Multi-seal split fixed ball valve of double-piston structure

A technology of multiple seals and fixed ball valves, which is applied in the direction of shaft seals, control valves, valve devices, etc., can solve the problems of the influence of the sealing performance of the valve seat at the outlet end, and the sealing surface of the valve is easily damaged and damaged, so as to ensure the sealing performance and improve the service life. Longevity and the effect of avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

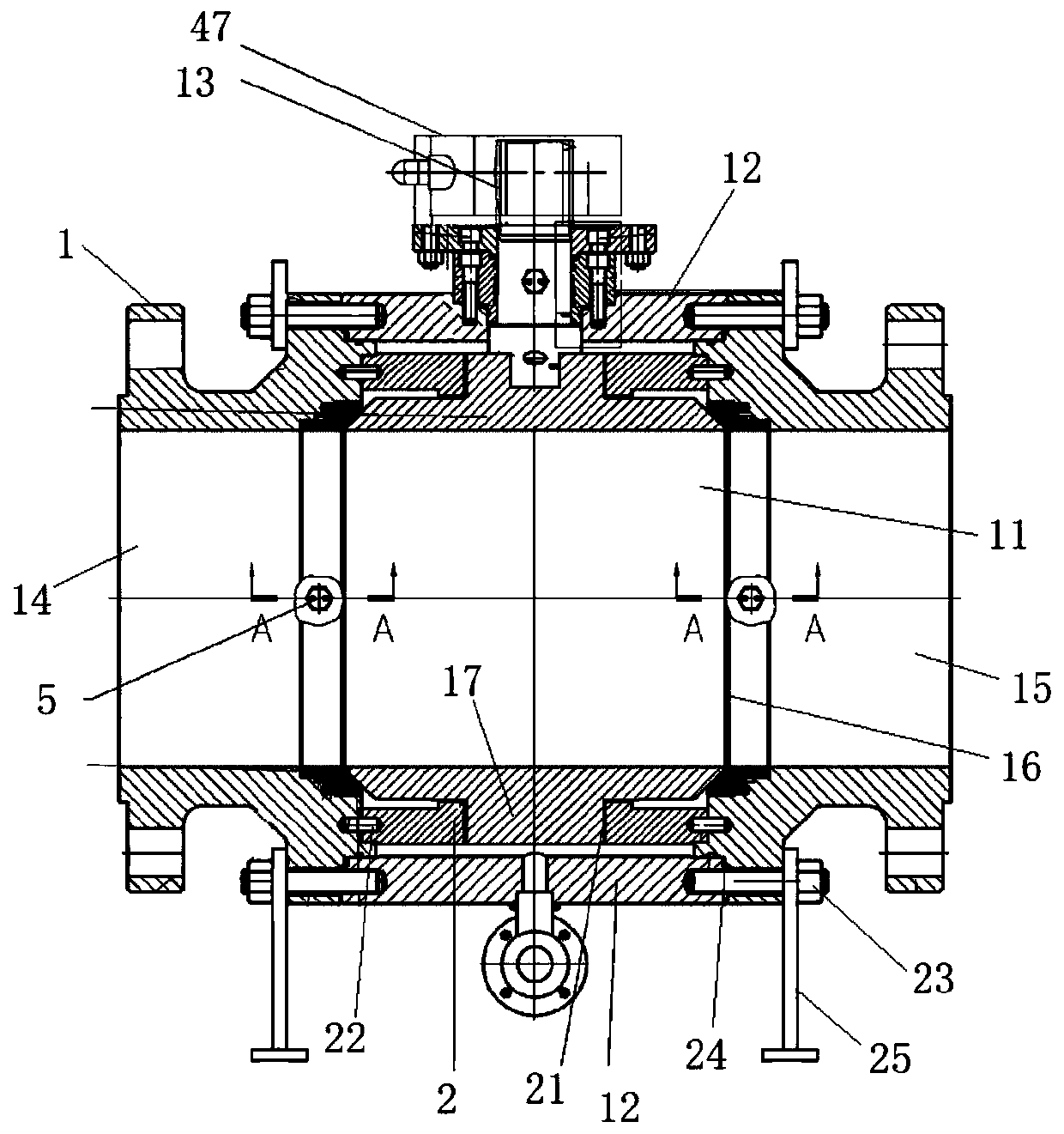

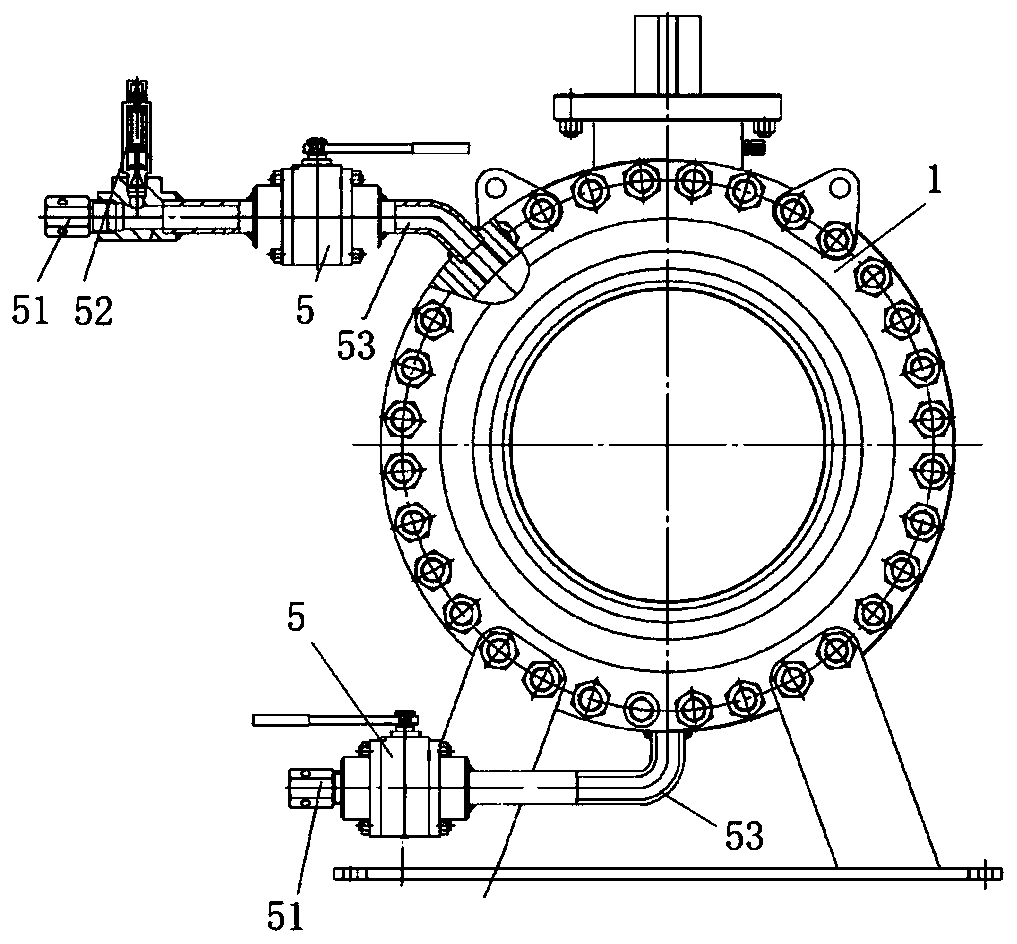

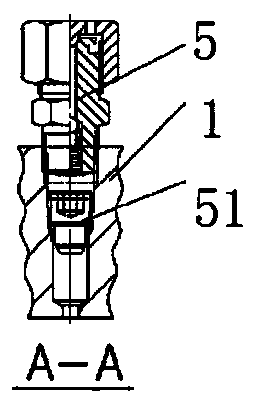

[0027] refer to Figure 1-6 As shown, this embodiment is a double-piston structure multiple seal split type fixed ball valve, including a valve body 1 separated and oppositely arranged, a ball 11 arranged in the valve body 1, end caps 12 arranged at the upper and lower ends of the valve body 1, connecting The top of the sphere 11 rotates the valve stem 13; the two ends of the sphere 11 and the contact surface of the valve body 1 are respectively provided with a sealing valve seat device, and the sealing valve seat device is used to elastically closely fit the surface of the supporting sphere 11, so that the bottom of the sphere 11 is in contact with the valve body 1. The valve body 1 is suspended at intervals, and a sealing end cover device is provided between the end cover 12 and the valve stem 13. The outer wall of the valve body 1 is provided with a grease injection device extending to its interior. After the ball 11 rotates, the opening edge of the channel and the valve bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com