Meat analog product

A technology for meat products and artificial meat, applied in the field of preparing artificial meat products, can solve problems such as inability to produce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] Artificial meat preparation method

[0085] According to the formulation of Example 2 or 3, the various required dry ingredients were weighed and mixed in a powder mixer for about 10 minutes to form the "dry ingredients". Place the dry ingredients in the hopper of the feeding equipment. Each required liquid is weighed according to the recipe and then mixed by a high shear mixer such as a Silverson mixer.

[0086] Single screw extruder is the most preferred equipment to produce artificial meat. Its screw shape is set to provide low shear to the raw meal, and its barrel temperature profile is set for optimum heat transfer to the raw meal.

[0087] The dry ingredients and the liquid are injected into the extruder where they are mixed and formed by the rotation of the screws to form the raw meal while cooking starts under the action of the thermal energy absorbed by the raw meal from the wall of the extruder barrel.

[0088] The processed raw meal is heated to a temperat...

Embodiment 2

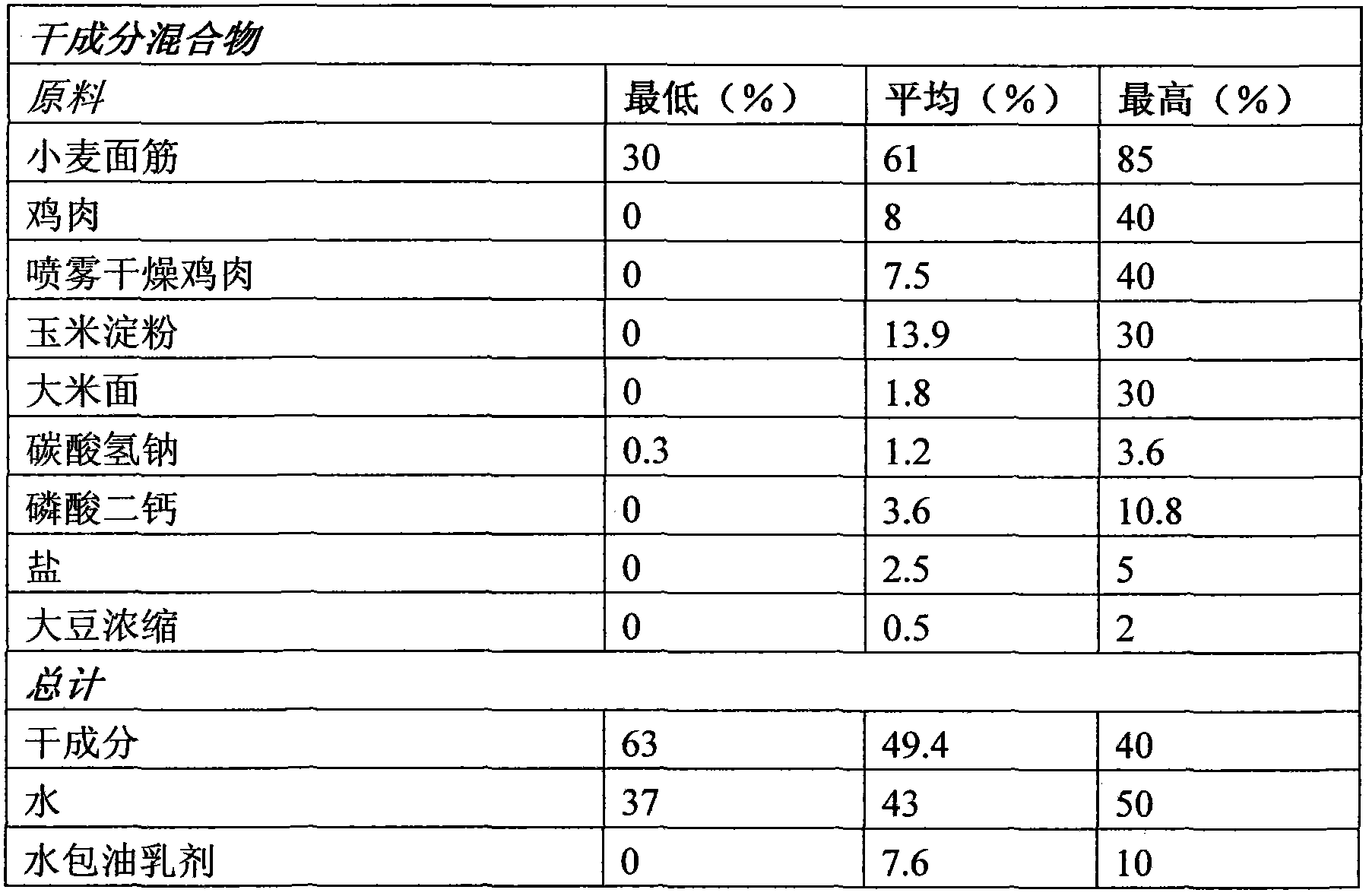

[0091] After realizing the basic recipe, further research tests were carried out to determine the advantageous range of raw materials to satisfy the amounts in the recipe and the type that would result in the artificial meat product according to the present invention.

[0092] The table below shows the ranges tried to create acceptable meat substitutes.

[0093]

Embodiment 3

[0095] In another embodiment, the inventive formulation comprises:

[0096]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com