Reactive foam injection system

A reactive and foam technology, applied in the field of construction material supply system, can solve the problems of clogging the front orifice of the gas drainage pipe, uncontrollable flow, waste of raw materials, etc., to improve the uniformity and stability of sealing holes, and save drainage Energy consumption and the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

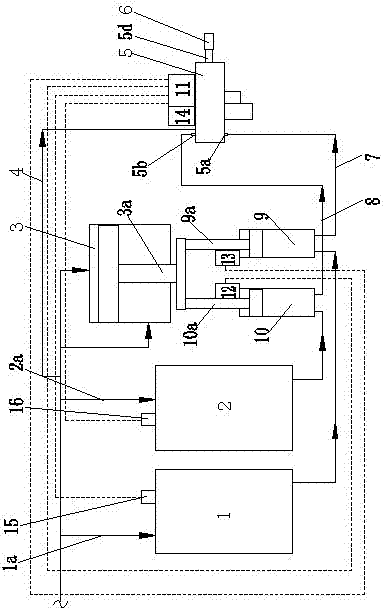

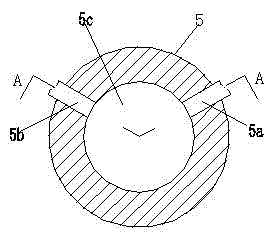

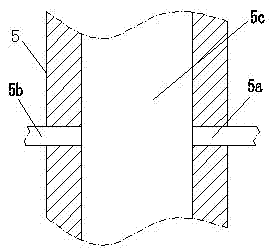

[0032] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 It is a schematic diagram of the flow path of the injection device of the present invention; image 3 for figure 2 A sectional view along the direction of A-A, as shown in the figure: the reactive foam injection system of this embodiment includes a sealing feeding device and a sealing injection device 5;

[0033] The feeding device includes a reactive A foam component feeding device and a reactive foam B component feeding device; the reactive foam A component feeding device includes a component A storage tank 1 and a component A booster Pressure pump 9, the suction port of the A component booster pump 9 is connected to the A component storage tank 1, and the reactive foam B component supply device includes the B component storage tank 2 and the B component booster pump 10 The suction port of the component B booster pump 10 is connected to the reactive type B component storage tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com