Composite circuit board device and manufacturing method thereof

A circuit board and composite technology, which is applied in printed circuit components, structural connection of printed circuits, and assembly of printed circuits with electrical components, can solve problems such as time-consuming assembly, save production costs, increase tension, and strengthen fixation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

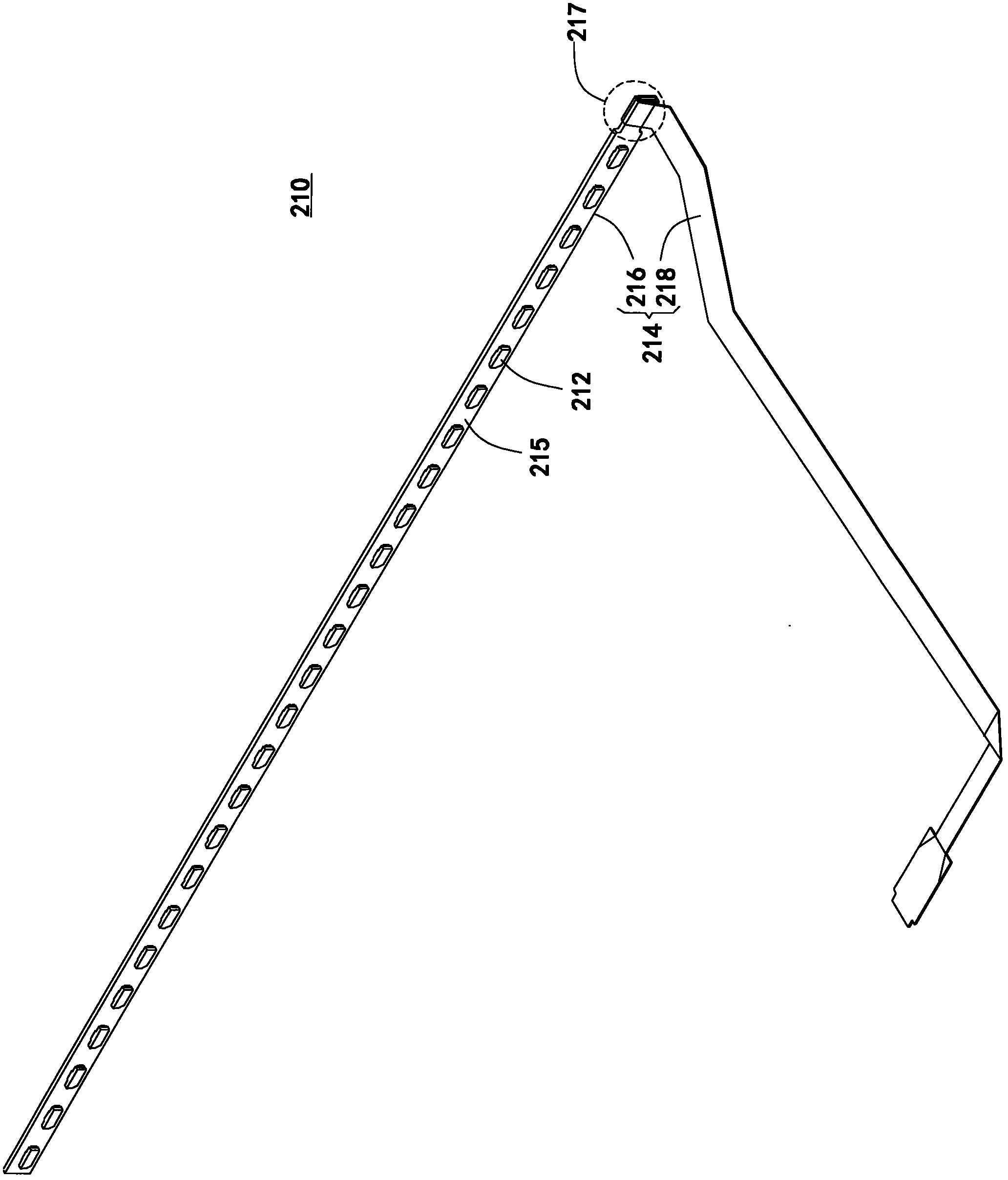

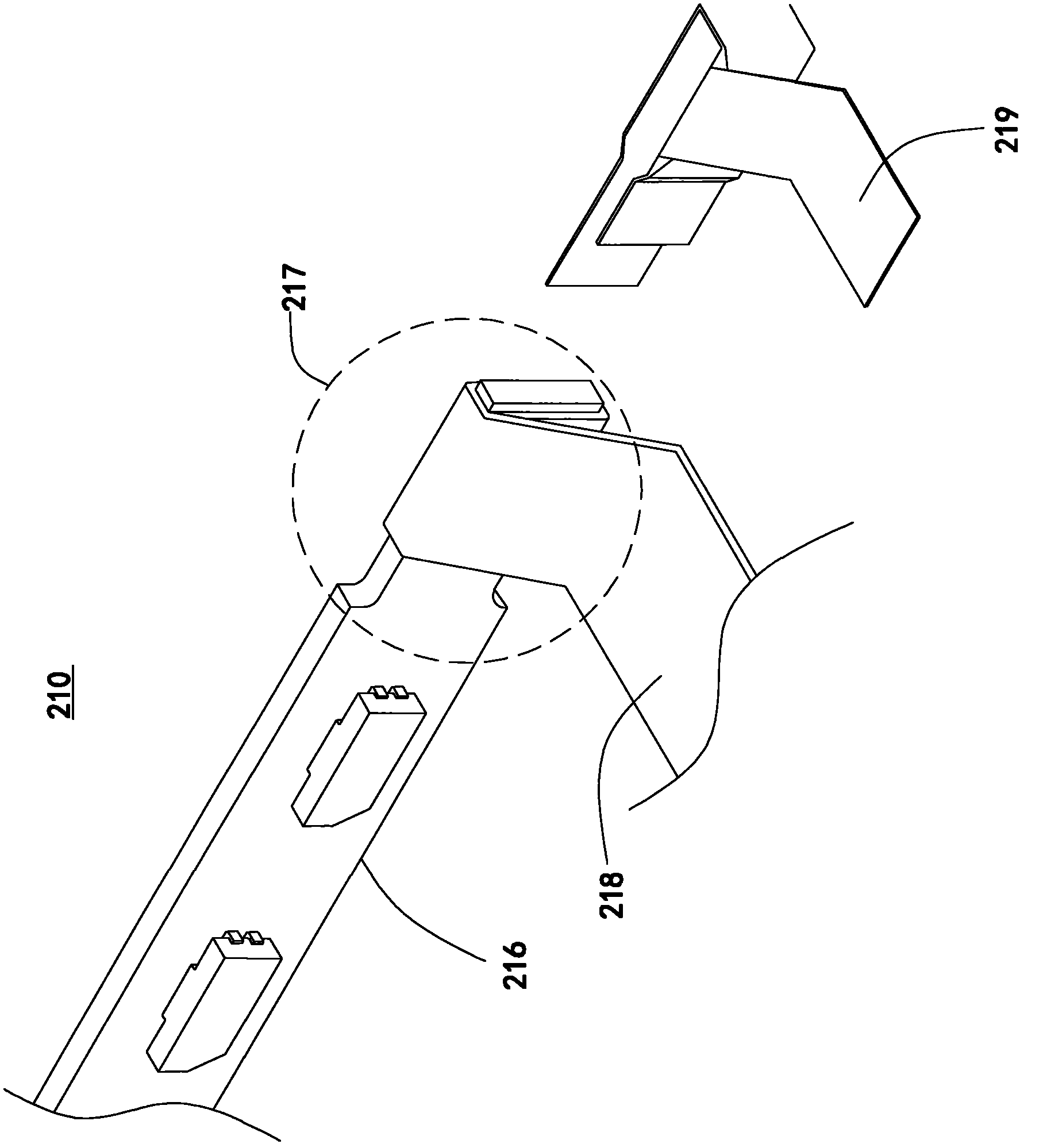

[0063] The present invention provides a composite circuit board device and manufacturing method, which can effectively increase the tensile force of the circuit board by means of structural combination, and strengthen and fix the rigid printed circuit board assembly and the flexible printed circuit board. In addition, the step of combining traditional attachment components is eliminated, which improves product manufacturing efficiency and reduces consumption of attachment components. The composite circuit board device and manufacturing method of the present invention have the advantages of strengthening the tension of the circuit board and reducing product cost.

