Small-size voltage transformer

A voltage transformer, small technology, applied in the field of substation, can solve the problems of shortened service life, unreasonable use of space, large magnetic leakage and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

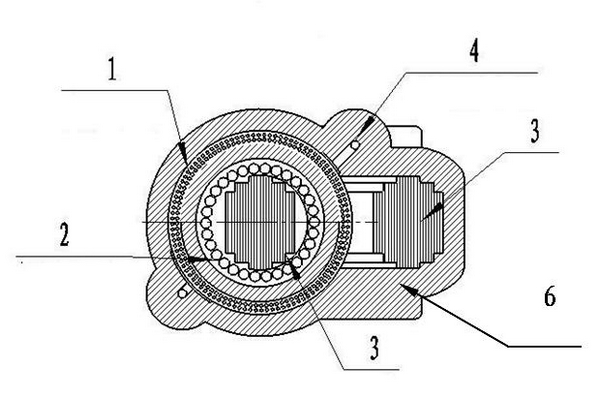

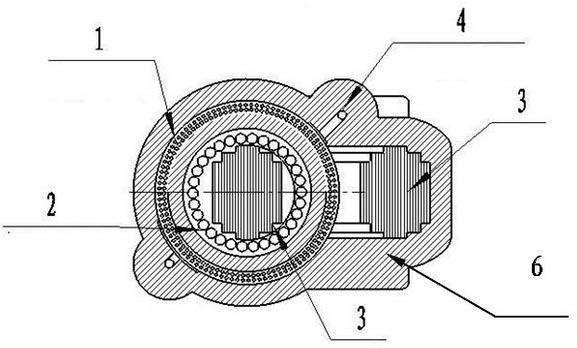

[0011] figure 1 Shown is a top sectional view of a small voltage transformer. It includes a high-voltage coil 1, a low-voltage coil 2, an iron core 3, a high-voltage lead wire 4, and a mounting board 5. It is characterized in that: the low-voltage coil 2 of the small voltage transformer is wound on the iron core 3; the low-voltage coil 2 is fully insulated ; The high-voltage coil 1 passes through the iron core 3, and is wound with the iron core 3 as the skeleton to the required number of through-core turns and then connected to the high-voltage lead wire 4; the iron core 3 is a ring structure; the voltage transformer is fully enclosed and poured epoxy The resin 6 is fixed on the mounting plate 5.

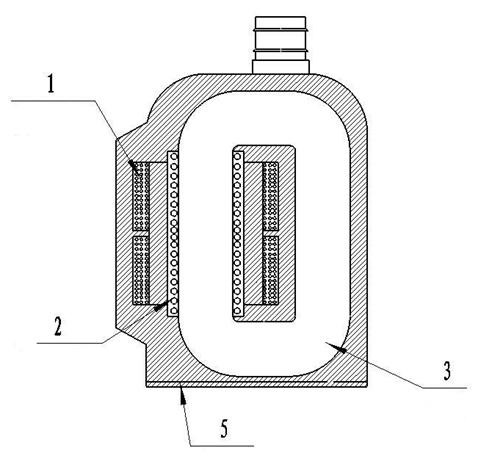

[0012] figure 2 It is a front sectional view of the present invention. The iron core 3 has a ring structure; the voltage transformer is poured with epoxy resin 6 once and fixed on the mounting board 5. The voltage transformer is a fully enclosed structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com