Plastic pencil and production process thereof

A production process and pencil technology, applied in non-moving pencils, printing, writing utensils, etc., can solve the problems of inability to achieve the comfort of wooden pencils, affecting the experience of using plastic pencils, damaging the skin of the hand-held part, etc., to avoid long-term use. Guaranteed stability and avoids sagging and bubbling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

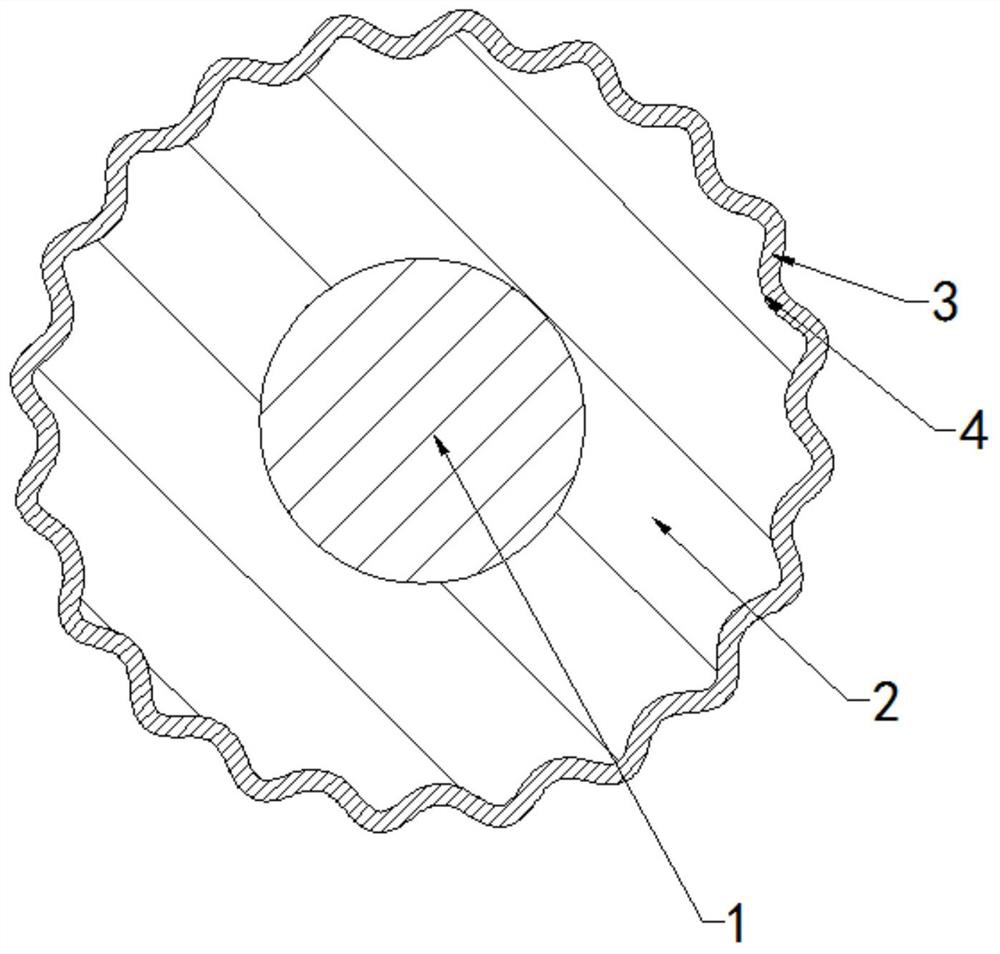

[0032] like figure 1 As shown, the present invention discloses a plastic pencil, in a specific embodiment of the invention, comprising a pen holder 2, a pen core 1 and a wrapping layer 3, the pen core 1 is located at the center of the penholder 2, and the wrapping layer 3 is wrapped around Outside the pen holder 2, the wrapping layer 3 is a wood fiber wrapping layer, the outside of the wrapping layer 3 is coated with paint to form a paint finish layer, and the thickness of the wrapping layer 3 is 0.5mm; the outer surface of the penholder 2 There are evenly distributed alveoli 4, and the wrapping layer 3 is in close contact with the outer surface of the pen holder 2.

[0033] In the present invention, the wrapping layer 3 is made of larch fibers; the paint finish layer includes a primer film coated on the outside of the wrapping layer, a reinforcing film coated on the outside of the primer film, and a reinforcing film coated on the External varnish film.

[0034] In the prese...

Embodiment 2

[0038] A production process of a plastic pencil, used to prepare a plastic pencil, in a specific embodiment of the present invention, comprises the steps:

[0039] S1: Prepare the raw materials for the pen core and the pen holder, use the extruder to extrude the pen core and the pen holder raw materials, extrude the pen core and the pen holder, and heat the barrel of the plastic extruder when the extruder extrudes the plastic pen holder 100-150 ℃, fasten the mold and form it, put it into the cooling equipment for cooling, take it out through the tractor after cooling, and make the pen holder wrapped with the pen core for use;

[0040] S2: Prepare the same amount of larch fiber, flax fiber, bamboo fiber and sisal fiber and put them into the beater for beating, and add an appropriate amount of water. After beating, squeeze and dehydrate through the extrusion equipment. The dryer is dried, extruded and dried to make a plate-shaped fiber mixture with a moisture content of 6%, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com