Fuel vapor storage and recovery apparatus

A technology of fuel vapor and recycling equipment, which is applied in the direction of mechanical equipment, fuel injection devices, and adding non-fuel substances to fuel, etc., can solve the problem of exhausting the fuel vapor capacity of ordinary carbon tanks, and achieve the effect of improving the desorption and removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

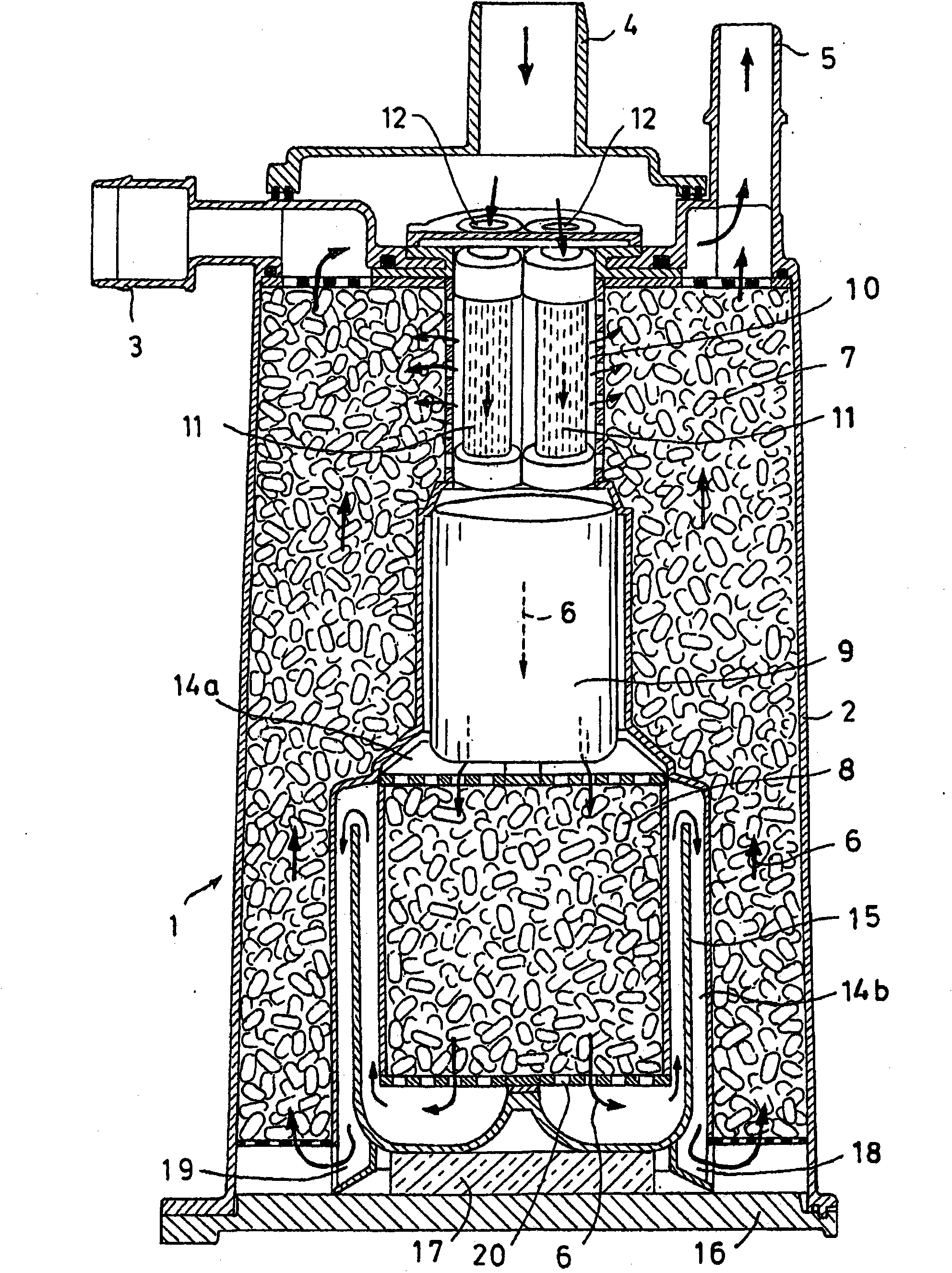

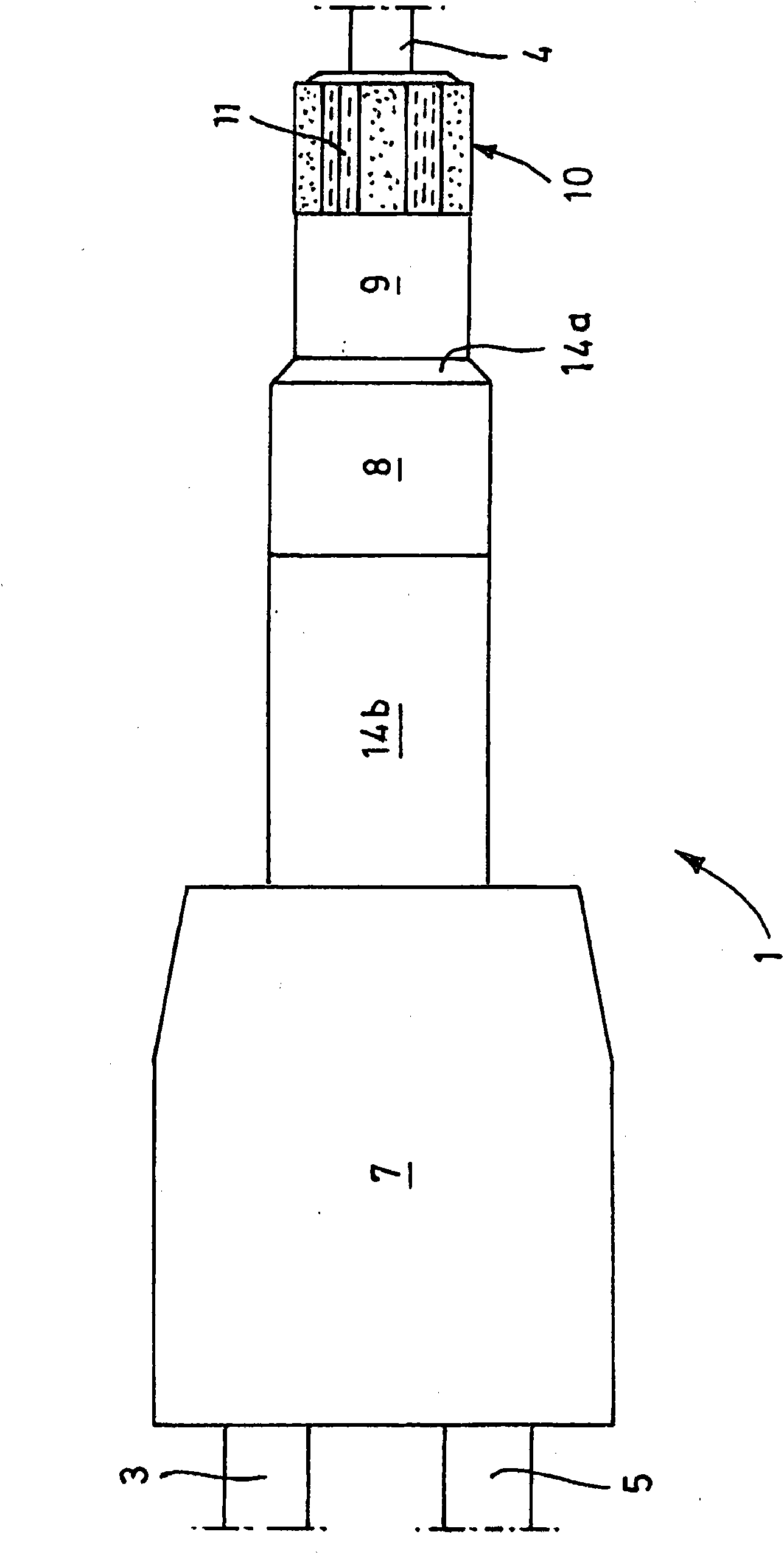

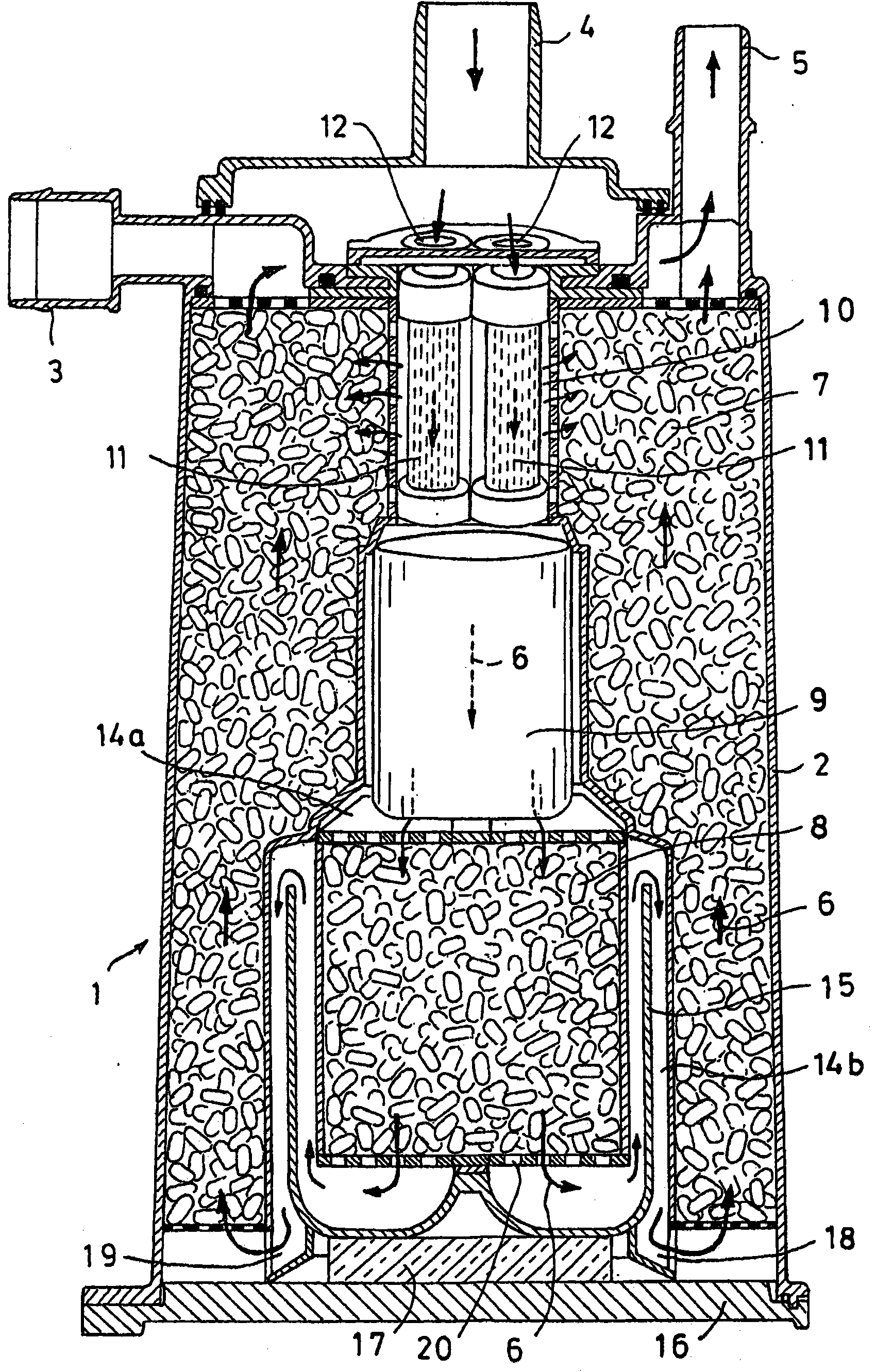

[0034] figure 1 A fuel vapor storage and recovery facility is shown in . The drawings are schematic only and components are not drawn to scale.

[0035] The fuel vapor storage and recovery device 1 includes a steam inlet 3, a vent 4 and a desorption port 5, the vapor inlet 3 is connected to a fuel tank (not shown), the vent 4 is communicated with the atmosphere, and the desorption port 5 is connected to the motor The vehicle's internal combustion engine (also not shown) is connected. The canister 2 contains an adsorbent in the form of granular activated carbon.

[0036] The canister 2 is connected to the fuel tank of the motor vehicle through the vapor inlet 3 and to the atmosphere through the vent 4 during periods when the motor vehicle's engine is stopped.

[0037] As explained at the outset of this application, during a standstill of the vehicle, the fuel in the fuel tank evaporates into the air space above the maximum fill level of the fuel tank. The steam-laden air flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com