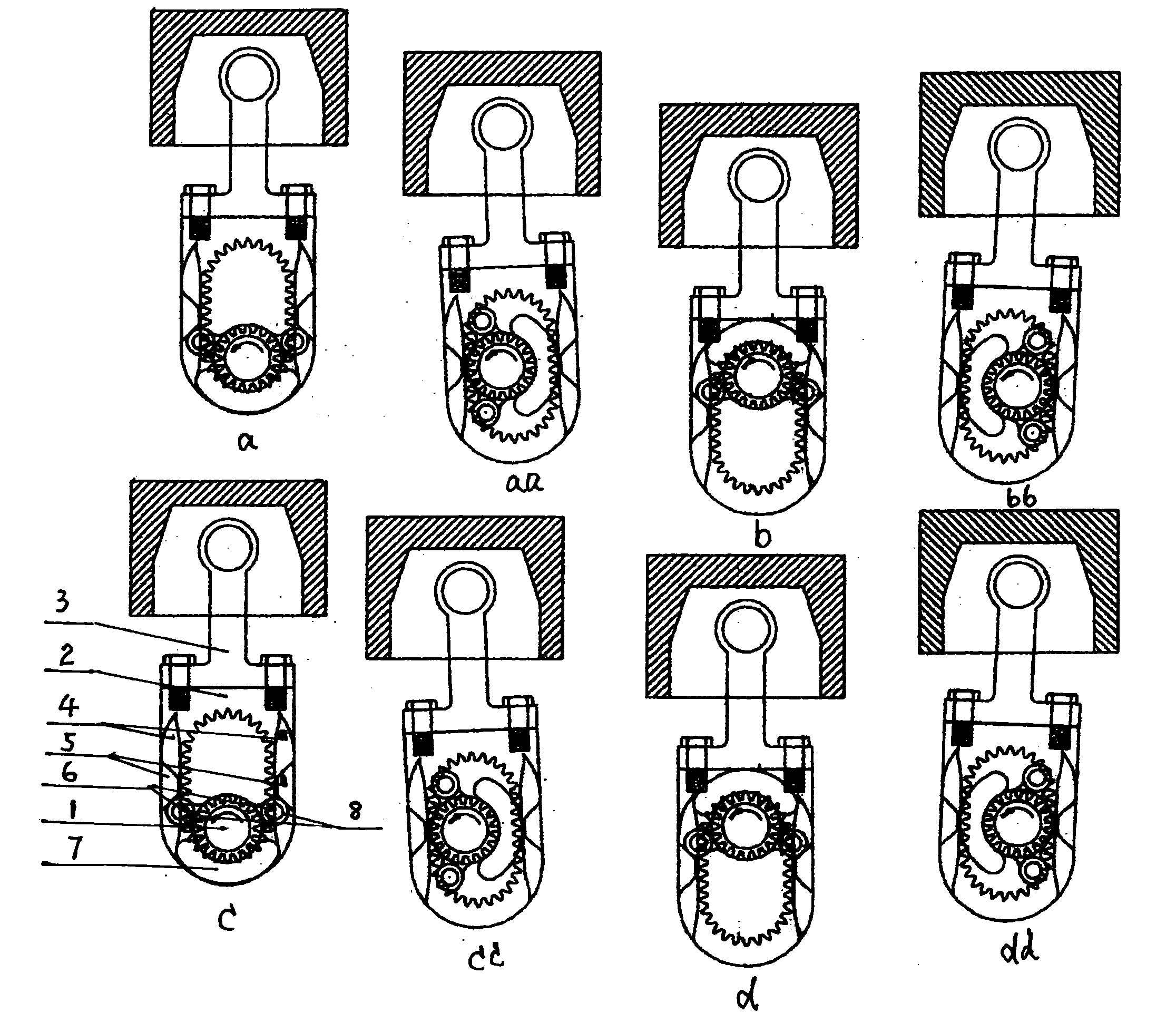

Internal gear rack linkage mechanism of gear shaft of engine

A rack, connecting rod and engine technology, applied in the direction of machines/engines, mechanical equipment, etc., can solve the problems of energy consumption and lower overall system efficiency, and achieve the effect of reducing fuel consumption and increasing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

