Bacterial cellulose strain

A technology of bacterial cellulose and bacterial strains, applied in the field of microorganisms, can solve the problems of low yield and instability of bacterial cellulose strains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

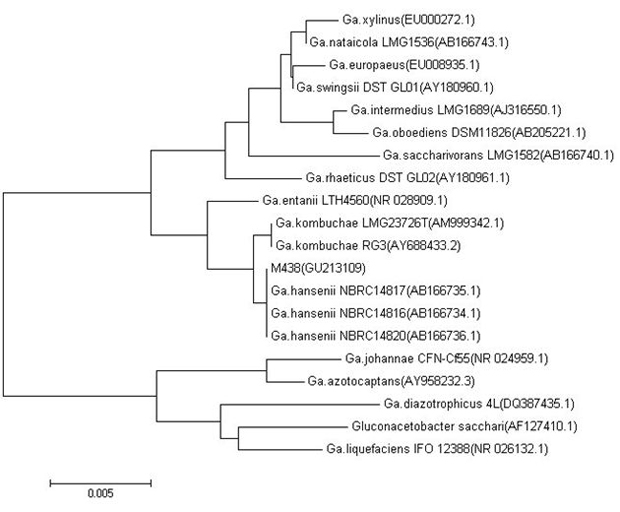

[0026] In order to obtain high-yielding and stable bacterial cellulose strains and increase the yield of bacterial cellulose, the present invention uses ultra-high pressure technology to conduct mutagenesis treatment on the screened bacterial cellulose strains on the basis of previous research to obtain high-yield bacterial cellulose The cellulose yield (wet film) of strain M438 can reach 40g / 100mL, while the highest bacterial cellulose yield reported so far does not exceed 30g / 100mL.

[0027] 1) Preparation of bacterial cellulose strain M438:

[0028] This embodiment relates to the bacterial cellulose strain M438 for screening, which is isolated and screened from buckwheat vinegar mash and obtained after high hydrostatic pressure mutagenesis, specifically including the following steps:

[0029] (1) Isolation and purification of bacterial cellulose strains:

[0030] Bacterial cellulose-producing bacteria were isolated from buckwheat vinegar mash brewed in the laboratory. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com