Cuprous chloride-modified honeycomb activated carbon adsorbing material and preparation method thereof

A honeycomb activated carbon, cuprous chloride technology, applied in chemical instruments and methods, separation methods, other chemical processes, etc., can solve the problems of low air velocity of the treated gas, no investigation of conversion adsorption, etc., to achieve increased adsorption capacity and cost. The effect of low and high adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

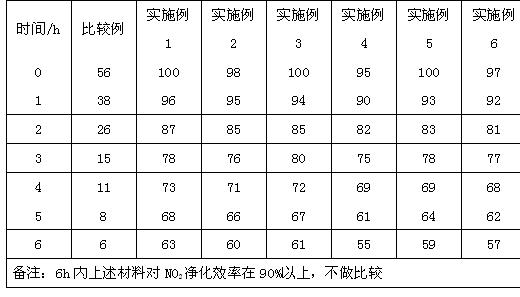

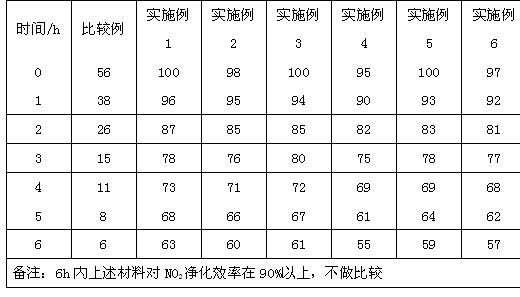

Examples

Embodiment 1

[0022] Example 1: Cut 200 holes / square inch of activated carbon into a cylinder with a diameter of 16mm and a height of 50mm, and dry it in an oven at 120°C for 1h. Prepare 20% cuprous chloride solution 2.5ml. Take Cu + :NH 3 + =1:4 ratio, add ammonia water to completely dissolve cuprous chloride;

[0023] Place the dried activated carbon in the solution and impregnate it for 1 hour; then take out the activated carbon and dry it in an oven at 120°C for 2 hours.

[0024] Take Cu + : Oxidant = 1:2 ratio to prepare potassium permanganate solution, immerse the dried activated carbon in the oxidant solution for 1 hour, and then dry it in an oven at 120°C for 2 hours to obtain modified activated carbon.

Embodiment 2

[0025] Example 2: Cut 200 holes / square inch of activated carbon into a cylinder with a diameter of 16mm and a height of 50mm, and dry it in an oven at 120°C for 1h. Prepare 20% cuprous chloride solution 2.5ml. Take Cu + :NH 3 + =1:2 ratio, add ethylenediamine, completely dissolve cuprous chloride;

[0026] Place the dried activated carbon in the solution and impregnate it for 1 hour; then take out the activated carbon and dry it in an oven at 120°C for 2 hours.

[0027] Take Cu + : Oxidant = 1:2 ratio to prepare potassium permanganate solution, immerse the dried activated carbon in the oxidant solution for 1 hour, and then dry it in an oven at 120°C for 2 hours to obtain modified activated carbon.

Embodiment 3

[0028] Example 3: Cut 50 holes / square inch of activated carbon into a cylinder with a diameter of 16mm and a height of 50mm, and dry it in an oven at 120°C for 1h. Prepare 20% cuprous chloride solution 2.5ml. Take Cu + :NH 3 + =1:2 ratio, add ammonia water to completely dissolve cuprous chloride;

[0029] Place the dried activated carbon in the solution and impregnate it for 1 hour; then take out the activated carbon and dry it in an oven at 120°C for 2 hours.

[0030] Take Cu + : Oxidant = 1:2 ratio to prepare ferric chloride solution, immerse the dried activated carbon in the oxidant solution for 1 hour, and then dry it in an oven at 120°C for 2 hours to obtain modified activated carbon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com