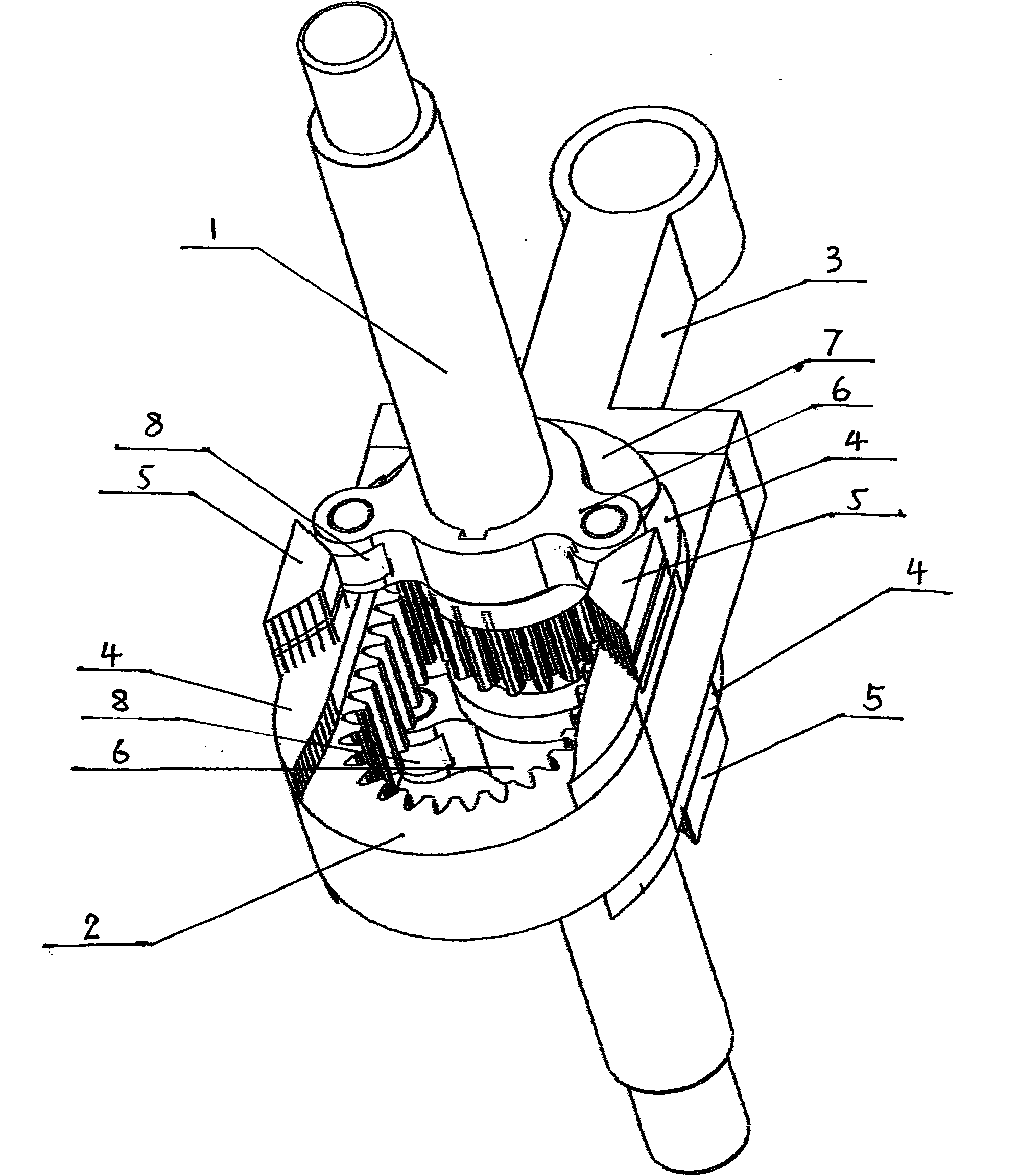

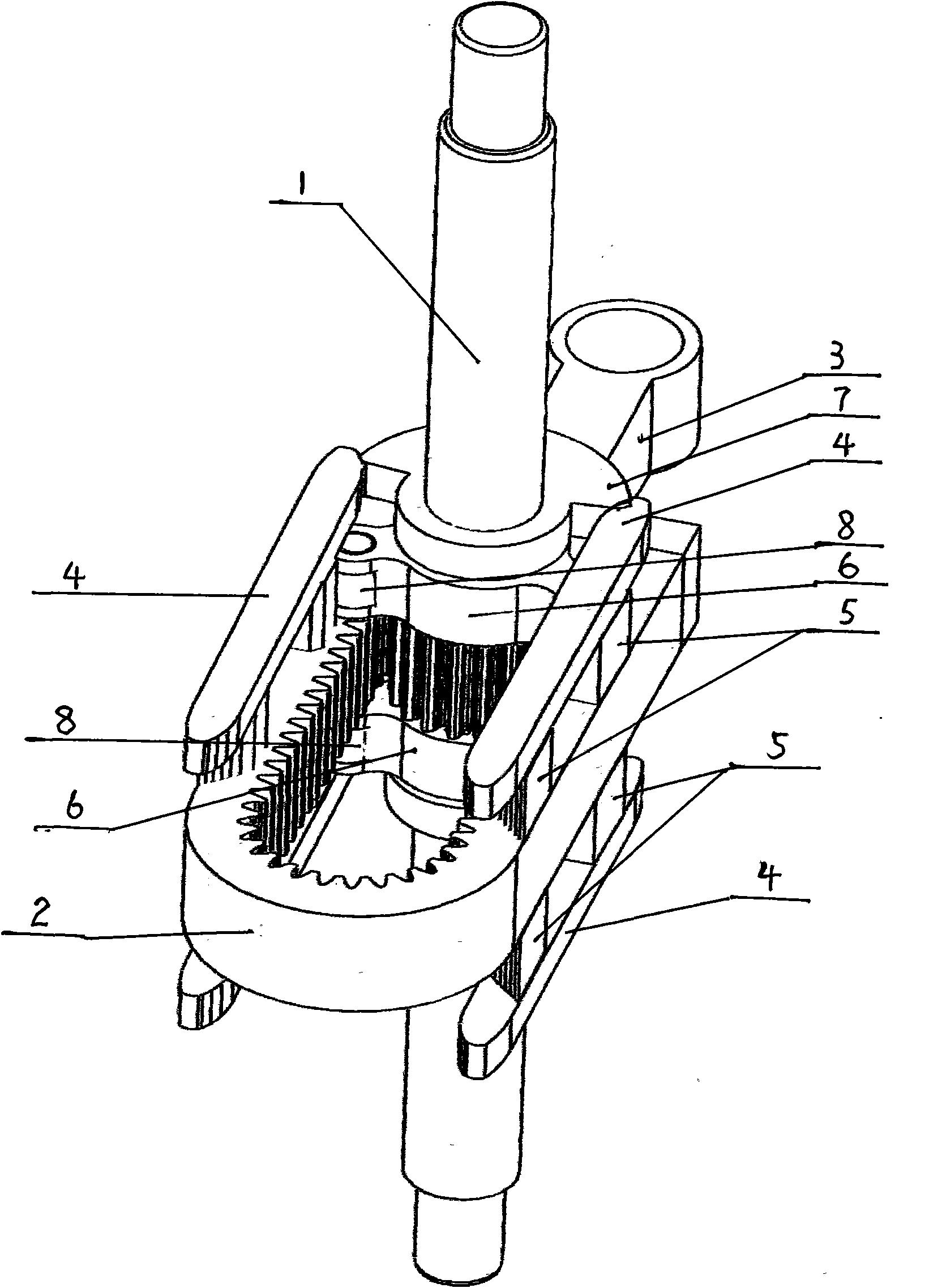

Embodiment Construction

[0012] exist figure 2 In the shown embodiment, the number of external teeth of the external gear shaft (1) is 18, the number of teeth of the internal rack compound internal teeth (2) is 36, and the modulus and pressure angle are the same as those of the external teeth. The number of teeth in the two sections of the rack is 6 teeth, the number of inner teeth is 24, and it passes through the center point of the inner teeth Figure 1A straight line connecting the two root center points divides the inner tooth into two identical parts. The modulus is determined by the engine stroke and torque. The fan angle of fan-shaped sliding guide block (7) is 120 degree, and radius is determined by modulus, and it is fixed on the axle of external gear shaft (1) by key close to the two ends of external gear. Bearing (8) size is determined by modulus. The included angle formed by the axis of the two bearings (8) on the V-shaped rolling guide block (6) and the axis of the external gear shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com