Automatic purifying device

A technology of automatic purification and filtration chamber, which is applied in chemical instruments and methods, filtration separation, dehydration/drying/concentrated sludge treatment, etc. It can solve the problems of non-recyclable use, high operating cost, waste of resources, etc., and achieve stable effluent quality. , long service life and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

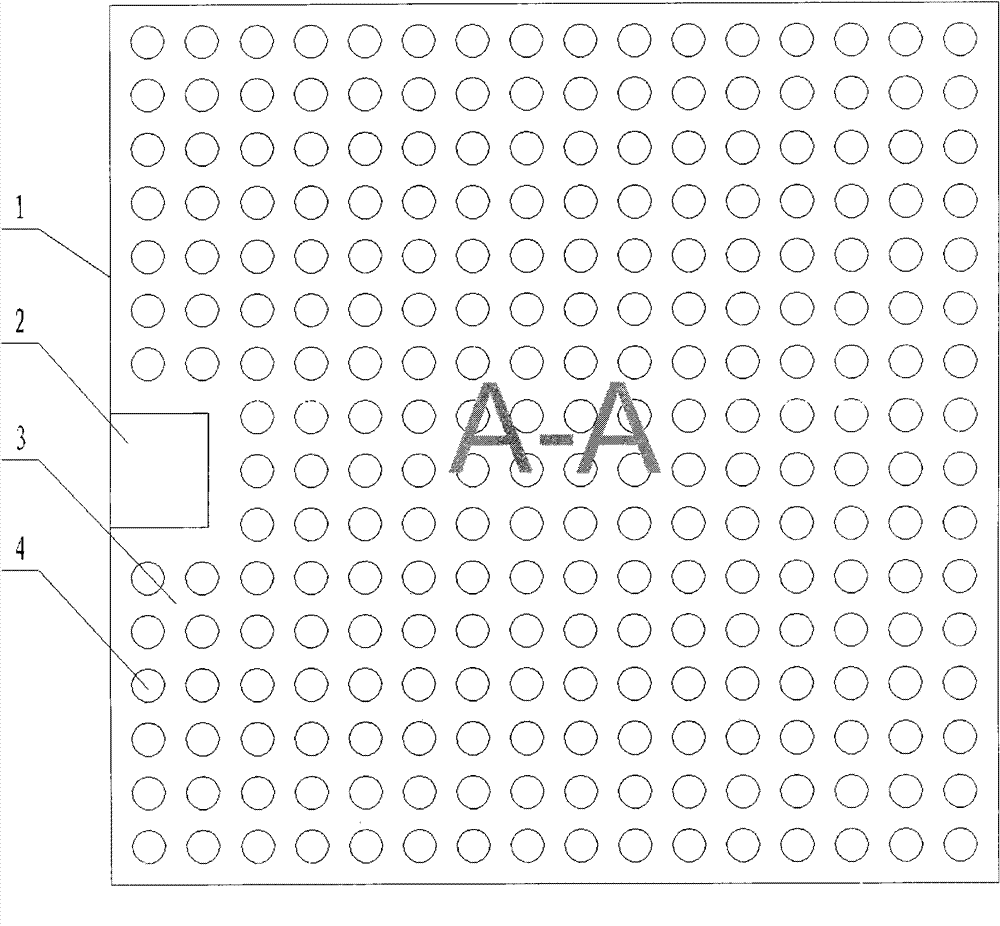

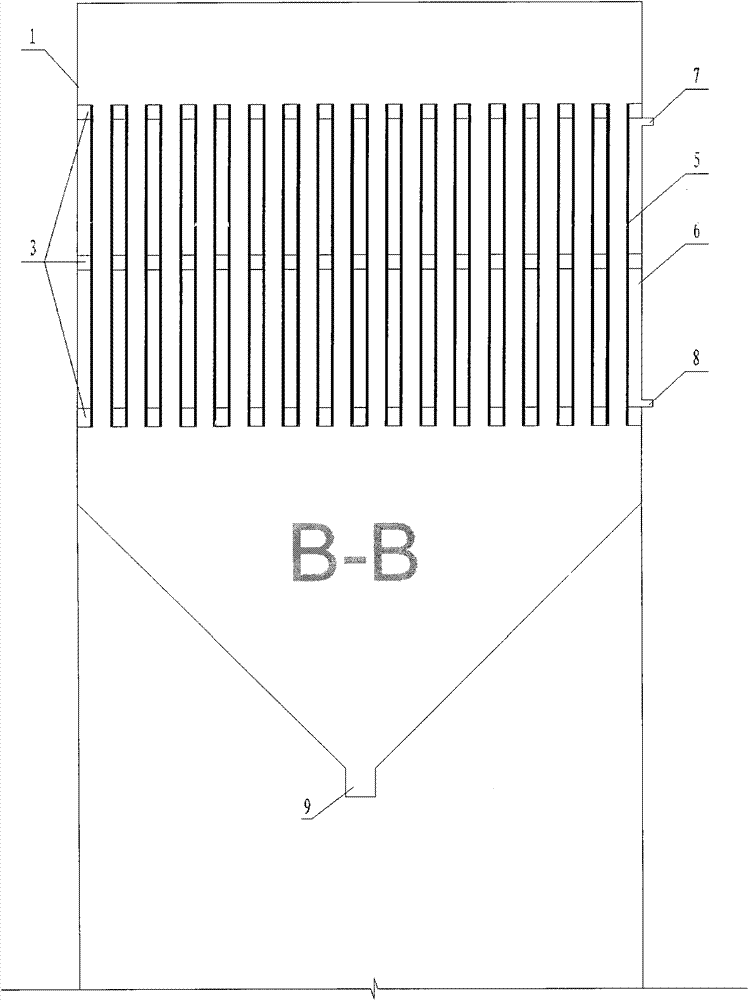

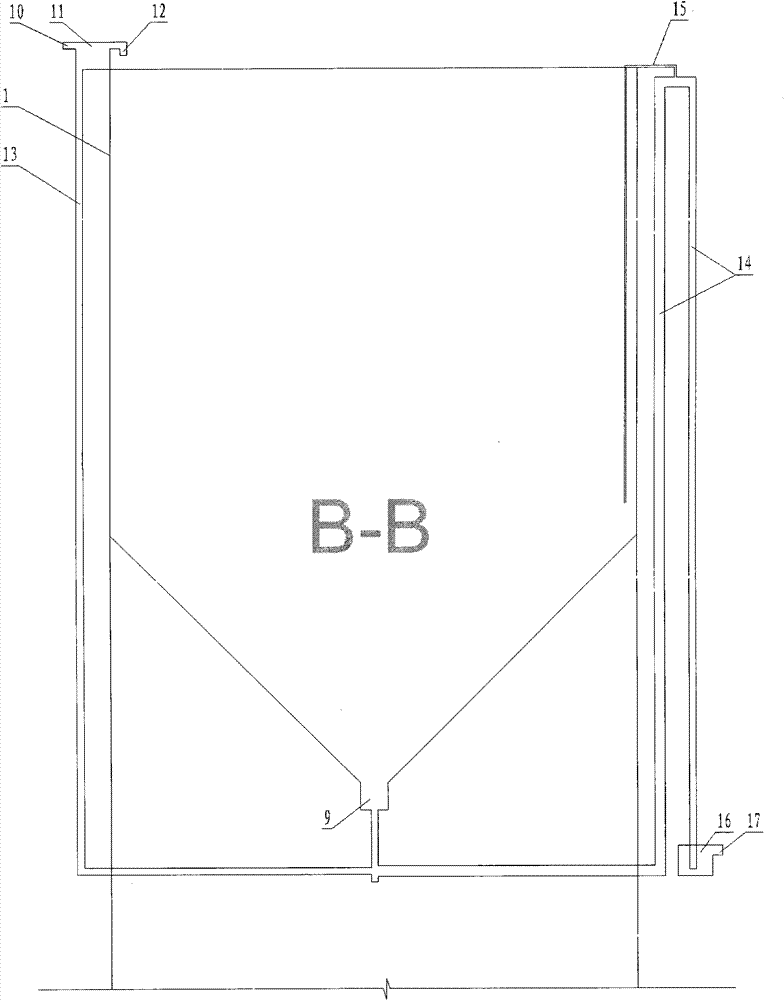

[0010] Firstly design the drawings for joint review, and then construct the purification and filtration device frame 1. In the frame construction, set the upper, middle and lower three-layer fixed laminates 3, and open the reserved holes 4 on the fixed laminates for the installation of microporous ceramic filter tubes 5. After the device frame is built, the microporous ceramic filter tube is installed, and the microporous ceramic filter tube 5 is installed and fixed through the reserved hole 4 of the upper, middle and lower fixed layer plates, and it is fixed on the upper, middle and lower layer plate 3. The special cement is blocked in the gap between the hole 4 and the microporous ceramic filter tube 5 to make it tightly sealed. Make various water bodies pass through the purification filter chamber 1, enter the inner surface of the microporous ceramic filter tube 5, and infiltrate into the clean water chamber 6 on the outer surface. Clear water flows out through reserved cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com