Thrust rod assembly

A thrust rod and assembly technology, which is applied in the field of parts and components, can solve the problems of rubber body rupture, uneven force, life discount of thrust rod, etc., and achieve the goal of prolonging service life, increasing load force, ensuring stability and reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

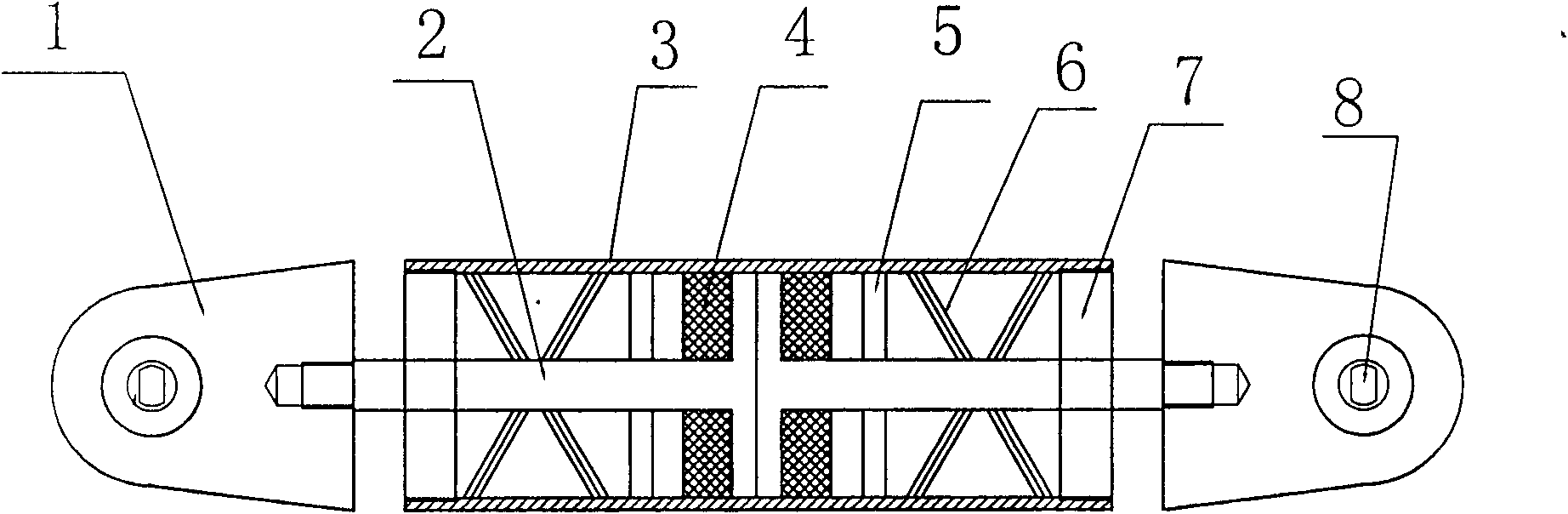

[0013] Thrust rod assembly of the present invention such as figure 2 shown.

[0014] The pull rod 2 is plunger-shaped and set back in the pull tube 3, from the root of the pull rod 2 plunger to the two ports of the pull tube 3, a rubber body 4, a retaining ring 5, a spring 6 and a blocking cover 7 are arranged in sequence.

[0015] The club head 1 is provided with a composite bearing 7 .

[0016] In actual work, because the metal bearing works with the rubber body and the spring at the same time, and interacts during work. The metal spring can adjust the displacement stroke and protect the rubber spring from excessive impulse value under a certain force value.

[0017] Due to the characteristics of this structure, no matter how much load the thrust rod is subjected to, the force of the rubber body is the overall force, and the force is very uniform, so the compressive strength of the rubber is greatly improved, so the risk of rubber rupture will be reduced. Reduced, thereb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com