Steel structural staircase for multi-storey industrialized house

A technology for steel structures and stairs, which is applied in the direction of stairs, stepped structures, building structures, etc. It can solve the problems of poor installation and positioning of ordinary steel structures, unfavorable large-scale production and installation, and no design of installation bolt holes, etc., to achieve good force bearing Performance and ease of use, reasonable force, and the effect of avoiding on-site welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

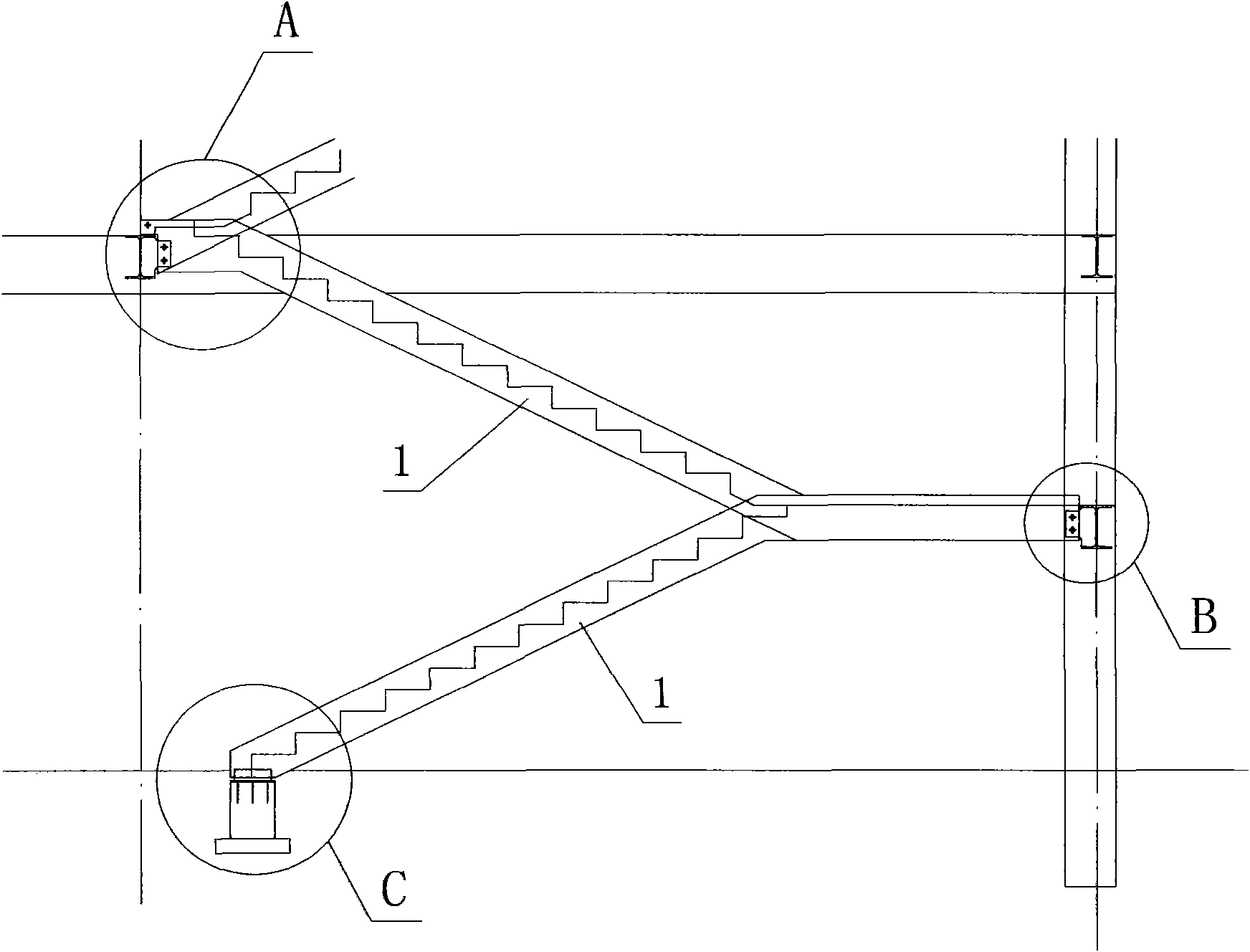

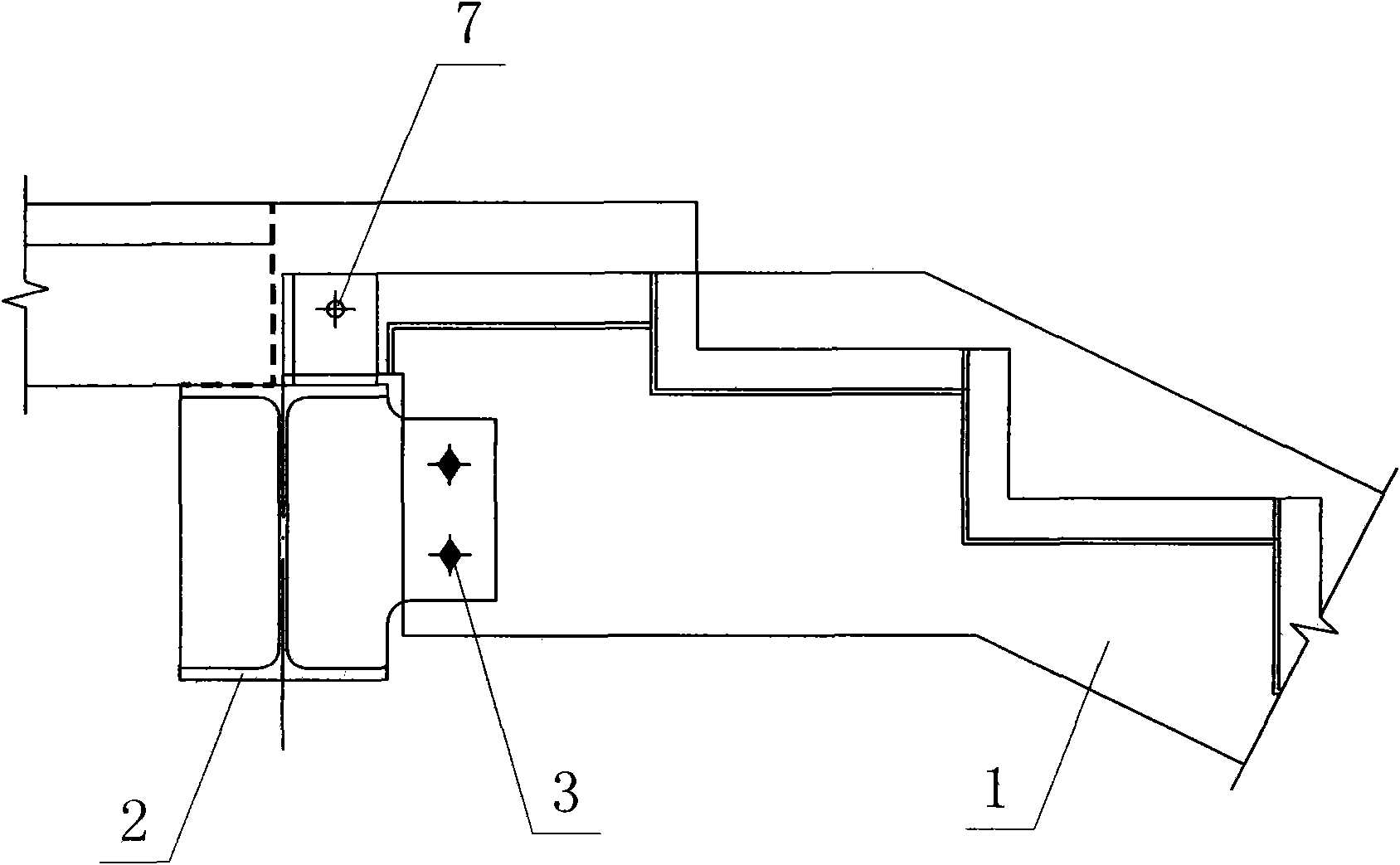

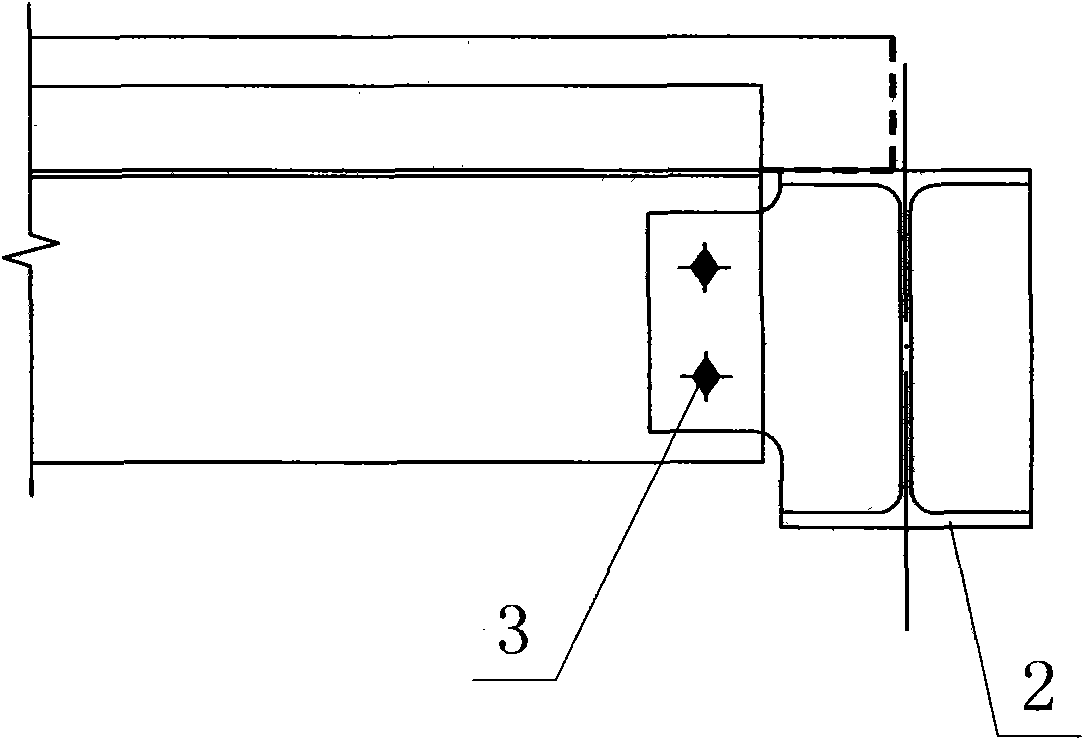

[0031] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a multi-storey industrialized residential steel structure staircase of the present invention includes an integral steel structure staircase section 1, a main structural steel beam 2, high-strength bolts 3, a steel staircase foundation 4, staircase embedded parts 5, and staircase connectors 6 , wherein the bottom of the integral steel structure stair section 1 at the bottom is connected with the stair embedded part 5 on the steel stair foundation 4 through the stair connector 6, and the bottom of the other integral steel structure stair section 1 is connected with the main structural steel The beams 2 are connected by high-strength bolts 3 , and the tops of all integral steel structure stair sections 1 are connected and fixed to the main structural steel beams 2 by high-strength bolts 3 . Mounting bolts 7 are also provided at the junction of the integral steel structure stair section 1 and the steel beam 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com