Giant magnetostrictive driver and high-speed electromagnetic valve driven thereby

A giant magnetostrictive and magnetostrictive technology, applied in the field of micro-drives, can solve the problems of long reset time, reduced output force, long response time, etc., so as to reduce the processing and manufacturing cost, the output force will not be reduced, and the structure can be simplified. design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

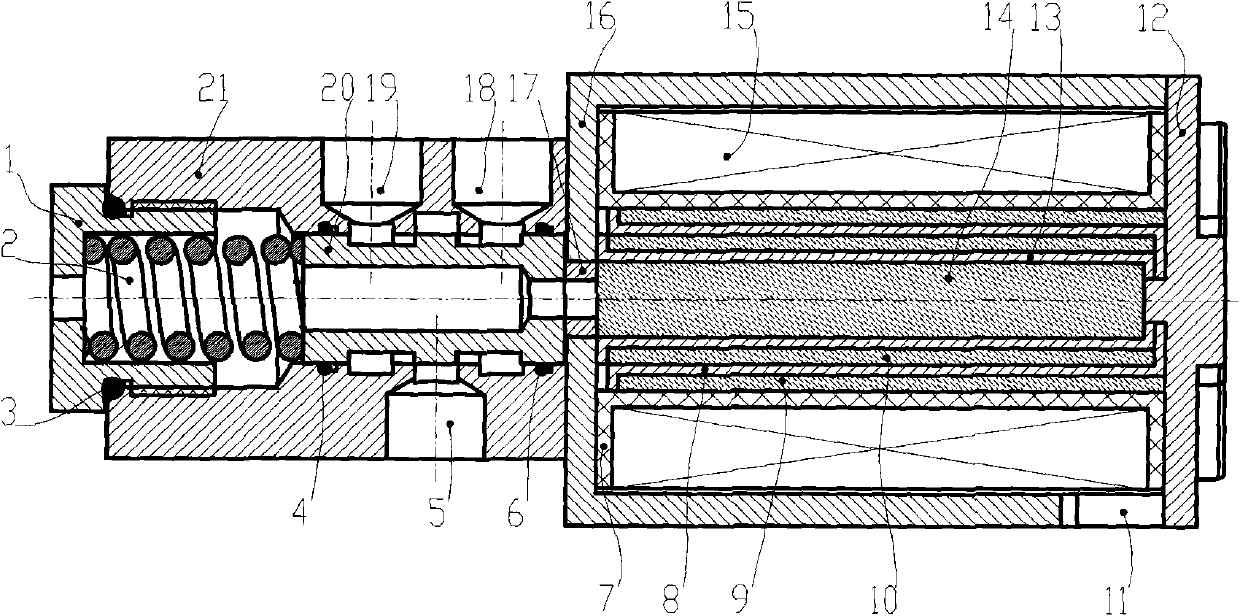

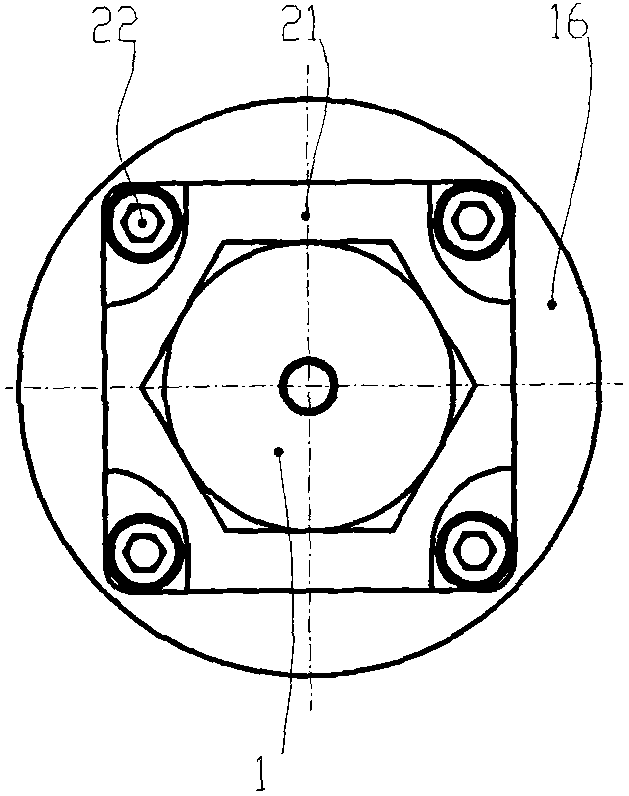

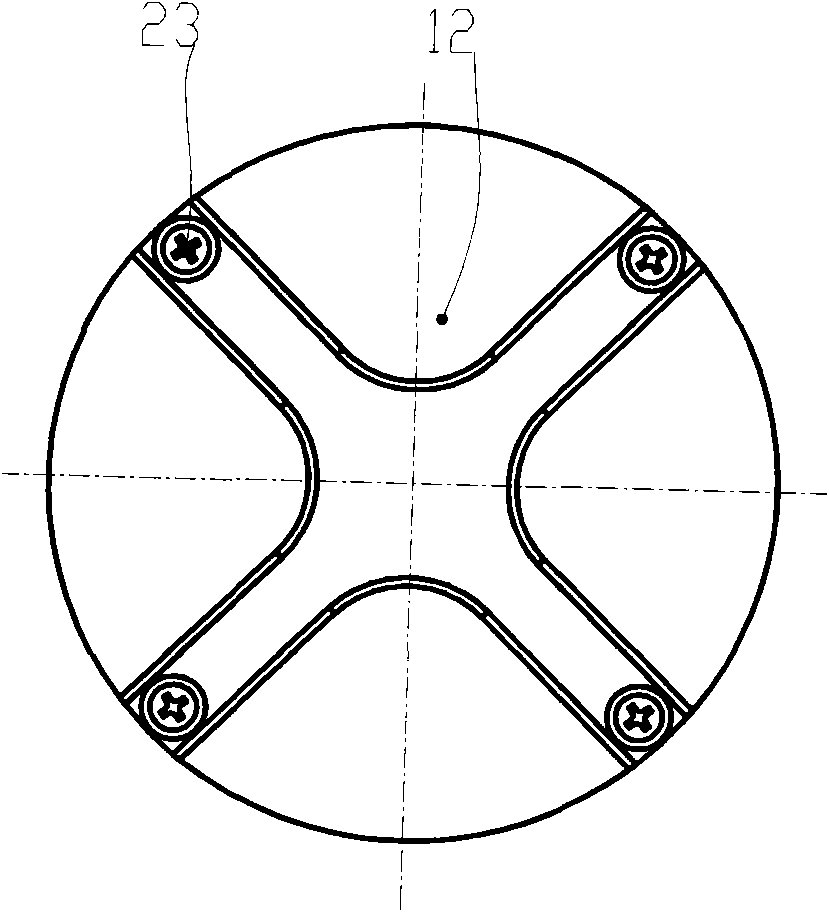

[0023] like figure 1 , 2 , Shown in 3, a kind of high-speed electromagnetic valve, electromagnetic valve comprises the giant magnetostrictive driver of right part and the hydraulic valve of left part, and wherein giant magnetostrictive driver comprises skeleton 7, at least two thermal compensation tubes and magnetostrictive tube , in the present embodiment, two examples are taken as examples, which are respectively represented by labels in the figure, thermal compensation tubes 8, 13, magnetostrictive tubes 9, 10, magnetically conductive end cap 12, magnetostrictive rod 14, coil 15 and guide Magnetic housing 16, magnetically conductive output rod 17; hydraulic valve includes screw plug 1, return spring 2, sealing rings 3, 4, 6, valve body 21, valve core 20, and connecting screw 22. As shown in Figure 4, the thermal compensation tube is a hollow circular tube with a central section of shape, A round hole is opened at the closed end of the shape, The open end of the shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com