Sectional extra-high-voltage composite post insulator with inner umbrella structure

A composite insulator, segmented technology, applied in the field of segmented UHV pillar composite insulators, can solve the problems of poor internal insulation performance, limited mechanical strength, insufficient mechanical strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

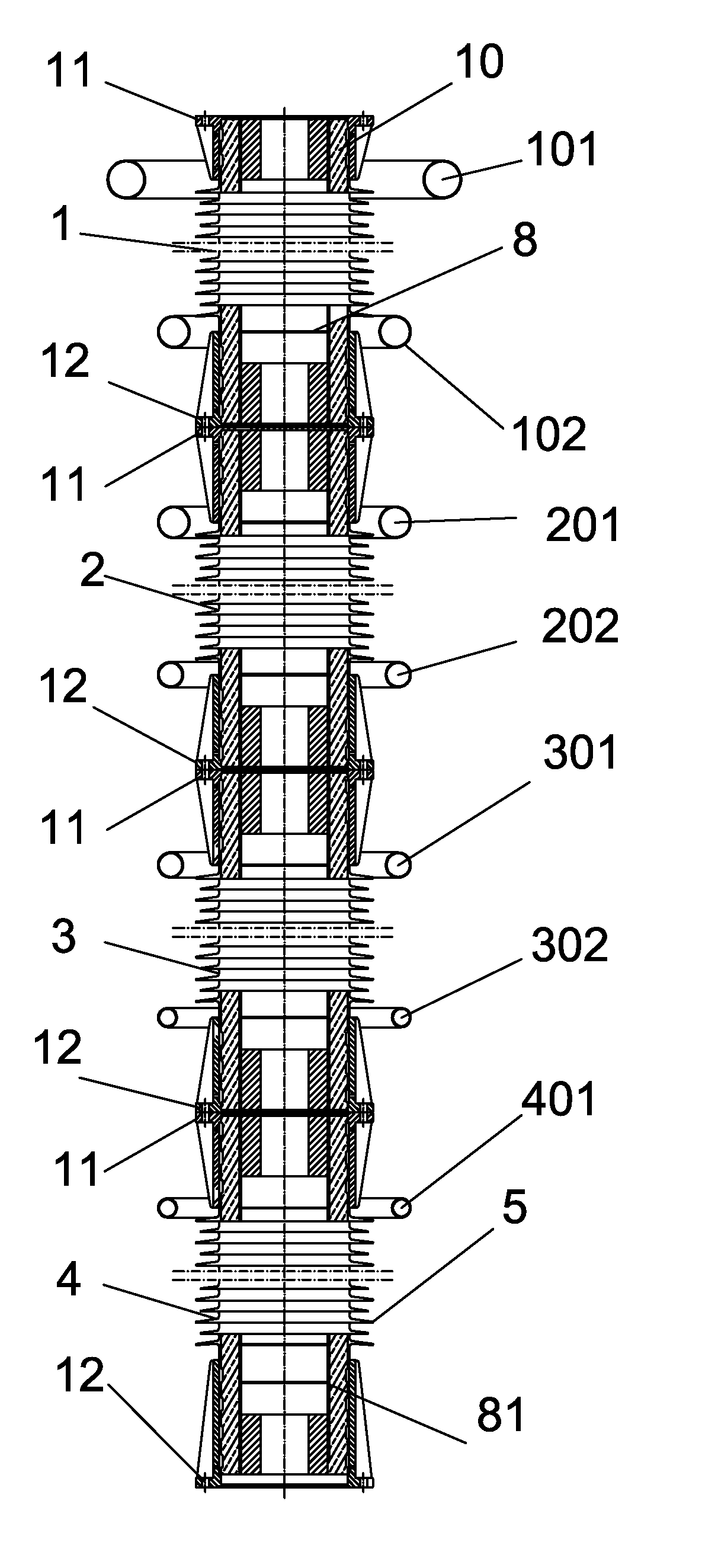

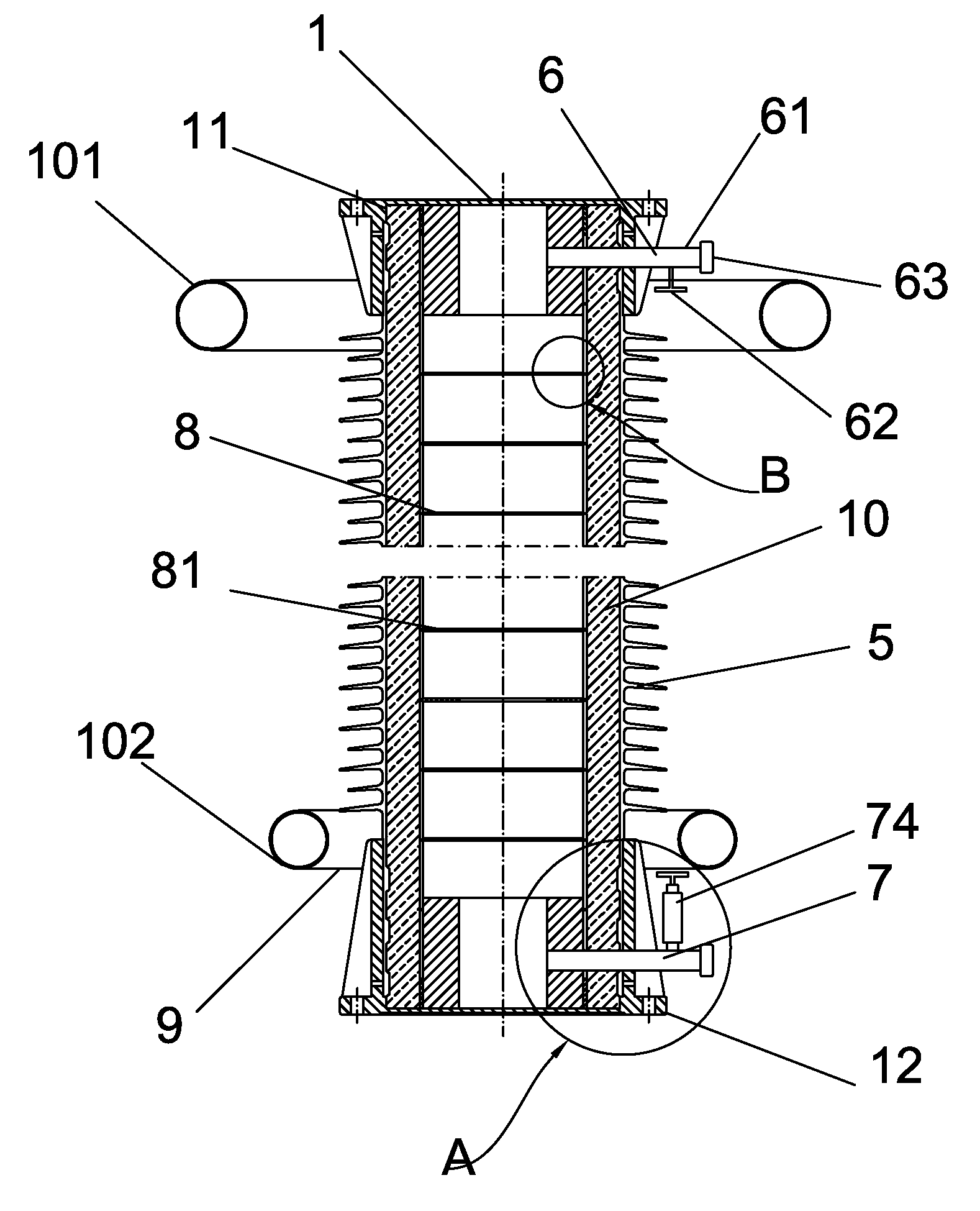

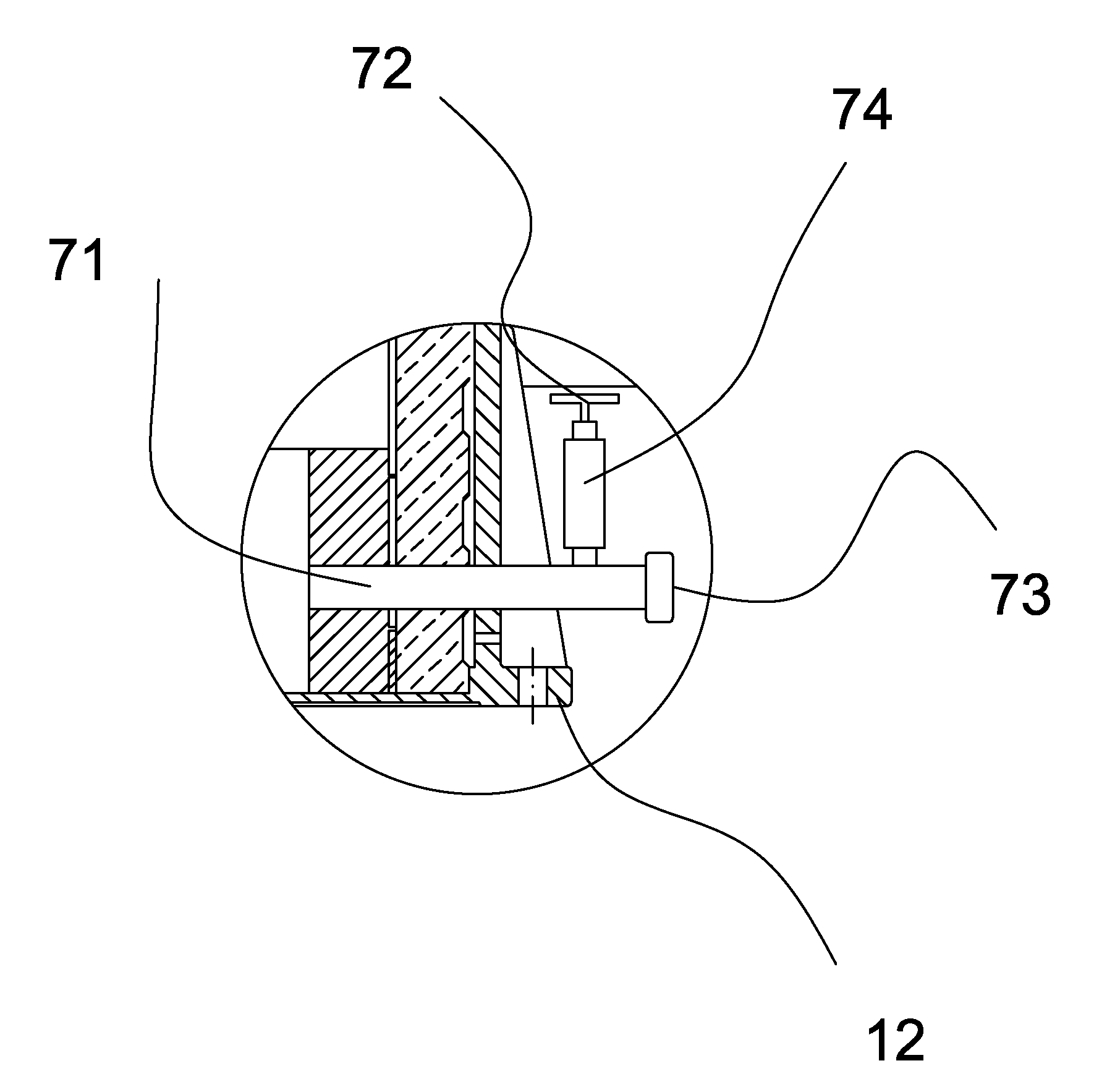

[0038] Embodiment 1 of the segmented UHV pillar composite insulator with inner shed structure of the present invention is as follows figure 1 , figure 2 , image 3 and 4 As shown, it includes a first composite insulator assembly 1, a second composite insulator assembly 2, a third composite insulator assembly 3 and a fourth composite insulator assembly 