Powder for laser remanufacturing of high-temperature furnace roller and repair process

A technology of laser remanufacturing and high temperature furnace, which is applied in the direction of manufacturing tools, metal material coating technology, laser welding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

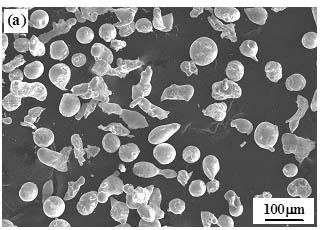

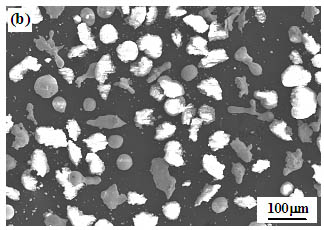

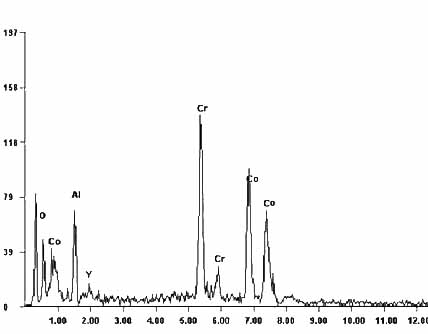

Image

Examples

Embodiment 1

[0049] A high-temperature furnace roll laser remanufacturing powder, characterized in that: the laser remanufacturing powder is a matrix material CoCrAlY alloy powder and metal oxide Al 2 o 3 Powder, the chemical composition of the CoCrAlY alloy powder is by weight percentage: Cr15.0%, Al3.0%, Y0.1%, and the balance is Co; Al 2 o 3 The proportion of powder to the total weight of powder for laser remanufacturing is 40.0%.

[0050] A powder repair process for laser remanufacturing of high-temperature furnace rolls, characterized in that: the high-temperature furnace roll SCH13 steel is used as the base material, the thickness of the preset alloy powder coating is 0.8mm, and the continuous wave CO 2 Laser processing machine for laser irradiation treatment; laser irradiation process parameters: laser output power 2.0kW, spot diameter 3.0mm, laser beam scanning rate 15mm / s, large-area scanning laser overlapping rate 45%, the obtained modified layer The thickness is 0.75mm.

Embodiment 2

[0052] A high-temperature furnace roller laser remanufacturing powder, characterized in that: the laser remanufacturing powder is a base material CoCrAlY alloy powder and metal oxide powder, and the chemical composition of the CoCrAlY alloy powder is: Cr28. 0%, Al10.0%, Y1.5%, the balance is Co; the metal oxide is Al 2 o 3 and Y 2 o 3 , where Y 2 o 3 The content accounts for 2.0% of the total weight of the metal oxide powder, and the rest is Al 2 o 3, , Al 2 o 3 and Y 2 o 3 The proportion of powder to the total weight of powder for laser remanufacturing is 40.0%.

[0053] A powder repair process for laser remanufacturing of high-temperature furnace rolls, characterized in that: the high-temperature furnace roll SCH13 steel is used as the base material, the thickness of the preset alloy powder coating is 0.8mm, and the continuous wave CO 2 Laser processing machine for laser irradiation treatment, laser irradiation process parameters: laser output power 1.5kW, spot di...

Embodiment 3

[0055] A high-temperature furnace roller laser remanufacturing powder, characterized in that: the laser remanufacturing powder is a base material CoCrAlY alloy powder and metal oxide powder, and the chemical composition of the CoCrAlY alloy powder is: Cr20. 0%, Al6.0%, Y1.0%, the balance is Co; the metal oxide is Al 2 o 3 and Y 2 o 3 , where Y 2 o 3 The content accounts for 3.0% of the total weight of the metal oxide powder, and the rest is Al 2 o 3 , Al 2 o 3 and Y 2 o 3 The powder accounted for 30.0% of the total weight of powder for laser remanufacturing.

[0056] A powder repair process for laser remanufacturing of high-temperature furnace rolls, characterized in that: the high-temperature furnace roll SCH13 steel is used as the base material, the thickness of the preset alloy powder coating is 0.8mm, and the continuous wave CO 2 Laser processing machine for laser irradiation treatment, laser irradiation process parameters: laser output power 2.5kW, spot diamete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com