Method for assembling outer ring axial broken thin-wall bearing

A thin-walled bearing and assembly method technology, applied to shafts and bearings, bearing components, mechanical equipment, etc., can solve the problems of low assembly efficiency, easily scratched steel balls, and difficult to recover from deformation, and achieves high assembly efficiency and meets large requirements. The effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

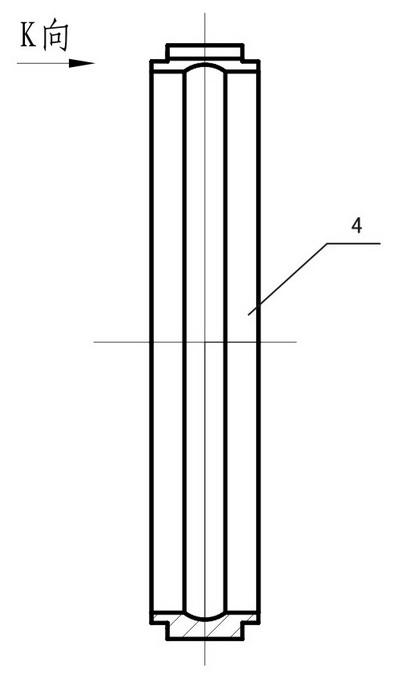

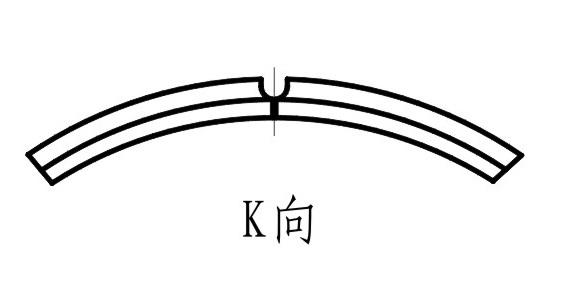

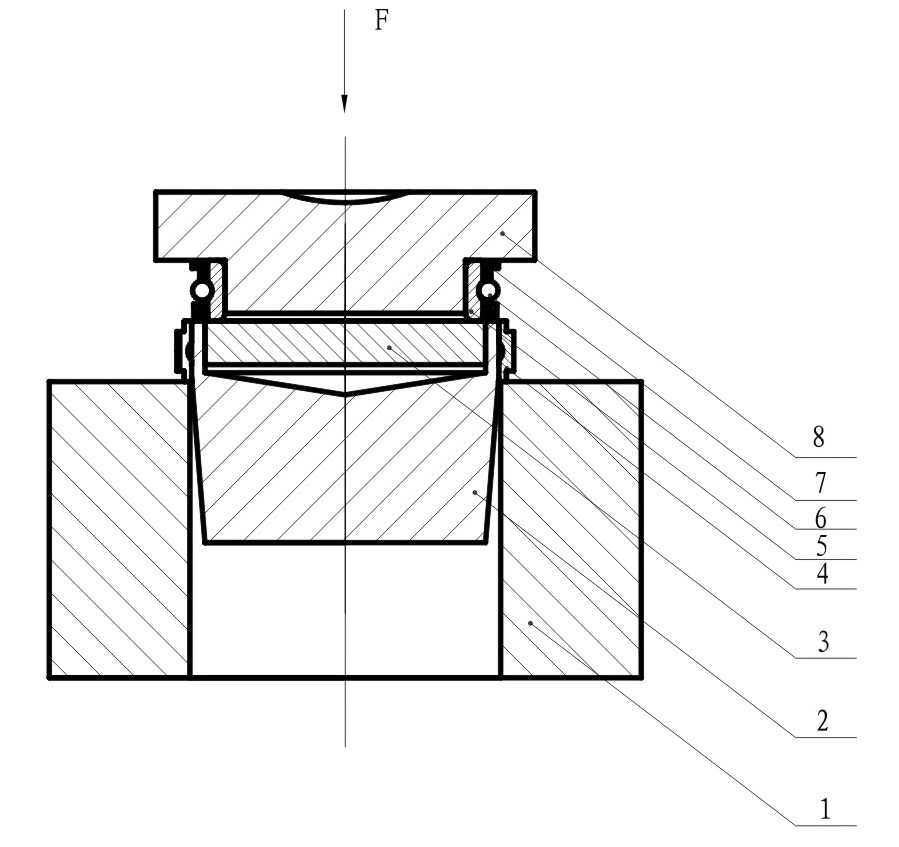

[0037] Since the thin-walled bearing is composed of the outer ring 4, the inner ring 5, the steel ball 6 and the cage 7, the following description directly calls the specific name of the thin-walled bearing.

[0038] combine image 3 The assembling method of the thin-walled bearing with axial fracture of the outer ring of the present invention includes two contents, one is the manufacture of the assembly accessory, and the other is the step of assembling the thin-wall bearing by using the assembly accessory, and the assembly accessory is to complete the step of assembling the thin-wall bearing Prerequisites, the two contents are as follows:

[0039] Ⅰ. Production of assembly accessories

[0040] The assembly accessories include a support ring 1, a tapered guide block 2, a steel ball tray 3 and a press-fitting block 8, wherein:

[0041] ① The inner diameter of the support ring 1 = the maximum outer diameter of the tapered guide block 2 + 0.4mm, the height of the support ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com