Preparation method of phosphorus pig iron cathode for aluminum electrolysis

A technology for phosphorus pig iron and aluminum electrolysis, applied in the field of aluminum electrolysis, can solve the problems of poor connection between the cathode carbon block and square steel, and achieve the effects of reducing the cathode pressure drop, prolonging the service life and reducing the power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

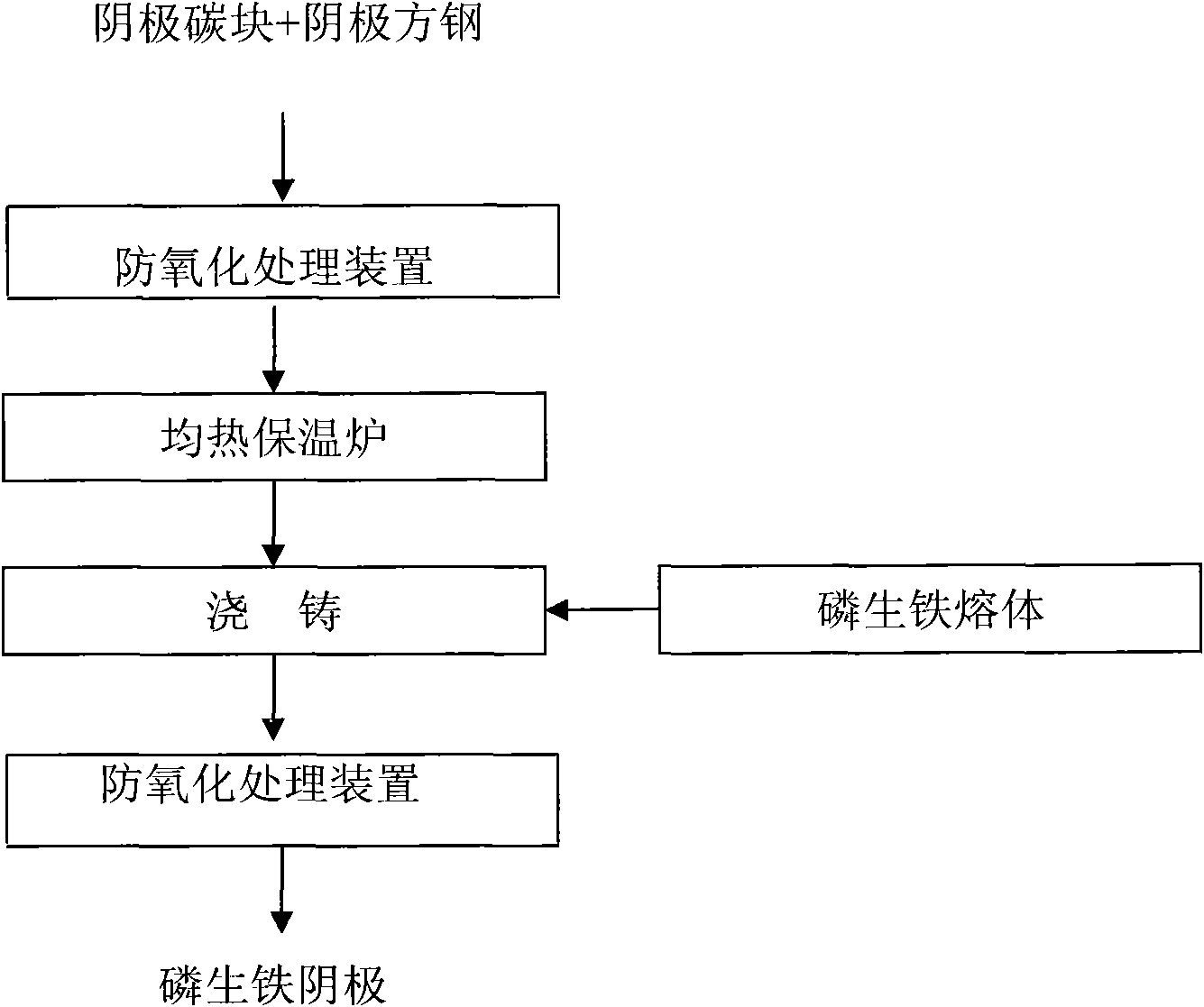

[0012] The pre-assembly of the cathode square steel and the cathode carbon block is sealed, that is, the oxygen in the box is discharged to avoid the oxidation of the cathode square steel and the cathode carbon block, and then it is heated in a soaking furnace at a heating temperature of 450 ° C and kept for 5 Hours, after being transported out of the soaking furnace, cast with the pre-prepared phosphorus pig iron water, and then seal it, discharge the oxygen in the box, and then put it into normal temperature for natural cooling, and the obtained phosphorus pig iron cathode can be used in the production of aluminum electrolysis . The weight percentages of impurities contained in the phosphorus pig iron are: Mn: 0.2%, P: 0.4%, Si: 1.5%, C: 2.5%, S<0.3%.

[0013] The prepared phosphorus pig iron cathode was applied in an aluminum electrolytic cell, and the pressure drop difference between the phosphorus pig iron cathode and the traditional hot stamped cathode was compared. Res...

Embodiment 2

[0015] The pre-assembly of the cathode square steel and the cathode carbon block is sealed, that is, the oxygen in the box is discharged to avoid the oxidation of the cathode square steel and the cathode carbon block, and then it is heated in a soaking furnace at a heating temperature of 650 ° C and kept for 10 Hours, after being transported out of the soaking furnace, cast with the pre-prepared phosphorus pig iron water, and then seal it, discharge the oxygen in the box, and then put it into normal temperature for natural cooling, and the obtained phosphorus pig iron cathode can be used in the production of aluminum electrolysis . The weight percent of the impurity contained in the phosphorus pig iron is: Mn: 1.2%, P: 1.8%, Si: 4.5%, C: 3.7%, S<0.3%.

[0016] The prepared phosphorus pig iron cathode was applied to an aluminum electrolytic cell, and the difference in pressure drop between the phosphorus pig iron cathode and the hot stamped cathode was compared. Results: When ...

Embodiment 3

[0018] The pre-assembly of the cathode square steel and the cathode carbon block is sealed, that is, the oxygen in the box is discharged to avoid the oxidation of the cathode square steel and the cathode carbon block, and then it is heated in a soaking furnace at a heating temperature of 800 ° C and kept for 20 Hours, after being transported out of the soaking furnace, cast with the pre-prepared phosphorus pig iron water, and then seal it, discharge the oxygen in the box, and then put it into normal temperature for natural cooling, and the obtained phosphorus pig iron cathode can be used in the production of aluminum electrolysis . The weight percentage composition of the impurity content contained in the phosphorus pig iron is: Mn: 0.8%, P: 1.2%, Si: 3.5%, C: 3.1%, S<0.3%.

[0019] The prepared phosphorus pig iron cathode was applied in an aluminum electrolytic cell, and the difference in pressure drop between the phosphorus pig iron cathode and the hot stamped cathode was co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com