Digital type thermal relay

A thermal relay, digital technology, applied in the field of digital thermal relay, can solve the problems of guide plate, lever position change, no correction error, thermal relay motor burnout, etc., to achieve the effect of correcting error, preventing large error, and protecting the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

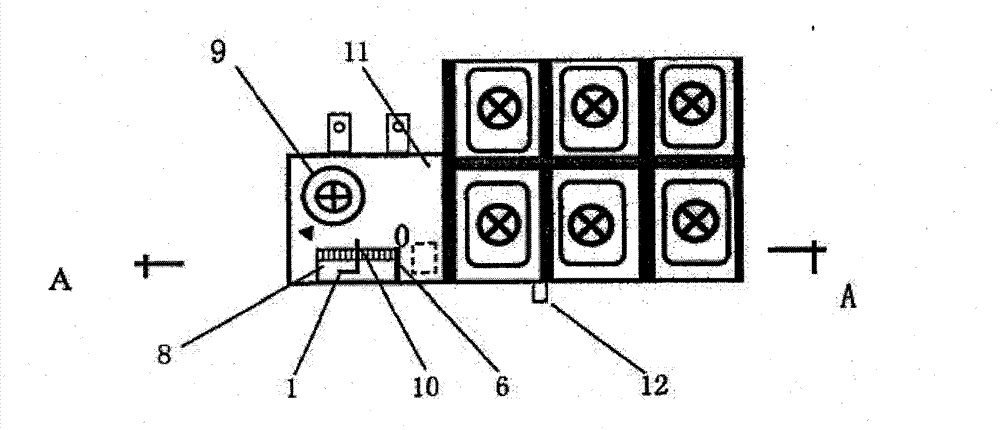

[0011] figure 1 It is a top view of the first embodiment of the present invention.

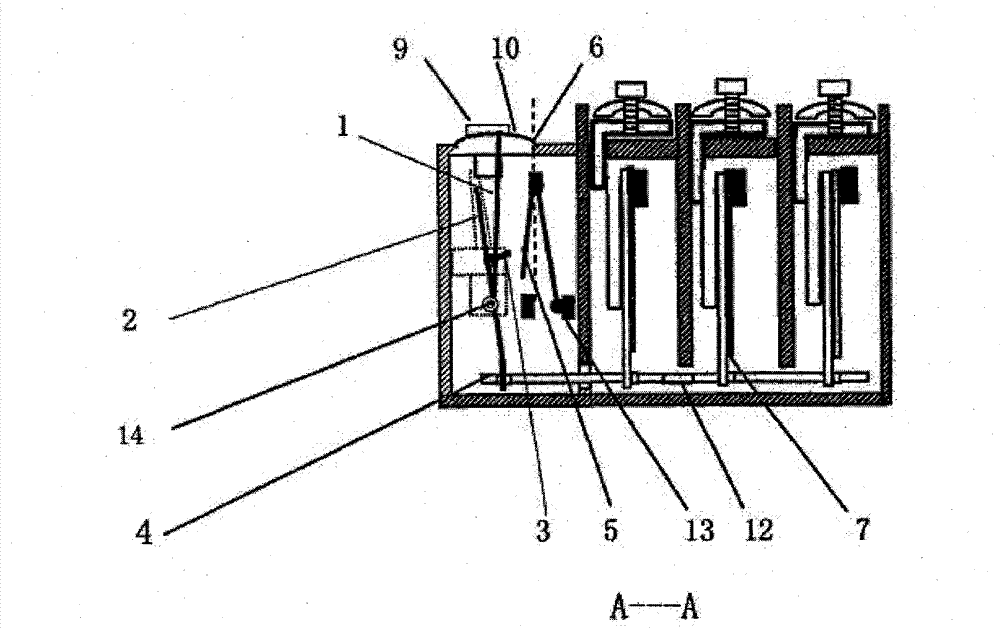

[0012] figure 2 yes figure 1 The A--A sectional view.

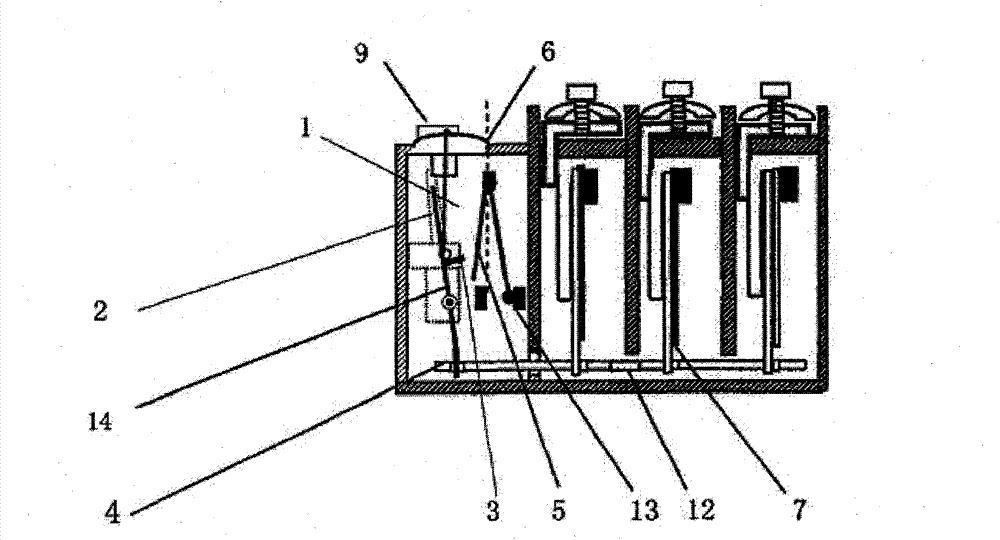

[0013] image 3 is the second embodiment

[0014] Figure 4 is the third embodiment

[0015] In the figure: 1. Pointer, 2. Lever, 3. Push rod, 4. Guide plate, 5. Switch contact, 6. Switch off position, 7. Bimetal, 8. Rectangular hole, 9. Current setting knob , 10. Digital scale, 11. Adjustment panel, 12. Test key 13. Switch, 14. Shaft

[0016] figure 1 : on the adjustment panel (11), there are digital scale (10), pointer (1), current setting knob (9); rectangular hole (8), test key (12), switch off position (6). The pointer table is composed of a pointer (1) and a digital scale (10). The number of the pointer 0 is the power-off position of the switch; the number displayed by the pointer table is 5, which indicates the distance between the push rod in the shell and the disconnected position of the switch contact (enlarge ) indic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com