Sealing tooth scraping tool

A technology of steam seal teeth and tools, applied in the field of steam seal teeth, can solve the problems of enlarged clearance and damaged steam seal teeth, and achieve the effects of shortening the manufacturing and installation cycle, ensuring safety and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

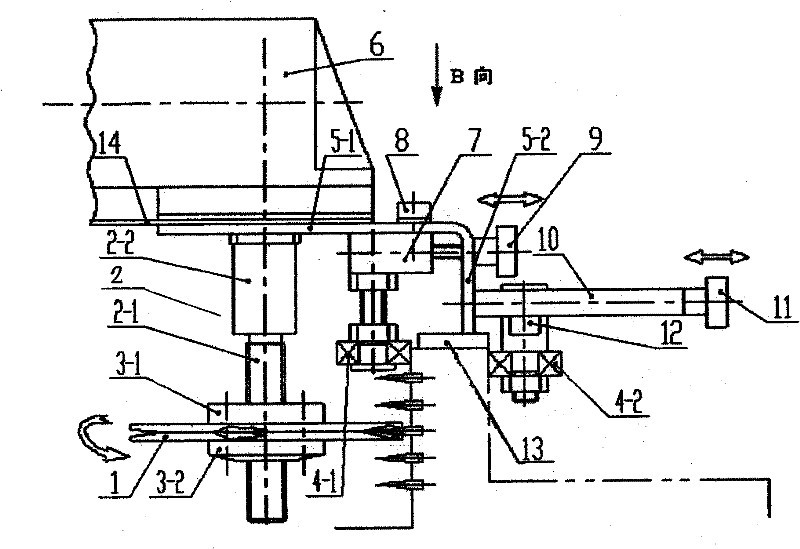

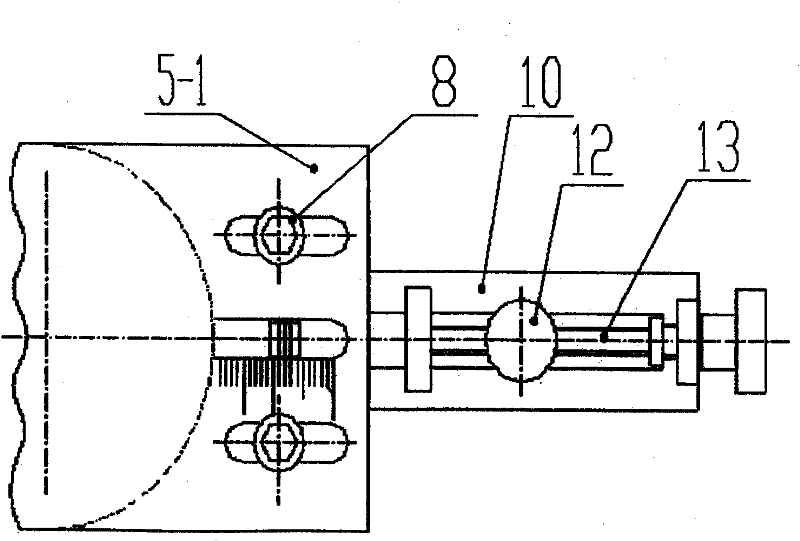

[0023] This steam seal gear scraping tool includes three parts, namely the cutting tool and its driving device and positioning mechanism, see figure 1 , figure 2 , Figure 3-1 , Figure 3-2 , Figure 3-3 , which are described in detail below.

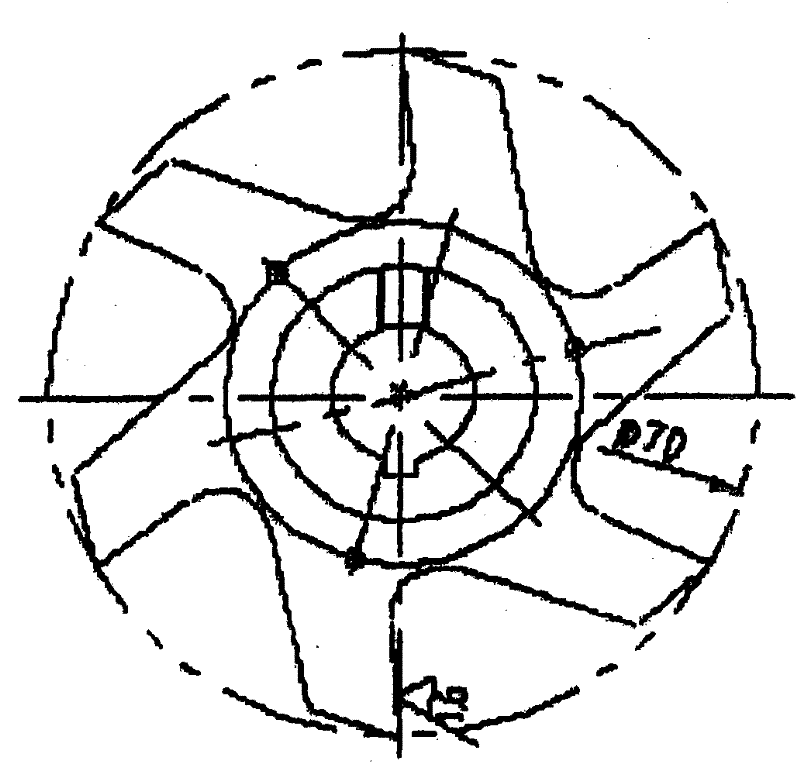

[0024] The cutting tool is composed of milling cutter 1 and its cutter shaft 2. The material of milling cutter 1 is W6Go5Cr4V2+4 high-speed steel, which is composed of left 1-1 and right 1-2 halves. The cutting teeth are 20 teeth, and the forming angle of the cutter tooth forming edge is 60 °.

[0025] The cutter shaft 2 is a segmented structure, consisting of a basic section 2-1 and a transition section 2-2. The two sections are screwed together as a whole. The milling cutter 1 is assembled on the basic section 2-1, and the transition section 2-2 is a set. The length changes in an equal gradient, and the length gradient is equal to the distance between adjacent steam seal teeth. When in use, use one of them one by one to proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com