One-stage prestressed concrete pipe

A concrete pipe and prestressing technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve problems such as water leakage, rubber ring slippage at the pipe socket, and poor adaptability, so as to ensure the overall quality and reduce Construction cost, easy counterpart effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

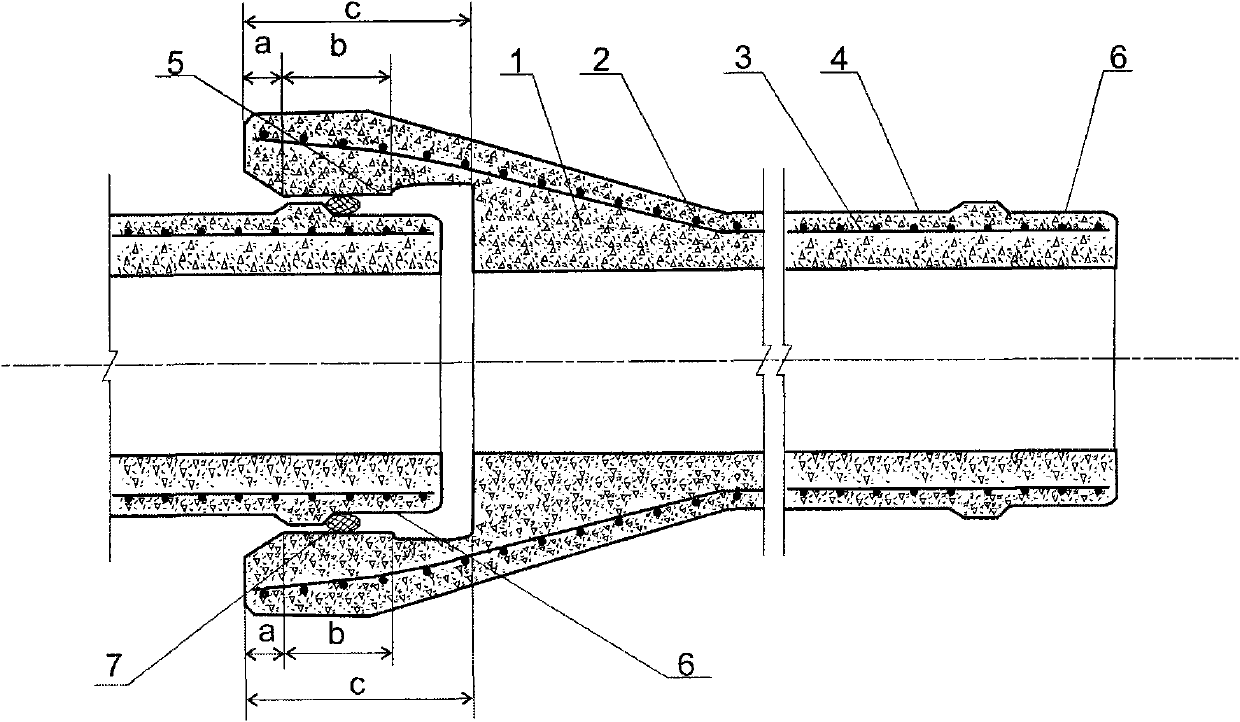

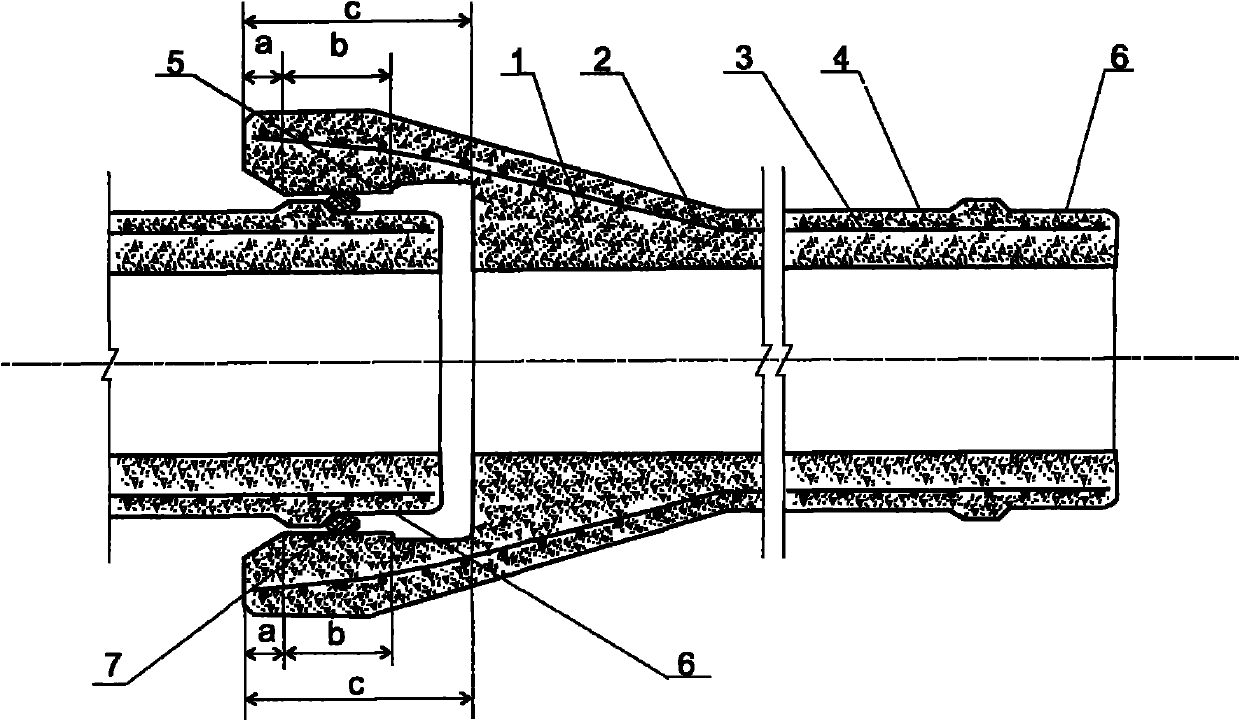

[0011] As shown in the figure: the one-stage prestressed concrete pipe (YYG) is a prefabricated prefabricated concrete pipe with two-way prestressed in the concrete pipe wall, which is prepared by vibratory extrusion process of concrete 1, circumferential prestressed steel bar 2 and longitudinal prestressed steel bar 3 Concrete pipe body 4. Its socket 5 is arranged on the left side of concrete pipe body 4, and socket 6 is arranged on the right side of concrete pipe body 4, and pipe socket and socket joint are sealed with a circular solid rubber sealing ring 7 during installation.

[0012] Shorten the length a of the outer slope of the socket by 20mm, that is, 30mm for DN400~1600, 40mm for DN1800~2000, and grind to a smooth level; shorten the length b of the socket face of the first-stage prestressed concrete pipe (YYG) Increase the value to more than 100mm, and grind it to the level of smoothness; increase the total depth c value of the first-stage prestressed concrete pipe (Y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com