Welding technology of submerged-arc welding of X-shaped groove of medium plate

A welding process and submerged arc welding technology, which is applied in the field of X-shaped groove submerged arc welding of medium and heavy plates, can solve the problems of long welding time, difficult grinding, and welding seam pores, so as to reduce welding man-hours and solve welding methods. , the effect of saving welding materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

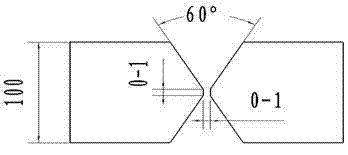

[0010] Example 1: Submerged arc welding of 100mm E36 steel plate

[0011] Welding test plate set pair such as figure 1 , welding process parameters are shown in Table 1.

[0012] Table 1 Welding process parameters of 100mm E36 steel plate submerged arc welding test

[0013]

[0014] Through the submerged arc welding test on the E36 steel plate with a thickness of 100mm, the welded joints of E36 steel have good tensile properties, bending properties and low-temperature impact properties, and the welded joints have excellent performance.

Embodiment 2

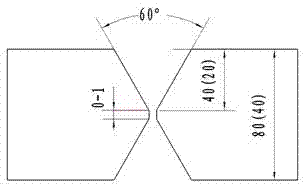

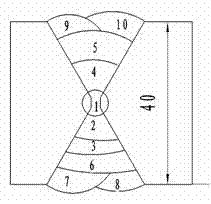

[0015] Embodiment 2: Submerged arc welding of 40mm Q370qE steel plate.

[0016] Welding test plate set pair such as figure 2 , the weld pattern is as image 3 , welding process parameters are shown in Table 2.

[0017] Table 2 Welding test parameters of 40mm Q370qE steel plate submerged arc welding

[0018]

[0019] The submerged arc welding test of the Q370qE+TM steel plate shows that the Q370qE+TM steel plate is welded under the condition of heat input of 35kJ / cm, and the tensile properties, bending properties and impact properties of the welded joint are good, which meets the standard requirements.

Embodiment 3

[0020] Embodiment 3: Submerged arc welding of 40mm NM360 steel plate.

[0021] Welding test plate set pair such as Figure 4 , the detailed welding process parameters are shown in Table 3, the preheating temperature is 100 ℃, and the interlayer temperature is ≤200 ℃.

[0022] Table 3 Welding test parameters of 40mm NM360 steel plate submerged arc welding

[0023]

[0024] Through the submerged arc welding test of NM360 steel plate, the results show that under the condition of NM360 steel plate with heat input of 30kJ / cm, NM360 steel and Q550D, Q690D dissimilar steel are welded with corresponding strength level welding wire, and the tensile properties and impact properties of the welded joint are good. , Excellent performance of welded joints.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com