation, petroleum industry, etc., can solve the problems of high-pressure furnace heat load, high process energy consumption, large direct steam volume, etc. Effect of heat load, reduction of processing capacity, and temperature reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

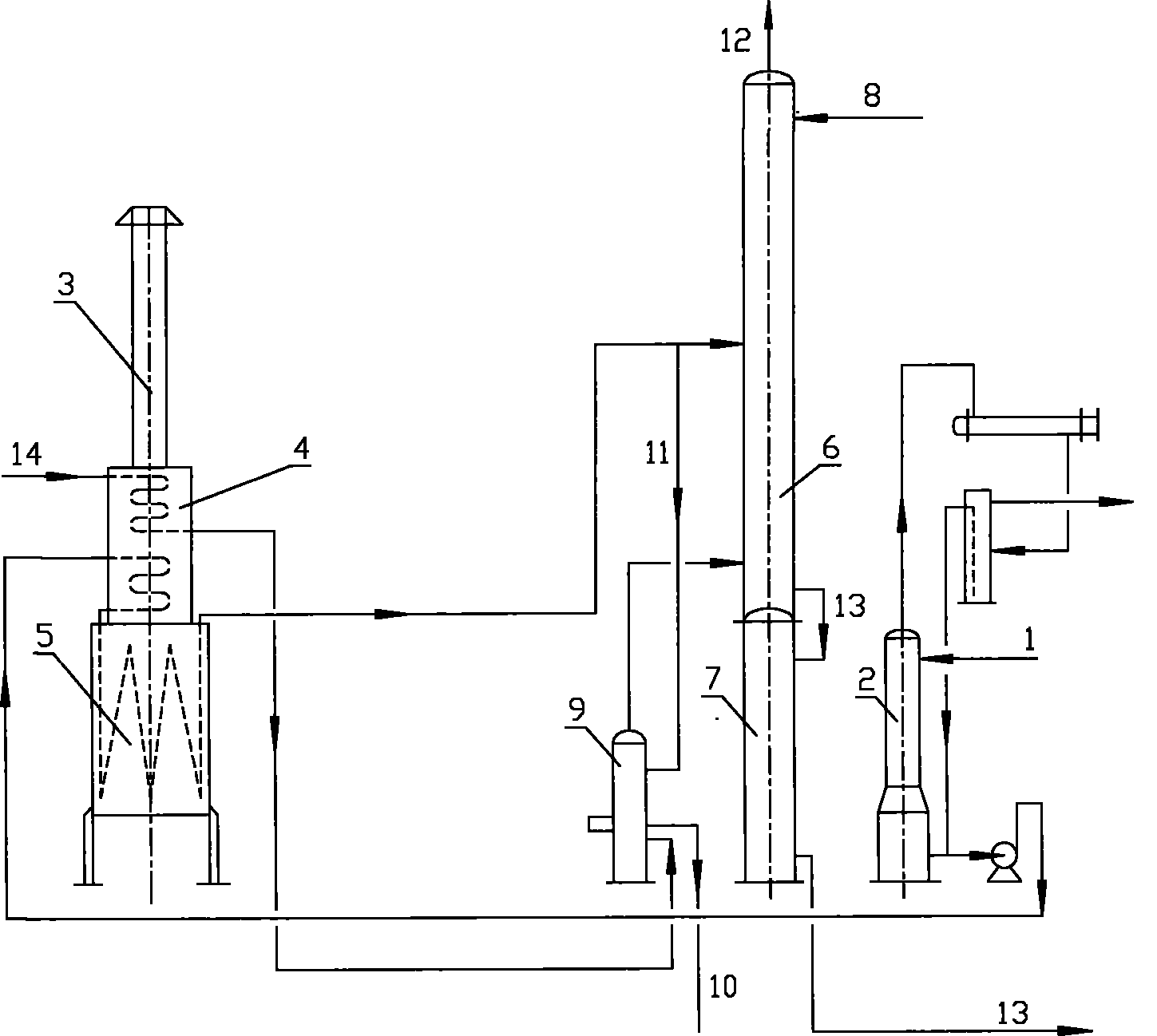

Method used

Image

Examples

Embodiment Construction

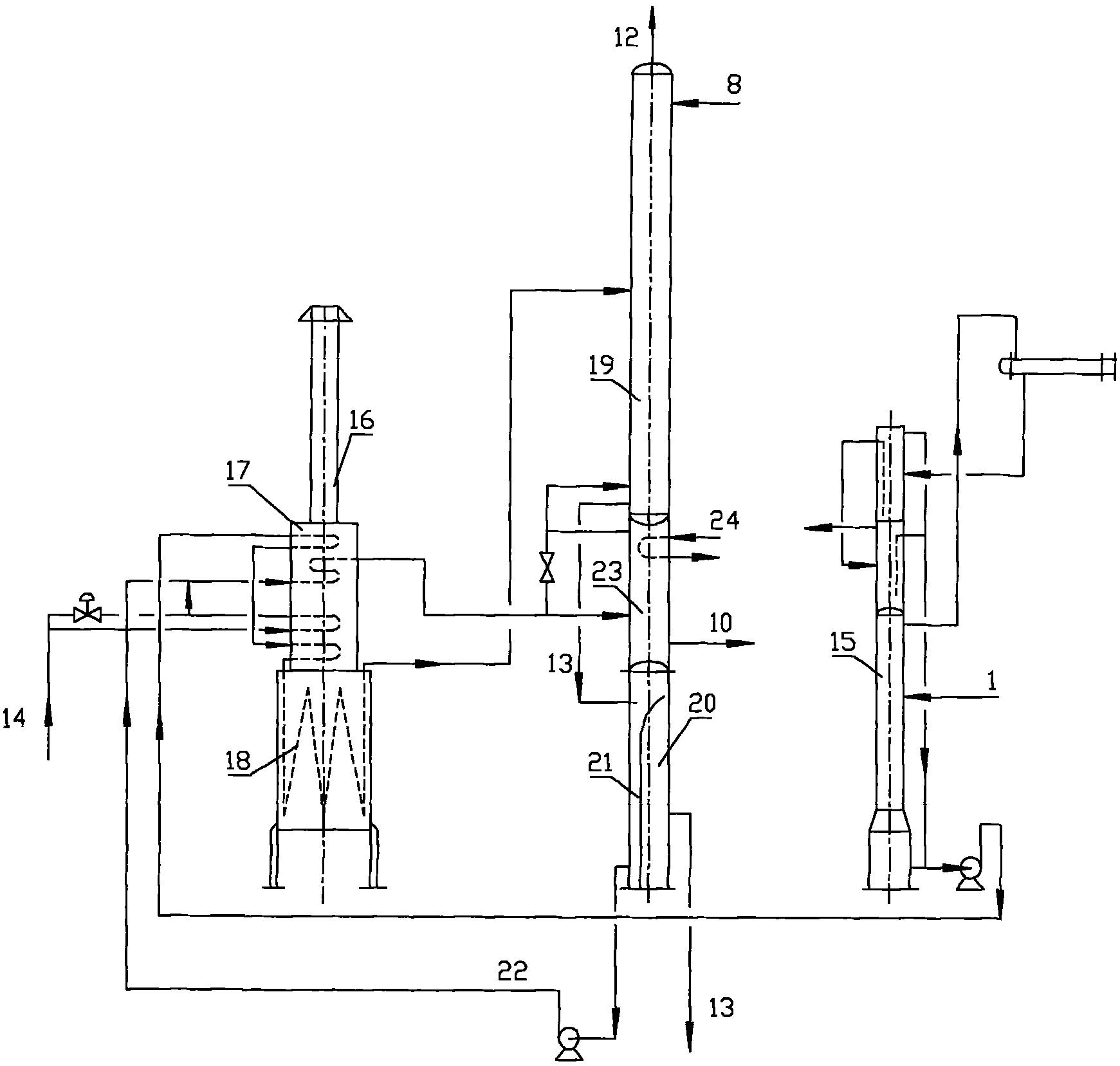

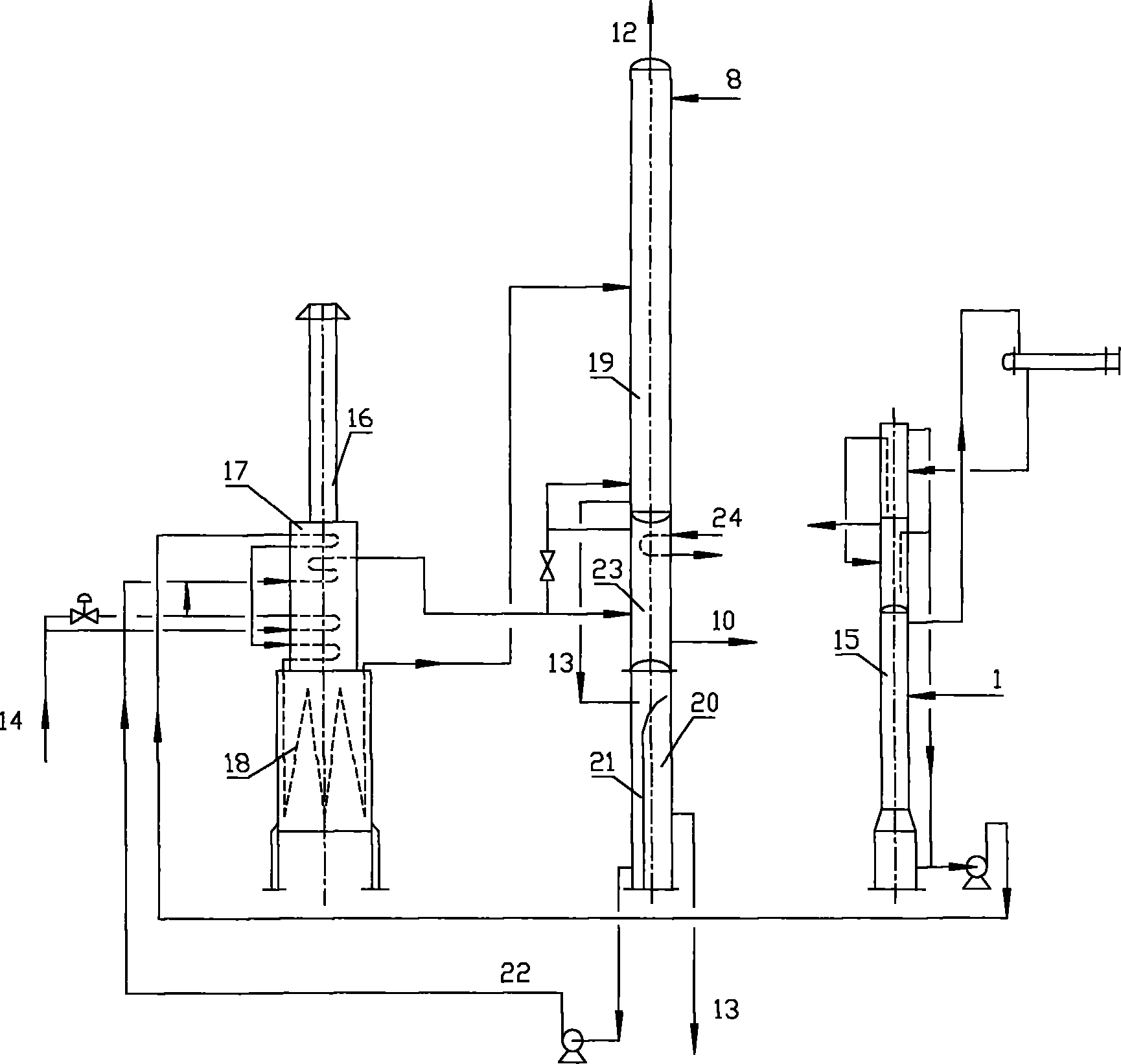

[0023] The present invention will be described in further detail below in conjunction with specific examples.

[0024] like figure 2 As shown, the circulating washing oil 1 that has absorbed benzene-group hydrocarbons from the washing process enters the dehydration tower 15 with an oil-water separator on the top after heat exchange and is pumped to the crude benzene distillation tube furnace 16 for flash dehydration. After being heated in the tube furnace 16 by the convection section 17 and the radiation section 18 of the tube furnace, it enters the distillation section 19 of the debenzene tower. The circulating washing oil 13 after debenzene flows into the oil storage section 20 at the lower part of the debenzene tower, which has the function of removing coal powder and coke powder entrained in the circulating washing oil 13 by gravity settling. Then pump it out and send it to the washing process for recycling after heat exchange and cooling.

[0025] The crude benzene vap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com