4 connected in series through flanges, the first composite insulator assembly 1, the second composite insulator assembly The insulator assembly 2, the third composite insulator assembly 3 and the fourth composite insulator assembly 4 respectively include: a hollow insulating tube 10, an upper flange 11 and a lower flange 12 set at both ends of the hollow insulating tube 10, the hollow insulating tube 10 is wound into a tubular shape by glass fiber epoxy resin, which plays the role of internal insulation and withstands mechanical bending, pressure and torsion. The outer wall of the hollow insulating tube 10 between the upper fl...

Embodiment 2

[0044] Embodiment 2 of the segmented UHV post composite insulator with inner shed structure of the present invention is as follows figure 1 , figure 2 , image 3 and 4 As shown, the two ends of the first composite insulator assembly 1 are respectively provided with a first voltage equalizing ring 101 and a second voltage equalizing ring 102, and the first voltage equalizing ring 101 and the second voltage equalizing ring 102 are respectively fixed on the upper side by the bracket 9. Flange 11 and lower flange 12; the two ends of the second composite insulator assembly 2 are respectively provided with a third pressure equalizing ring 201 and a fourth pressure equalizing ring 202, and the third pressure equalizing ring 201 and the fourth pressure equalizing ring 202 pass through The bracket 9 is respectively fixed on the upper flange 11 and the lower flange 12; the two ends of the third composite insulator assembly 3 are respectively provided with a fifth equalizing ring 301 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com