Roll mark spot wiper for rolling mill

A wiper and rolling mill technology, applied in the field of rolling mills, can solve the problems of poor cleaning effect of manual wiping rolls, affecting the surface accuracy of rolling pieces, unsatisfactory cleaning effect, etc., achieving ideal cleaning effect and low maintenance cost. , the effect of eliminating safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing.

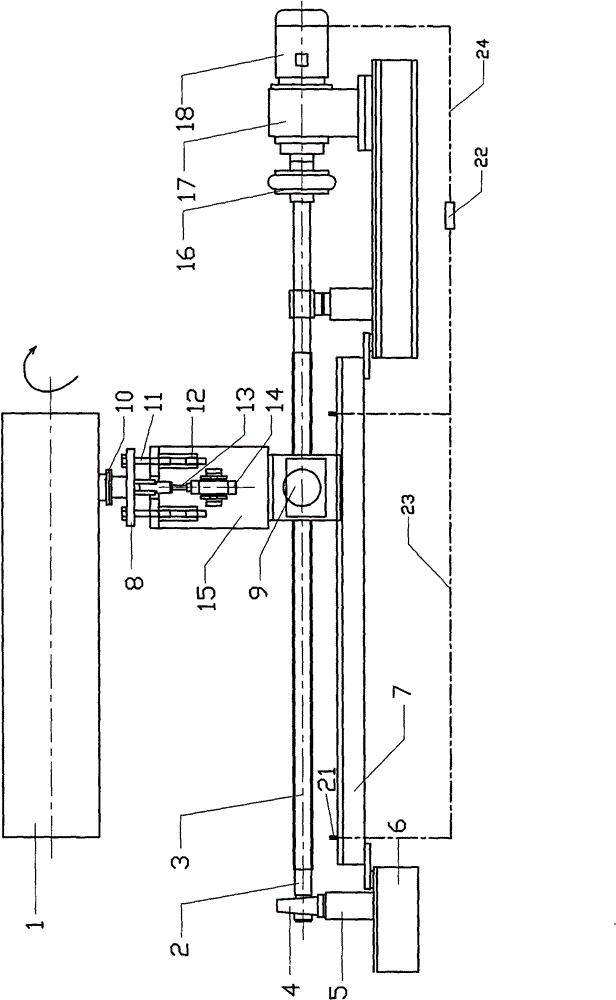

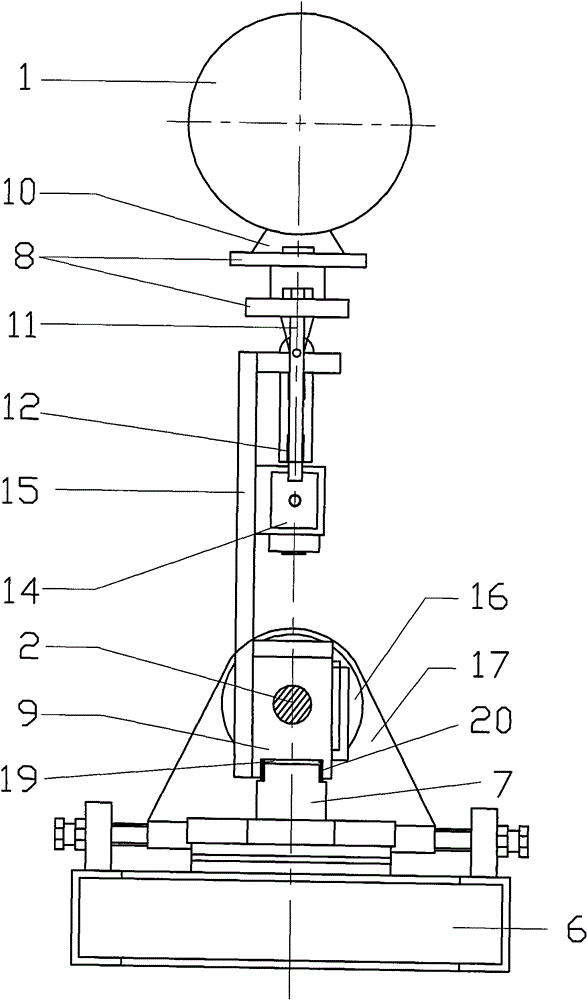

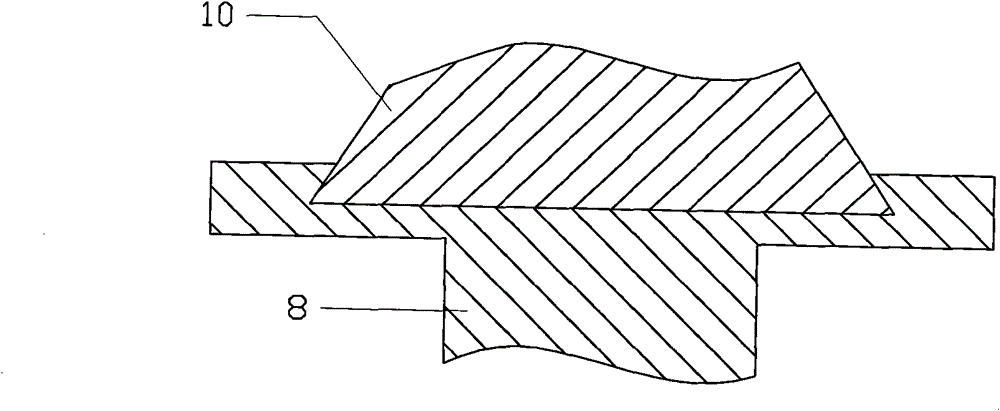

[0029] figure 1 It is a front view of a preferred solution of the present invention. The screw mandrel 2 is installed on the base 6 through the bearing 4 and the bearing seat 5. The threaded section 3 on the screw mandrel is located directly below the working section 1 of the roller shaft. The power transmission and conversion The transmission mode of the screw pair is adopted, the output shaft of the motor 18 is connected with the screw rod 2 through the reduction box 17 and the coupling 16, and a nut 9 matching it is set on the threaded section 3 of the screw rod, and the upper part of the nut 9 is close to the roller shaft. A support 15 is installed on one side of the working section 1, a cylinder 14 is housed on the support 15, and the wiping head 10 is fixed on the movable support 8 on the piston rod 13 upper end of the cylinder 14, and the movable support 8 is fixed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com