Lifting drive system by steel wire ropes in stereo garage

A technology of lifting transmission and three-dimensional garage, which is applied in the direction of buildings, building types, and buildings where cars are parked. It can solve the problems of large installation space, asynchronous lifting of the vehicle loading plate, and random buckling of wire rope drums, etc., to achieve safe use. , compact structure and simple mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below through non-limiting embodiments and in conjunction with the accompanying drawings.

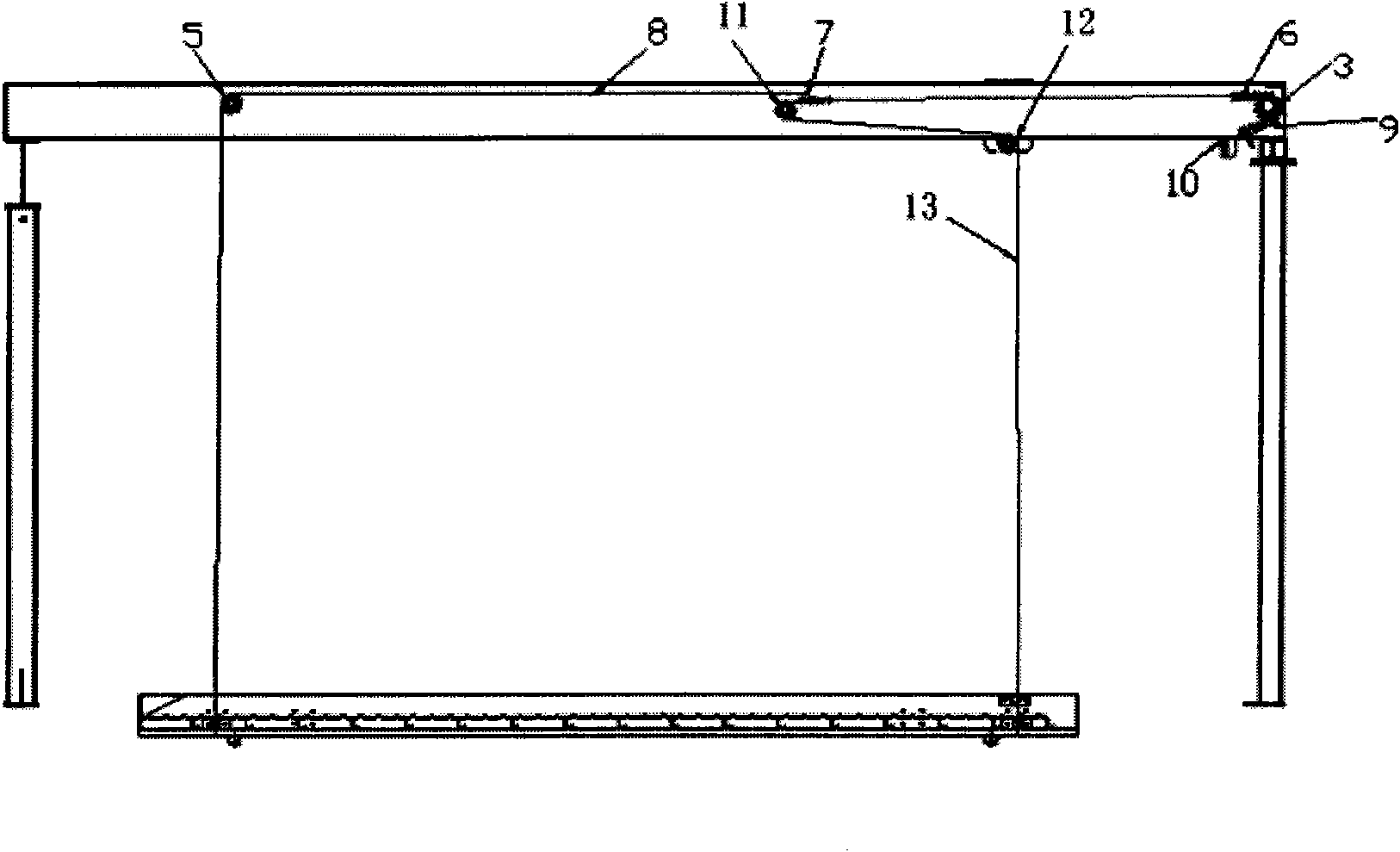

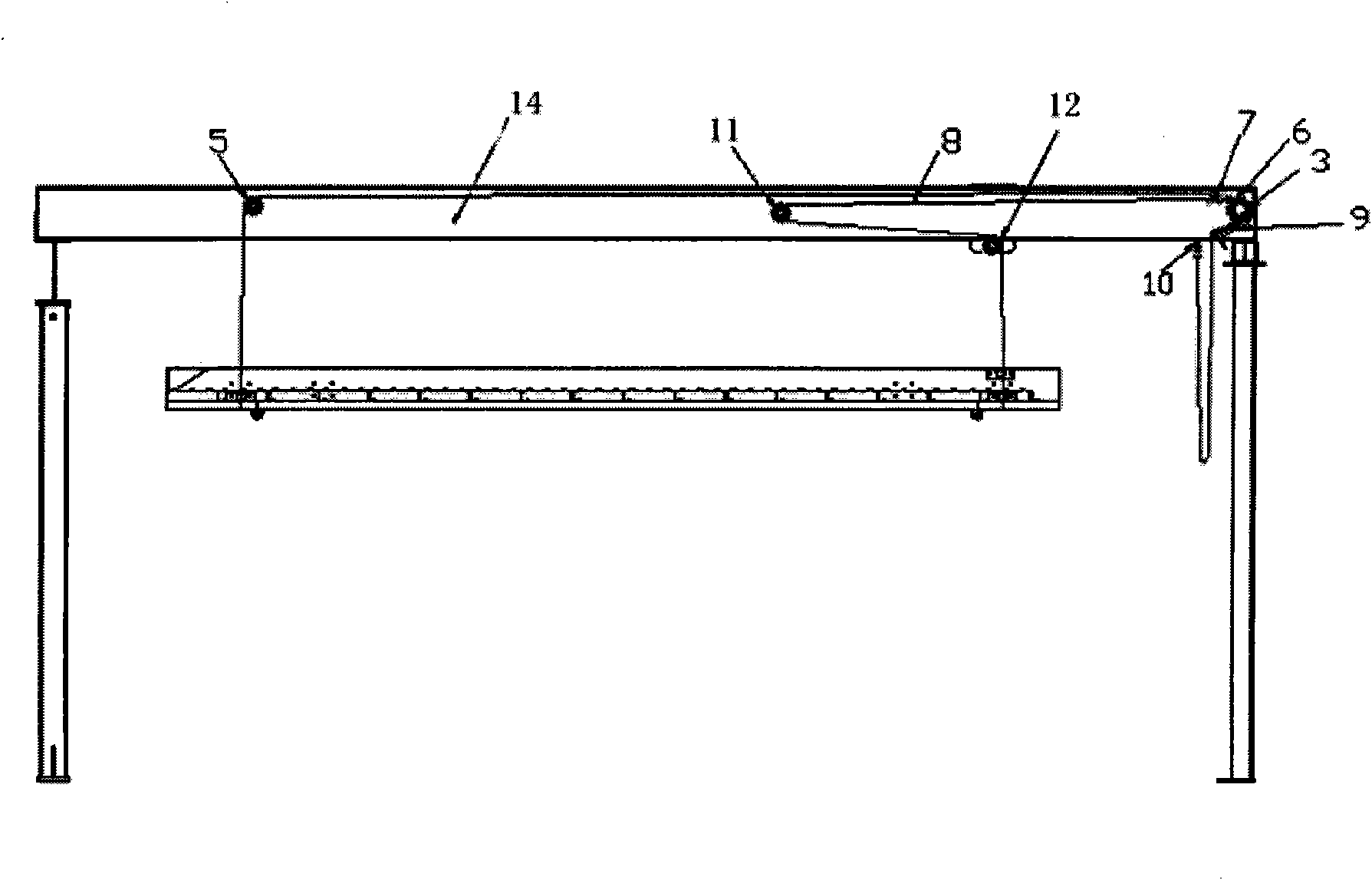

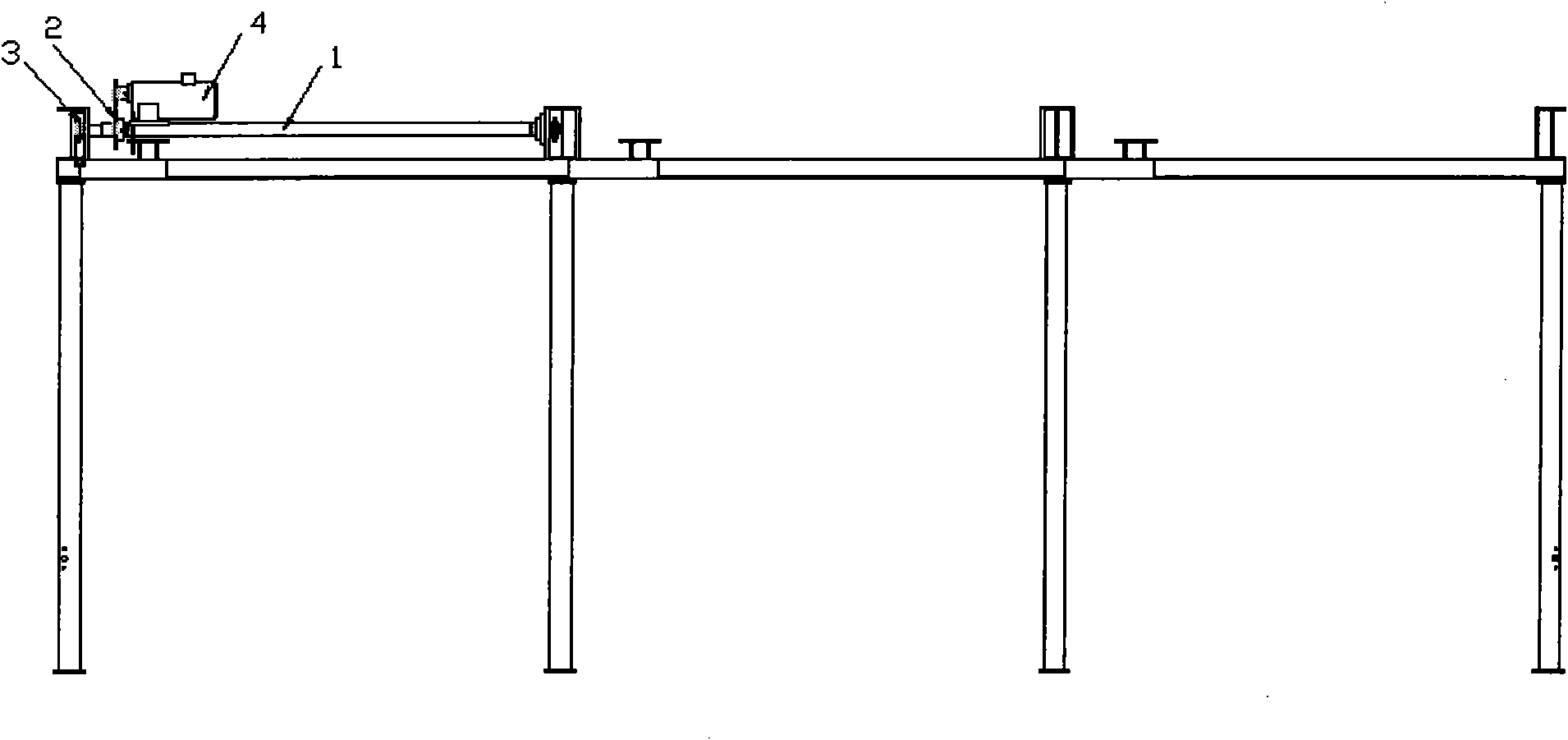

[0016] exist Figure 1 to Figure 3 In a specific embodiment of the present invention shown, the main transmission shaft 1 of the three-dimensional garage wire rope lifting transmission system is arranged on the rear end of the longitudinal beam 14, and the output shaft of the motor 4 is equipped with a driving sprocket, and the transmission chain is connected to the drive shaft. Drive the lifting sprocket 2 arranged on the main transmission shaft 1 to rotate the main transmission shaft, and the two ends of the main transmission shaft 1 are provided with a lifting driven sprocket 3; A pair of rear suspension rings of the vehicle-carrying board, the first pulley 5 corresponding to the front suspension ring of the vehicle-carrying board, the second pulley 12 corresponding to the rear suspension ring of the vehicle-carrying board are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com