Preparation method for high-precision bearing steel balls

A bearing steel ball, high-precision technology, applied in the field of steel ball processing, can solve the problems of unstable retained austenite, surface waviness difficult to meet the standard, not stable enough, etc., to achieve high quality, enhanced load capacity, and best quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

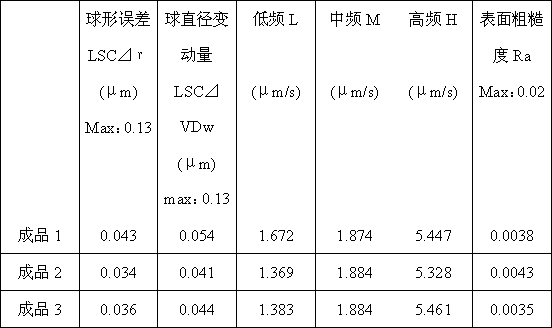

Examples

Embodiment 1

[0019] The preparation method of high-precision bearing steel ball comprises the following steps in sequence:

[0020] (1) Cold heading: Using bearing steel wire as raw material, it is stamped into steel rough balls. The material of the bearing steel wire is 100CR6.

[0021] (2) Light grinding: use grinding equipment and cast iron discs to carry out light grinding treatment on steel rough balls to obtain smooth ground steel balls. Among them, the processing speed is 20rpm, the processing pressure is 1Mpa, and the grinding medium is cutting fluid.

[0022] (3) Heat treatment: Throw polished steel balls into a drum-type continuous furnace for quenching and tempering heat treatment to obtain preliminary hardened steel balls. Among them, the quenching heating temperature is 840°C, the quenching heating time is 50 minutes, the quenching medium is 40°C fast bright quenching oil, the tempering temperature is 160°C, the tempering holding time is 120 minutes, and nitrogen is used as ...

Embodiment 2

[0032] The preparation method of high-precision bearing steel ball comprises the following steps in sequence:

[0033] (1) Cold heading: Using bearing steel wire as raw material, it is stamped into steel rough balls. The material of the bearing steel wire is 100CR6.

[0034] (2) Light grinding: use grinding equipment and cast iron discs to carry out light grinding treatment on steel rough balls to obtain smooth ground steel balls. Among them, the processing speed is 50rpm, the processing pressure is 3Mpa, and the grinding medium is cutting fluid.

[0035] (3) Heat treatment: Throw polished steel balls into a drum-type continuous furnace for quenching and tempering heat treatment to obtain preliminary hardened steel balls. Among them, the quenching heating temperature is 850°C, the quenching heating time is 60 minutes, the quenching medium is 60°C fast bright quenching oil, the tempering temperature is 180°C, the tempering holding time is 150 minutes, and nitrogen is used as ...

Embodiment 3

[0042] The preparation method of high-precision bearing steel ball comprises the following steps in sequence:

[0043](1) Cold heading: Using bearing steel wire as raw material, it is stamped into steel rough balls. The material of the bearing steel wire is 100CR6.

[0044] (2) Light grinding: use grinding equipment and cast iron discs to carry out light grinding treatment on steel rough balls to obtain smooth ground steel balls. Among them, the processing speed is 100rpm, the processing pressure is 5Mpa, and the grinding medium is cutting fluid.

[0045] (3) Heat treatment: Throw polished steel balls into a drum-type continuous furnace for quenching and tempering heat treatment to obtain preliminary hardened steel balls. Among them, the quenching heating temperature is 860°C, the quenching heating time is 80 minutes, the quenching medium is 100°C fast bright quenching oil, the tempering temperature is 200°C, the tempering holding time is 180 minutes, and nitrogen is used as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com