Electronic mechanical braking device

An electro-mechanical brake and brake disc technology, which is applied in the direction of brake transmission, brake, transportation and packaging, etc., can solve the problems of complex brake device structure, complex brake structure, and difficult loading and application, and achieve effective It is beneficial to the protection of the ecological environment, accurate braking, and the effect of shortening the adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

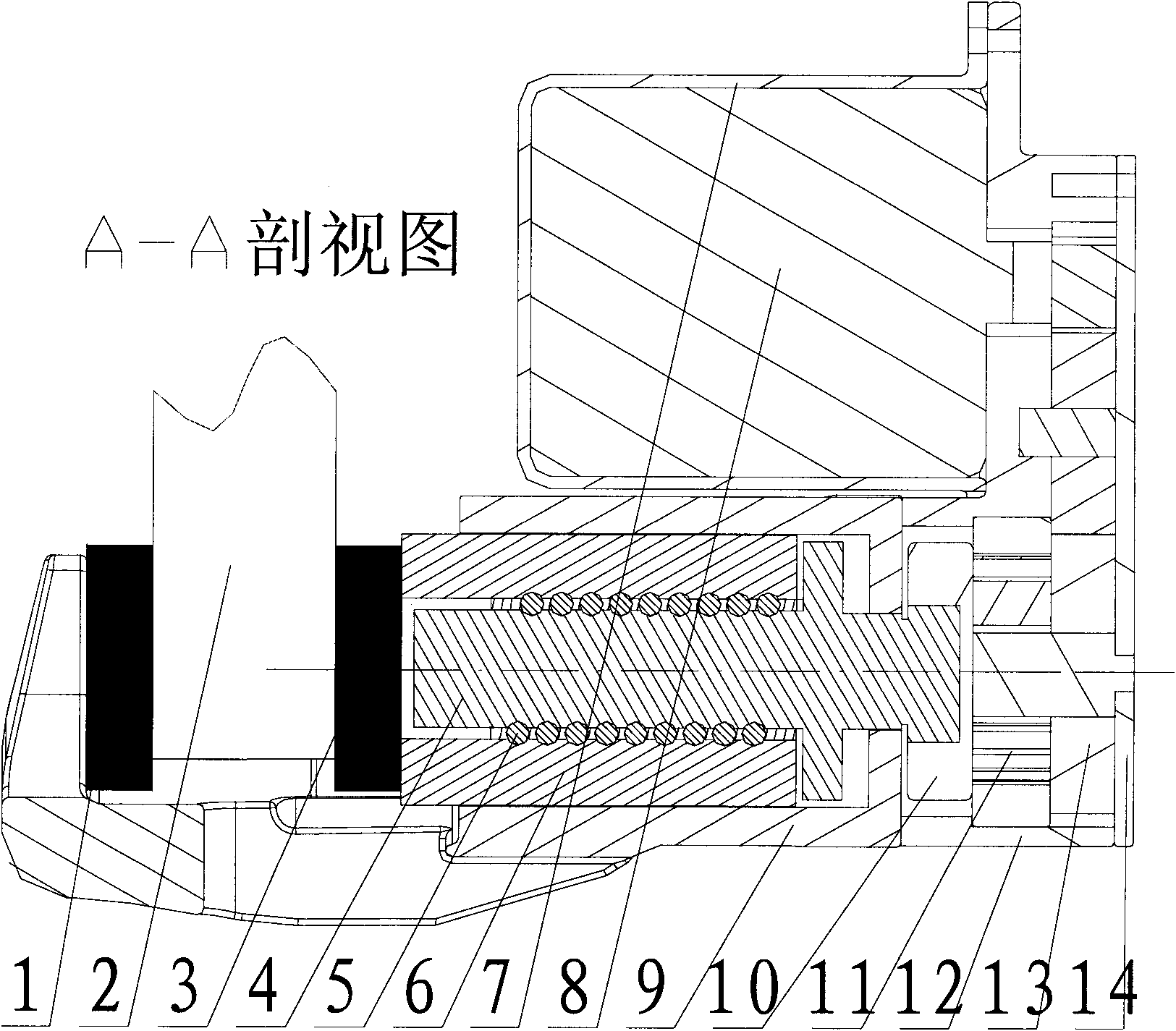

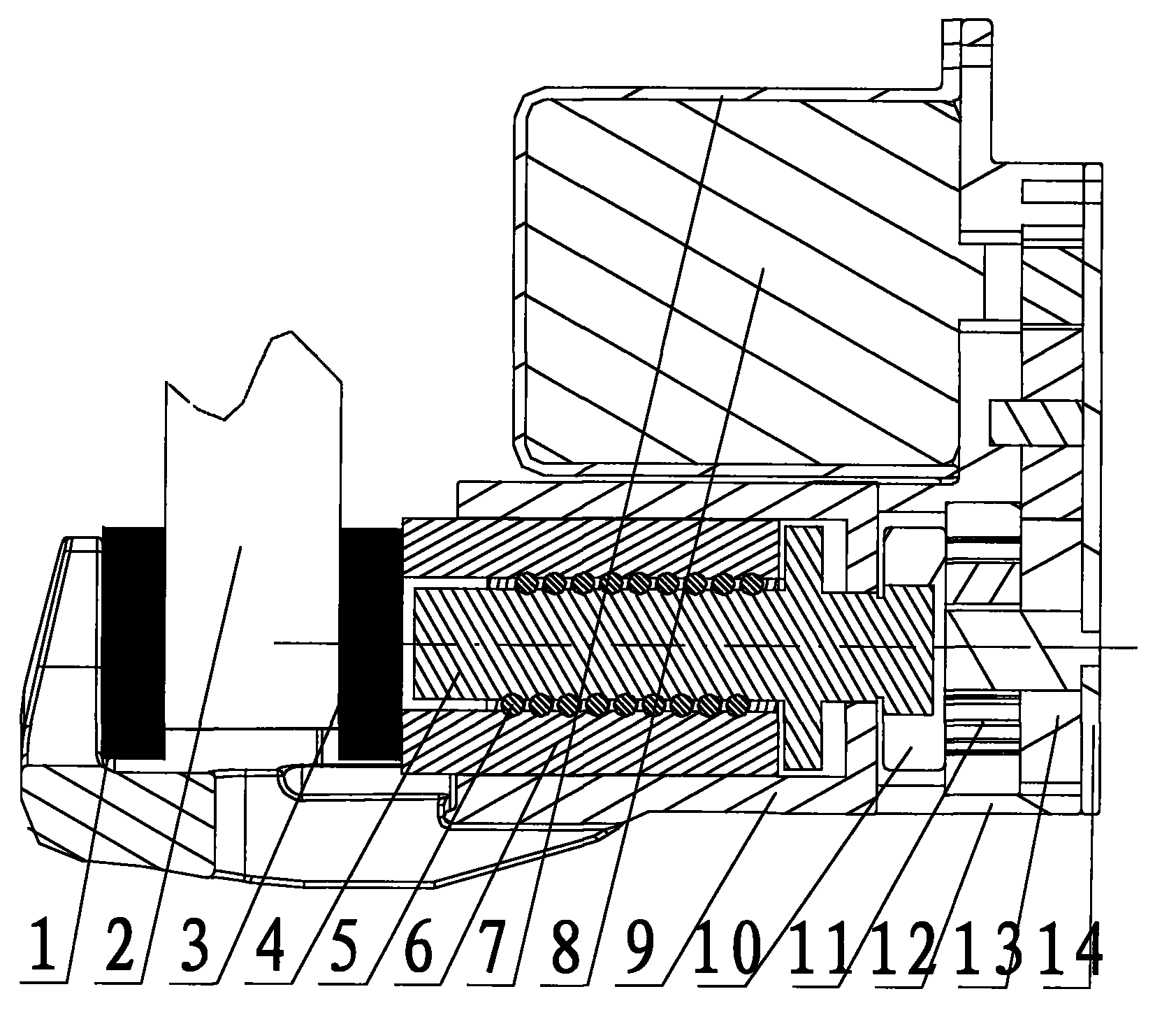

[0025] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

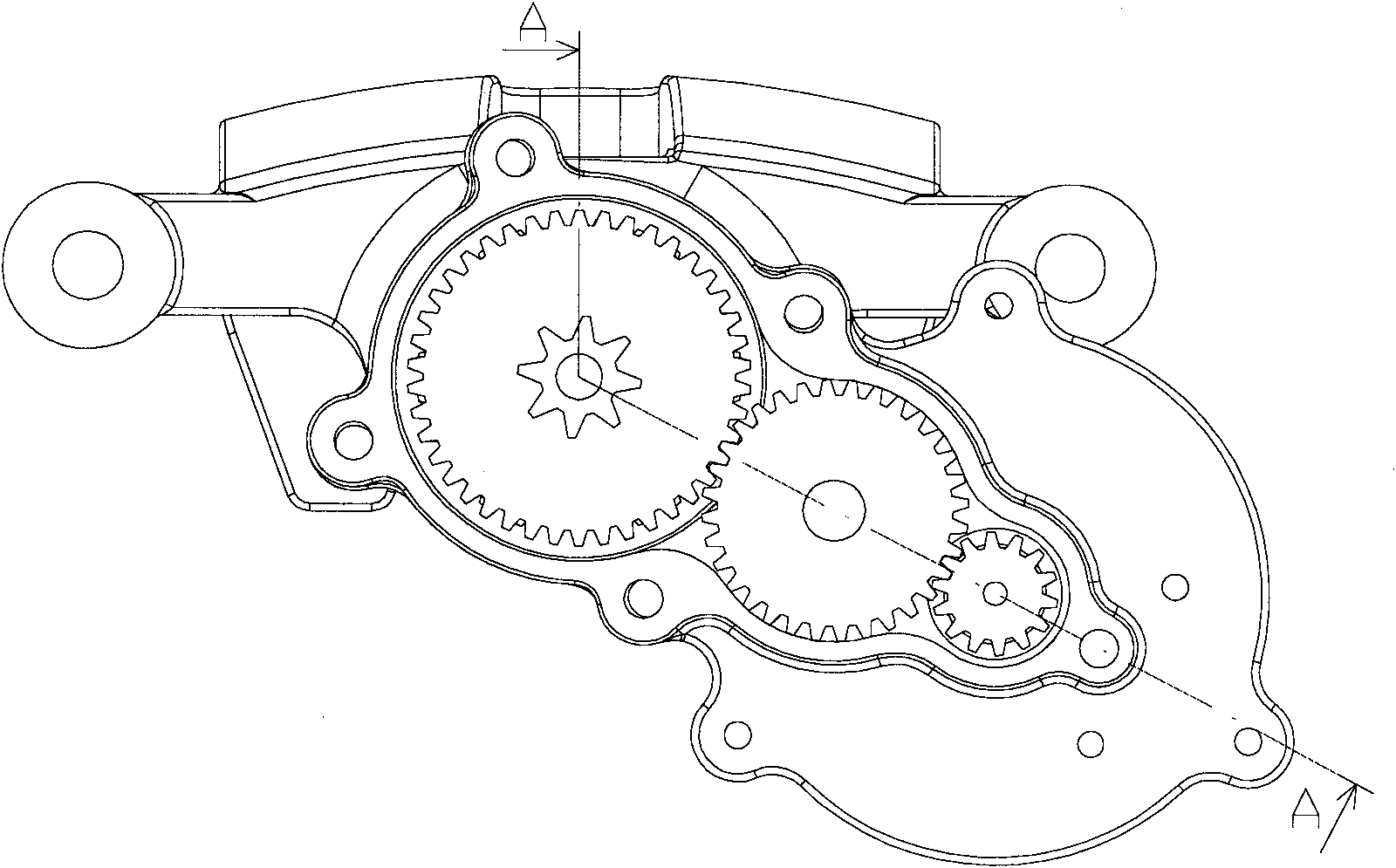

[0026] Such as figure 1 , 2 As shown, the electromechanical braking device of the present invention mainly includes an electronic control unit ECU, a power mechanism, a torque amplification mechanism, a ball screw mechanism, a friction plate 1 and a friction plate that are movable on both sides of the brake disc 2 and can clamp the brake disc. Sheet 3, and the wheel speed sensor ( figure 1 , 2 not shown).

[0027] In this embodiment, the power mechanism adopts the motor 8, and the motor 8 adopts a high-power brushless DC motor; the torque amplification mechanism adopts a reduction gear mechanism and a planetary gear mechanism connected in sequence. The reduction gear mechanism includes a plurality of reduction gears m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com