Gasket of electric oven

A technology for electric ovens and gaskets, which is applied in the direction of roasters/barbecue grids, applications, kitchen utensils, etc., which can solve problems such as poor high temperature resistance, safety hazards, and poor insulation, and achieve high insulation performance and protection Good safety and high temperature resistance

Inactive Publication Date: 2011-04-06

王红霞

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the poor high temperature resistance and short service life of the existing gaskets, some gaskets are not easy to clean, and most of them can only be used once, which brings great waste and poor insulation. directly lead to safety hazards

Some products volatilize toxic substances after high temperature and cannot directly contact food

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

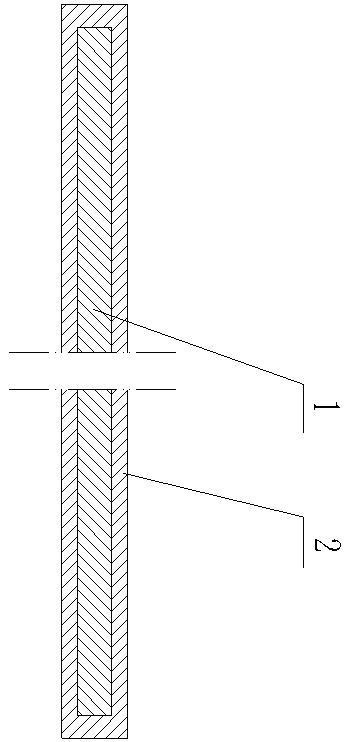

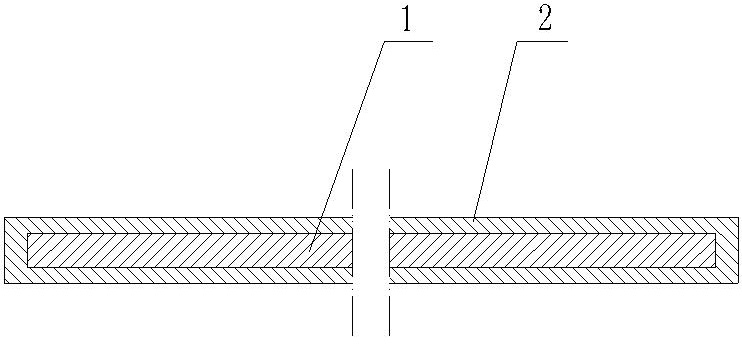

[0007] Such as figure 1 As shown, a rectangular or circular glass fiber cloth sheet 1 is wrapped with silica gel 2.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a gasket of an electric oven, which relates to the technical field of production of gaskets. The gasket of the invention comprises a glass fiber cloth and silica gel, wherein the silica gel covers outside the glass fiber cloth. The gasket of the invention has high insulation property and good high temperature resistance, ensures safe use, and can be used for infinite times theoretically. Even part of the gasket is damaged or ruptured, the gasket can be used as usual, and the gasket can be cleaned conveniently by washing with water or wiped with a dry or wet cloth to remove dirt thereon. The gasket of the electric oven also has the characteristic of no volatile toxic substance after being heated at high temperature, and guarantees safety of eating.

Description

Technical field [0001] The invention relates to the technical field of production of gaskets. Background technique [0002] Due to eating habits, many people like to eat baked foods, and people put raw foods in an oven to heat them until cooked. People generally need to wrap the food with heat-resistant materials, or lay a heat-resistant gasket in the oven, and then place the food on the gasket to prevent oil or food scraps produced during the heating process from contaminating the oven. Because the existing gaskets have poor high temperature resistance and short service life, and some gaskets are not easy to clean, most of them can only be used once, which brings great waste and has the problem of poor insulation. Directly cause safety hazards. Some products volatilize toxic substances after high temperature and cannot directly contact food. Summary of the invention [0003] The purpose of the present invention is to provide a safe, non-toxic, durable and easy to clean electri...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B32B17/02B32B17/10B32B27/28A47J37/06

Inventor 王红霞

Owner 王红霞

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com