Auxiliary compressor defrosting system for air source heat pump

An auxiliary compressor, air source heat pump technology, applied in compressors, refrigerators, lighting and heating equipment, etc., can solve the problems of long defrosting time, hidden safety hazards of compressors, and reduced heat supply, and achieve low cost. , Improve indoor comfort and reduce the effect of suction superheat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

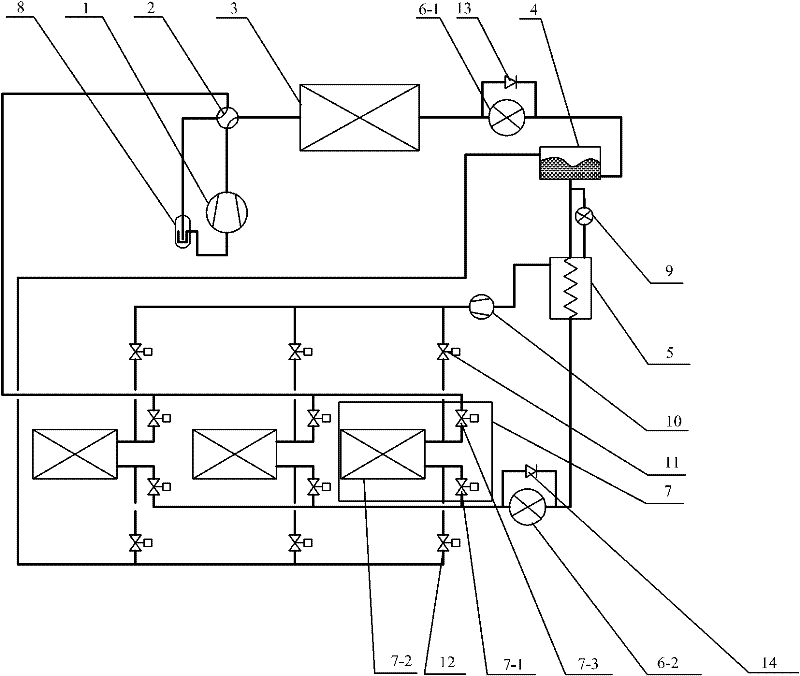

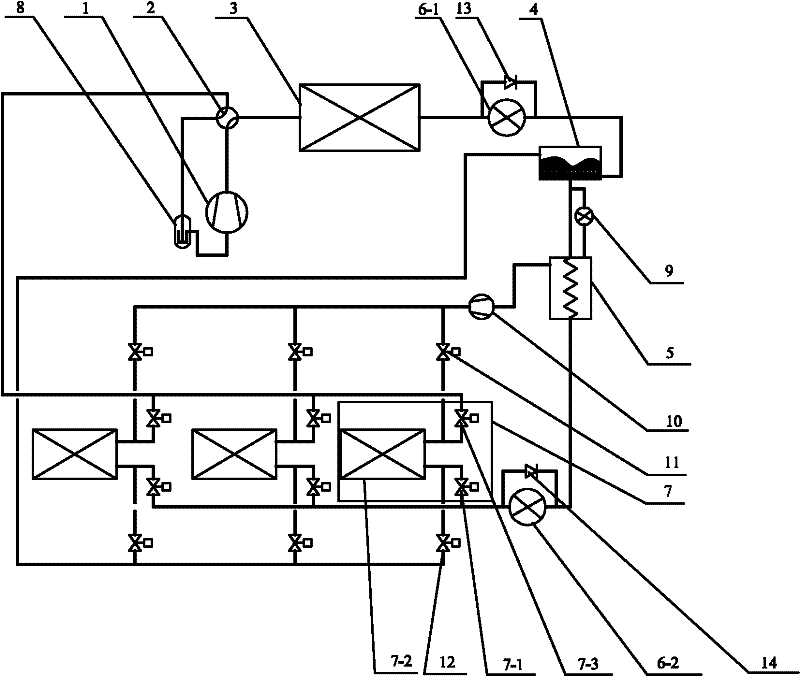

[0009] Specific implementation mode one: combine figure 1 Describe this embodiment, the system of this embodiment includes a main compressor 1, a four-way reversing valve 2, an indoor unit 3, a liquid receiver 4, a first throttle valve 6-1, a second throttle valve 6-2, Multiple outdoor units 7 and gas-liquid separators 8 are arranged in parallel. Each outdoor unit 7 is composed of a first electromagnetic valve 7-1, an outdoor unit 7-2 and a second electromagnetic valve 7-3. The first The solenoid valve 7-1, the outdoor unit 7-2 and the second solenoid valve 7-3 are arranged in series in sequence, the outlet port of the compressor 1 communicates with one of the ports of the four-way reversing valve 2, and the port of the four-way reversing valve 2 One of the remaining three ports communicates with the inlet port of the indoor unit 3, the outlet port of the indoor unit 3 communicates with the inlet port of the first throttle valve 6-1, and the outlet port of the first throttle v...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination figure 1 Describe this embodiment, the system of this embodiment also includes a first one-way valve 13 and a second one-way valve 14, the first throttle valve 6-1 is arranged in parallel with the first one-way valve 13, the second throttle valve 6 -2 is set in parallel with the second one-way valve 14, when heating in winter, open the first one-way valve 13, close the second one-way valve 14, the refrigerant passes through the first one-way valve 13 (not through the first throttling Valve 6-1) flows into the liquid receiver 4, so that the refrigerant is throttled at the second throttle valve 6-2; when running in summer, the first one-way valve 13 is closed, the second one-way valve 14, refrigeration The refrigerant flows through the second one-way valve 14, so that the refrigerant is throttled at the first throttle valve 6-1. The function of the first one-way valve 13 and the second one-way valve 14 is exactly to ensure th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com