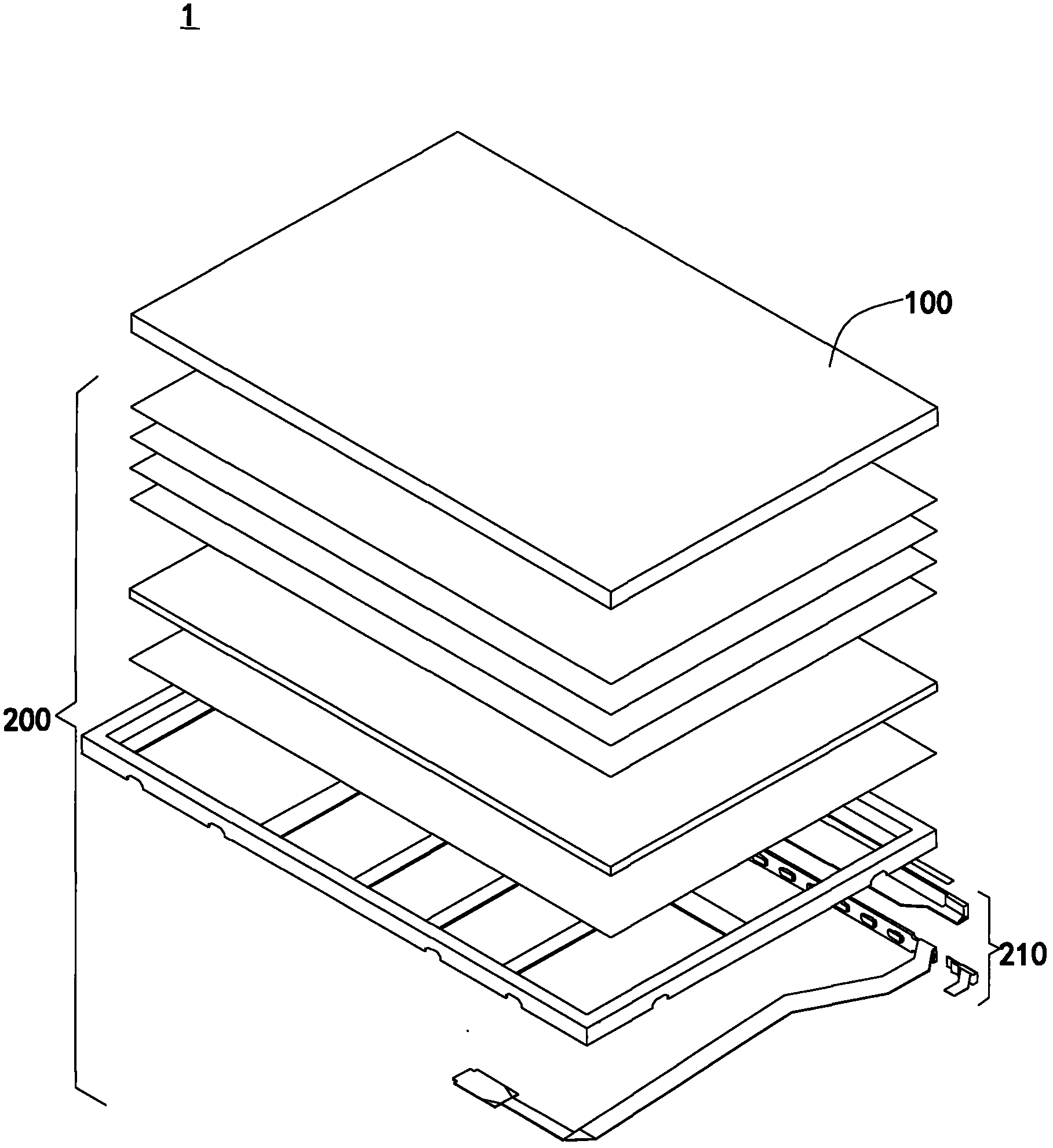

[0064] like Figure 3A In the illustrated embodiment, the composite circuit board device includes a rigid printed circuit board assembly 300 and a flexible printed circuit board 400 . The rigid printed circuit board assembly 300 has a connecting section 310 and a connecting section 320 . The carrying section 310 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com